Why can’t I tune pa correctly?

-

@Alucardi If you are unable or unwilling to try anything other than PA, then I have no more suggestions. Filament will ooze out of a nozzle when it's heated, due to gravity and thermal expansion. At low speed and with a large nozzle, the pressure on the filament going in to the hot end will likely be immeasurably small. So what you are tying to do with PA is control that oozing (due to gravity and thermal expansion) by applying a negative pressure to the incoming filament. But PA isn't designed to do that - it's designed to compensate for pressure (which you don't have). As well as decreasing the extruder speed at the end of a move, PA will increase extruder speed at the start of a move to compensate for the lag between the carriage accelerating and the filament flow which accelerates at a slower rate. Which is why it won't compensate well for "natural" oozing due to gravity and thermal expansion. You may see some slight improvement but it's the wrong tool for the job. You need to get the printer working well at low speed without PA and only then introduce PA to help with the pressure that will encounter when you start printing at higher speeds.

-

@deckingman i just said I will try a smaller nozzle. I can’t work with jerk since I can’t go higher then 400, that’s all.

I am used to la which seem to work better in my case. Since the same extruder but running marlin fixes this issue. But like I said I will start with a smaller nozzle -

@Alucardi I would be curious to know the technical differences between the implementations of PA and LA. It's starting to sound like they give substantially different results, but it has been half a decade since I used anything other than RRF.

-

This post is deleted! -

@deckingman doing the change to a .4 nozzle I noticed the throat a bit lose on the hotend. So during disassembly I found that the extruder body was only mounted with 3 out of 4 bolt. The one missing being one of the clamping bolts for the hotend. I have honestly torn the entire printer apart since I got it but never thought about the extruder 🤬 New problem there is my z offset lol

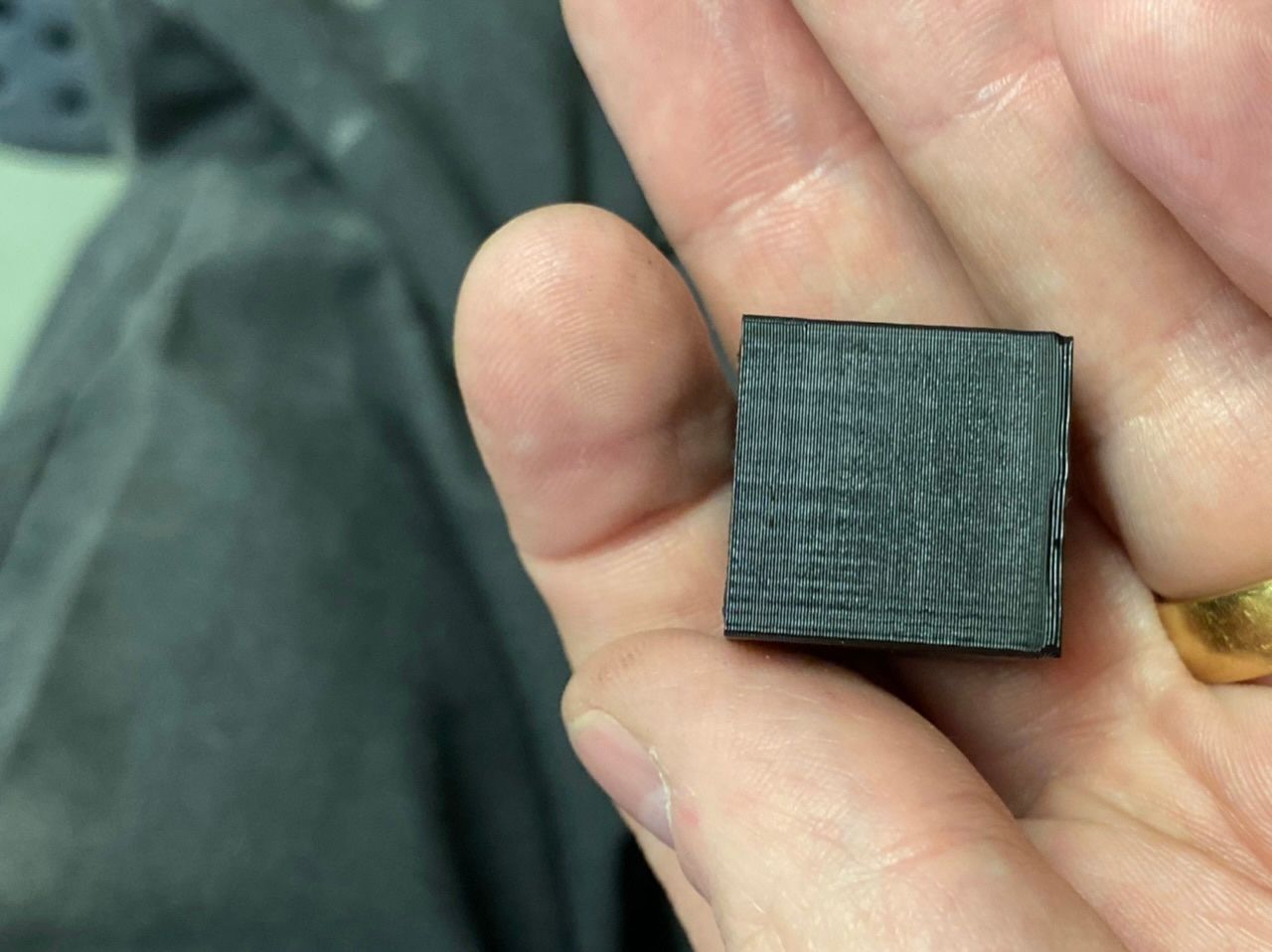

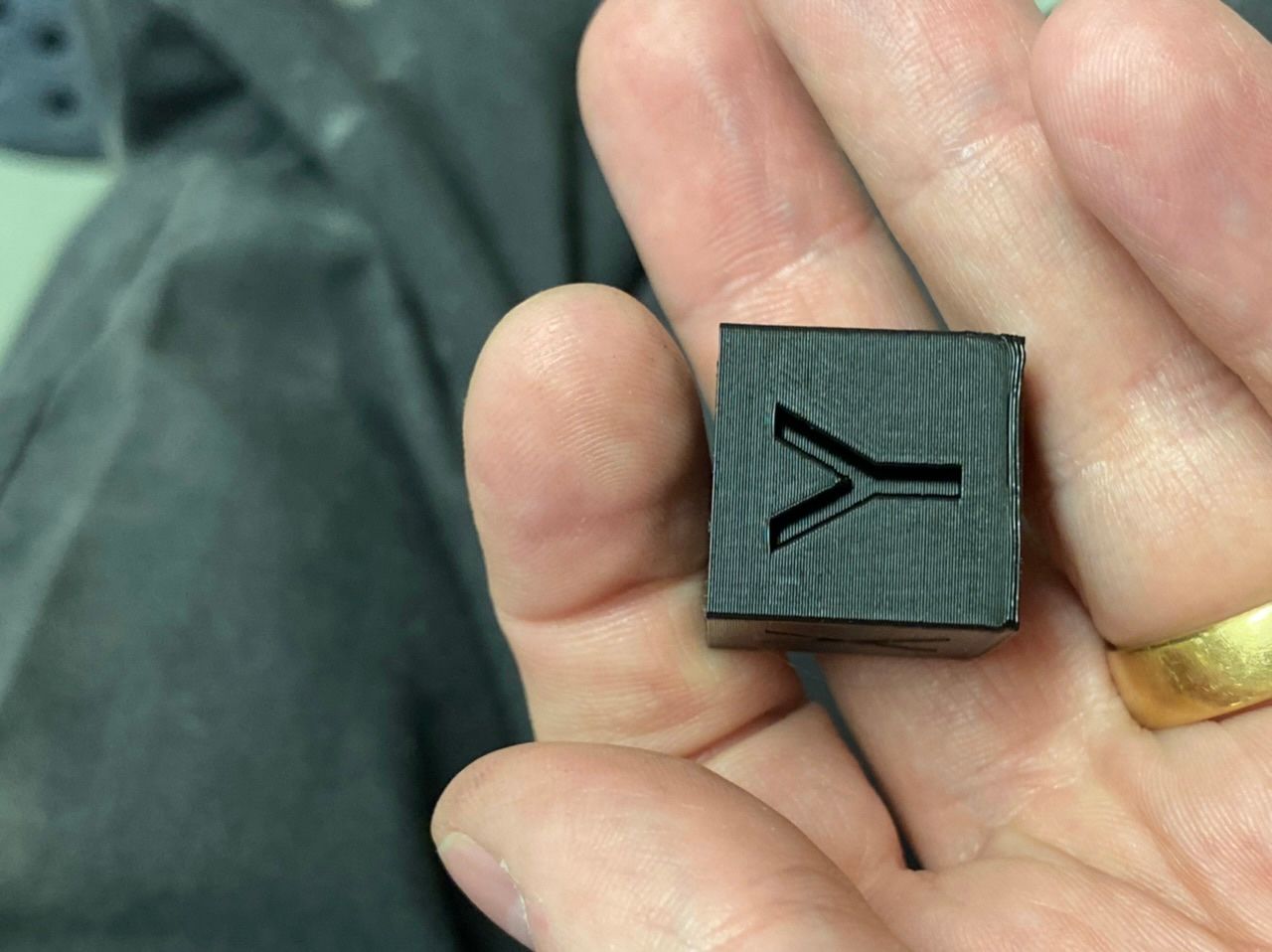

So after fixing that I seem to be able to get better results. Previous model was printed with 400 jerk, 1000 acceleration and 25mm/s outer perimeter. New cube is 600 jerk, 1200 acceleration and 30mm/s outer layer and the seam is not there anymore.

-

When things don't make sense, look deeper, eventually they will.

-

Was that an E3D V6 by any chance?

-

@mrehorstdmd yes it is.

-

@Alucardi Good. Now you can try printing faster. Then you'll be able to use pressure advance to compensate for pressure, rather than trying to use it to compensate for a wobbly hot end

-

@deckingman said in Why can’t I tune pa correctly?:

you'll be able to use pressure advance to compensate for pressure, rather than trying to use it to compensate for a wobbly hot end

May be worth adding this piece of wisdom to https://duet3d.dozuki.com/Wiki/Pressure_advance . E.g. "before you start using pressure advance, make sure you get good prints at low speed.", or something like that.

-

@zapta Good suggestion.

-

@deckingman on the cube I posted I actually have pa on. I forgot to remove it from my start g code. And seams are ok. So going up in acceleration/jerk/speed and maby using a .4mm nozzle instead helped.

-

@Alucardi I've had the heat break come loose on those things many times. It's a lousy design because there's no way to securely tighten it into the heatsink. I switched to a cheapo hotend from China that has been in my printer for about 2 years of trouble free operation now. The fan that comes with it is bad, so I spent $7 more for a decent Sunon fan. The heat break is held in with set screws, so it doesn't come loose and is easy to take out when needed (rare). The fan is held in place with a metal bracket screwed to the heatsink, so it doesn't rotate or touch the heater block and melt. More info on my install here.

-

@Alucardi said in Why can’t I tune pa correctly?:

@deckingman on the cube I posted I actually have pa on. I forgot to remove it from my start g code. And seams are ok. So going up in acceleration/jerk/speed and maby using a .4mm nozzle instead helped.

I assumed that was the case. TBH, if you are still using that 0.068 value, it's likely having minimal effect, especially as you are still printing at relatively slow speeds. So the improvement was due to the increased XY jerk and/or the 0.4mm nozzle. Now that you've sorted the loose hot end, you could go back and try the 0.5mm nozzle and maybe up XY jerk to something like 1,000 or more.

-

@deckingman pretty sure I’ll get ringing at those speeds with a dd setup on a hevo. I have 10mm rods but still 900+ is a lot to ask for on a setup like that don’t you think?

PA value was Power btw. -

@Alucardi Dunno - try it and see. Ringing is all about stiffness and rigidity of the frame and especially the hot end and it's mount. V6 groove mounts aren't the best in this respect but until you push the envelope you won't know what the limits are.

The reason I mention it is that I use 1200 XY jerk and a 0.5mm nozzle. But mine is a completely different animal because I use multi input hot ends and my XY gantry tips the scales at around 2Kgs (the UV gantry which carries the extruders and follows the XY gantry is over 3Kgs). When you have that sort of mass, ringing is not an issue because you have to have very rigid rails, frames and mounts but also, the resonant frequency is too low.