If you remove the nut does the leadscrew wiggle on top during rotation? If it does then that is likely the reason for z banding. Leadscrew nuts are almost never a problem nor is their clearance because they are just used for pushing up and down. After a lot of experiments I've concluded that most of info on the topic of z-banding is simply wrong and now I have a fix that works for my printers every time.

So I had these problems appearing semi randomly (because I often disassemble the printer) until I realized that due to the coupling there is sometimes a bit of wiggle which is caused by screws that tighten coupler to the leadscrew and to the motor shaft (different diameters of the leadcrew and the motor shaft don't help here). This was actually discussed on this forum so you can look up these discussions. Screws should however not affect the coupler you use as much since it clamps, however that coupler is not really built to keep the leadcrew perfectly centered and in my tests it had biggest eccentricity compared to three other types of couplers (its called elastomeric coupling after all). With rigid couplers the procedure I use now is to mess with tightening the coupler until there is no wiggle on top then just add the nut afterwards. The nuts I use are very cheap ones with huge clearance and they work just fine.

You can already notice that constraining the leadcrew is related to the couplers and over-constraining is a problem only when you use rigid coupling at the bottom that is not centered, however the coupler you use requires constraining the leadscrew preferably from both sides (you want a straight leadscrew). Just check the design of CNC machines and you will notice how these couplers are used. Note that ballscrew does not magically solve this problem but because it should have almost no play with well constrained bed it will force relatively precise movement in z axis (for 3d printer at least) even when it eccentric but its definitely a waste of money considering other solutions.

If you don't want to mess much with z axis design you can always get stepper motors with integrated leadscrews which will make the whole problem disappear. Paradoxically the price of these motors from aliexpress will almost match the price of motor + coupler + leadscrew.

The problem is definitely more visible with 2mm lead. Additionally you want to isolate all other variable i.e. do a print without heated bed, turn off bed leveling compensation, turn off z hop, have bed rails aligned and squared and so on. When solving this printing cubes close to all leadscrews plus one at the center of the build plate helps to find out which one the screws is the worst offender.

Good luck!

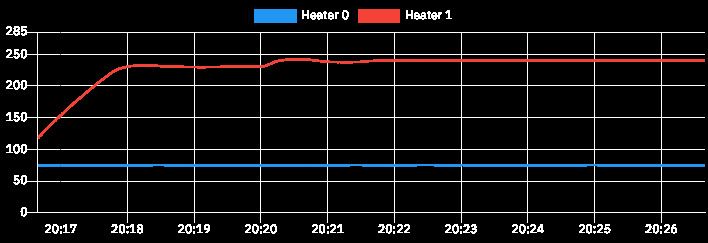

at 20:20 there is a bump in temperature by 10 degrees and you can see the first oscillation. Note the graph is with very slow test print, with faster printing it gets much worse but anyhow its hard to see those small oscillations of this scale.

at 20:20 there is a bump in temperature by 10 degrees and you can see the first oscillation. Note the graph is with very slow test print, with faster printing it gets much worse but anyhow its hard to see those small oscillations of this scale.

(this is btw not a joke)

(this is btw not a joke)