Need suggestions for what is causing this print issue

-

Hello All - I am experiencing a print issue with my new setup that I have not run across before and I am having issues resolving it. If anyone might have encountered this before could you please let me know what the issue might be. I have a couple of pictures and my config.g setup, and the g-code for the cube (using Simplify slicer) below.

*Additional useful information - using Duet3

Board: Duet 3 MB6HC (MB6HC)

DSF Version: 1.2.4.0

Firmware: RepRapFirmware for Duet 3 MB6HC v0.6 or 1.0 3.0 (2020-01-03b3)All of the stepper motors (including extruder) have a motor step angle of 0.9.

Duel Z-Axis motors in parallel.*Thanks in advance for the assistance.

PS - This is obviously zoomed in quite a bit so for reference the cube is 20mm x 20mm

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Mon Apr 20 2020 15:22:56 GMT-0400 (Eastern Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name M564 H0 ; allow movement prior to homing ; Drives M569 P1.0 S1 ; physical drive 1.0 goes forwards M569 P1.1 S0 ; physical drive 1.1 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S0 ; physical drive 0.2 goes backwards M569 P0.0 S1 ; physical drive 0.0 goes forwards M584 X1.0 Y1.1 Z0.1:0.2 E0.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y160.00 Z800.00 E360.00 ; set steps per mm M566 X600.00 Y600.00 Z12.00 E800 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E800 ; set accelerations (mm/s^2) M906 X900 Y900 Z900 E900 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X300 Y300 Z400 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!1.io0.in" ; configure active-high endstop for low end on X via pin !1.io0.in M574 Y1 S1 P"!1.io1.in" ; configure active-high endstop for low end on Y via pin !1.io1.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"io7.out" ; create servo pin 0 for BLTouch M558 P9 C"io7.in" H5 F100 T4000 ; set Z probe type to bltouch and the dive height + speeds G31 P25 X-52 Y5 Z2 ; set Z probe trigger value, offset and trigger height M557 X60:280 Y70:250 S20 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M308 S1 P"spi.cs0" Y"rtd-max31865" ; configure sensor 1 as thermocouple via CS pin spi.cs0 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ; Fans M950 F0 C"out4" Q500 ; create fan 0 on pin out4 and set its frequency M106 P0 S0.25 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out7" Q500 ; create fan 1 on pin out7 and set its frequency M106 P1 S1 H1 T90 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 S"Volcano Extruder" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

Hey,

maybe have a look at this topic ... seems kind of similar. I ran into similar problems recently and was not able to solve them.

https://forum.duet3d.com/topic/15356/inconsitent-extrusion-duet-2-wifi-custom-corexy?_=1587582743122

-

@taconite Thanks for the reply. I just reviewed your thread and I would say that the answer 'almost' has to lie within the motor/stepper/interpolation values. Its hard for me to believe we would be reproducing the same issues when I am using a Cartesian printer, different lead screws, etc etc. I think the commonality lies within the stepper settings.

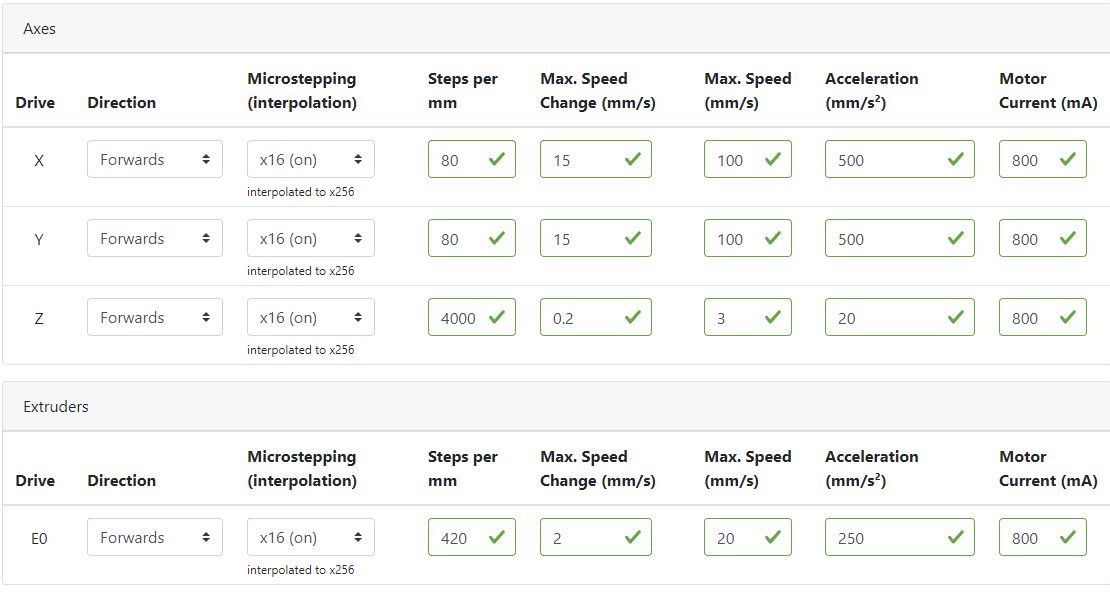

I have been trying to use the RepRap Config tool to generate different combinations and so far the pictures above are as close as I've gotten - which I don't believe is a very good print.

The 'general' settings are:

Unfortunately I am not sure what the right combination is - and there are way to many variables to just guess and test. What I do know as far as my setup is that I am using 0.9 degree motors for all drives. For the Z drive my lead screws have 8mm pitch. I have tried x16(on), x128(on), x256(on)...etc.

But I'm at a loss so any suggestions would be great.

-

The slicer is rotating which corner the seam is being situated.

The offset layers appear that way for the same reason.

If you force the slicer to place the seam in a single corner or on the side you'll see it as a straight vertical seam and the layers will appear more uniform because the variations will all stack cleanly and be less noticeable to the eye. The bulging and unevenness can be addressed by tuning your acceleration and jerk settings along with pressure advance.

-

It will be easier to continue tuning if you stop using the web configurator and move to editing the config.g using the DWC itself. You can quickly edit the values and reboot the board to have them take effect.

for microstepping stick to x16 with interpolation.

For X and Y jerk, try 10mm/s instead of 15.

Slightly increase the values for the Z axis to speed up the layer change time (less time for the nozzle to ooze)

And increase the speed values for the extruder to improve the retraction and layer change times, which should also help with the bulges.

Post the contents of your config.g and I can point out how and where in the file to edit those things.

-

@Phaedrux thanks for the pointers - my config.g file is in my initial post. I am using the DWC I was just referencing the RRF Config as the point where I started. Any suggestions you can provide based on the numbers I am currently using would be great! Thanks again.

Posting the config.g below as well:

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Mon Apr 20 2020 15:22:56 GMT-0400 (Eastern Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name M564 H0 ; allow movement prior to homing ; Drives M569 P1.0 S1 ; physical drive 1.0 goes forwards M569 P1.1 S0 ; physical drive 1.1 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S0 ; physical drive 0.2 goes backwards M569 P0.0 S1 ; physical drive 0.0 goes forwards M584 X1.0 Y1.1 Z0.1:0.2 E0.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y160.00 Z800.00 E360.00 ; set steps per mm M566 X600.00 Y600.00 Z12.00 E800 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E800 ; set accelerations (mm/s^2) M906 X900 Y900 Z900 E900 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X300 Y300 Z400 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!1.io0.in" ; configure active-high endstop for low end on X via pin !1.io0.in M574 Y1 S1 P"!1.io1.in" ; configure active-high endstop for low end on Y via pin !1.io1.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"io7.out" ; create servo pin 0 for BLTouch M558 P9 C"io7.in" H5 F100 T4000 ; set Z probe type to bltouch and the dive height + speeds G31 P25 X-52 Y5 Z2 ; set Z probe trigger value, offset and trigger height M557 X60:280 Y70:250 S20 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M308 S1 P"spi.cs0" Y"rtd-max31865" ; configure sensor 1 as thermocouple via CS pin spi.cs0 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ; Fans M950 F0 C"out4" Q500 ; create fan 0 on pin out4 and set its frequency M106 P0 S0.25 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out7" Q500 ; create fan 1 on pin out7 and set its frequency M106 P1 S1 H1 T90 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 S"Volcano Extruder" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@rmgriffin said in Need suggestions for what is causing this print issue:

M566 X600.00 Y600.00 Z12.00 E800 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E800 ; set accelerations (mm/s^2)

A lot of it will come down to your slicer settings as well, but your firmware speed settings will need to be in order first.

try

M566 X600 Y600 Z60 E3000 ; set maximum instantaneous speed changes (mm/min) M203 X12000 Y12000 Z600 E5000 ; set maximum speeds (mm/min) M201 X500 Y500 Z200 E3000 ; set accelerations (mm/s^2)You may also want to work through this guide for calibrating your extruder, starting with PID tuning your hotend.

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s161