First layer after remachining delta parts

-

Share all your config files and slicer start gcode?

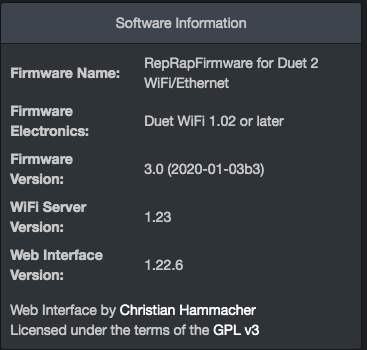

Firmware version? what duet board? -

@gperman

Do you have a predator by any chance? -

Hi,

I worked and worked on my 3 delta's trying to get really good results.

Then I got an FolgerTech FT-5.

That worked so well with so little effort I scrapped the delta's for parts.

Frederick

-

@jay_s_uk yes I do.

-

@Phaedrux homedelta.g heightmap.csv config.g config-override.g bed.g

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Sun Apr 05 2020 18:40:43 GMT-0400 (Eastern Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Anycubic Predator" ; set printer name M665 R211.7 L440 B185 H433.0 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z80.00 E406.90 ; set steps per mm M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; set minimum Z ; Endstops M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop M574 Z2 S1 P"zstop" ; configure active-high endstop for high end on Z via pin zstop ; Z-Probe M558 P5 C"zprobe.in" H2 F100 T15000 ; set Z probe type to switch and the dive height + speeds G31 P1000 X0 Y0 Z16.819 ; set Z probe trigger value, offset and trigger height M557 R170 S17 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M308 S1 P"e0temp" Y"thermistor" T100000 B3950 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss M501 ; Allows stored parameters to be readPrusaSlicer start G-code:

G28 ; home all axes G1 Z5 F5000 ; lift nozzle

-

Take G28 out of your start Gcode

Are you calibrating before every print attempt them loading your print file? -

When you send G28 to home it's calling homedelta which is moving all the carriages to the endstops. This is clearing your calibration.

When are you running G32 to call your bed.g file?

-

This post is deleted! -

So I was getting a lot of assistance today from Jay_s_uk which helped a little. He gave me his bed calibration file to try and I updated the firmware to the 3.1.1 zip whole package.

None of it really helped my issues really but it was good info.Much thanks to him and everyone helping me out with this.

So, What I do is run Autocalibration G32 3 times than upload the results using M500. Then I run Mesh bed leveling G29 once and upload it G29 S1. Then I home the machine by hitting home all and then start the G-Code.

You're saying every time the machine is homed it clears the calibration? I didn't know this. Why does it clear the calibration? I suppose I will have to stop homing the machine before prints.

Should I just include the Bed.g code+M500 in my slicer code upon startup so It runs a calibration before every print?Should I mesh bed level every print or just G32?

What do ya'll use for bed calibration?

I have a smart effector en route but it will take a while to get that up and running.

Also, here is the quality prints i've been dealing with:

First layer is too close to the bed inconstantly and has gaps between shell and infill. Dimensional stability is AWFUL. Circles are not circles, straight lines wander around. Top layer is EXTREMELY underextruded.

I PID calibrated the nozzle 5 times and bed the same. Changed hot end to Mosquito, no change. Changed heater cartridge to mosquito, no change. Changed thermister to filamentone high temp cartridge. Received calibration data from them for the cartridge, no change. New fans, no change. Capricorn bowden, no change. Bondtech extruder assembly, changed steps to match, no change.

I changed extrusion multiplier up, down and all around, no change.

-

Hi gperman,

Can you delete the config_override raise the Rin your config to R231.750 then restart the board to make sure it takes effect

Then run G28, then heat the bed to 60c and hot end to 130c run G32 M665 M500 and check the Radius R of the new config_override see if it has changes please. -

Sorry run the G32 let it finish calibration then M665 from the console then M500 from the console then check the file.

-

@gperman said in First layer after remachining delta parts:

Then I home the machine by hitting home all and then start the G-Code.

When you do that you're resetting the position of where the firmware thinks the bed based on the location of the endstops which are never 100% accurate. You need to establish where the bed is with G30 before starting the print and before doing the mesh.

-

-

Make sure you take G29 S1 out of your bed file and anywhere else you may have put it and delete your heightmap.cv file you will need to remake a new one when you get your probing sorted but that is probably hindering you at the moment so best get rid and remove all your start gcode from your slicer for now as its wrong we can sort that once your probing is accurate.

Also are you sure your rod length is exactly 440. not 440.### something ? -

Performed G32 -> M665 -> M500 three times. no homing. Which resulted in this:

Calibrated 9 factors using 16 points, (mean, deviation) before (-0.001, 0.016) after (-0.000, 0.013)

Auto calibration successful, deviation 0.013mmM665:

Diagonals 440.847:440.847:440.847, delta radius 212.607, homed height 432.734, bed radius 185.0, X 0.632°, Y -0.509°, Z 0.000°All at 130 deg nozzle and 60 deg bed.

No signs of G29 in any file. Deleted my heightmap.

Compensation in use: none

Still issues with dimensional stability and inconsistent nozzle height.

-

Thats good..now copy the height and the radius to your config one at a time click save then when asked if you want to

restart click No

We haven't done a height map yet which we are getting to.. -

@Carlo

yeah but better ! -

@Carlo

So once you have copied those 2 setting across..The most important being arm length.

We need to actually set the real height

We don't use 9 factor max 6 redo your bed file for 6 please -

So now you copied those to config.g

switch machine off and on

heat the nozzle to 130c and bed to 60c run calibrate

Now we want an accurate height but you need to get that so you are going to get a feeler gauge 0.1mm or piece of standard paper sure you have gauges though and credit goes to another awesome user NexxCat for helping me

lower the nozzle to just only just touching the gauge read the height in dashboard and either add or subtract the remaining from your height H in config.g so when we command the nozzle to 0.1 it just touches the gauge/paper

so what ever is left subtract -the 0.1mm this may take a couple of goes then set your trigger to height in G31 line of config.g to Z-0.1

Once it consistently on command goes to 0.1mm then do G30 S-1 then G1 Z5 repeat these 2 steps a few times to get your trigger once its a consistent height always @ 130c nozzle 60c bed once you get your trigger height add it to your config.g G31 line

After this you won't need a config_override unless you have some changes you want in there (I don't use override)then do G28 and calibrate once calibrate is done do without homing G29 and that gives you your hopefully correct height map

Then try a test print but 6 factor bed file only the other reset your arm length which we don't want!So the proccess going forward is once you switch machine on you home

heat your nozzle and bed make coffee do your calibration or G30 once thats done we don't re-home no need

you print and print if you re-home you need to run calibration before you print but only if you home everyone calibrates before printing it takes seconds and it will be part of your start gcode once we get you calibrated fully and I'll give you the start code and nozzle purge to copy into your Prusa slicer which is what I use -

This will take only around 10mins