Adding a 24V safety relay for the heaters, any thoughts?

-

@DaBit said in Adding a 24V safety relay for the heaters, any thoughts?:

Much safer than your TV set or vacuum cleaner anyway.

Printers tend to run for longer, so thats in favour of the TV and vacuum.

My issue with thermal fuses: For the bed they are fairly easy to add, but for the heaters (main source of danger...) I have not yet found a clean solution.

You don't have to use 250°C on the heater block. 50-100°C or whatever the normal ambient would suggest on the heatsink mount should also work?

-

@DaBit said in Adding a 24V safety relay for the heaters, any thoughts?:

AFAIK the Duet RRF software won't deactivate PS_ON when it is not printing and a sensor/heater anomaly is detected

This seems to be a safety concern. Any reason why duet3d doesn't have this feature?

for the heaters (main source of danger...) I have not yet found a clean solution. A 'micro' fuse already posesses a 15mm long/4mm diameter body or so, they are hard to get above 250C trip temperature, and mounting them to a regular E3D v6 block and not losing the possibility to use standard silicone socks is not easy either.

I think what we need are nozzle heaters with builtin protection. Leading companies such as E3S and Prusa could pave the way and China will follow. This will be a drop in replacement that can fit in any existing printer and will sell like hot cakes.

-

@zapta said in Adding a 24V safety relay for the heaters, any thoughts?:

Leading companies such as E3D and Prusa

I was indeed genuinely surprised to see the Hemera didn't have this either in the heater cartridge or part of the heatsink.

-

I do wonder if the lack of obvious protective measures is down a little to tryin to maintain the CE certification as IT Equipment rather than under the machinery directive.

-

@zapta said in Adding a 24V safety relay for the heaters, any thoughts?:

@DaBit said in Adding a 24V safety relay for the heaters, any thoughts?:

AFAIK the Duet RRF software won't deactivate PS_ON when it is not printing and a sensor/heater anomaly is detected

This seems to be a safety concern. Any reason why duet3d doesn't have this feature?

It will deactive it, but after 600s (default value) if the fault isn't cleared.

-

@dragonn are you sure it will drop PS_ON while the printer is Idle? I was under the impression it was still only while printing.

Work around is to ensure your warmup and cool down script is in in the build gcode itself and the M80/M81 is in there. Personally I prefer to let my machine sit for while warming up, but once my zprobe and probe offset is nailed down a bit better I think it will be ther way to go.

-

Isn't it fun to have strong opinions on the internet? Here are mine:

(1) Trusting firmware for safety, if not designed from the very beginning around total shutdown driven by a hardware watchdog (charge pump, etc), is not safe.

(2) Physical/physics based systems, such as temperature based fuses, can be safe when inserted at the right points in a larger system.

And if you have (2), what was the point of (1) again? Oh, yeah, to protect any one-shot devices in (2). That's how you should think of (1)... not safety, just a convenience. Only (2) can yield safety.

To be clear: Relays are useless, and possibly worse than useless, by given a false sense that they accomplish something.

-

@Danal Just to play Devil's advocate, one could make a case to say that the more components there are and the more complex the wiring, the less safe the piece of equipment becomes. For example fitting a thermal fuse to a mains heated bed could in itself be construed as a safety hazard. If it carries mains voltage then potentially if it fails or if a wire to it gets chaffed, same part of the printer which might not be properly grounded could then become "live". But at least you would pass through the pearly gates comfortable in the knowledge that your house didn't burn down.

(To be clear, if you miss the smiley this wasn't intended as a serious post - just feeling a bit mischievous).

-

@Danal said in Adding a 24V safety relay for the heaters, any thoughts?:

Isn't it fun to have strong opinions on the internet? Here are mine:

And here is mine

"Perfect is the enemy of good".

"Perfect is the enemy of good".Take heat block thermal fuses for example, they are difficult to install so instead we can gain some protection with software based runaway logic.

Perfection and 'all or nothing' approach in engineering often lead to paralysis or sub optimal designs compare to more practical approach that is driven by cost/benefit analysis.

YMMV.

-

Valid points.

On complexity: Agreed. At the same time, that is a large part of my resistance to relays and dual ssrs and... often the proposed solutions are layer after layer of complexity. Which peaks reliability and then goes downhill.

On Perfect v Good: Agreed. Very much agreed. I just don't see firmware (that's not backed by silicon) as good (enough). Which is why I have "fireballs" on top of my printers. (Common in Europe, seem uncommon in the US... they are 2 kilos of the same powder that's in a small fire extinguisher, with a tiny bit of black powder to blow it around if the ball itself burns. Physics.) Of course, I'm not going to turn off any of the firmware monitors...

-

@deckingman said in Adding a 24V safety relay for the heaters, any thoughts?:

fitting a thermal fuse to a mains heated bed could in itself be construed as a safety hazard.

If you do not ground all metal parts in the neighbourhood of a mains powered device, you get all the risks on a silver tablet, even without the fuse.

However, complexity is a concern, that’s right. While a thermal fuse adds little to it, other safety measures may increase it considerably. Nevertheless, they can help… as long as they follow @Danal’s law #2

– In other words: if you monitor a system, don’t rely on data or functionality of the system you want to observe.

– In other words: if you monitor a system, don’t rely on data or functionality of the system you want to observe.@zapta True, you can over-engineer a system, which is then less than perfect. But to rely on the values from the thermistor in your hot end is not „good“, to stay with your terms. As it is already part of the internal safety management of the Duet, you don’t add security at all - you just duplicate the efforts the firmware already takes to prevent a thermal disaster.

So, my „strong opinion“

: employ a second thermistor for a circuity which is completely independent from the Duet. Still not perfect, but better than not-good.

: employ a second thermistor for a circuity which is completely independent from the Duet. Still not perfect, but better than not-good. -

@infiniteloop said in Adding a 24V safety relay for the heaters, any thoughts?:

second thermistor for a circuity which is completely independent...

Not trying to convince, just having fun clarifying: I like physics based things as the second (final?) layer.

-

@Danal said in Adding a 24V safety relay for the heaters, any thoughts?:

I like physics based things as the second (final?) layer.

Deal: As a third layer, perhaps?

-

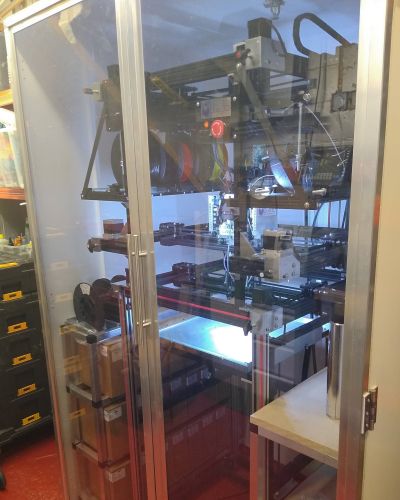

@Danal On the subject of fire balls, my printer now has a new home

and in the top there is this

It's a clean agent fire extinguisher. That is to say, it floods the chamber with an inert gas - much kinder to sensitive electronics than powder.

More info here........

https://www.fireandsafetycentre.co.uk/advice-centre/clean-agent-extinguishers/ -

@infiniteloop said in Adding a 24V safety relay for the heaters, any thoughts?:

@deckingman said in Adding a 24V safety relay for the heaters, any thoughts?:

fitting a thermal fuse to a mains heated bed could in itself be construed as a safety hazard.

If you do not ground all metal parts in the neighbourhood of a mains powered device, you get all the risks on a silver tablet, even without the fuse.

Of course that's true - you must have missed my last sentence so I'll copy and paste it again - quote..........

"(To be clear, if you miss the smiley this wasn't intended as a serious post - just feeling a bit mischievous)."

-

@Danal said in Adding a 24V safety relay for the heaters, any thoughts?:

To be clear: Relays are useless, and possibly worse than useless, by given a false sense that they accomplish something.

Worthless comment without clarification or reference. They accomplish a very sound backup to cut power to a failed MOSFET as trusted by safety circuits in industrial equipment when complimented by diagnostic coverage, which can be covered to a degree by procedure.

They are as "useless" as seatbelts in a car. Tyres and brakes are great and avoid most serious injuries due to accidents - perhaps all of them for a life time of a driver - but most would accept the minor inconvenience of a belt regardless of it not completely removing all risk of serious injury or death.

-

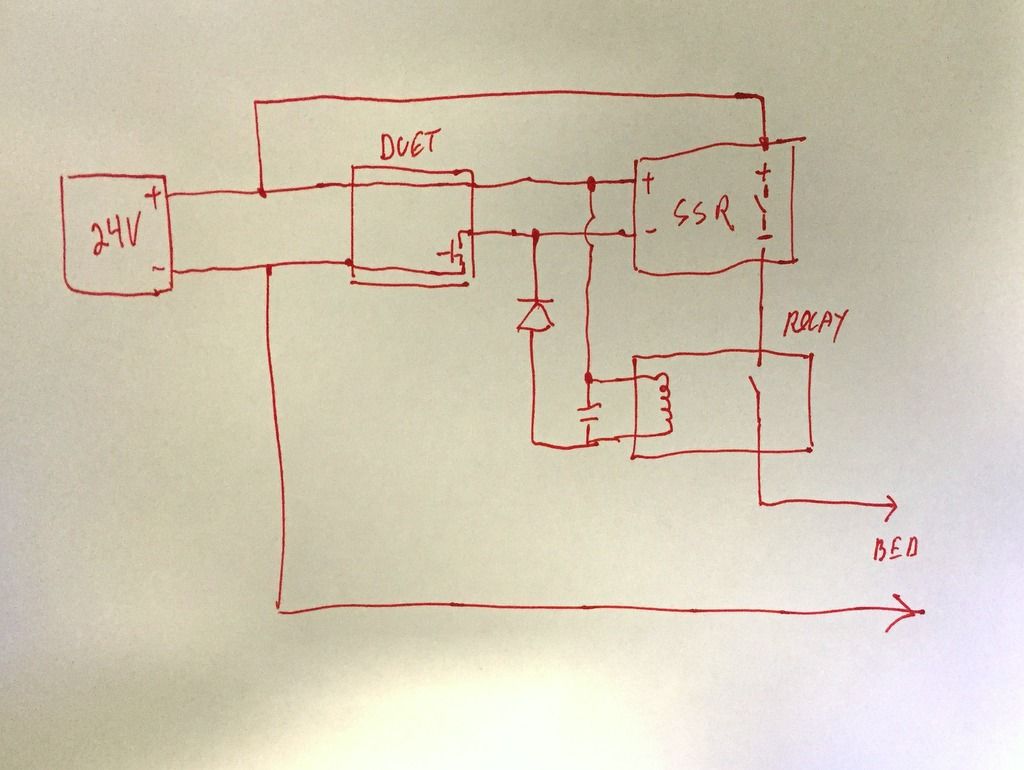

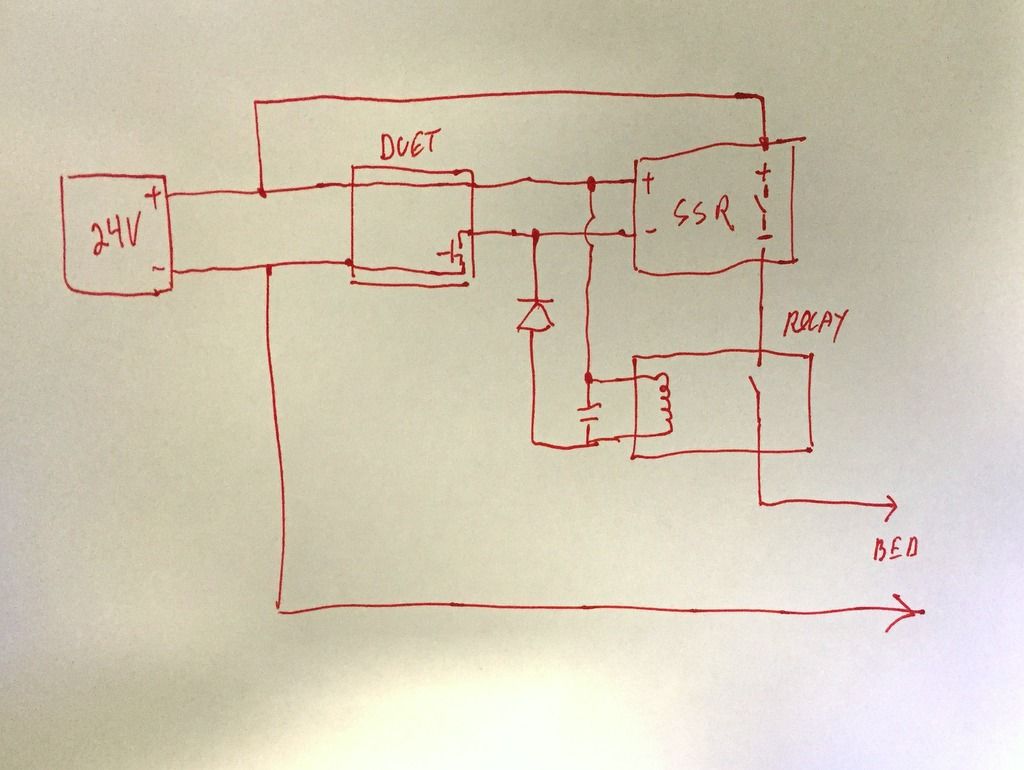

On a second thought, maybe the mechanical relay can be added without using the PS_ON signal. Something along the lines of the diagram below. The mechanical relay closes the circuit as long as the duet sends PWM to the heated bed. Once the duet stops sending PWM, the circuit will break even if the SSR's mosfet get shorted (the duet's mosfet drives a small load so much less likely to get damaged).

Will this work?

-

@zapta said in Adding a 24V safety relay for the heaters, any thoughts?:

the circuit will break

the circuit may break, i.e. still a chance albeit much lower that the relay fails to open as well

-

@bearer said in Adding a 24V safety relay for the heaters, any thoughts?:

the circuit may break, i.e. still a chance albeit much lower that the relay fails to open as well

My assumption is that mechanical relay is good at not getting shorted and solid stay relay is good at fast PWM switching so this may achieve the good of both worlds.

-

@zapta said in Adding a 24V safety relay for the heaters, any thoughts?:

On a second thought, maybe the mechanical relay can be added without using the PS_ON signal. Something along the lines of the diagram below. The mechanical relay closes the circuit as long as the duet sends PWM to the heated bed. Once the duet stops sending PWM, the circuit will break even if the SSR's mosfet get shorted (the duet's mosfet drives a small load so much less likely to get damaged).

Will this work?

Looks to me like you basically duplicated the SSR function in the relay so that if either SSR or Relay fails, there is no power to the heat bed.

If you ae going to the trouble of a safety circuit then you might as well make it completely redundant by running the relay coil through a thermal fuse to the 24V power supply. As long as there is 24V and the fuse is ok, the bed has power that can be controlled by the SSR. In the event of an overheat situation, the fuse blows and the relay drops out.

Not sure why you have the diode in there and not a flyback diode.