@Phaedrux thanks for the pointers - my config.g file is in my initial post. I am using the DWC I was just referencing the RRF Config as the point where I started. Any suggestions you can provide based on the numbers I am currently using would be great! Thanks again.

Posting the config.g below as well:

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.8 on Mon Apr 20 2020 15:22:56 GMT-0400 (Eastern Daylight Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M564 H0 ; allow movement prior to homing

; Drives

M569 P1.0 S1 ; physical drive 1.0 goes forwards

M569 P1.1 S0 ; physical drive 1.1 goes backwards

M569 P0.1 S0 ; physical drive 0.1 goes backwards

M569 P0.2 S0 ; physical drive 0.2 goes backwards

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M584 X1.0 Y1.1 Z0.1:0.2 E0.0 ; set drive mapping

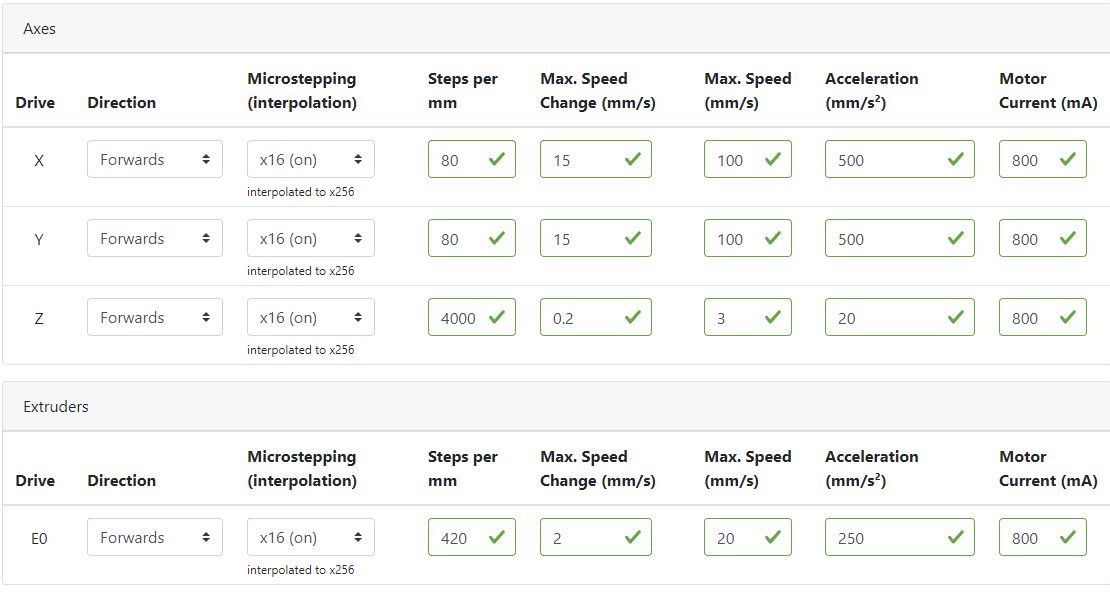

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z800.00 E360.00 ; set steps per mm

M566 X600.00 Y600.00 Z12.00 E800 ; set maximum instantaneous speed changes (mm/min)

M203 X9000.00 Y9000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E800 ; set accelerations (mm/s^2)

M906 X900 Y900 Z900 E900 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X300 Y300 Z400 S0 ; set axis maxima

; Endstops

M574 X1 S1 P"!1.io0.in" ; configure active-high endstop for low end on X via pin !1.io0.in

M574 Y1 S1 P"!1.io1.in" ; configure active-high endstop for low end on Y via pin !1.io1.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

; Z-Probe

M950 S0 C"io7.out" ; create servo pin 0 for BLTouch

M558 P9 C"io7.in" H5 F100 T4000 ; set Z probe type to bltouch and the dive height + speeds

G31 P25 X-52 Y5 Z2 ; set Z probe trigger value, offset and trigger height

M557 X60:280 Y70:250 S20 ; define mesh grid

; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

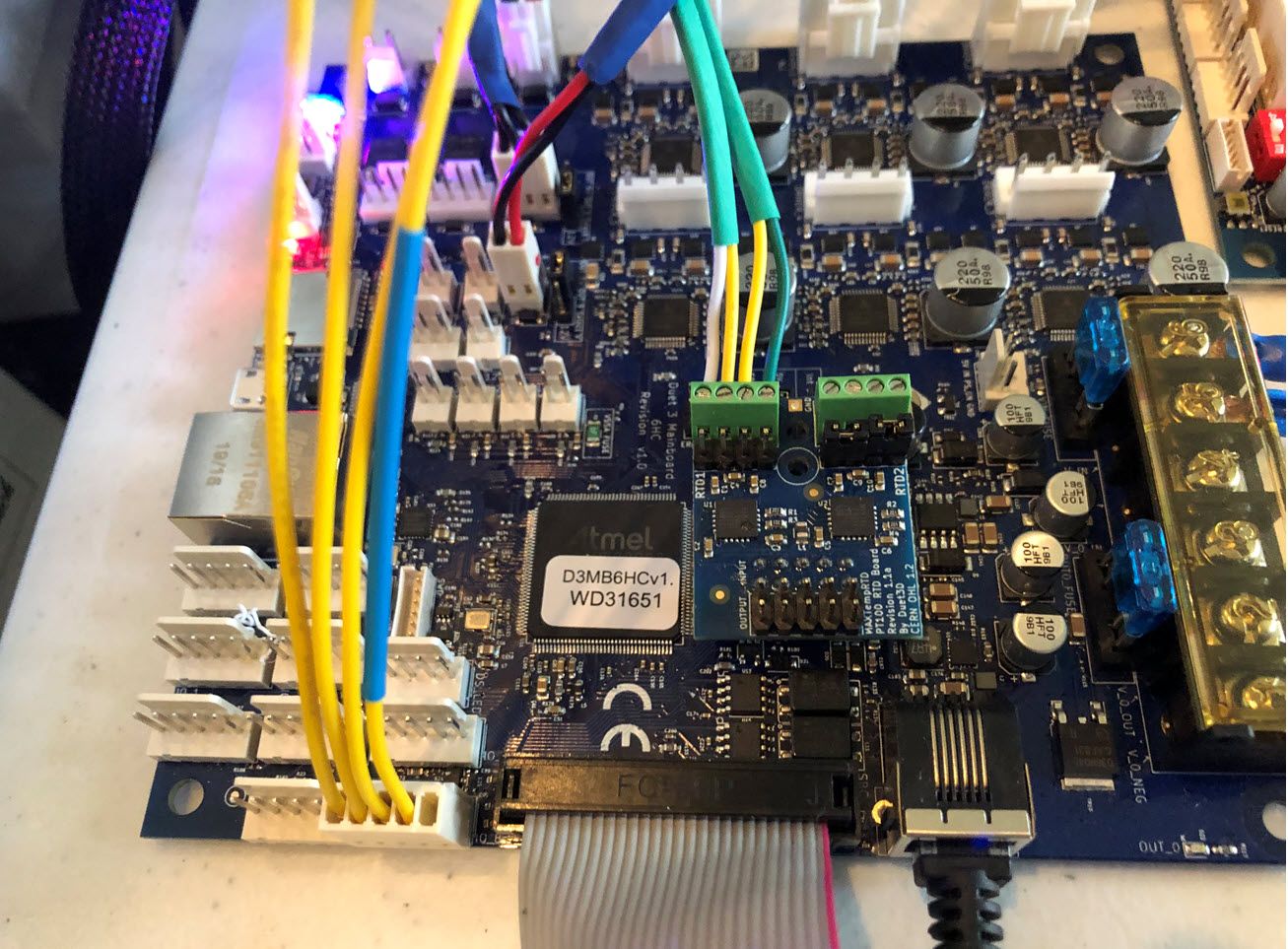

M308 S1 P"spi.cs0" Y"rtd-max31865" ; configure sensor 1 as thermocouple via CS pin spi.cs0

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

; Fans

M950 F0 C"out4" Q500 ; create fan 0 on pin out4 and set its frequency

M106 P0 S0.25 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"out7" Q500 ; create fan 1 on pin out7 and set its frequency

M106 P1 S1 H1 T90 ; set fan 1 value. Thermostatic control is turned on

; Tools

M563 P0 S"Volcano Extruder" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss