Need help with stopend switch.

-

Hi, I am new, have tried to fix endstops for my 3d with duet2wifi RepRapFirmware for Duet 2, 2.02 (RTOS) (2018-12-24b1) has built itself a BLV_mgn12. The problem is that can not understand how would microswitch work, have contacted switch to the outermost contacts on the switch NC and on duet2wifi on signal and ground, but without results. can any of you help me with that.

Regards Christian -

did you have this switch?

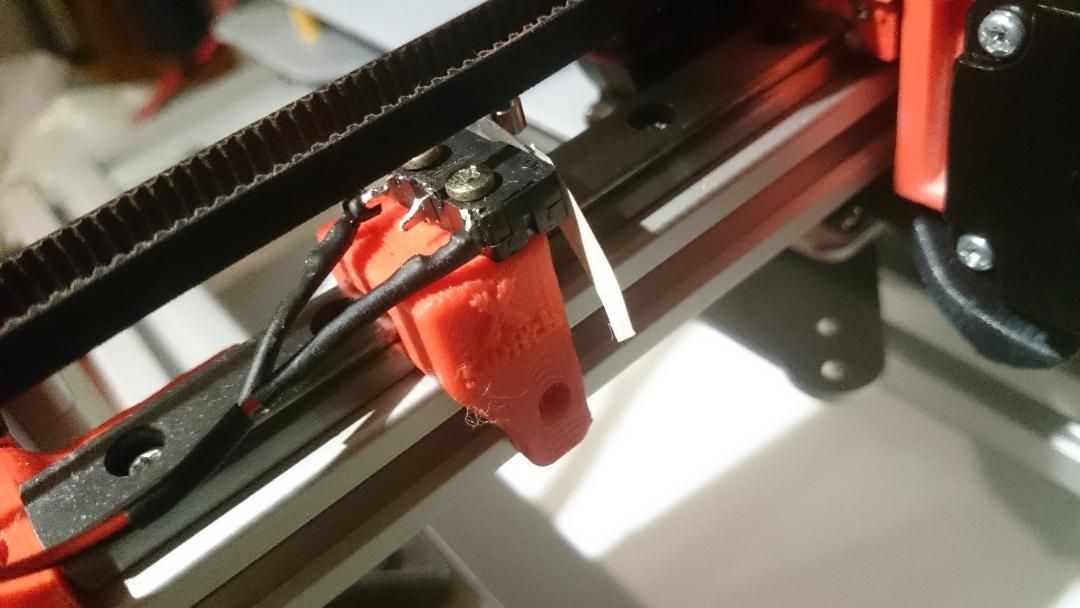

endstop microswitch

if yes on the thirt picture you see the cabel red is +3.3V black is gnd(-) and green is signal. -

No I have , connected to 1 and 2 (NC-C)

-

NC normaly means not conneted you have to use NO & C

-

Have followed this, do you know rotation on x y z stepper motor, maybe also my problem with switch.

https://duet3d.dozuki.com/Wiki/Connecting_endstop_switches#3.3V-compatible_optical_endstop

-

@SIam said in Need help with stopend switch.:

NC normaly means not conneted you have to use NO & C

on a switch NC is normally normally closed, and its preferred for limit switches as it would prevent movement if the wire breaks.

-

@chris4 said in Need help with stopend switch.:

can any of you help me with that.

maybe post a picture of switch and duet connection?

-

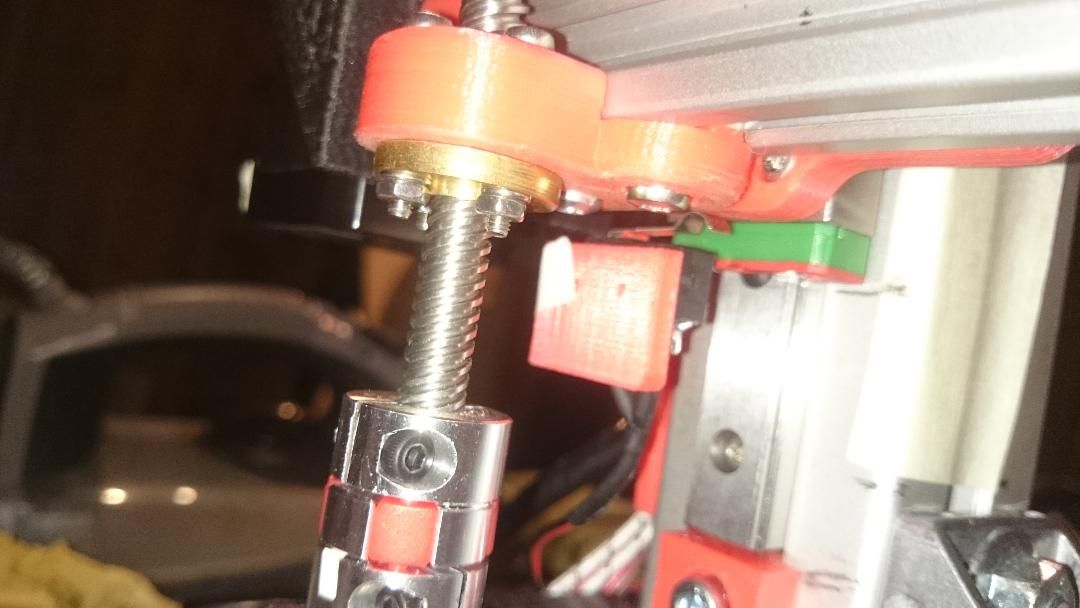

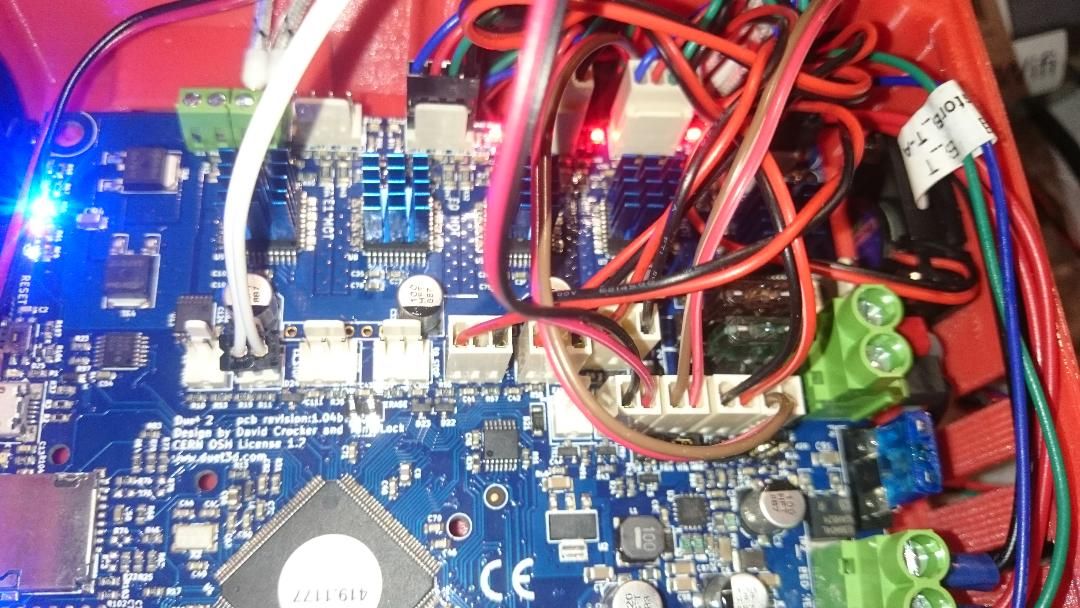

some pictures , where it appears that the endstop LED is on, but Z Y X is not in the home position, if I press each switch, the endstop LED is off on duet2wifi.

Should it be so?

home position OFF, not home location ON!

duet2wifi1).jpg

-

And the config.g

code_text

; Configuration file for Duet WiFi (firmware version 2.03)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.8 on Mon Feb 17 2020 10:46:54 GMT+0100 (centraleuropeisk normaltid); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Anet A8" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X100.00 Y100.00 Z400.00 E100.00 ; set steps per mm

M566 X600.00 Y600.00 Z18.00 E300.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E6000.00 ; set maximum speeds (mm/min)

M201 X1500.00 Y1500.00 Z100.00 E10000.00 ; set accelerations (mm/s^2)

M906 X500 Y500 Z500 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-33 Y-10 Z0 S1 ; set axis minima

M208 X220 Y220 Z240 S0 ; set axis maxima; Endstops

M574 X1 Y1 Z1 S0 ; set active low and disabled endstops; Z-Probe

M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M557 X20:200 Y20:200 S40 ; define mesh grid; Heaters

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4725 C7.060000e-8 R4700 ; set thermistor + ADC parameters for heater 0

M143 H0 S130 ; set temperature limit for heater 0 to 130C

M305 P1 T100000 B4725 C7.060000e-8 R4700 ; set thermistor + ADC parameters for heater 1

M143 H1 S275 ; set temperature limit for heater 1 to 275C; Fans

M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

T0 ; select first tool -

Homeall:

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Mon Feb 17 2020 10:52:04 GMT+0100 (centraleuropeisk normaltid) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-258 Y-235 F1800 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X5 Y5 F6000 ; go back a few mm G1 H1 X-258 Y-235 F360 ; move slowly to X and Y axis endstops once more (second pass) G1 H1 Z-245 F360 ; move Z down stopping at the endstop G90 ; absolute positioning G92 Z0 ; set Z position to axis minimum (you may want to adjust this) ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioning -

; homex.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Mon Feb 17 2020 10:55:31 GMT+0100 (centraleuropeisk normaltid) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-258 F1800 ; move quickly to X axis endstop and stop there (first pass) G1 H2 X5 F6000 ; go back a few mm G1 H1 X-258 F360 ; move slowly to X axis endstop once more (second pass) G1 H2 Z-5 F6000 ; lower Z again G90 ; absolute positioning -

; homey.g ; called to home the Y axis ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Mon Feb 17 2020 10:50:45 GMT+0100 (centraleuropeisk normaltid) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 Y-235 F1800 ; move quickly to Y axis endstop and stop there (first pass) G1 H2 Y5 F6000 ; go back a few mm G1 H1 Y-235 F360 ; move slowly to Y axis endstop once more (second pass) G1 H2 Z-5 F6000 ; lower Z again G90 ; absolute positioning -

; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Mon Feb 17 2020 11:09:06 GMT+0100 (centraleuropeisk normaltid) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 Z-245 F1800 ; move Z down until the endstop is triggered G92 Z0 ; set Z position to axis minimum (you may want to adjust this) ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioning -

I suggest you start by testing the endstop switch and wiring. See https://duet3d.dozuki.com/Wiki/Connecting_endstop_switches#Section_Test_endstop_switches.

-

Have fixed now, by changing the switch to NO and working now.

Thanks for the help.But one more question, how can change the speed of Z axis on the way to endstop (low switch) to a slow speed last cm to endstop. The same speed, as on the x and y axis. I have this config.g

; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Thu Feb 20 2020 13:12:07 GMT+0100 (centraleuropeisk normaltid) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Printer" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S0 ; physical drive 2 goes backwards M569 P3 S0 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y160.00 Z2560.00 E873.08 ; set steps per mm M566 X900.00 Y900.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X400.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X-33 Y-10 Z0 S1 ; set axis minima M208 X230 Y230 Z240 S0 ; set axis maxima ; Endstops M574 X1 Y1 Z1 S0 ; set active high endstops ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X-18:215 Y5:195 S20 ; define mesh grid ; Heaters M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C T0 ; Custom settings are not defined and the homez.g

homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Fri Feb 21 2020 13:36:08 GMT+0100 (centraleuropeisk normaltid) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 Z-245 F1800 ; move Z down until the endstop is triggered G92 Z0 ; set Z position to axis minimum (you may want to adjust this) ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioning Thanks Christian

-

@chris4 said in Need help with stopend switch.:

how can change the speed of Z axis on the way to endstop (low switch) to a slow speed last cm to endstop.

It's not possible to slow down before the endstop, because it doesn't know where the endstop is before being homed. Typically homing would be done in two passes. A fast movement to the endstop, followed by a short movement back, and then a slower movement towards the endstop again for better accuracy.

-

@Phaedrux said in Need help with stopend switch.:

It's not possible to slow down before the endstop, because it doesn't know where the endstop is before being homed. Typically homing would be done in two passes. A fast movement to the endstop, followed by a short movement back, and then a slower movement towards the endstop again for better accuracy.

Thanks.