Smart Effector part cooling

-

Hi there,

This weekend I have been able to finally install the smart effector on my Duet-driven Kossel. The upgrade has been easier than expected and so has been the software side of it.

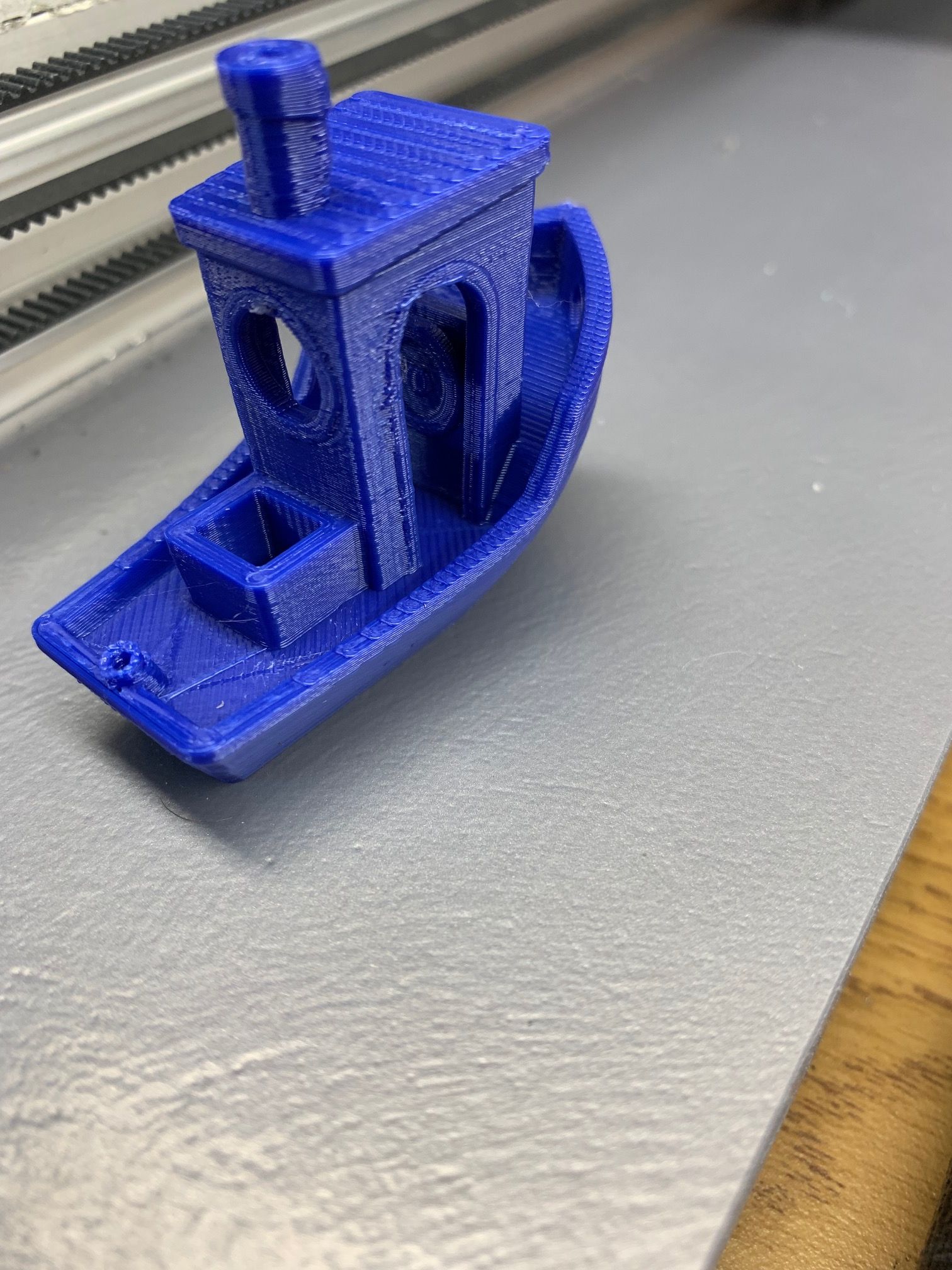

On a first instance, I used the suggested part cooling fan adapter. The first Benchy I did was not bad, but the side on the other side of the duct doesn't look all that well... (see picture).

Assuming it was because the duct, I printed the 270º of this thing on thingiverse:https://www.thingiverse.com/thing:2808152

The second Benchy looks even worse. While printing some of the edges start warping upwards, which ultimately causes the bad Benchy.

Something similar occurred the first time using the printer with Marlin and I was able to solve it by changing one of the physical measurements of the printer (I think it was the length of the delta rods).Any idea what could be causing it? With the other effector, I didn't experience something like this...

Thanks in advance

-

@FelixH if you’ve changed the effector and/or rods, has the rod length or delta diameter changed? If so, you’ll need to recalibrate, or the nozzle will not travel in a flat plane in XY. See https://duet3d.dozuki.com/Wiki/Calibrating_a_delta_printer#Section_Setting_up_your_initial_delta_parameters

Ian

-

@droftarts said in Smart Effector part cooling:

@FelixH if you’ve changed the effector and/or rods, has the rod length or delta diameter changed? If so, you’ll need to recalibrate, or the nozzle will not travel in a flat plane in XY. See https://duet3d.dozuki.com/Wiki/Calibrating_a_delta_printer#Section_Setting_up_your_initial_delta_parameters

Ian

that I certainly did. I run a delta calibration and stored the new parameters on config.g before printing...

-

@FelixH hard to say from the picture. Is it over extrusion, an extrusion blob (running too hot), or has the nozzle moved off the path (maybe something loose)? Or just insufficient cooling on the back side from the part fan?

Ian

-

I mostly don't run a part fan on my big delta, and I tend to print things pretty hot, to intentionally get really good layer bonding.

YMMV

-

@FelixH I’ve been using the 270 fan duct on a smart effector for some time now and have not had an issue. I print PLA at 225c, 75mm/s with an E3D Volcano hotend.

On printers that had part cooling issues, for me, it’s typically the bow that has issues.

HTH

-

@bricor said in Smart Effector part cooling:

@FelixH I’ve been using the 270 fan duct on a smart effector for some time now and have not had an issue. I print PLA at 225c, 75mm/s with an E3D Volcano hotend.

On printers that had part cooling issues, for me, it’s typically the bow that has issues.

HTH

The bow??

-

@FelixH The front underside curved part of the boat.

The bow (/baʊ/) is the forward part of the hull of a ship or boat

-

@bricor said in Smart Effector part cooling:

@FelixH The front underside curved part of the boat.

The bow (/baʊ/) is the forward part of the hull of a ship or boat

Oh... I see... I thought you were talking about a part of a printer...

-

@FelixH

What are the specs of the Delta printer?

Which extruder and hotend are you using?

What is the length of diagonal rods that you are using?

What type of material and heater settings are you printing with?

If you post your config file it may help in diagnosing the issue. -

@bricor My printer is an Anycubic Kossel Linear Plus XL. The OEM delta rods were 267 mm in length, but I have recently upgraded to an Smart Effector, original from Duet with the original E3D V6 hotend designed for this effector. The temp sensor is a thermistor, not a PT100. I purchased a Magball kit with a length of 288.18 mm.

I changed the effector this weekend in what I would consider a painless process. Following the online guide I set it up without headaches: I changed the delta rod lengths on the M665 command, the lines regarding the Z probe sensor and so on and then I run a Delta calibration. I got the results of the delta calibration and I typed it into the M665 and M666 commands on the config.g file. Then, I calculated the Y offset (edited the value on config.g), run a mesh grid calibration and here we are.

I am printing PLA on this machine. 210ºC first layer and 200ºC the rest. Cooling disabled for the first 2 layers and 95% the rest, I believe. This settings lead to nice results on cartesian printers I have.

my config.g file is as follows; Configuration file for Duet WiFi (firmware version 1.20 or newer) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool on Thu Jul 12 2018 20:54:00 GMT-0500 (Central Daylight Time) ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; After G32 auto-calibrate, copied from config-override.g ; Note: G31 Z (below) affects M665 H, and this is NOT yet calibrated. M665 L288.18 R139.59 H228.72 B106.0 X-0.192 Y-0.277 Z0.0 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0.16 Y-0.40 Z0.24 A0.00 B0.00 ; Put your endstop adjustments here, or let auto calibration find them ; Network M550 P"Kossel" ; Set machine name M552 S1 ; Enable network ;*** Access point is configured manually via M587 M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives M569 P0 S0 ; Drive 0 goes forwards M569 P1 S0 ; Drive 1 goes forwards M569 P2 S0 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes forwards M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation M92 X80 Y80 Z80 E96 ; Set steps per mm M566 X300 Y300 Z300 E300 ; Set maximum instantaneous speed changes (mm/min) M203 X12000 Y12000 Z12000 E12000 ; Set maximum speeds (mm/min) M201 X3000 Y3000 Z3000 E3000 ; Set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E1000 I50 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; Set minimum Z ; Endstops M574 X2 Y2 Z2 S1 ; Set active high endstops ; Z-Probe M558 P8 R0.4 F1200 H5 T6000 ; Set Z probe type to switch and the dive height + speeds G31 P100 X0 Y0 Z-0.14 ; Set Z probe trigger value, offset and trigger height M557 R105 S20 ; Define mesh grid ; Heaters M307 H0 B0 S1.00 ; Disable bang-bang mode for the bed heater and set PWM limit M305 P0 T100000 B4267 C0 R4700 ; Set thermistor + ADC parameters for heater 0 M143 H0 S95 ; Set temperature limit for heater 0 to 120C M305 P1 B4725 C7.060000e-8 ; Set thermistor + ADC parameters for heater 1 ; M305 P1 T100000 B4267 C0 R4700 M143 H1 S280 ; Set temperature limit for heater 1 to 280C M307 H1 A462.8 C245.1 D4.5 V24.2 B0 ;Hotend Autotune //Changed M307 H0 A141.2 C700.0 D0.4 V24.1 B0 ;Bed Autotune //Changed ; Fans M106 P0 S0 I0 F500 H-1 ; PART FAN - Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H1 T45 ; HOTEND FAN - Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on M106 P2 S0.20 I0 F500 H-1 ; ELECTRONICS FAN - Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off ; Tools M563 P0 D0 H1 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Automatic power saving M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss ; Custom settings are not configured -

As a follow up, I lowered the fan duct on the effector by aprox 2,25mm because I noticed it was quite higher than other printers. The Benchy was significantly better, but still showed a bloop on on of the stern corners. See photo. I beginning to suspect that may!be the fan is not powerful enough for part cooling tasks...

-

the axial fan blowing almost directly against a wall will not give you good cooling results. When my delta was still up and running, I used https://www.thingiverse.com/thing:3229241 with reasonable success.

-

@FelixH Take a look at these past posts. They might help. (the parts that relate to the AKLP config)

https://forum.duet3d.com/topic/13813/aklp-ckeck/2?_=1584349301962

One point to mention, I'm using a Bontech QR extruder.

I just checked, I'm using a PT100 so use the posted data for reference only and focus on the bits that apply directly to your machine like delta parameters and speeds. Not the extrusion and thermistor parameters.

-

@bricor

I see from one of your posts that you seem to fill in the delta settings without running a delta calibration... is that right?; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ;M665 R133.969 L272.869 B110 H287.79 ; Set delta radius, diagonal rod length, printable radius and homed height ;M666 X0 Y0 Z0 ; Put your endstop adjustments here, or let auto calibration find them M665 L288 R138 H304.65 B110.0 X0 Y0 Z0 M666 X0 Y00 Z0 A0.00 B0.00also, how come your height is 304 if you are using the Kossel frame?

finally, I found this value for the thermistor setting (original from E3D):

M305 P1 B4725 C7.060000e-8could somebody confirm it is correct?

-

@FelixH The Delta values in my config file are the default settings I use based on measurements. I set the tower heights (end stop switches) also based on measured values (that is why they are set to 0 in the config file). I then run auto calibration each time I start the printer. I only need to run auto calibration twice to get the desired result.

I posted the exact measurements of my printer, you should get the same results for height plus 8.5mm for the V6 compared to the Volcano that I use.

The thermistor values you posted are correct, I use the same for my other printers that use a standard E3D thermistors.

-

well, then... Everything seems to be accounted for, but still doesn't nail one of the corners of the stern of the Benchy. My last test was with a lower temperature (by 10°C) but no change at all.

I will try another filament now and wait until tomorrow to get new 40mm fans...

-

What infill % are you using? I typically use 20%.

-

15% is my default

-

@FelixH In case you missed it, I edited my last post and included some pictures of a benchy I ran last night