Bed heater recommendation

-

This is an opinion, and your chosen solution may vary:

I would just stick with 0.4W/CM2, AND obtain safety by having Keenovo install a physical thermal cutout. They charge about $8 or $10, I've had them do it before.

There are a lot of reasons behind that and it would take a lot of typing. To keep it short, here are two sides of the coin:

- Tens of thousands of printers operate at 0.4 (or thereabouts) and any actual fire hazard seems to come from terminals, not the bed itself.

- The thermal cut is a "physics thing", very highly reliable.

-

@akstrfn Personally I prefer to match the heater to the application because it is inherently the safest option but using a bigger heater isn't necessarily a complete no-no - especially if you take the precautions that @Danal has highlighted.

A couple of other things that you might not have thought about. Consider using rigid or semi-rigid insulation under the bed. I use the type that is used with under floor heating. It greatly reduces the warm up time, but it will also serve to hold the heat pad in place if and when the adhesive eventually lets go (although some people use RTV or similar to stick the heat pad). Insulation will also reduce the power consumption if that is of interest to you.

Also, give consideration to the positioning of the temperature sensor. I found that when using a thickish aluminium bed, having the sensor close to the junction between the heater and the underside of the bed caused the heater to cycle on and off very quickly, resulting in a very long warm up time before the upper surface reached the desired temperature. My solution was to drill a hole in the edge of the aluminium, as deep as possible and as close to the top surface as possible, and fit the sensor in the bottom of that hole.

-

@Danal I forgot to say that the heater Keenovo offered to modify for me has thermostat (160C) and pt100 sensor but if heater cant cross 190C then I don't think any thermal cutout is necessary? (less terminals to worry about?)

From these diagrams https://www.horngmbh.com/en/heating-systems/#tech3 I got an idea that maybe 0.35W/cm2 could do the job perfectly (unfortunately this company doesnt seem to sell to private customers):

@deckingman I also prefer to match the heater hence the reason why I don't want the recommended 600W one since I don't want to run in on 0.4 PWM even thought that setup should have faster heatup. I read your posts on the bed heating topic and found experience from you, @mrehorstdmd and @dc42 very valuable so I would put semi-rigid insulation (heater cant fall off), use some other high temp silicone adhesive (RTV?) instead of 468MP adhesive and use additional temperature sensor at the edges of the bed as you do

My worry is that 300W will take too long and I don't know how to compute this graph for different aluminium thickness so that I can precisely determine how much power I need. Since Keenovo is willing to size the heater perfectly I should do my homework and determine the perfect size.

-

@akstrfn said in Bed heater recommendation:

cant cross 190C then I don't think any thermal cutout is necessary? (less terminals to worry about?)

No extra terminals, it is built in.

That statement "Can't cross..." is interesting. Example scenario 1 of 34,317: Wear over time gouges the heater, unnoticed on bottom of bed, and suddenly all current is going through 1/2 the traces. Which get twice as hot.

Etc. Etc.

Spending a lot of time and energy on making a heater "safe"... the real world doesn't work that way. Thermal cutouts are required on all kinds of appliances that should never overheat (and I mean overheat by a huge margin, unsafe).

-

@akstrfn I have to confess that I don't always practice what I preach and I did go for a heater which is, in theory, overpowered for my bed. But you have to find the solution that you are comfortable with.

Rightly or wrongly, my rationale was three fold. Firstly, I wanted a faster warm up time. Secondly, if things did go awry and say the mosfet failed in the fully on state then things would go awry slowly rather than quickly due to the high thermal mass compared to say a hot end, giving me more time to react (providing of course that I was close enough to the printer and/or checked it frequently enough). Thirdly, it's difficult and expensive to change a bed heater that has been attached to an aluminium plate with high temperature adhesive. So I wanted to be sure that the heater was sufficiently powerful. Don't forget that whatever you put on top of the aluminium as a build surface will also need to be heated (in my case, that's another 6mm of float glass).

Also bear in mind that we regularly print at over 200 deg C - much higher for some filaments. So if your bed was overpowered to the extent that it could reach say 300 deg C, how bad would that be? Does it constitute a fire hazard? Only you can decide if you are comfortable with that.

-

@Danal adding a thermal cutout as an extra safety feature is a good idea but I'd definitely wont buy one from keenovo. They have thermostat which is another line of defense but voron team reported that it did not work reliably in their testing. I'll probably put thermal cutout though thx for the advice

There is no 100% safe anything but there is damn close to it. If you have 2 safety elements with medium failure probability you have low probability of failure for the whole system.

To prove the point lets consider your scenario. Disregarding the fact that there will be a fuse to limit max current to the printer (which every printer should have btw) the scenario you just mentioned would work under very very specific conditions without actually being noticed by RRF i.e. simultaneout and instant failure of both RRF and one part of the traces. Also less powered heater with half the traces wont suddenly become four times as powerful without actually damaging the heater wire. Additionally consider that RRF catches when I remove the spring steel cover from my Ender 3 after I did PID tuning of the bed... And additionally imagine half of the traces failing with heater that was 3 times more powerful to begin with

If you want crazy scenarios consider that fuses sometimes dont work as well (I think dc has a story on this). Just the other day on voron discord someone posted how his thermal fuse actually cracked when it triggered and fuse that breaks in a wrong way might still maintain the contact.

@deckingman yes my concern is that heating would be too slow and then I'd have to redo everything and waste money. If its not possible to underpower the heater I wont do it but I first want to collect experiences from you

300 degrees on hotend is not quite the same as 300 degrees on the bed imho. Voron parts are printed in abs so it would fall appart entirely at that bed temperature and silicone would fail but with smaller max temperature i.e. around 180 degrees plus aluminium or metal holders for the bed would basically make the whole thing much more stable.

@deckingman do you mind doing a test with a PWM limit on your bed to around 0.3W/cm2 and let me know how did it go?

In principle we are building machines with minimal testing so I'd rather have multiple points that need to fail simultaneously than one, additionally if the only thing I need to sacrifice in order to greatly increase safety factor is heating time to 10 instead of 5 minutes I'll accept that trade in an instant.

-

@akstrfn This site will give a pretty accurate estimate of the time required to heat to a specified temperature with a specified amount of power: https://jscalc.io/calc/uS8JYjYISgIvzJ1x

You might be able to speed it up a bit by insulating the bottom of the heater, but if you want to print ABS you'll need a warm enclosure anyway, so there isn't much need to insulate the bottom of the bed. Heat "lost" that way contributes to warming the enclosure. If the enclosure isn't too big that might be enough heat for printing ABS (I have found 50C to be adequate to prevent warping and delamination). Insulating the underside of the heater will increase the cool-down time, and it's generally a bad idea to pry prints off the bed until it has cooled, so you'll have a wait a little longer to take your prints out of the machine.

-

@akstrfn said in Bed heater recommendation:

300 degrees on hotend is not quite the same as 300 degrees on the bed imho. Voron parts are printed in abs so it would fall appart entirely at that bed temperature and silicone would fail but with smaller max temperature i.e. around 180 degrees plus aluminium or metal holders for the bed would basically make the whole thing much more stable.

I thought you were either mistaken or joking so I took a gander at the Voron and see that you were neither. I just assumed that the bed would be "all metal". IMO, plastic bed mounts are a seriously bad idea for so many reasons.

-

@mrehorstdmd said in Bed heater recommendation:

Insulating the underside of the heater will increase the cool-down time, and it's generally a bad idea to pry prints off the bed until it has cooled, so you'll have a wait a little longer to take your prints out of the machine.

..............Unless you use a removable build surface, in which case you can slide one out, slide another in a be printing again with the minimum of down time between prints (but we've had this discussion before so I guess we must agree to differ)

-

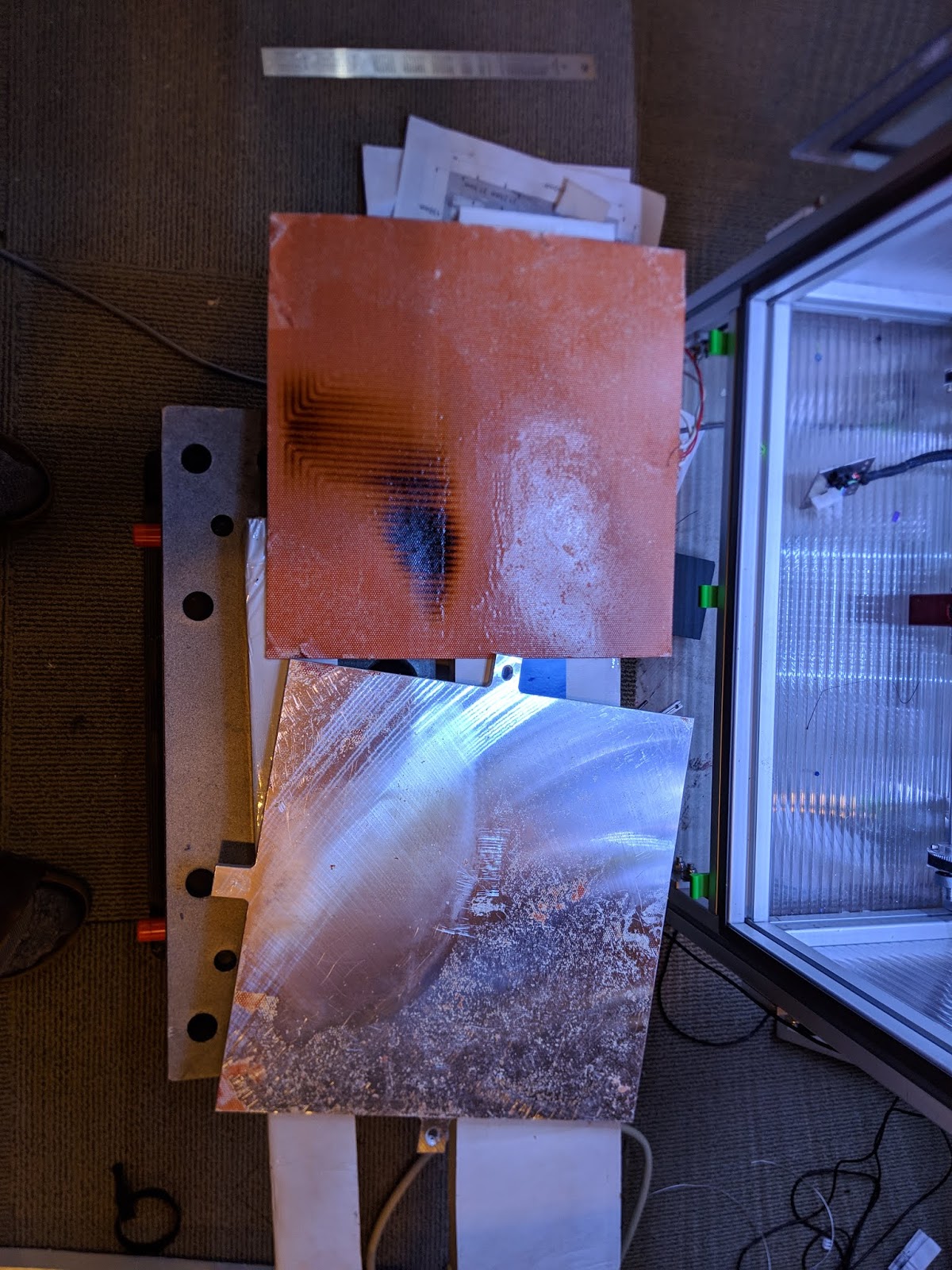

@akstrfn Your diagrams of temperature vs heater power are very nice but assume perfect adhesion to the metal plate, that is hard to guarantee. This is what happens when there's an air bubble between the heater and the plate:

It got hot enough to char the silicone in that area.

This heater was stuck to the plate using the 468MP adhesive that came on the heater from Keenovo. The air bubble developed after some use, probably because I did not follow Keenovo's instructions to seal the edges of the heater with silicone. I suspect the heat and exposure to oxygen causes chemical changes in the adhesive that cause it to fail over time.

I've had PEI sheets glued down with 468MP come off the bed, too. I think my next bed plate will be about 4 or 5 mm larger than the PEI so I can seal the edges with silicone. I have switched to using high temperature silicone to glue the heater to the bed. Keenovo sells the heaters with and without adhesive.

-

@deckingman I'm gonna replace the abs parts that hold the bed to aluminium ones after I get the printer up and running.

-

@mrehorstdmd I saw you posted this on few places and saved it as a reference. It is an important point to take care of. I am testing this one at the moment https://www.amazon.de/-/en/gp/product/B00GFACVWO/ref=ppx_yo_dt_b_asin_title_o01_s00 and the smell is very strong I hope it goes away. I believe you recommend TRV one?

-

@mrehorstdmd Thats a nice calculator and it estimates 11 minutes for my setup with 300W heater. Nice

Edit: do you know how the calculations are done? -

@akstrfn Your words on thermal cutouts are well taken when it applies to a mechanism. There are better and worse.

I'm really referring to the ones that are "just physics". They contain a selected alloy and/or salts that have a known melting point. They are in a whole different league of reliability, or really trust of being a "safety net", than any mechanical, human designed, cutout.

Heater safety is always a very far ranging discussion, and there is fact and truth (and at least grains of truth) in many many threads of that conversation. And LOTS of opinion.

At the same time, I tend to push all that aside and focus on these "physics based" devices. To me, their presence makes the far ranging discussions moot.

-

@akstrfn Replacing the bed mounts with metal might be tricky- With plastic mounts the leveling screws (assuming there are some) will fit tightly in the mounts and won't allow the bed to wobble. As soon as you go to metal, if the screws have to be adjustable, the bed may wobble on the screws. Tapped holes always allow clearance in the threads - that's why a screw will wobble loosely inside a nut. If there are leveling screws, consider using a higher temperature plastic like PTFE- you drill undersized holes and let the screws roll their threads into the plastic. It will be solid, but still allow easy adjustment of the screws. Stainless/steel screws are not very good thermal conductors so the temperature of the PTFE will be well below the bed temperature, and far below any temperature that will cause the PTFE to soften or break down.

-

Point taken

The fact that there are so many opinions is what makes it hard to find the right answer... I spent a while looking for the right sources for this and generally duet forum and reprap forum so far have the highest quality imho.

-

@akstrfn said in Bed heater recommendation:

@mrehorstdmd I saw you posted this on few places and saved it as a reference. It is an important point to take care of. I am testing this one at the moment https://www.amazon.de/-/en/gp/product/B00GFACVWO/ref=ppx_yo_dt_b_asin_title_o01_s00 and the smell is very strong I hope it goes away. I believe you recommend TRV one?

That stuff should be fine. The acetic acid smell goes away as the stuff cures.

-

@mrehorstdmd the bed screws are not plastic but the holders for the platform are. The printer is open source but I dont know if its available on the github. Here is a link from their discord https://a360.co/2zVYtGY. As you can tell if the bed heats to dangerous temps the whole platform would drop. Thats why they spec thermal fuse to 120-125C I believe.

-

Coming a bit late to this conversation, but recently purchased (but haven't yet received) a silicone heater pad, so thought I'd share my experiences and what I learned in the process...

300x300x8 is a massive slab of aluminum to heat with only 300W. Keep in mind that while the heater is trying to transfer heat energy into that thick metal over a surface area of 900 sq cm , that thick slab of aluminum is also trying to transfer the same heat energy into the surrounding air via the other side of that 900 sq cm surface area. I don't know how easy it would be to reach and maintain 100C.

When I was shopping for my 310mm diameter (round) bed (~750 sq cm), I considered 400W to be the bare minimum. I ended up with a 280mm diameter 500W heater. (The heater is smaller than the bed to allow room for mounting screws, etc.)

The thermistor (or PT100) built into the keenevo silicone heaters is embedded in the heater itself. The heater itself will reach any set temperature (such as 100C) much faster than the aluminum bed will and the duet, seeing a temp of 100C on the bed, turns off the heater. As the heat energy transfers from the silicone heater to the aluminum bed, the heater cools down and the duet turns it back on. Until the heat energy fully equalizes between the heater and aluminum, the duet will show an inaccurate temperature and will turning the heater on/off somewhat blindly. This extends the heating time considerably.

If possible, install a thermistor (or RTD) in/on the aluminum bed itself. For myself, I ordered a little aluminum block that should (I hope) accept a e3d 3mm thermistor cartridge and screw under the edge of my build plate. (There should be room enough to attach this because my bed is larger than my heater.) Here's the block: https://www.seemecnc.com/products/copy-of-thermistor-cartridge-ntc-100k-3mm-dia

Keep in mind that the calculator that @mrehorstdmd posted likely assumes that the heater will run at full power until the aluminum bed is up to temperature. If the thermistor (or RTD) is installed in the heater (and not the bed itself), the times to heat will be much longer (for reasons described above.)

Finally, I also purchased a keenevo bed with the built in "thermostat." If your is the same as mine, keep in mind that it may be self-resetting. (Keenovo isn't completely clear on how it works other than to say that it is mechanical bi-metal and snap action.) That could mean an endless cycle of the heater turning itself off when it reaches ~150C, and then back on again when it cools down a bit. A secondary thermal control would probably be a good idea.

-

Funny how I went through all these points in my considerations as well, I guess I did my homework

@garyd9 said in Bed heater recommendation:

Coming a bit late to this conversation, but recently purchased (but haven't yet received) a silicone heater pad, so thought I'd share my experiences and what I learned in the process...

300x300x8 is a massive slab of aluminum to heat with only 300W. Keep in mind that while the heater is trying to transfer heat energy into that thick metal over a surface area of 900 sq cm , that thick slab of aluminum is also trying to transfer the same heat energy into the surrounding air via the other side of that 900 sq cm surface area. I don't know how easy it would be to reach and maintain 100C.

I got idea for 300W heater from dc i.e. check his answer with his delta here https://reprap.org/forum/read.php?1,807307,807400#msg-807400

When I was shopping for my 310mm diameter (round) bed (~750 sq cm), I considered 400W to be the bare minimum. I ended up with a 280mm diameter 500W heater. (The heater is smaller than the bed to allow room for mounting screws, etc.)

The thermistor (or PT100) built into the keenevo silicone heaters is embedded in the heater itself. The heater itself will reach any set temperature (such as 100C) much faster than the aluminum bed will and the duet, seeing a temp of 100C on the bed, turns off the heater. As the heat energy transfers from the silicone heater to the aluminum bed, the heater cools down and the duet turns it back on. Until the heat energy fully equalizes between the heater and aluminum, the duet will show an inaccurate temperature and will turning the heater on/off somewhat blindly. This extends the heating time considerably.

Since aluminium is good heat conductor I've found user report that the bed itself does not lags just a few minutes (300x300x8mm size). If you check one of my posts I mention that one user tested with 40% heater that equates to 280W for him and got heatup time in 5 minutes and said few minutes more for alu bed itself to get to temp.

If possible, install a thermistor (or RTD) in/on the aluminum bed itself. For myself, I ordered a little aluminum block that should (I hope) accept a e3d 3mm thermistor cartridge and screw under the edge of my build plate. (There should be room enough to attach this because my bed is larger than my heater.) Here's the block: https://www.seemecnc.com/products/copy-of-thermistor-cartridge-ntc-100k-3mm-dia

This is the plan. I saw this from others that have posted in this thread.

Keep in mind that the calculator that @mrehorstdmd posted likely assumes that the heater will run at full power until the aluminum bed is up to temperature. If the thermistor (or RTD) is installed in the heater (and not the bed itself), the times to heat will be much longer (for reasons described above.)

Finally, I also purchased a keenevo bed with the built in "thermostat." If your is the same as mine, keep in mind that it may be self-resetting. (Keenovo isn't completely clear on how it works other than to say that it is mechanical bi-metal and snap action.) That could mean an endless cycle of the heater turning itself off when it reaches ~150C, and then back on again when it cools down a bit. A secondary thermal control would probably be a good idea.

I think if powers on and off just like a thermostat works, I believe that it is not precise but thats not very important. I am not sure why many people find it problematic that it turns on/off? RRF would react in that case and turn it off entirely if SSR is not dead. Considering that it survives thermal fuse blowing :paranoid: