oozeBot Elevate

-

@Haggan90 We may be the only ones out there with this design as I worked with LDO on the specs for it. Testing is near complete and we will be placing an order soon. This will be something we stock in our parts store as soon as it launches.

And FYI, they work great!

-

@oozeBot Ok!

I have a belt driven Z-axis as well, and a break like this would be great to have! -

Another ABS/ASA fan here: really nice ABS prints!

You don't use chamber heating, right?I might want to try that IC3D stuff too, so far I am unable to complete prints the size of your Ctulhu without layer splitting in either Prusament or Formfutura ASA or eSun ABS. in my enclosed printer.

-

@DaBit said in oozeBot ele^gant:

You don't use chamber heating, right?

Yes, our printers are all enclosed with chamber heaters. For ABS, we set the chamber temperature to 60c and never have delamination issues. The Cthulhu was a hard one as we really pushed the printer with a 1.2mm nozzle and 1.8mm extrusion width..

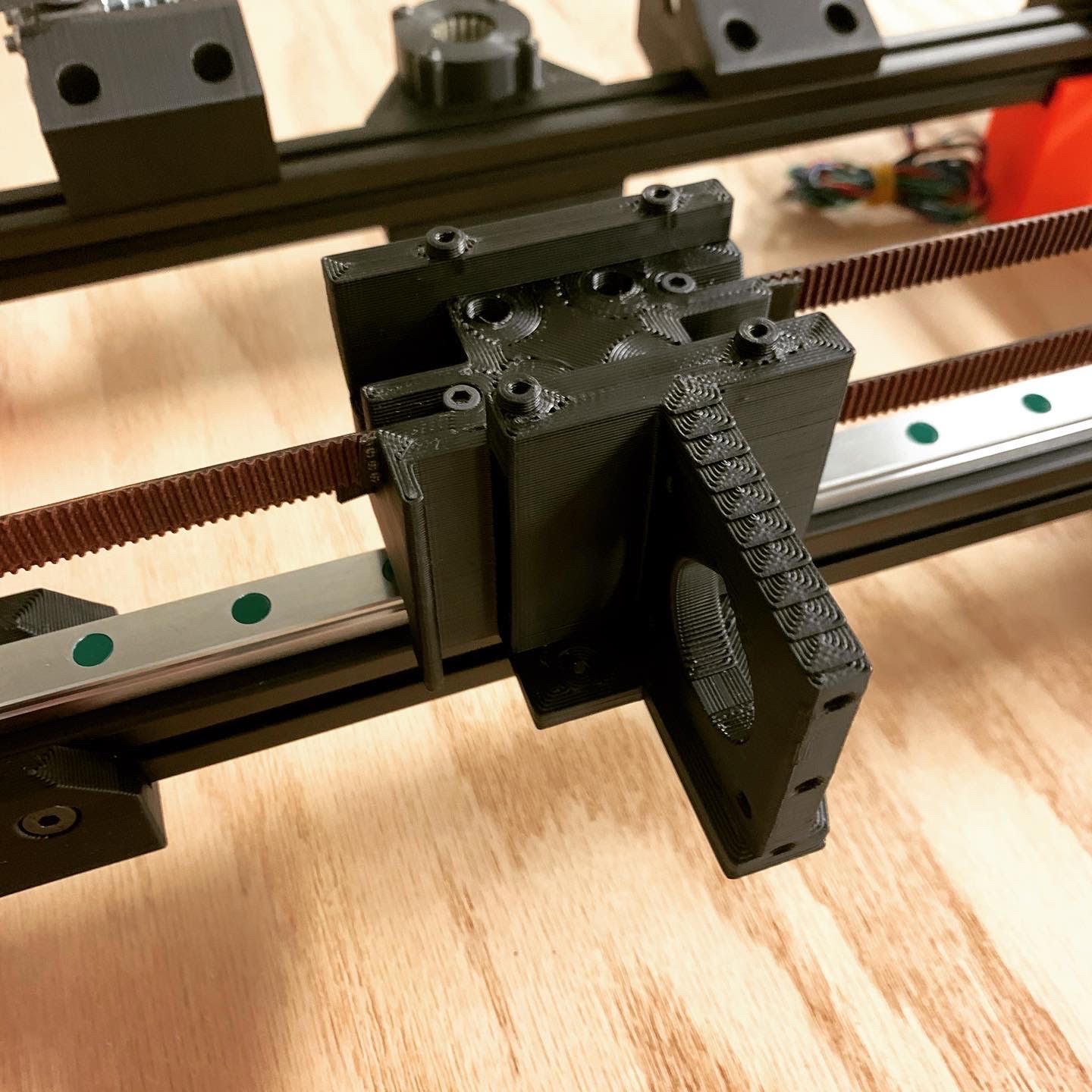

We are in process of printing the first parts for our release candidates. I'll be posting much more about them soon as they are considerably different than our prototypes. Here is one of the first parts off the printer! In ABS of course..

-

@oozeBot said in oozeBot ele^gant:

@Haggan90 We may be the only ones out there with this design as I worked with LDO on the specs for it. Testing is near complete and we will be placing an order soon. This will be something we stock in our parts store as soon as it launches.

And FYI, they work great!

Interesting.

On my recent belted Z axes conversion of my Mark Forged style printer I used three Z steppers with integral 5-to-1 planetary gear boxes.

The bed stays put when power is cut. It doesn't seem to need any sort of brakes.

Frederick

-

@fcwilt we briefly evaluated geared steppers but went a different direction. With our solution, we were able to move the z-axis much faster than with a geared stepper allowing for considerably faster z-hops, etc.

-

@oozeBot said in oozeBot ele^gant:

@fcwilt we briefly evaluated geared steppers but went a different direction. With our solution, we were able to move the z-axis much faster than with a geared stepper allowing for considerably faster z-hops, etc.

Interesting.

I have no problem moving the bed at the needed speeds.

But I see you appear to be moving the entire XY gantry - curious.

Are you seeing any Z belt stretch as the center of mass of the gantry moves?

Frederick

-

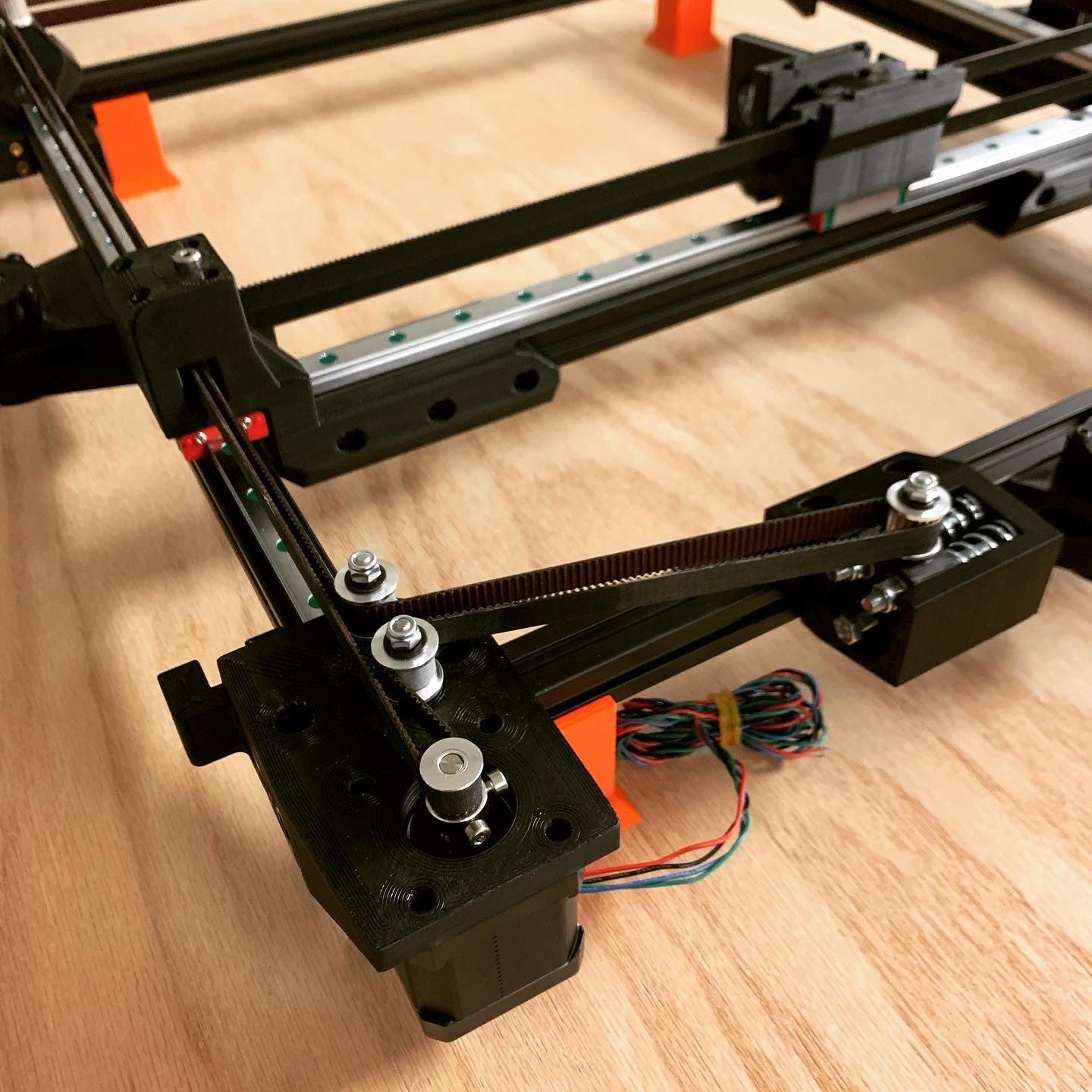

@fcwilt We use 9mm fiberglass reinforced Gates 2GT belts and have not experienced any stretch or degraded performance throughout the gantry’s range of motion- and we have really been pushing our prototypes hard.

-

@oozeBot said in oozeBot ele^gant:

@fcwilt We use 9mm fiberglass reinforced Gates 2GT belts and have not experienced any stretch or degraded performance throughout the gantry’s range of motion- and we have really been pushing our prototypes hard.

Thanks for the info.

Frederick

-

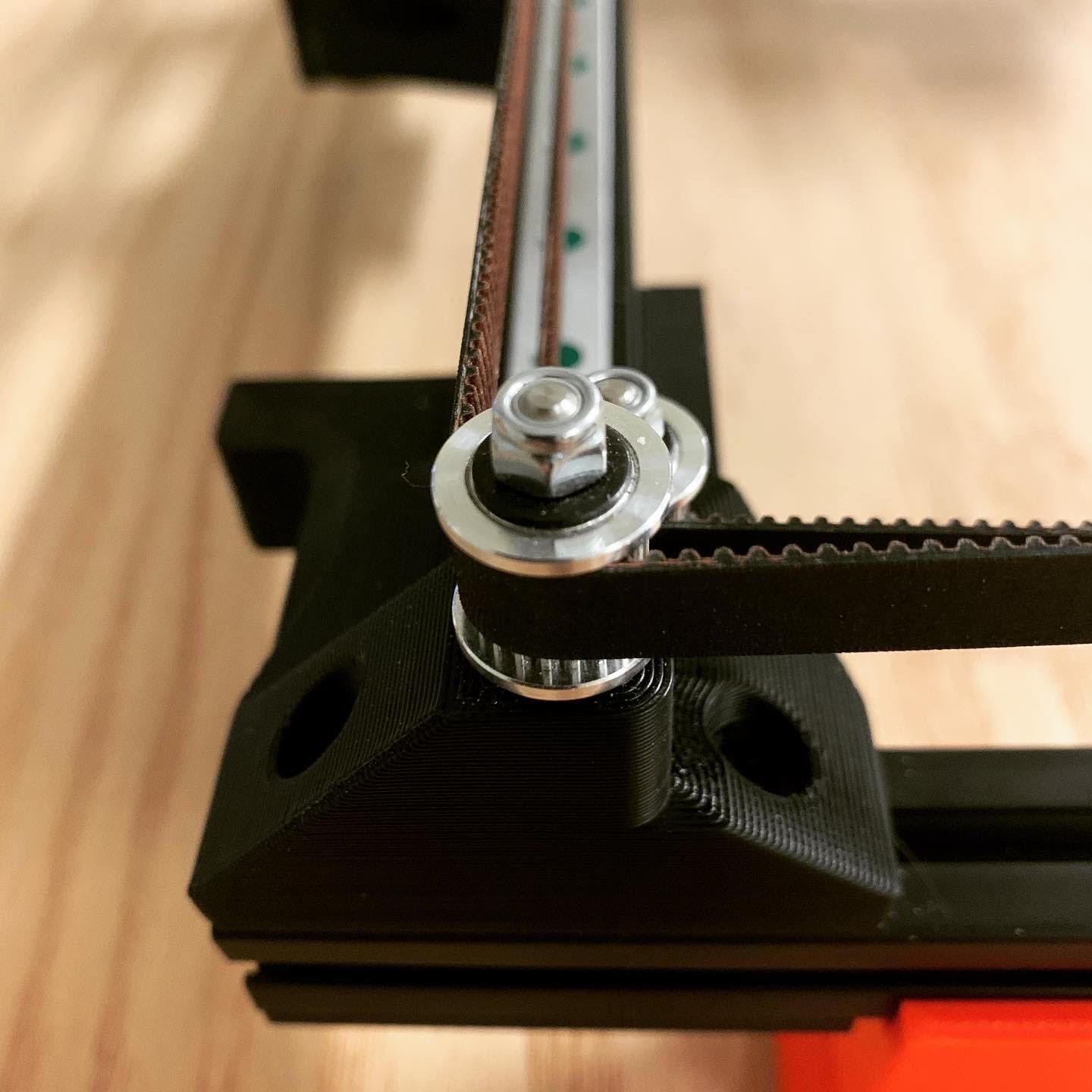

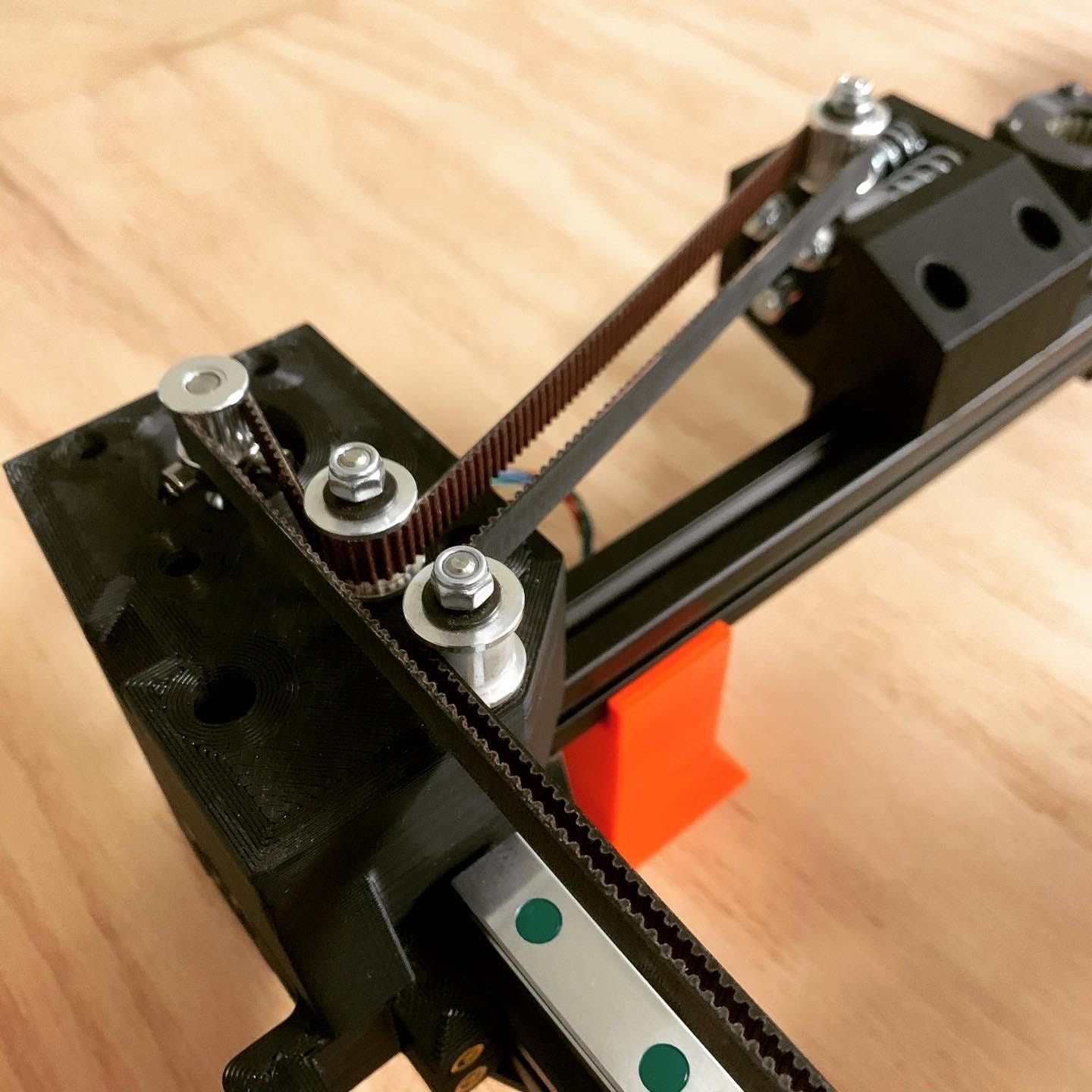

We've been heads down for awhile now wrapping up the design for our release candidate.. and finally have something to show - our new gantry! It has been completely redesigned to be smaller, lighter, and stiffer than the prototypes.

We are in love! Check out the belt work..

-

@oozeBot said in oozeBot ele^gant:

We are in love! Check out the belt work..

What is the rational for the idler nearest the stepper? The belt leaving the stepper could have run straight to a tensioner positioned closer to the stepper.

Thanks.

Frederick

-

@fcwilt If that idler is removed, the belt would only wrap half of the pulley and the belt could slip.

-

@fcwilt said in oozeBot ele^gant:

What is the rational for the idler nearest the stepper? The belt leaving the stepper could have run straight to a tensioner positioned closer to the stepper.

Thanks.

Frederick

Maximum surface area on the pulley.

-

@oozeBot said in oozeBot ele^gant:

Maximum surface area on the pulley.

Thanks.

Would you consider posting your calculations showing that much contact area was needed?

Thanks again.

Frederick

-

Man that looks sharp

-

@fcwilt Gates recommends a minimum of 6 teeth in mesh between the belt and the sprocket. We are using 16 tooth pulleys. Removing that smooth idler would only allow for 4-5 teeth to fully engage. I strongly prefer to fully utilize 180+ degrees of the pulleys to engage 8 teeth minimum.

-

@oozeBot said in oozeBot ele^gant:

@fcwilt Gates recommends a minimum of 6 teeth in mesh between the belt and the sprocket. We are using 16 tooth pulleys. Removing that smooth idler would only allow for 4-5 teeth to fully engage. I strongly prefer to fully utilize 180+ degrees of the pulleys to engage 8 teeth minimum.

Oh.

Thanks.

Frederick

-

We just wrapped up our new build plate, with 3-point leveling, made from .25” ATP-5 precision cast aluminum tooling plate. Fresh off the CNC!

Can’t wait to get it mounted for testing!

-

@oozeBot said in oozeBot ele^gant:

We just wrapped up our new build plate, with 3-point leveling, made from .25” ATP-5 precision cast aluminum tooling plate. Fresh off the CNC!

Boy, whoever cut that plate has a real hard time making straight cuts!

Frederick

-

@fcwilt we took a bit of creative freedom with the design.. decided not everything on our machines had to be square!