Switching from Duet Maestro to Duet WIFI

-

@Stephenbright said in Switching from Duet Maestro to Duet WIFI:

The pin outs on the Maestro and the Wifi are in fact reversed. I had to flip all the connections to get the motors going the right directions. Not a big deal and that is now sorted...

An alternative would have been to edit your M569 commands in config.g, changing S0 to S1 or vice versa.

According to the wiring diagrams the VIN power is on the left and the GND is on the right. Correct? This is listed on BOTH diagrams.

If you are viewing the board with the E0/E1 heater connections at the top edge, that is correct.

HOWEVER on the Maestro board it says the Molex connectors are 2 amp and the screw terminal are 5 amp. I have to use the screw terminals on the WIFI board. Do I need to make change somewhere with a jumper etc?

No. We added the Molex connectors on the Maestro so that OEMs using 24V power could use them instead of the screw terminals. OEMs don't generally like screw terminals because they take too long to connect. The Molex connectors are connected in parallel with the screw terminals.

-

This post is deleted! -

I have everything sorted except for the extruder motors are NOW clicking / grinding? Could the voltage me wrong? It looks to be set at E400? Is the 400 mA? Should I go down to 300 mA? I know the Wifi board steps in 100 mA intervals vs the Maestro 50 mA...

Thank you !

; machine_steppercurrent.g

; October 1, 2018; This document sets the stepper motor currents.

; This is an advanced feature and should only be changed if you REALLY know what you're doing!

; Increasing stepper motor currents beyond their limit can result in damage to them!M906 X680 Y680 Z600 E400 I60; Set motor currents (mA) and idle current percentage

-

400mA seems low for an extruder. What current were you using when you had the Maestro installed? What is the rated current of the motor? What printer is it?

-

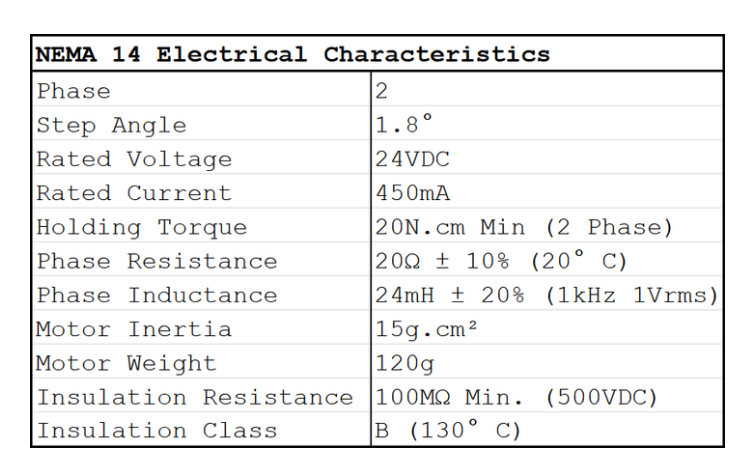

It looks to be rated at 450mA however the stock setting using the Maestro was set like this which is think is 400 mA :

M906 X680 Y680 Z600 E400 I60; Set motor currents (mA) and idle current percentage

It seemed to work fine with the Maestro even if it was low. I can set it to whatever you think would be appropriate.

-

If it worked at 400mA on the Maestro, it should work at 400mA on the Duet 2. Maybe only one of the phases is working. Can you tell whether the extruder is rotating normally when it doesn't have to push filament?

-

@dc42 said in Switching from Duet Maestro to Duet WIFI:

If it worked at 400mA on the Maestro, it should work at 400mA on the Duet 2. Maybe only one of the phases is working. Can you tell whether the extruder is rotating normally when it doesn't have to push filament?

No it is not rotating normally.

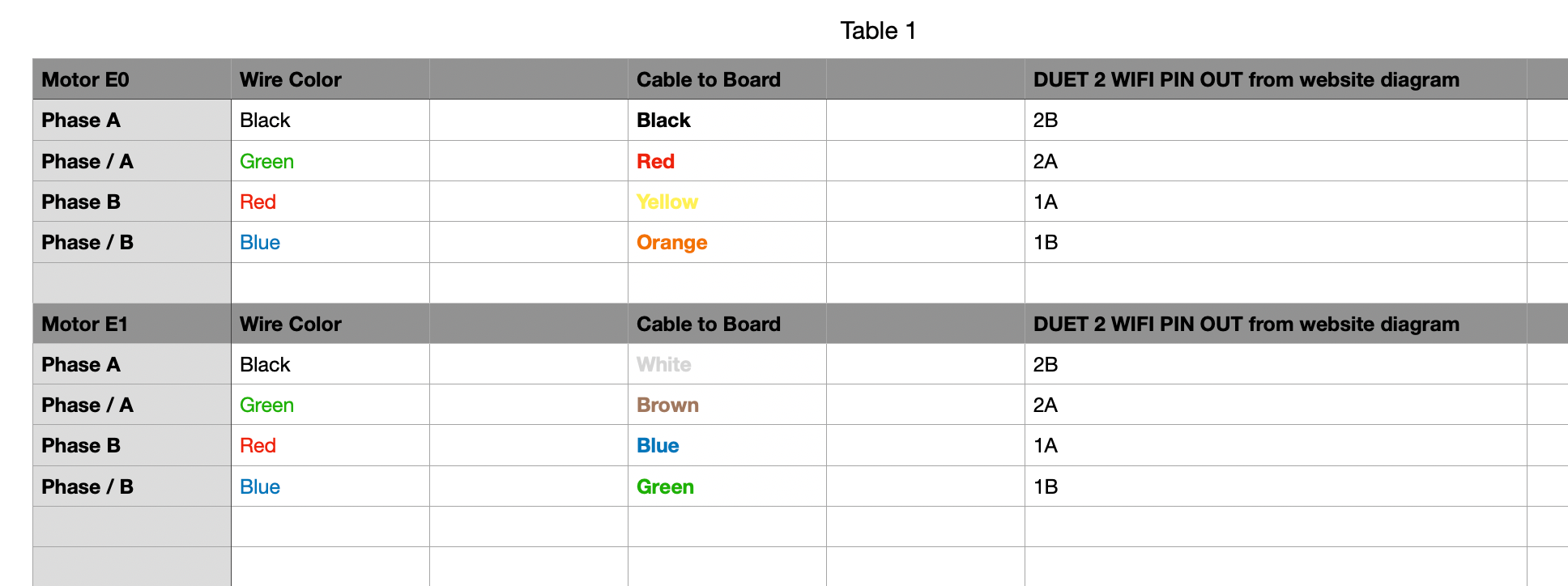

When I put the filament in, it is moving but in a clicking / stepping motion, like you can feel the filament vibrating and it's not really loading the filament. This is a pict of the connection.

I mapped out this chart if it helps for the cable colors to the board.

-

It really does sound like one of your motor phases is not connected properly. Bad crimp or broken wire. If you have the means, try re-crimping the ends, or replace the wires entirely.

Are you getting any error messages in the console saying a motor phase may be disconnected? It would be strange to get the behaviour but not the error message, so maybe it's something else.

Have you tested the motor on a different driver?

-

@Phaedrux If you mean just swap the connectors no... I just double checked the wiring and it is connected and secure as it was before no broken wire or anything like that... NOW however I'm not getting any movement from the motor? Odd...

-

@Phaedrux said in Switching from Duet Maestro to Duet WIFI:

Are you getting any error messages in the console saying a motor phase may be disconnected? It would be strange to get the behaviour but not the error message, so maybe it's something else.

The "may be disconnected" message is suppressed when the motor current is less than 500mA, to avoid false warnings.

@Stephenbright, you could temporarily set the motor current to 500mA to see if you get those warnings.

-

@Stephenbright The white wire in your photo looks broken to me. and I would question the rest of them in the same connector .

-

This post is deleted! -

@hdtechk Nothing Is broken. I should have taken a better picture as that was just for the color reference. There are all in solid and in that orientation. I am going to check them again and maybe put new ends on it to be sure...

Then I bump it up to 500mA and try that...

As always everyone THANK YOU !

-

@dc42 said in Switching from Duet Maestro to Duet WIFI:

@Phaedrux said in Switching from Duet Maestro to Duet WIFI:

Are you getting any error messages in the console saying a motor phase may be disconnected? It would be strange to get the behaviour but not the error message, so maybe it's something else.

The "may be disconnected" message is suppressed when the motor current is less than 500mA, to avoid false warnings.

@Stephenbright, you could temporarily set the motor current to 500mA to see if you get those warnings.

I set the motor to 500mA and in fact got the error:

Warning: motor phase A may be disconnected reported by driver(s) 3

-

@dc42 said in Switching from Duet Maestro to Duet WIFI:

@Phaedrux said in Switching from Duet Maestro to Duet WIFI:

Are you getting any error messages in the console saying a motor phase may be disconnected? It would be strange to get the behaviour but not the error message, so maybe it's something else.

The "may be disconnected" message is suppressed when the motor current is less than 500mA, to avoid false warnings.

@Stephenbright, you could temporarily set the motor current to 500mA to see if you get those warnings.

If this is a PHASE issue, what wires do I switch around to get it to work?

-

@Stephenbright said in Switching from Duet Maestro to Duet WIFI:

Warning: motor phase A may be disconnected reported by driver(s) 3

It means that one of the wires isn't connected in Phase A.

On Duet 2 Maestro and Duet 3, the four motor connector pins are labelled 'B1 B2 A1 A2' on the back of the board and on the wiring diagram. The 'A' and 'B' refer to the coil or phase, the '1' and '2' refer to the positive and negative.

So that should let you narrow it down to which wire pair isn't connected. It could be a bad crimp, broken wire, or possibly even the driver itself. You may want to try testing with a different motor and wiring harness.

-

@Phaedrux Thanks everyone they are finally working. I just re crimped the wires on both ends and still had a bit of work to get them to seat properly. The looked fine and felt solid each time I redid it, but a 3rd times was a charm. It must be crazy sensitive as they really felt and looked great right the start, however moving them around a bit to make sure they were 100% seated and connected seemed to do it...

That being said if 400mA seems low for an extruder motor and the motor is rated for 450mA should any other adjustments be made? Will going to 500 mA provide more torque etc?

As always, thank you ALL for the help !

-

@Stephenbright With a phase resistance of 20 ohms, and inductance of 24mH (from your earlier post https://forum.duet3d.com/post/173124 ), it has plenty of torque (20N.cm is similar to 34mm NEMA 17 motors) even at low current, it just won't be able to move very fast. Which is probably fine for an extruder motor, unless you want to do very fast retractions. You can use the EMF calculator here https://www.reprapfirmware.org/ to calculate the maximum speed the motor can do, but that might not be quite the whole story, as the motor may be more physically limited.

For more info on choosing motors, see: https://duet3d.dozuki.com/Wiki/Choosing_and_connecting_stepper_motors

Ian

-

Question: Still not getting my nozzle fans to work correctly. These are brand new fans from M3D. Right now they aren’t coming on at all and I’ve just doubled checked the wiring…

Thoughts?

Are the fan gan jumpers the set the same on a Wifi as they were on the Maestro?

; --- SECTION: FANS ( ) ---

M106 P0 S1 I0 F4 H-1 L0.3 ; Filter fan. Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off, Minimum fan value 0.3, Speed 100%

M106 P1 S0 I0 F4 H-1 L0.3 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off, Minimum fan value 0.3, Speed 100%

M106 P2 S0 I0 F4 H-1 L0.3 ; Nozzle fan. Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off, Minimum fan value 0.3, Speed 100% -

How do you have the fan jumper set?

What is your vin?

What are your fan voltages?