Smart Effector part cooling

-

The test with another filament was even worse...

@bricor could you send me a picture of your part cooling fan? -

@FelixH what exactly do you need a picture of, the fan or the label on the fan or the whole assembly?

Did you try the print at 20% infill?

-

@bricor said in Smart Effector part cooling:

@FelixH what exactly do you need a picture of, the fan or the label on the fan or the whole assembly?

Did you try the print at 20% infill?

Just a picture of the fan would be enough, I guess. I going to try the 20% right now. Stay tunned!

-

-

Looks exactly like the one I've just installed. 9 blades. I'm printing right now and it looks better than with the other fan, which only had 7 blades...

-

@FelixH are you still printing at 15% infill?

The reason I ask is that making multiple changes makes it difficult to diagnose the issue and determining what exactly fixed the issue.

-

@bricor yeah, that's the scientific method, one step at a time. Today I printed another Benchy with the new cooling fan. I went much better than yesterday, and yes, I'm still at 15%.

It still doesn't master that one corner, but it's much better than before. Maybe it prints way too fast, I don't know. I guess that at slower speed, it would have more time to cool down. Right now a Benchy on this printer is 1 hour 7 minutes.

Do you have the same duct as I have?

-

@FelixH I am using the 270 version of this https://www.thingiverse.com/thing:2808152. I believe you mentioned the same.

For S&Gs you may want to try 20% infill, it may give you a result, worth the try.

My print time is about the same at 20% infill. -

@bricor I'm on it

-

@bricor I'll be dammed!

It looks much better in real life, I must say.

At this point, I'm going ahead and hypothesize that the cooling problem is over but there is still retraction tuning to be done...

-

@FelixH if you’re using the stock extruder that may be part of the issue. Extruder calibration may also help. If that’s done you may want to try printing at 95% extrusion (set in DWC).

Slicer settings may also help, like align the seams/layer start point. -

I'm using the original E3D hotend I ordered from Duet. I came with an all-metal barrel, which I know it is prune to give problems on a Bowden system. I don't know why don't they send the one with a teflon lining, as nearly all deltas are Bowden...

I'll have a look at the retraction settings and I'll try to tune it a bit more, but it's getting close to good-enough-for-me, as I don't print artistic things or figurines. I have a Photon for that...

-

@FelixH My apologies, when I said extruder I meant filament drive.

The hotend assembly you are describing is top notch. I would stay away from any teflon lined hotend (heat break). I only use all metal hotends. -

@bricor said in Smart Effector part cooling:

@FelixH My apologies, when I said extruder I meant filament drive.

The hotend assembly you are describing is top notch. I would stay away from any teflon lined hotend (heat break). I only use all metal hotends.On a Telegram group I'm in, they are famous for getting stuck continuously...

-

@FelixH said in Smart Effector part cooling:

@bricor said in Smart Effector part cooling:

@FelixH My apologies, when I said extruder I meant filament drive.

The hotend assembly you are describing is top notch. I would stay away from any teflon lined hotend (heat break). I only use all metal hotends.On a Telegram group I'm in, they are famous for getting stuck continuously...

Teflon-lined hot ends are great if you only print PLA, because they are much more tolerant of large retractions. When I first switched to all-metal hot ends, I had problems with jams. Since then I've learned to avoid jams, by avoiding over-retraction, and by retracting filament extremely slowly and at an appropriate temperature when I want to remove it completely.

-

@dc42 I took a screenshot of your response and I'm going to post it on the group.

On the Kossel I'm only printing with PLA, so if can't get the reatraction tuned I'll consider switching to PTFE lined ones.

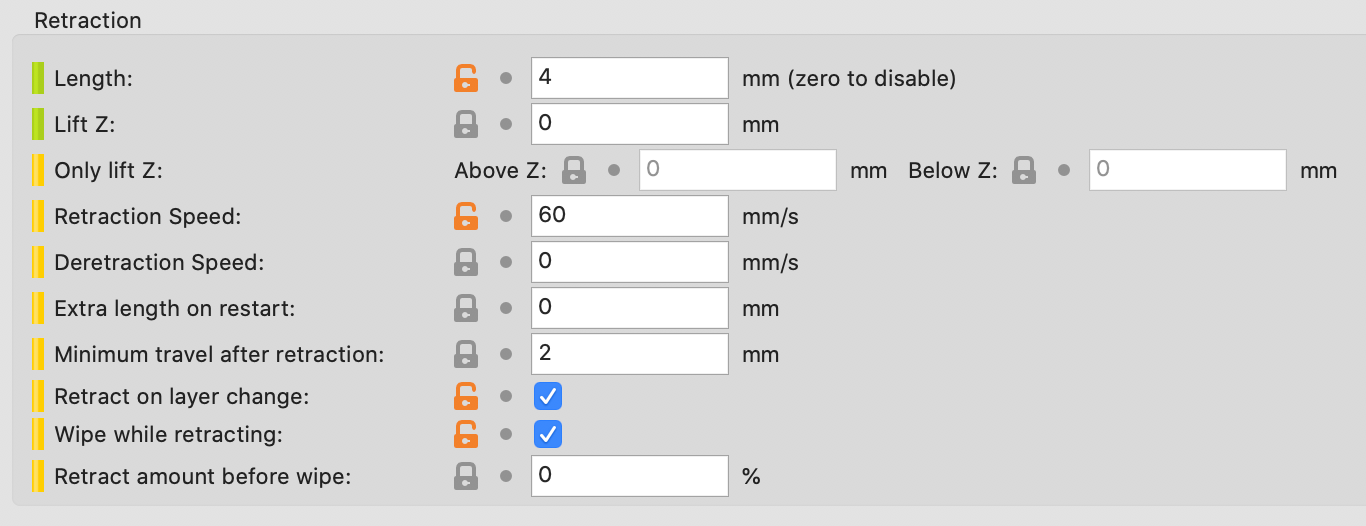

I'm using the settings above with the OEM extruder and an approximate 500mm long bowden tube. Any tips there?

-

@FelixH I use 3mm - 30mm/s for PLA as a general starting point, it works well for me (V6 or Volcano). I rarely need to change the values. Some PLA requires some tweaking as well as other material types.

Retraction is somthing you need to “dial in” to find the best results.

Regarding PTFE lined hotends, the only time I had issues with filament travel and jams is with PTFE lined hotends/heatbreaks. I can’t rule out user error it’s always possible but with the all metal hotends the only time I’ve had an issue is when I neglected to plug it the hotend fan after making a hardware change.