Mosquito and blobs at the end of perimeter

-

Have you seen this guide yet?

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40

It goes through initial calibration of things like the extruder.

Your cubes still look a little hot and over extruded, but that could just be due to the fact they are such tiny objects. Try either printing a larger object or print two cubes at once separated on the bed to allow for longer layer times.

-

Since you changed hotends (and nozzle? ) is it possible that the nozzle is not the diameter you think it is? If you extrude into air, what is the diameter of that material and is it consistent?

-

@3DPMicro yep, nozzle is brand new e3d 0.4, extrusion is consistent and of the proper diameter. I started thinking, maybe the problem is not in the hotend but in mechanics? When updating the hotend, I slightly changed the configuration of my carriage sliders, they look more or less stable but could that provoke blobs?

-

@Phaedrux that is actually a good idea, last time I calibrated the extrusion rate when I was using AiO EVO hotend that actually has consistent underextrusion

-

@Phaedrux that is quite curious, extrusion width in vase mode was 0.55-0.6, going to try a complex model with 0.87 extrusion multiplier. My extruder is calibrated to be completely accurate, so how overextrusion is even possible?

-

Okay, that is even more curious - I decided to experiment with the retraction speed, and lowering speed actually fixed the problem, no idea how is that even possible.

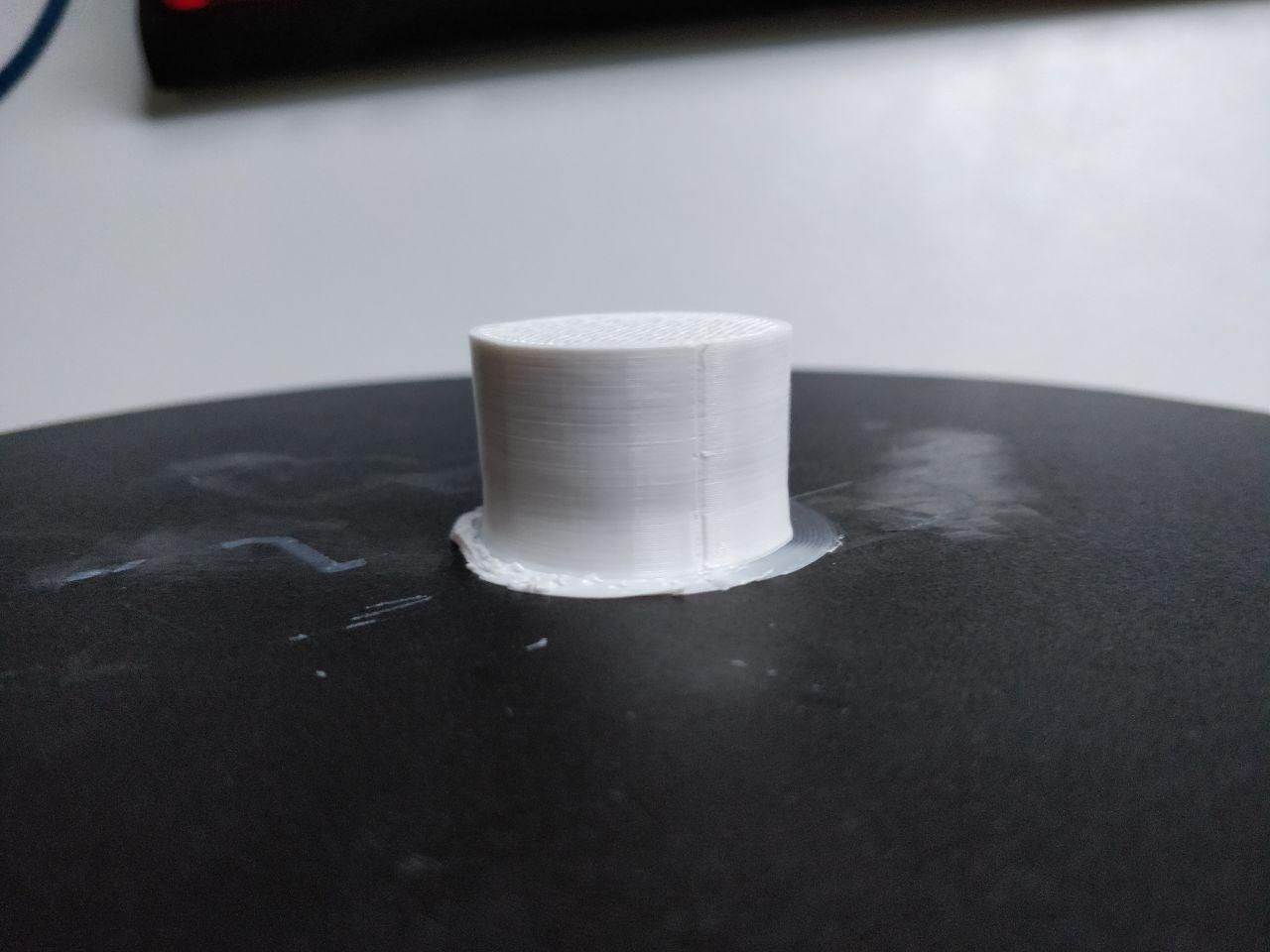

On this photo, I change the retraction speed from 100 to 25 each 5mm, so speeds from 25 to 75 provide best results.

-

@skayred said in Mosquito and blobs at the end of perimeter:

I change the retraction speed from 100 to 25

Purely speculation, but perhaps such fast retraction was breaking the filament inside the nozzle and introducing some air? Then when unretracting it was causing the bubble to pop?

Either way, once you have PA tuned, you should retune retraction since the amount required will likely go down a bit.

-

@skayred said in Mosquito and blobs at the end of perimeter:

I change the retraction speed from 100 to 25

Is it PETG? Then you can find that dependency on the web.

I had similar issues.

The biggest I have noticed was: I had extreme under extrusion after retraction. Witch leads to gaps printing a single perimeter cube.

After changing extruder, nozzle, hotend.....without success, I noticed that a much lower temperature was reducing the gaps.

That set me on the path looking for the right filament settings.

In the end decreasing the retraction speed to around 30mm/s did the trick…

“The faster, the better” isn’t valid for PETG. -

@DIY-O-Sphere yep, exactly PETG, and I have no idea why 100mm/s retraction for the same spool was fine for E3D V6 with PTFE but not so fine with all metal Mosqito

-

@Phaedrux well, it could be but impossible to analyze

All the prints with 100mm/s had two common issues - overextrusion right after retraction, and some kind of 'extra extruded filament' on the other side, so what you said seems to be the most logical idea. I cannot blame Mosquito, it could happen because of various reasons - from spiral-like bowden tube to strange pneumatic clamp I use (accidentally bought small clamp for aluminium and then had to press the brass part inside)

All the prints with 100mm/s had two common issues - overextrusion right after retraction, and some kind of 'extra extruded filament' on the other side, so what you said seems to be the most logical idea. I cannot blame Mosquito, it could happen because of various reasons - from spiral-like bowden tube to strange pneumatic clamp I use (accidentally bought small clamp for aluminium and then had to press the brass part inside)