WIP CoreXY with heated chamber

-

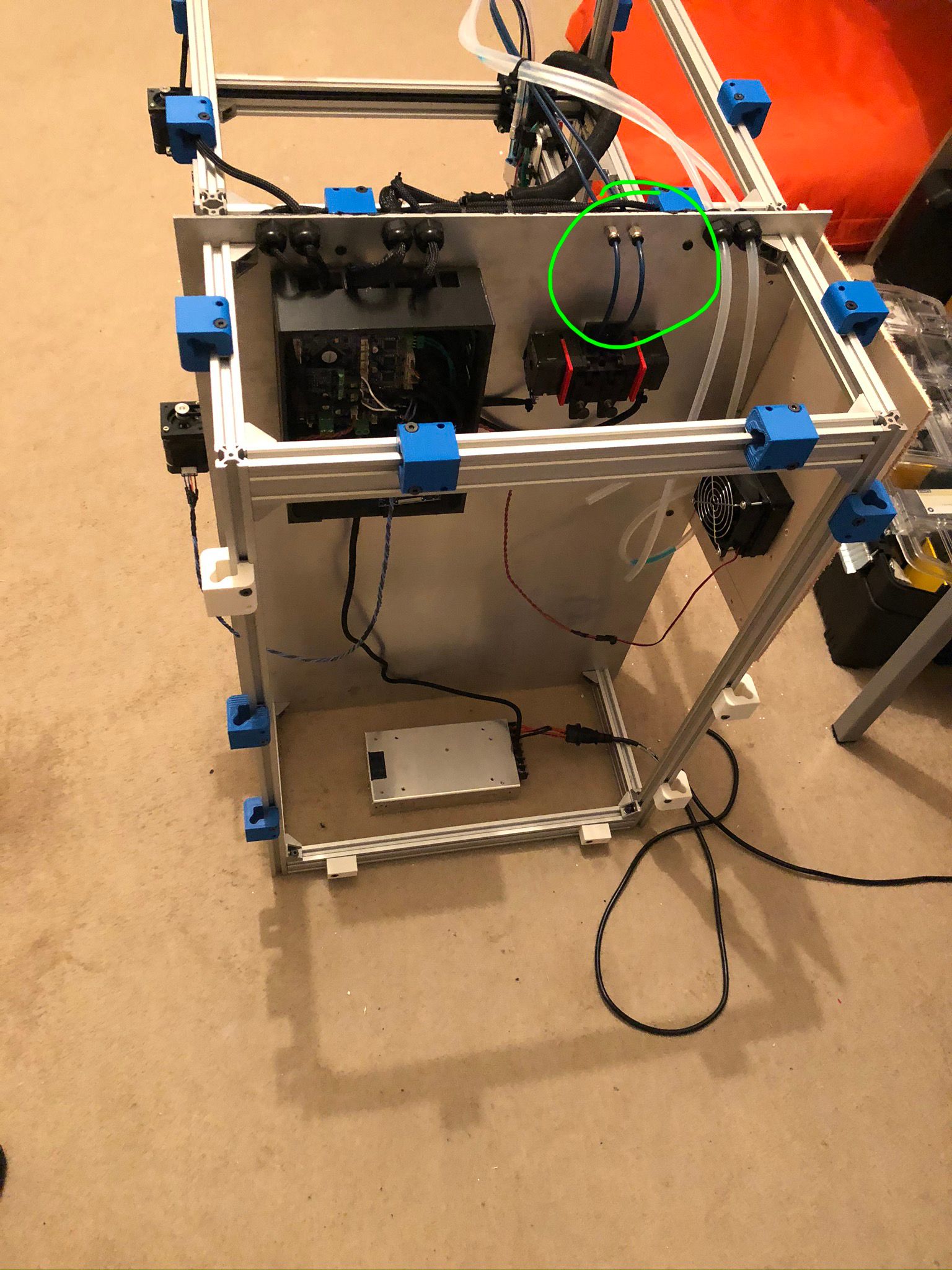

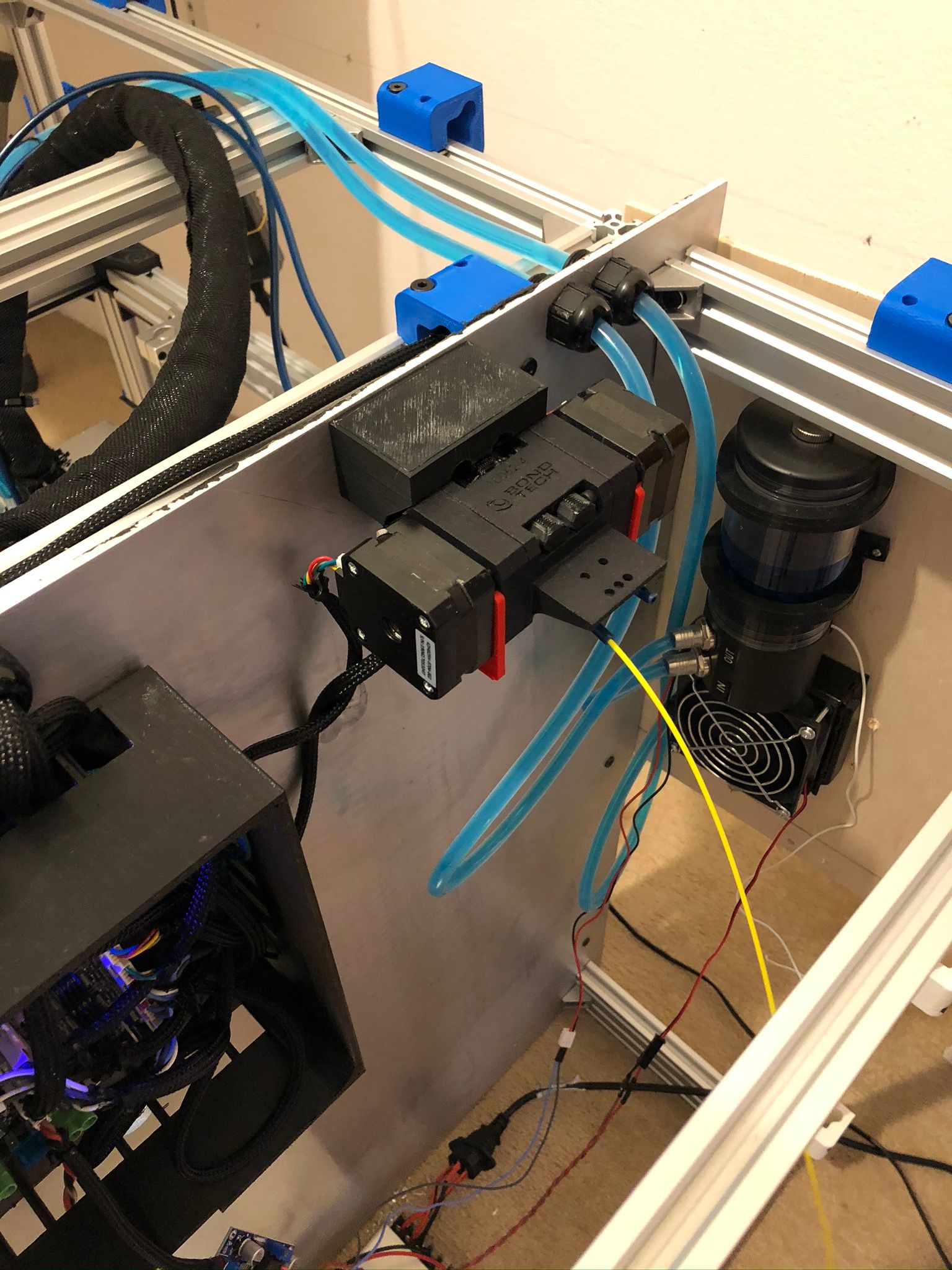

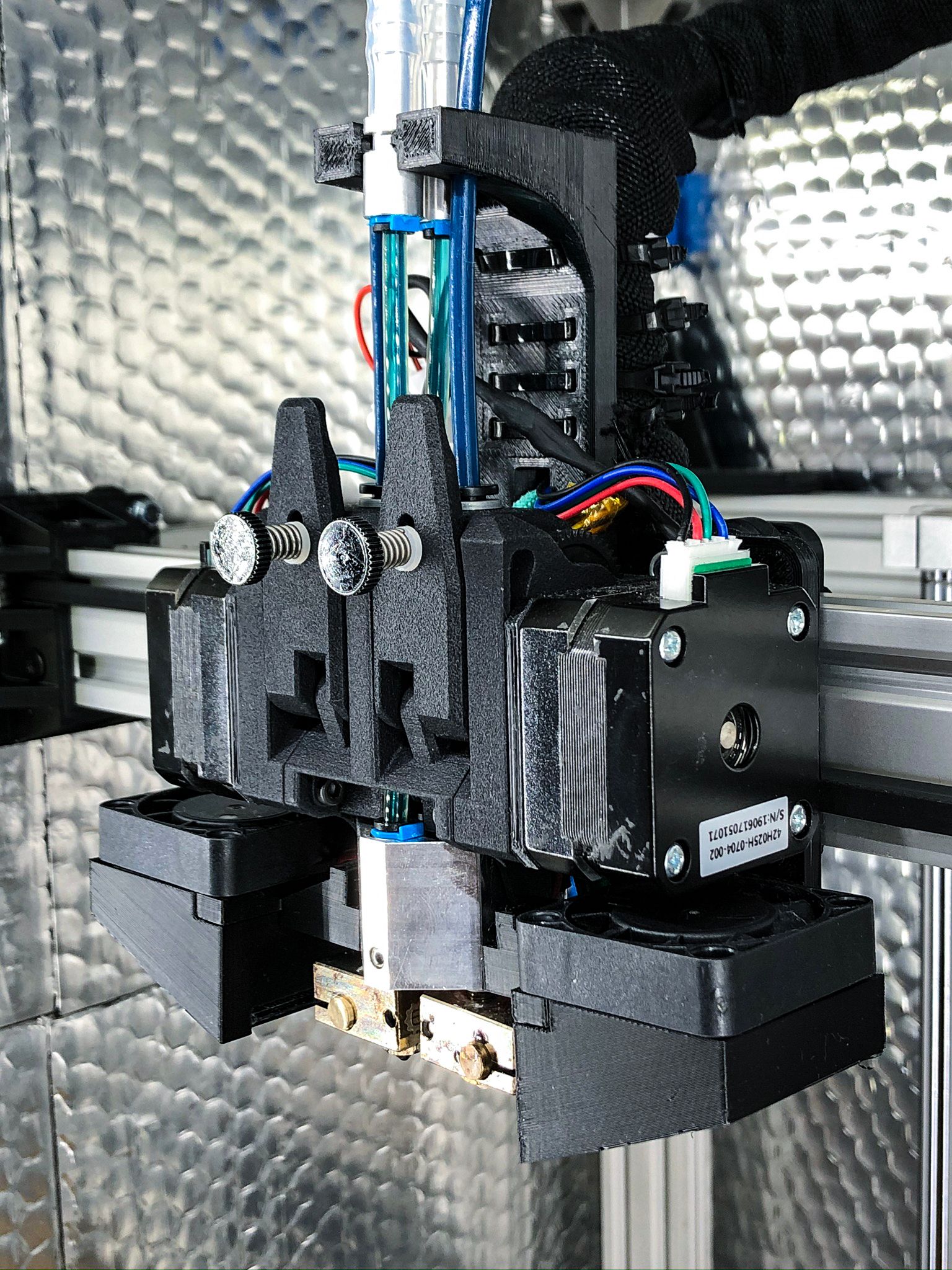

I found another problem with my bowden tube, that bend on the picture was causing all unnecessary blobing... I also managed to shorten bowden tube to 650mm.

This was before:

This is a new mount for extruder eliminating that bend:

And my first Marvin with 50microns layer height

Tomorrow I should get magnetic flexplate from FIlafarm, after almost two months of waiting!

-

@felt342 said in WIP CoreXY with heated chamber:

Dual extrusion doesn't really work as I expected - maybe my tool change files should be adjusted properly. But it does leak then it switching tool then it goes to continue print - but I think this is just spending more time on tweaking feed rates and pressure advance.

I found that dual extrusion can work well under the following conditions:

- Use a large amount of retraction when retracting filament from the unused tool. This only really works with PTFE-lined hot ends, which are great for PLA but limiting with other filaments (E3D quotes max 240C for the Lite6).

- Use the standby temperature facility of RRF to keep the non-printing nozzle at a lower temperature, e.g. 160C when printing PLA.

A remaining disadvantage of dual nozzle printing is that when the non-printing nozzle passes over filament that has just been laid down, it leaves a mark.

IDEX dual extrusion printers do not have these disadvantages. Perhaps your printer can be converted to IDEX?

-

IDEX - that looks like a proper way to do it, I even will not lose any building volume as I do have good free spacing on a side! Thanks for a suggestion. I investigated a bit and found Dyze hotends exist with liquid cooling addition, sadly I didn't find anything similar from E3D. Do you maybe have a suggestion of another single liquid cooling hotends?

Haven't look yet for a CoreXY conversion to IDEX, but it should be doable with just Duet wifi what I have now?

-

@felt342 said in WIP CoreXY with heated chamber:

IDEX - that looks like a proper way to do it, I even will not lose any building volume as I do have good free spacing on a side! Thanks for a suggestion. I investigated a bit and found Dyze hotends exist with liquid cooling addition, sadly I didn't find anything similar from E3D. Do you maybe have a suggestion of another single liquid cooling hotends?

Haven't look yet for a CoreXY conversion to IDEX, but it should be doable with just Duet wifi what I have now?

E3D doesn't sell a water cooled version of the V6 (except for a water-cooled version of the Titan Aero), but if you search "water cooled e3d v6 heatsink" then there are a few hits, such as this one https://youprintin3d.de/hotendszubehoer/e3d/wasserkuehlung/792/water-cooled-heatsink.html. I've no experience of either those or the Dyze hot ends.

An IDEX printer requires at least 6 stepper drivers, so one more than you have on your Duet WiFi.

-

Oh yes I see, will need an extension board

Thanks for a E3D water-cooled heatsink! -

So far I am having decent results using a Chimaera for different support material. I placed the support nozzle ~30u higher than the main nozzle, which prevents dragging. Extensive cooling and wiping during a toolchange takes care of the ooze.

It is slow as hell though. Idex or toolchanger would be way better.

-

Can you post your tool change files, please?

-

Sure: https://www.icecoldcomputing.com/directlink/3dprinter/Dabit3D_config_10feb2020.zip

Mind you, these files are a work-in-progress also. I reworked the tpostX.g files yesterday to improve the wiping process, and did not test them yet.

-

Thank you! I will give a try to it.

-

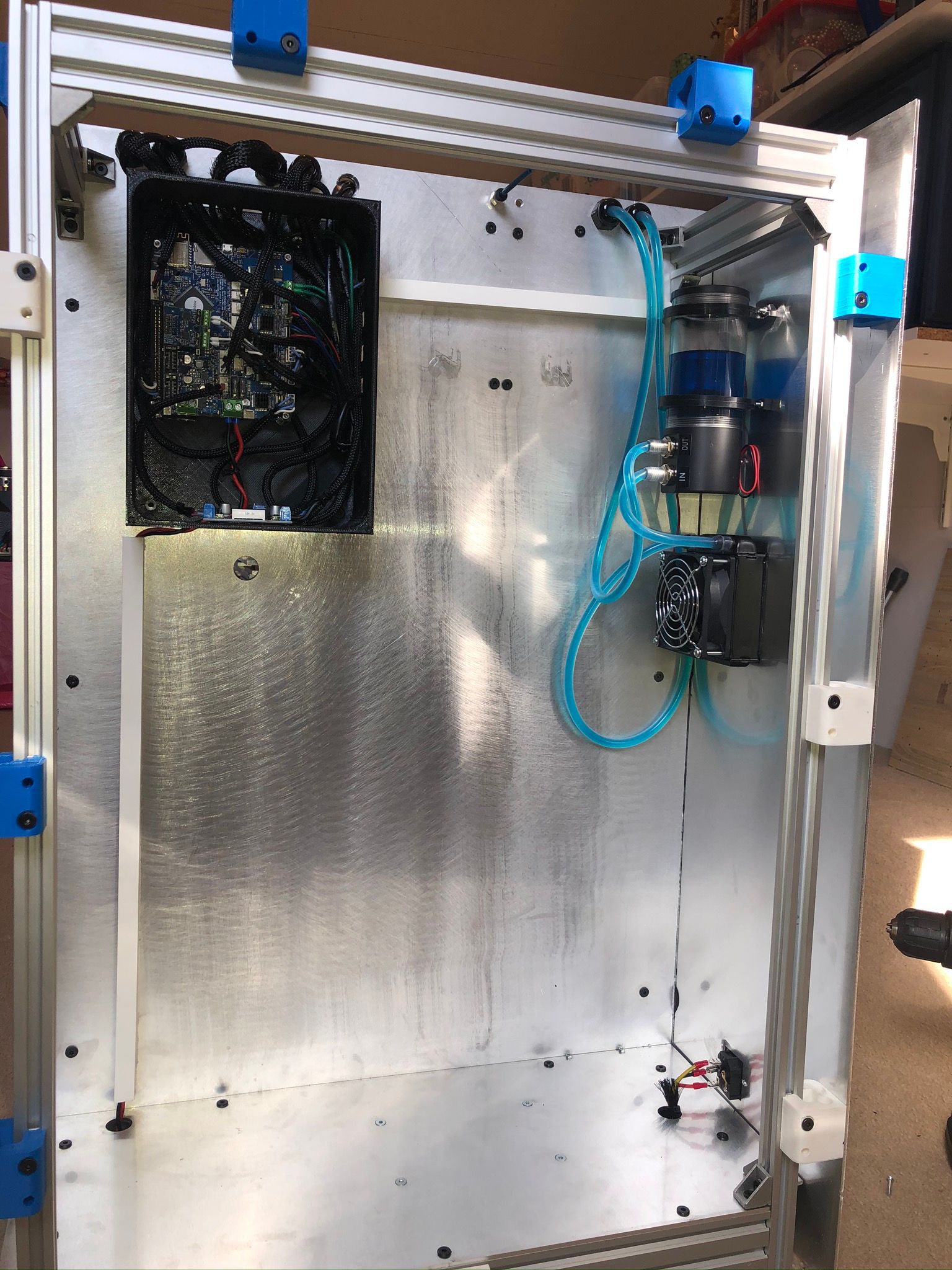

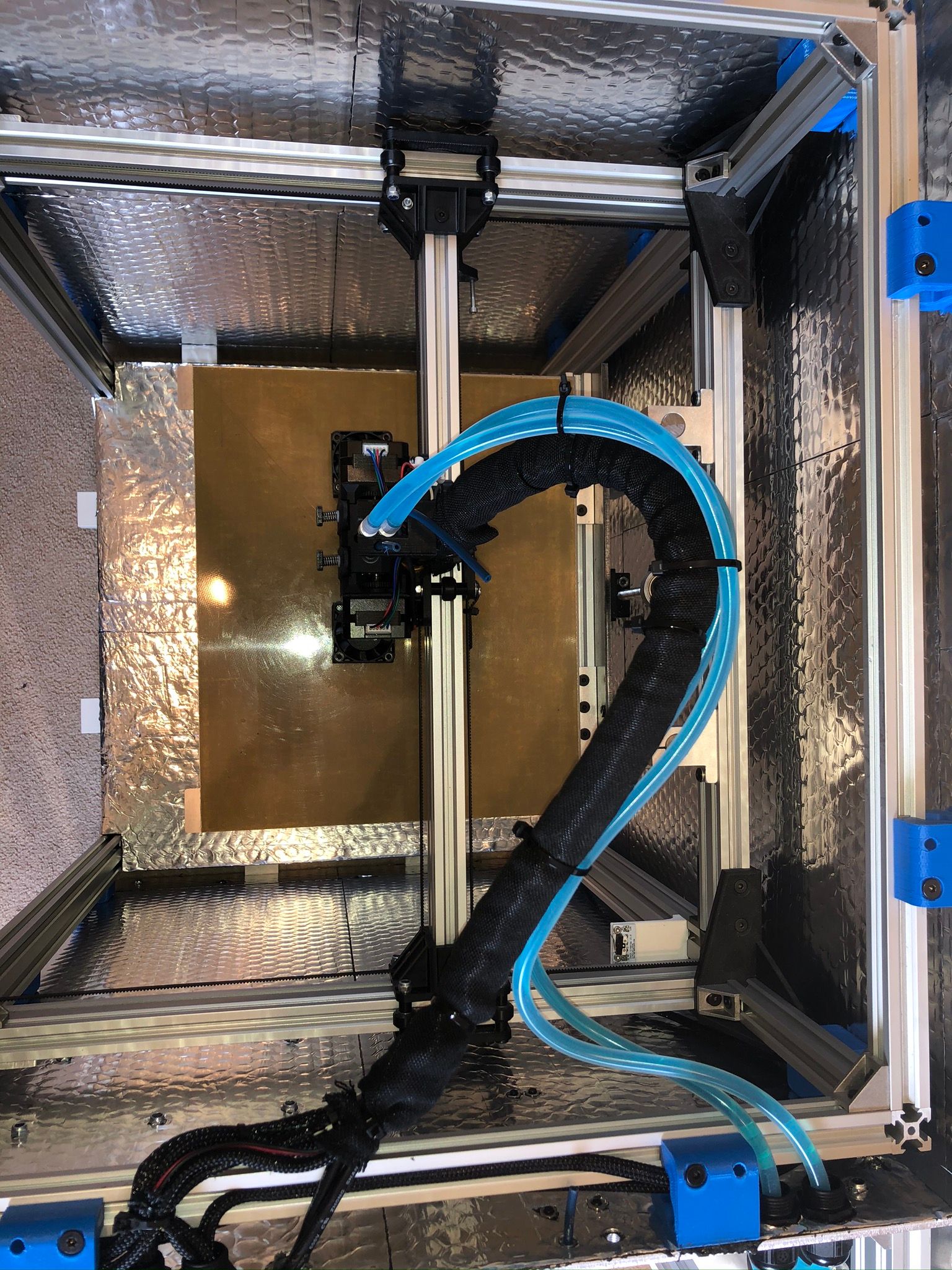

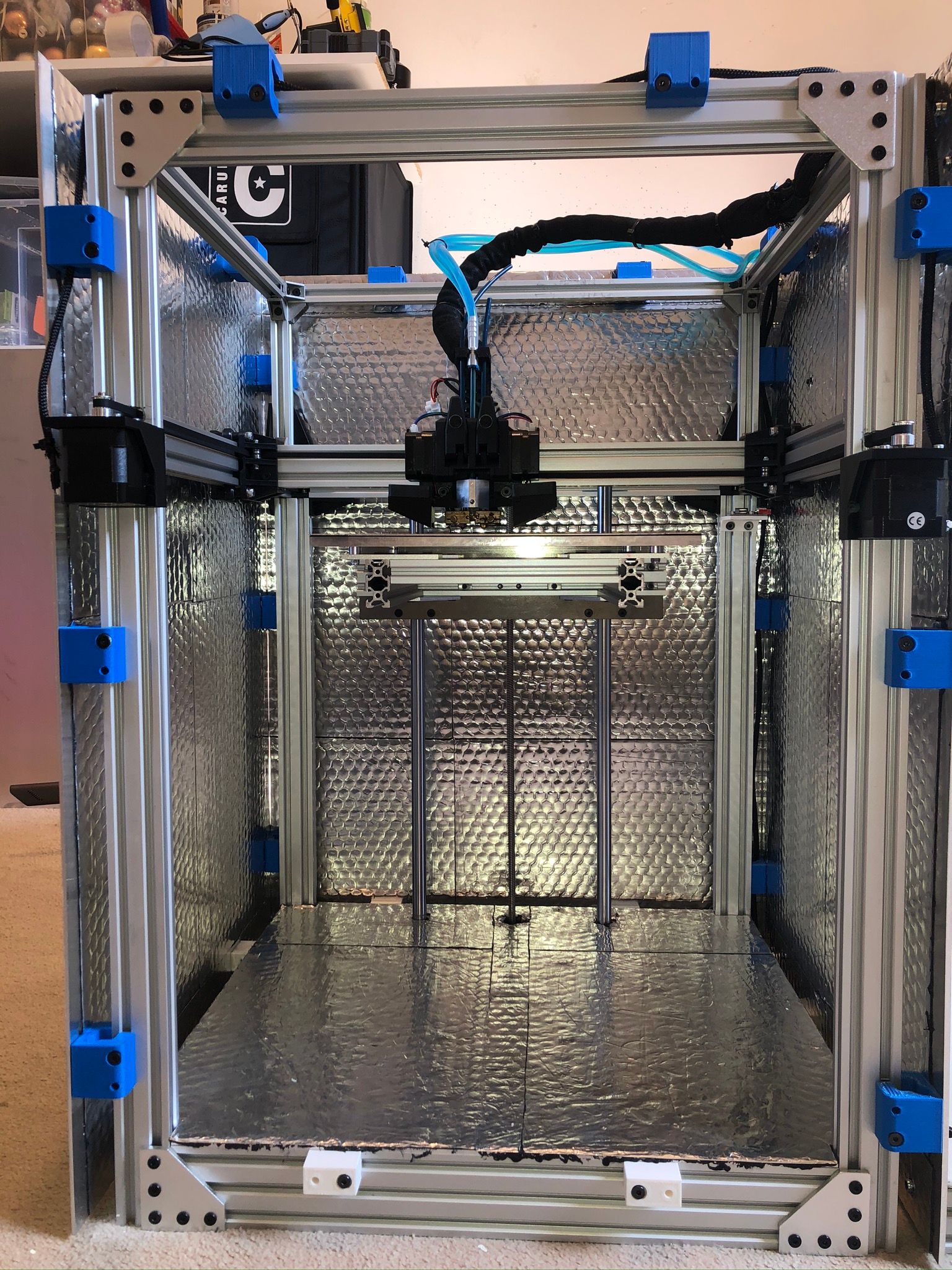

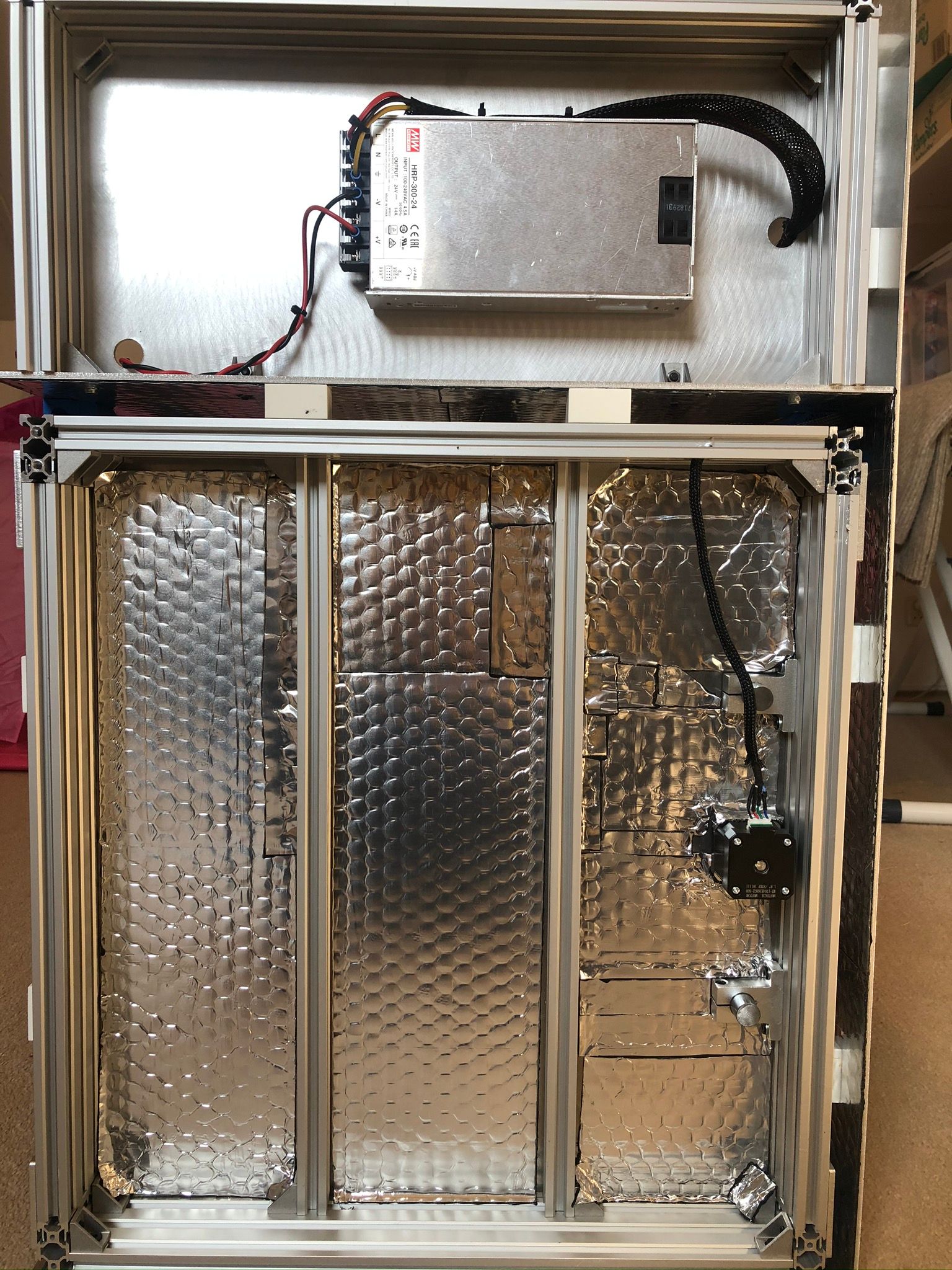

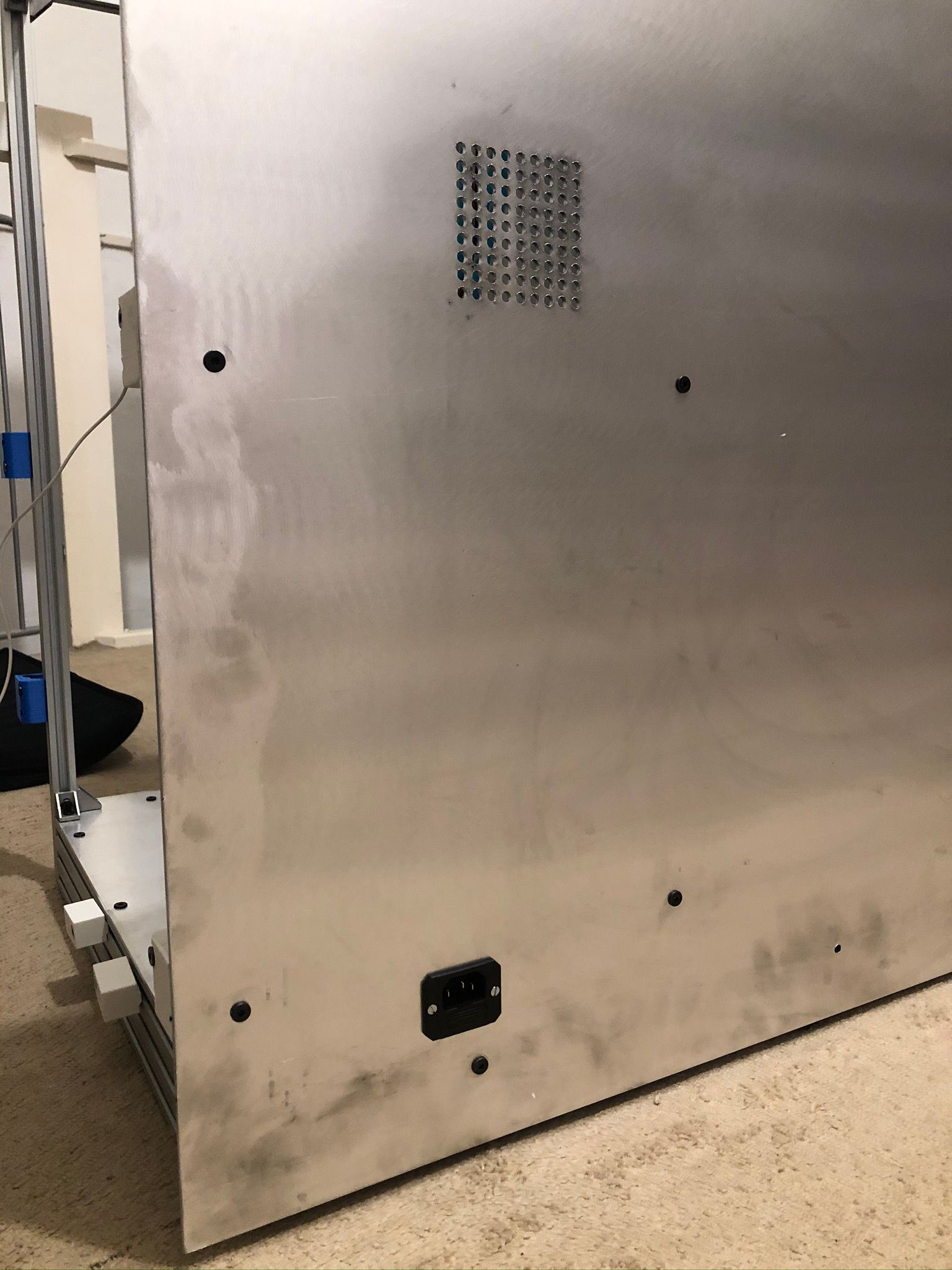

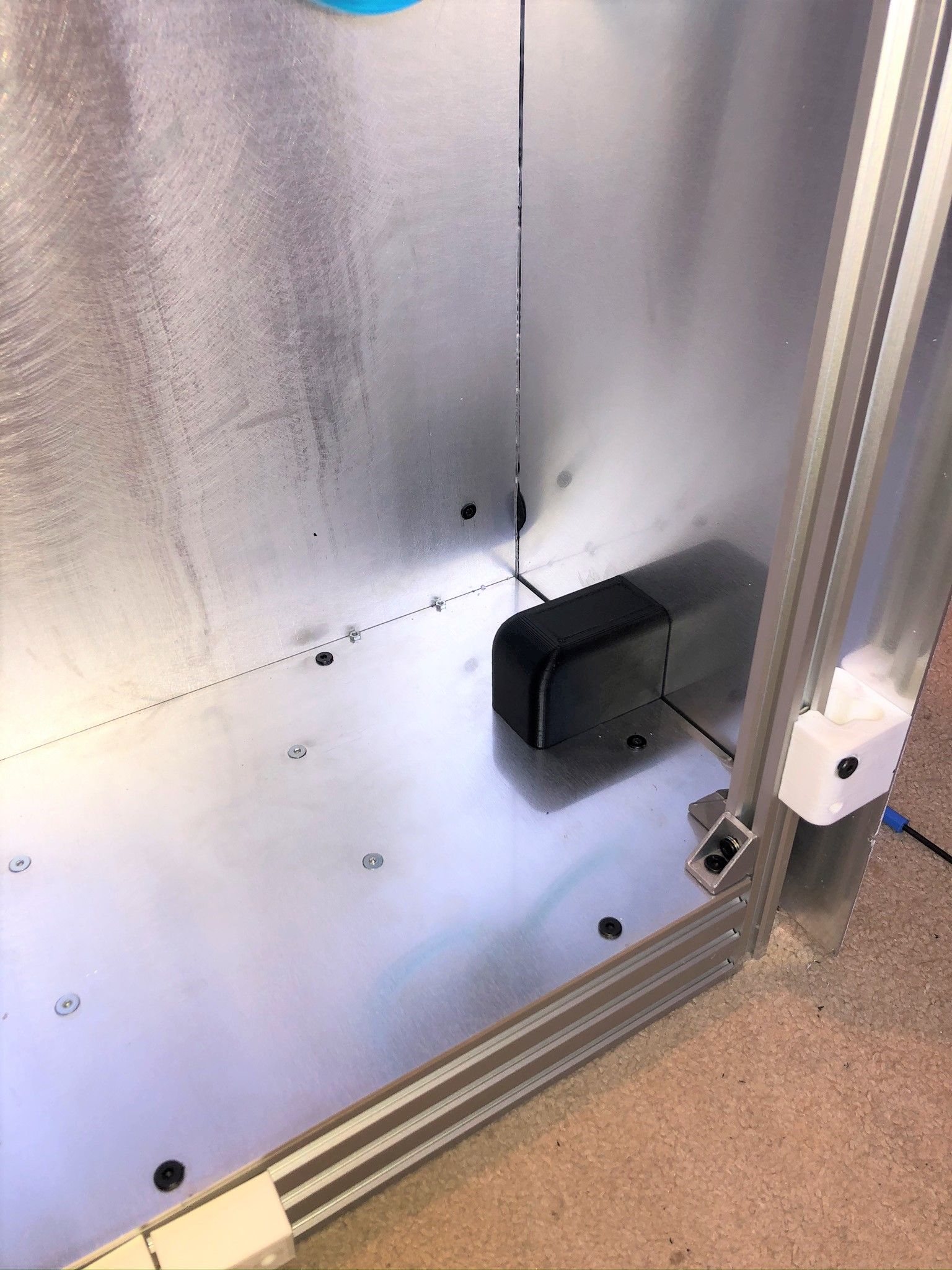

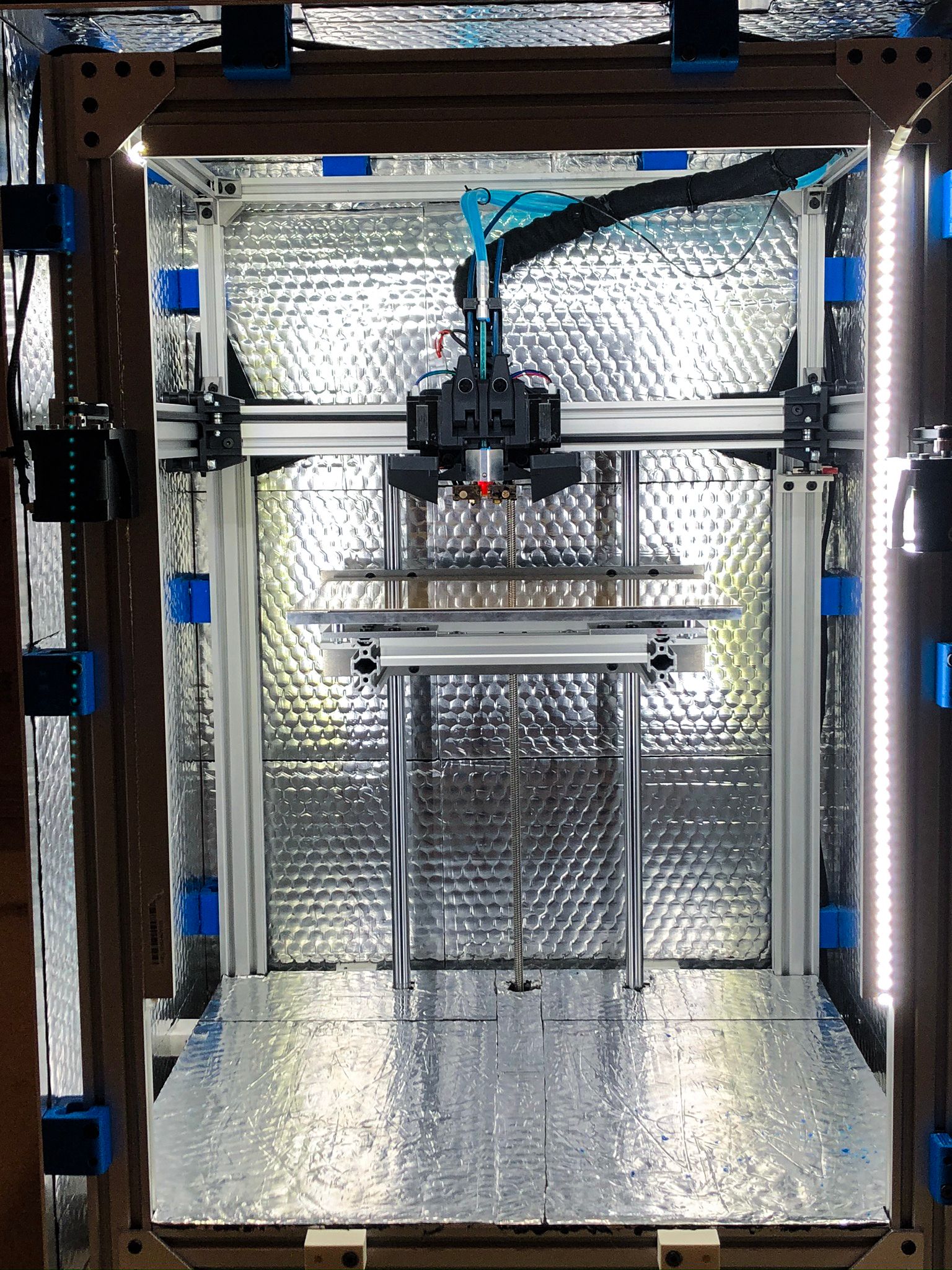

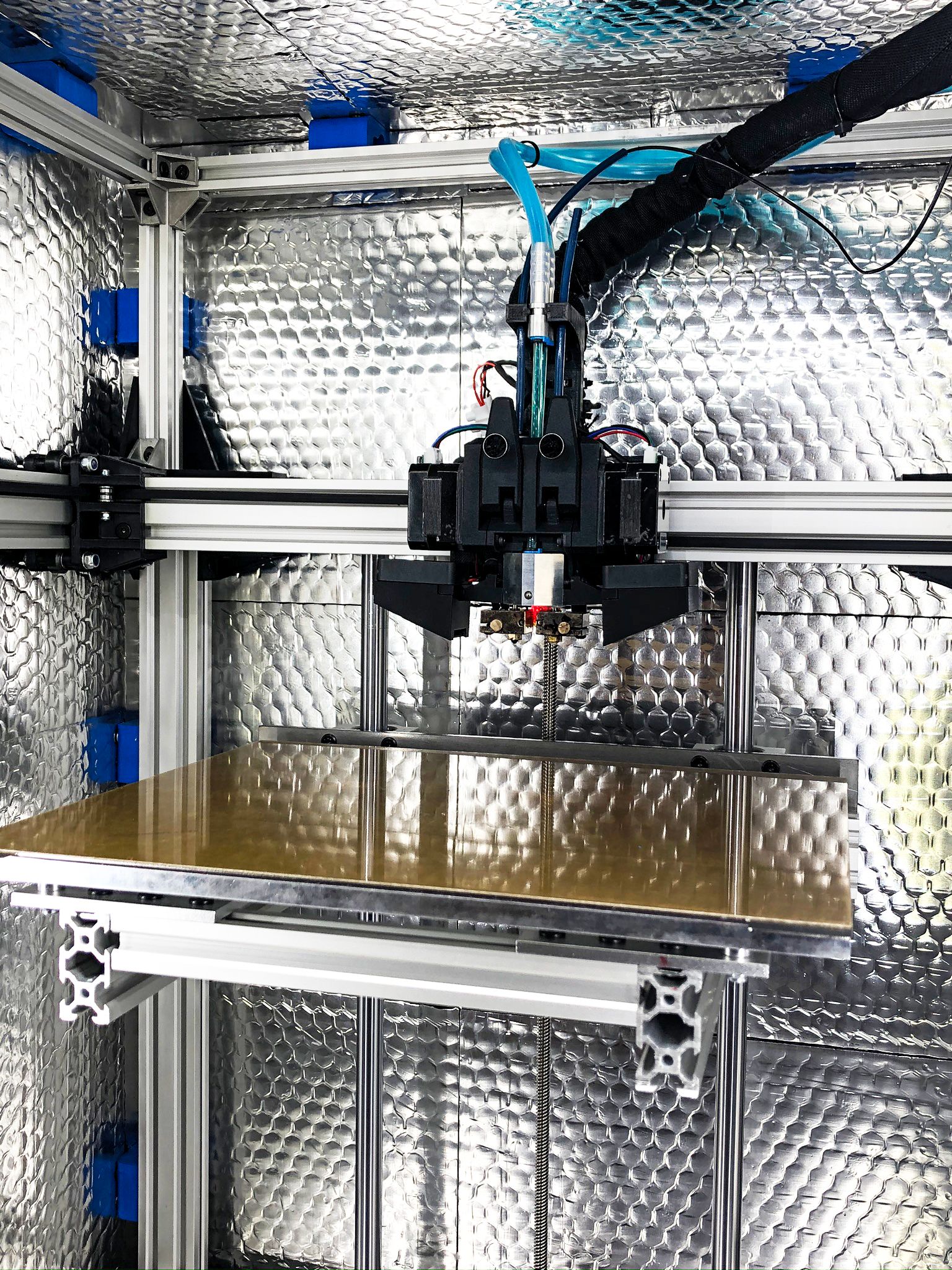

Some updates on work in progress machine

At this moment I am - working on lighting, sealing the chamber with aluminum foil, figuring out the door mechanism, wheels, and feet! Eventually, it became direct drive extruder, much happier with results!

https://www.icloud.com/photos/#07fyEOQcG_z7WxKabaN22UowA -

Nice! Looks like you're getting great print quality, too.

Does that center frame member on the top of the machine interfere with the extruder carriage cables/hoses? It looks like it might depending on the position along the X axis.

-

Thank you!

Yes indeed it looks like it might, but I moved it to the right so it does not interfere. In the end, I will remove it, otherwise, the cable hose and liquid hose will be in touch with top cover and probably will mount cable chain.

The big thing I want to mount and test is a heated bed, but with this world situation of Corona I am already in a delay of 3 months...There is my latest benchy

-

A bit of safety first! Kids around...

-

Its also visible how cantilevered bed is quite stable.

Print test - 100mm/s internal perimeters, exterior got 77 mm/sec. -

And there is lighting, and top covered. Still waiting for a heated bed to come...

-

Do those print cooling fans actually move any air? Axial fans don't usually work against the back pressure that any sort of flow restrictor produces.

-

They do seems enough, but I must say they always on 75% to make me desirable result, meaning very loudly also :)).

Will you suggest to change on something else? I fully am open to comments and experience! -

Radial blowers move more air against the pressure produced by flow restrictors. This type of thing usually works better: https://www.amazon.com/FYSETC-Cooling-50x50x15mm-Radiator-Accessories/dp/B07NTKG9K4/ref=sr_1_15?crid=O279YCVTBA45&dchild=1&keywords=radial+fan+24v+for+3d+printer&qid=1585683940&sprefix=radial+fan%2Caps%2C168&sr=8-15

-

Thanks! Ordered! Need to figured out the connection method, as I want to place watercooling block later on the extruder motors... It doest not matter the position of how I can place radial fans?

-

@felt342 I don't think the orientation of the blower matters, but probably best to check a data sheet if there is one.