oozeBot Elevate

-

@oozeBot said in oozeBot ele^gant:

@fcwilt We use 9mm fiberglass reinforced Gates 2GT belts and have not experienced any stretch or degraded performance throughout the gantry’s range of motion- and we have really been pushing our prototypes hard.

Thanks for the info.

Frederick

-

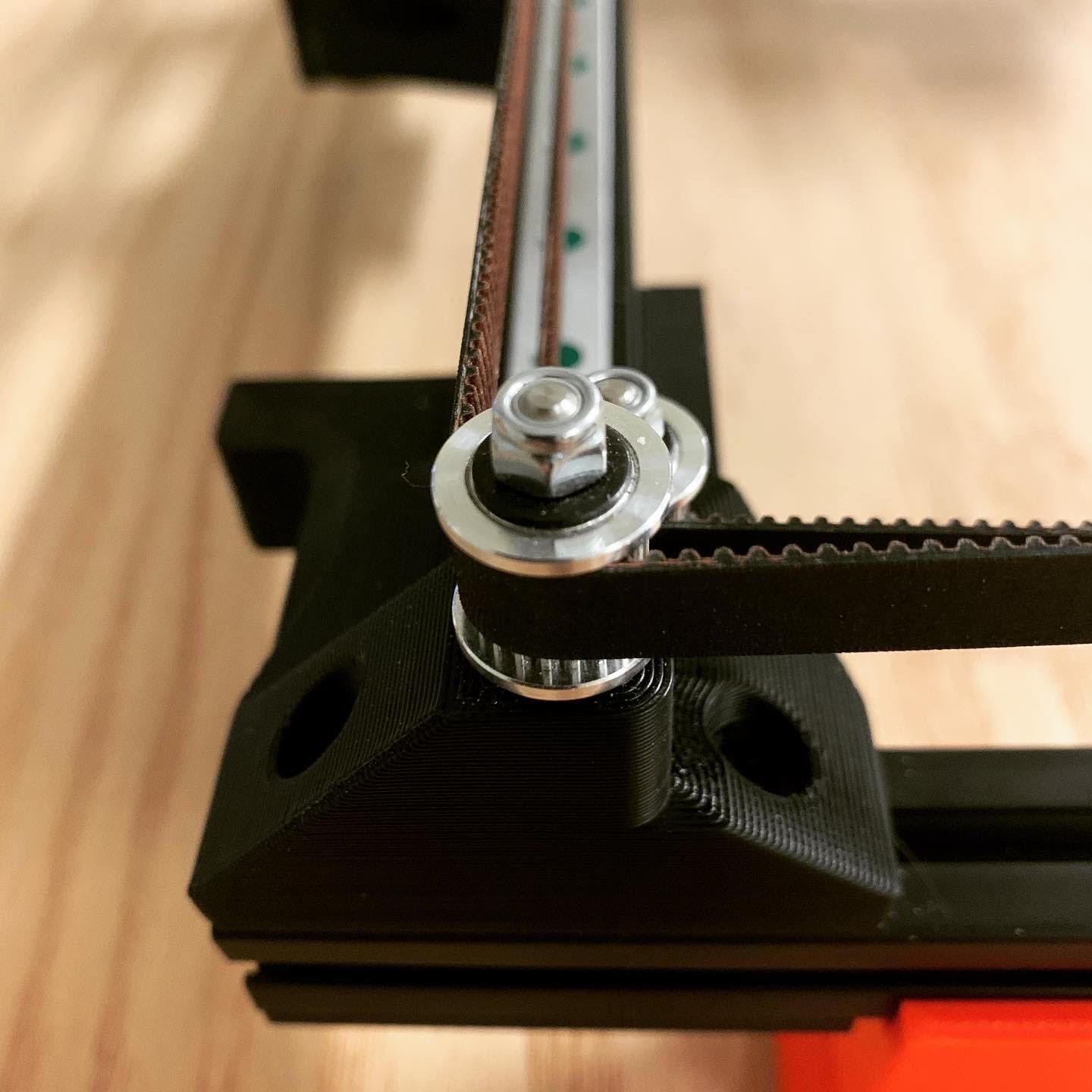

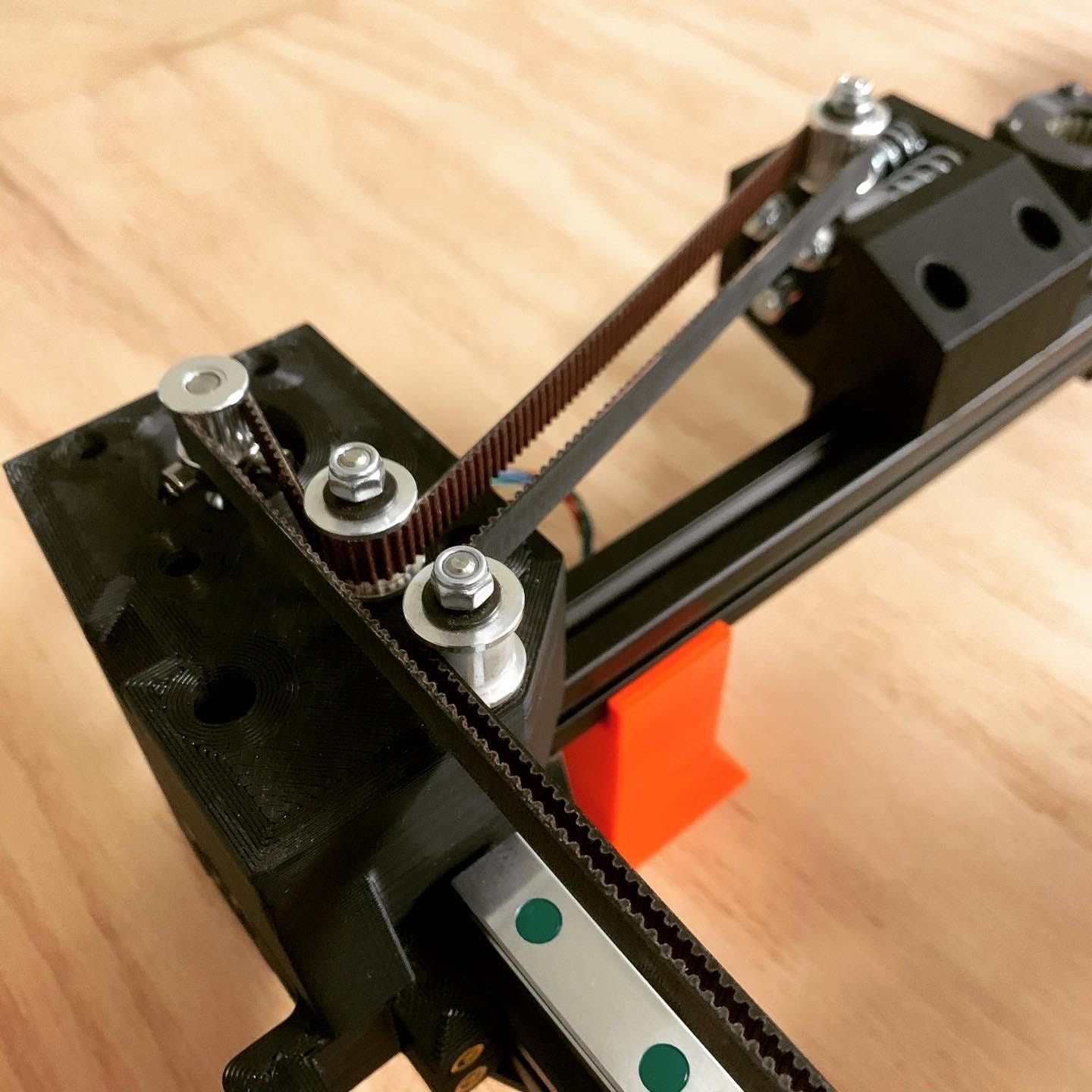

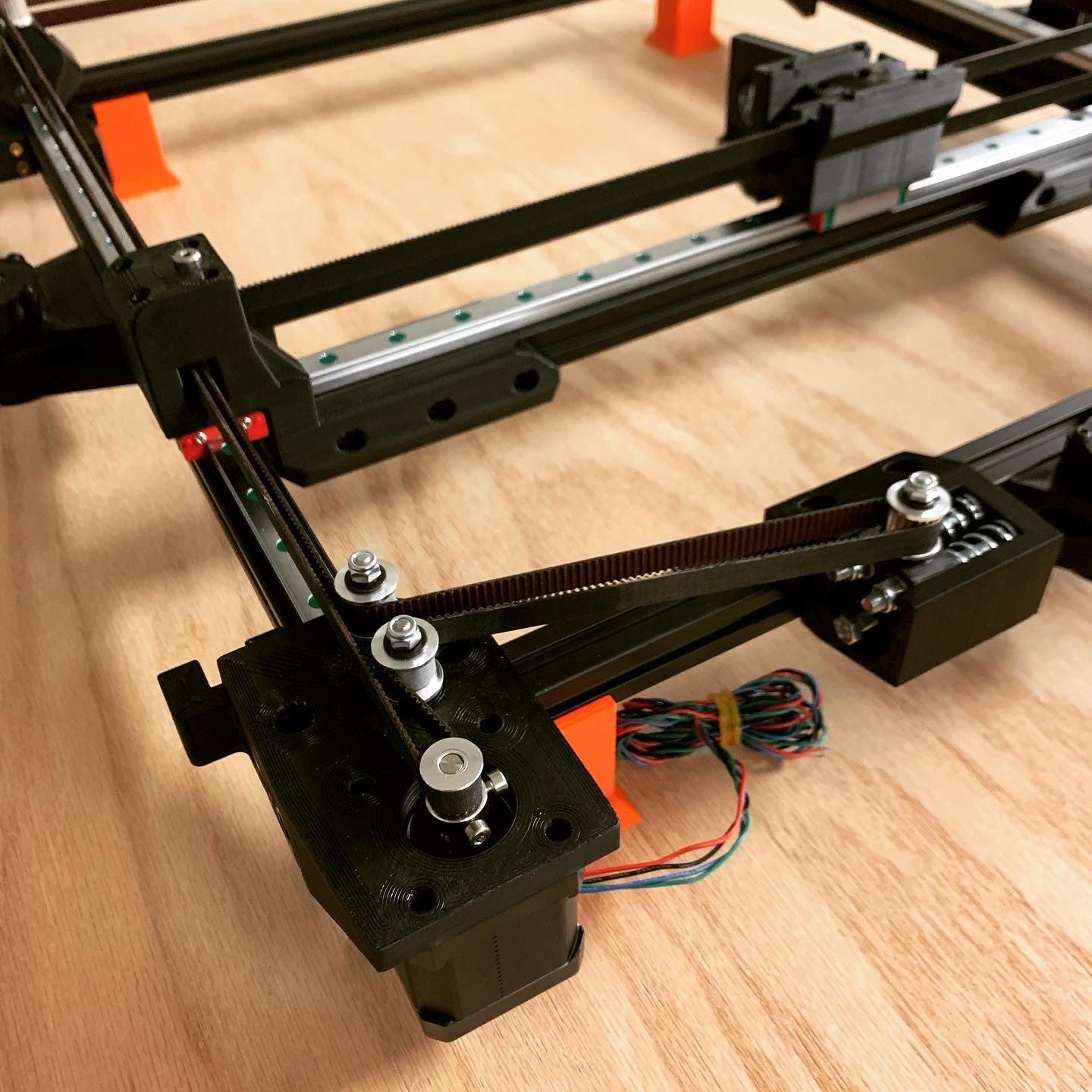

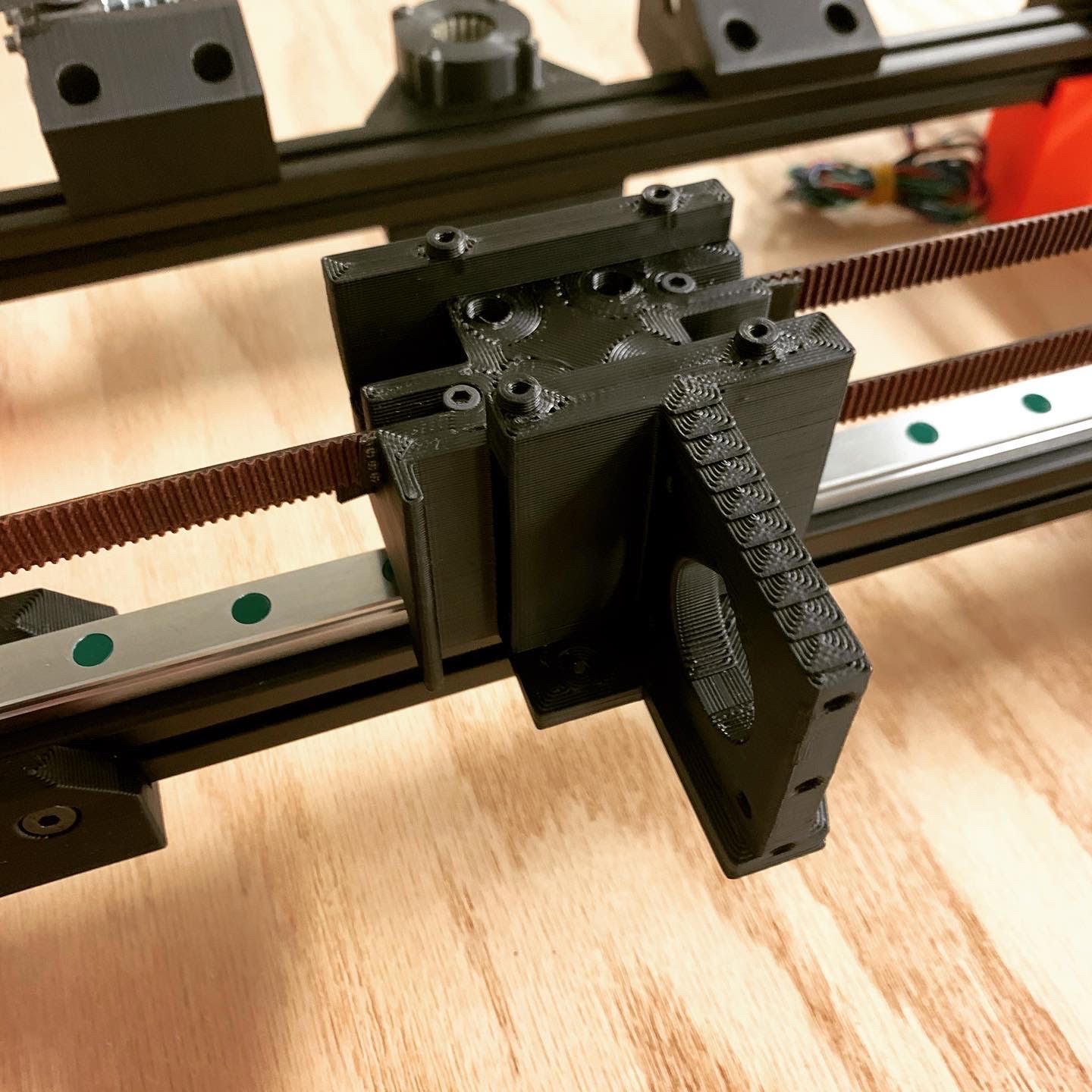

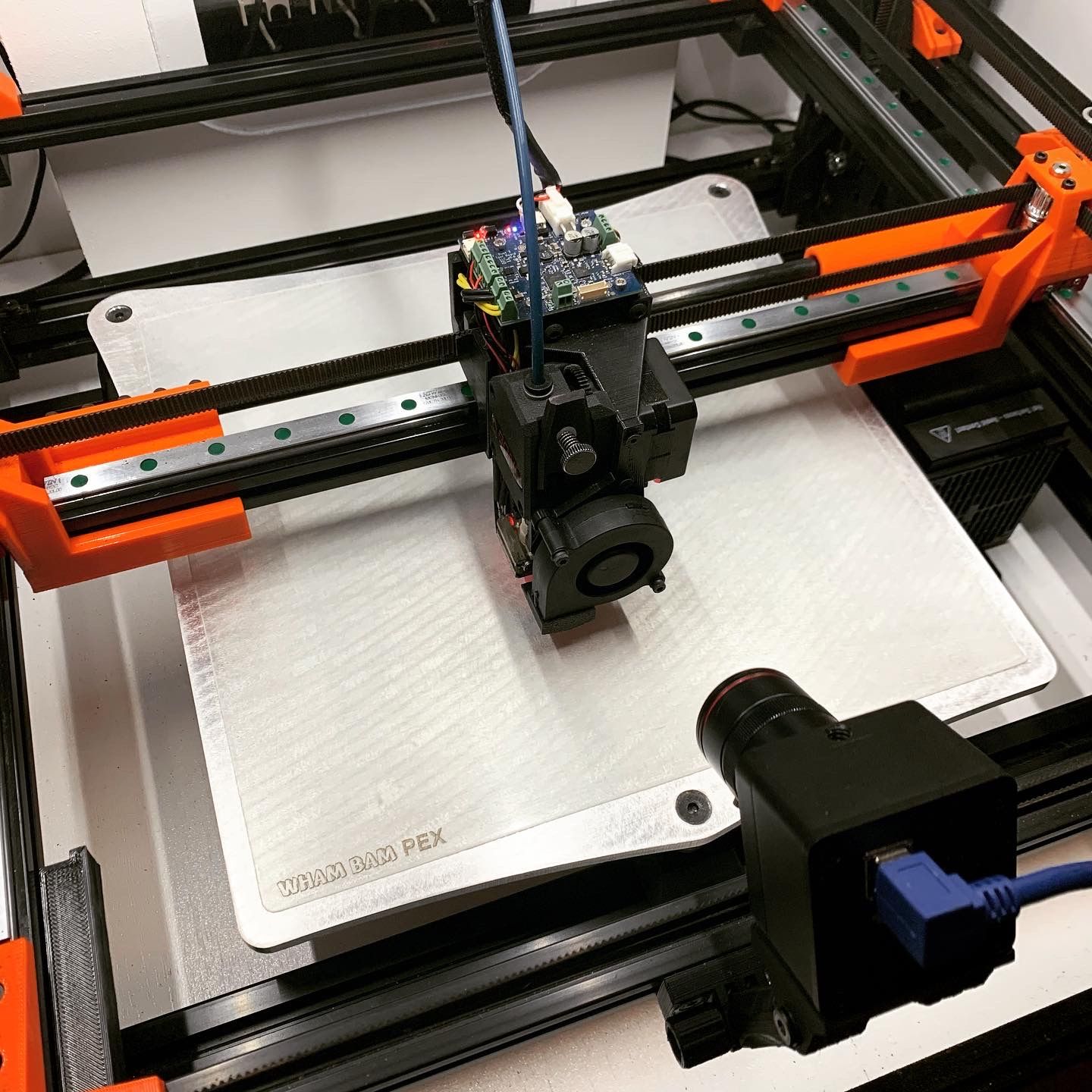

We've been heads down for awhile now wrapping up the design for our release candidate.. and finally have something to show - our new gantry! It has been completely redesigned to be smaller, lighter, and stiffer than the prototypes.

We are in love! Check out the belt work..

-

@oozeBot said in oozeBot ele^gant:

We are in love! Check out the belt work..

What is the rational for the idler nearest the stepper? The belt leaving the stepper could have run straight to a tensioner positioned closer to the stepper.

Thanks.

Frederick

-

@fcwilt If that idler is removed, the belt would only wrap half of the pulley and the belt could slip.

-

@fcwilt said in oozeBot ele^gant:

What is the rational for the idler nearest the stepper? The belt leaving the stepper could have run straight to a tensioner positioned closer to the stepper.

Thanks.

Frederick

Maximum surface area on the pulley.

-

@oozeBot said in oozeBot ele^gant:

Maximum surface area on the pulley.

Thanks.

Would you consider posting your calculations showing that much contact area was needed?

Thanks again.

Frederick

-

Man that looks sharp

-

@fcwilt Gates recommends a minimum of 6 teeth in mesh between the belt and the sprocket. We are using 16 tooth pulleys. Removing that smooth idler would only allow for 4-5 teeth to fully engage. I strongly prefer to fully utilize 180+ degrees of the pulleys to engage 8 teeth minimum.

-

@oozeBot said in oozeBot ele^gant:

@fcwilt Gates recommends a minimum of 6 teeth in mesh between the belt and the sprocket. We are using 16 tooth pulleys. Removing that smooth idler would only allow for 4-5 teeth to fully engage. I strongly prefer to fully utilize 180+ degrees of the pulleys to engage 8 teeth minimum.

Oh.

Thanks.

Frederick

-

We just wrapped up our new build plate, with 3-point leveling, made from .25” ATP-5 precision cast aluminum tooling plate. Fresh off the CNC!

Can’t wait to get it mounted for testing!

-

@oozeBot said in oozeBot ele^gant:

We just wrapped up our new build plate, with 3-point leveling, made from .25” ATP-5 precision cast aluminum tooling plate. Fresh off the CNC!

Boy, whoever cut that plate has a real hard time making straight cuts!

Frederick

-

@fcwilt we took a bit of creative freedom with the design.. decided not everything on our machines had to be square!

-

@oozeBot said in oozeBot ele^gant:

@fcwilt we took a bit of creative freedom with the design.. decided not everything on our machines had to be square!

It looks very good - somebody at your end is creative.

I have next to no creativity - using round corners is about as creative as I can get.

Frederick

-

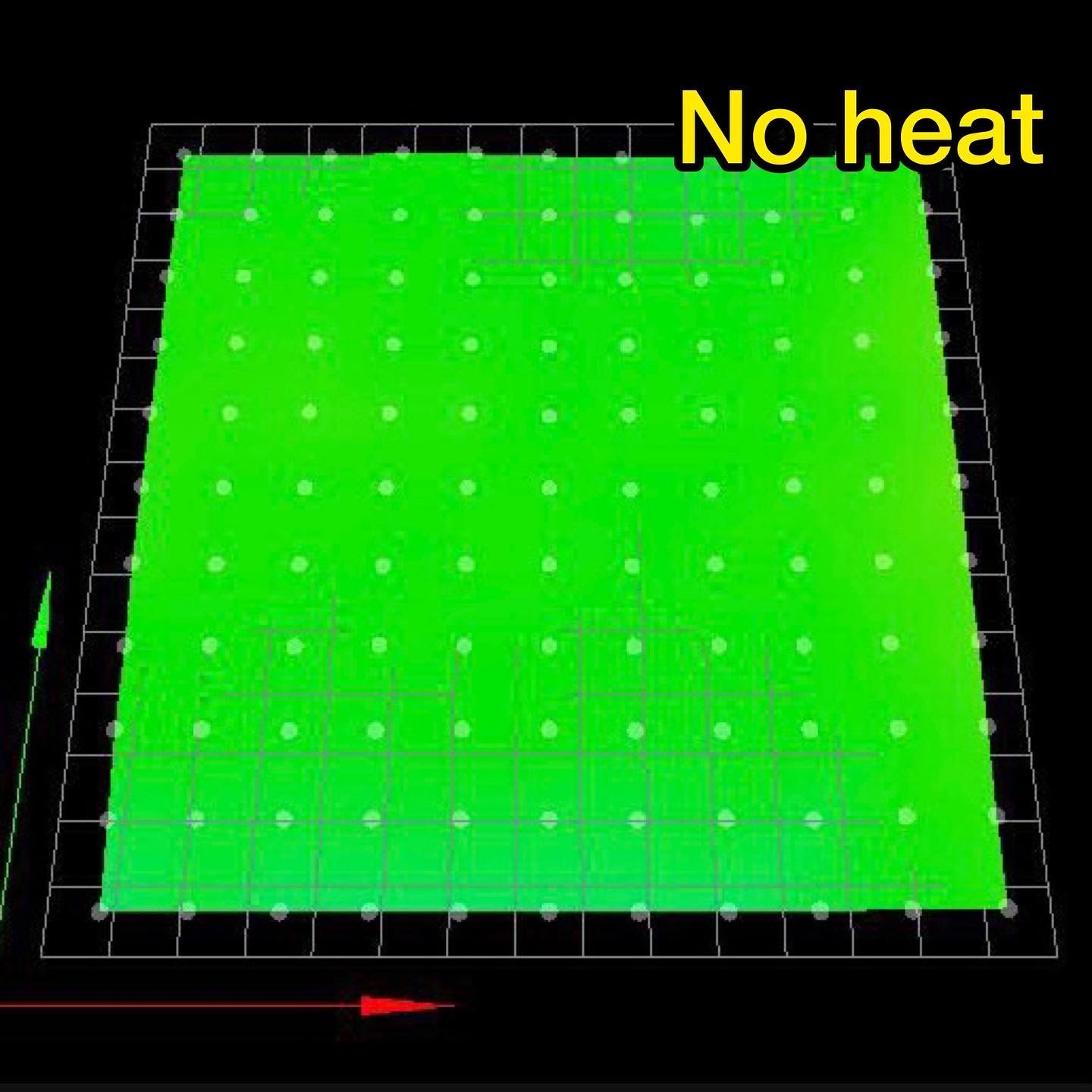

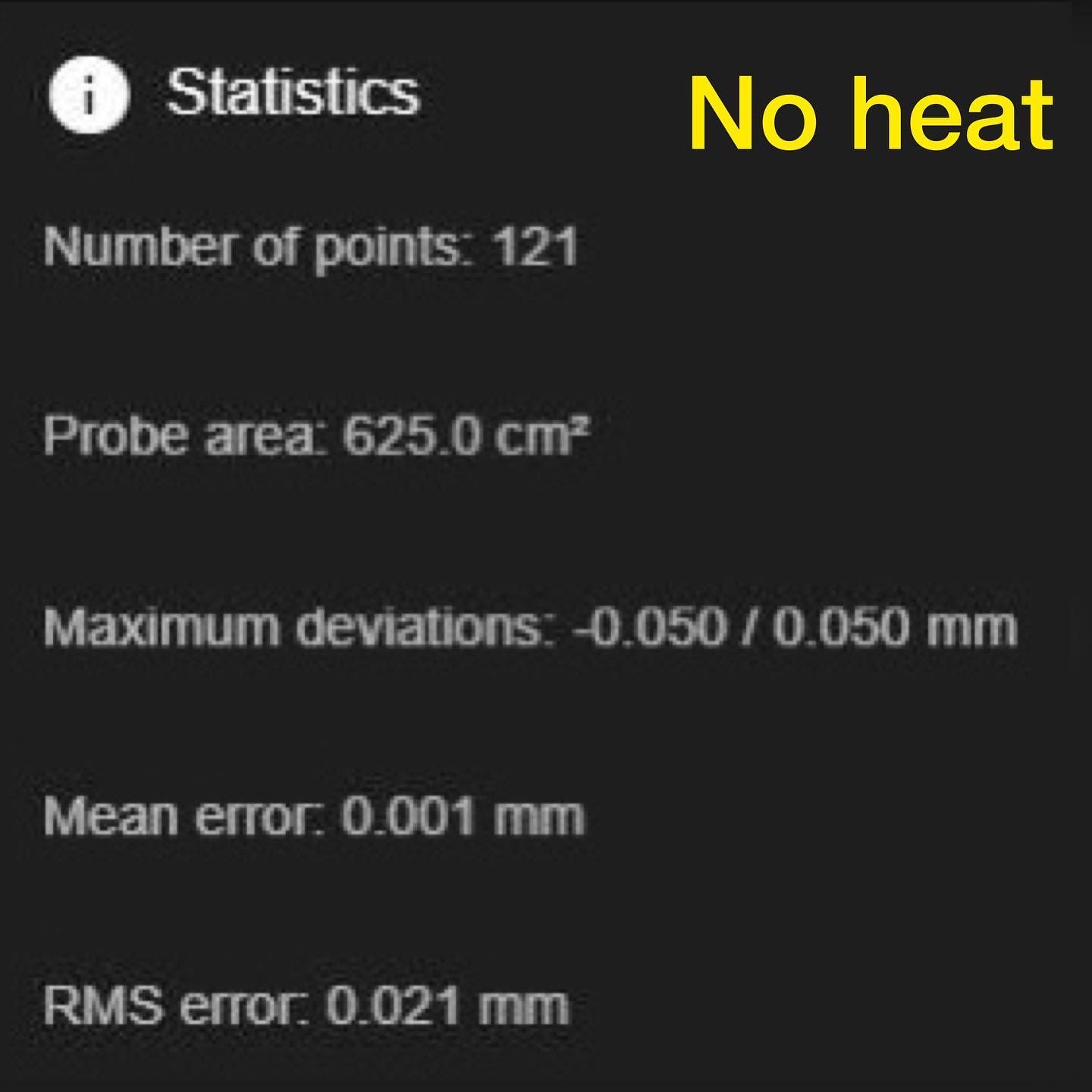

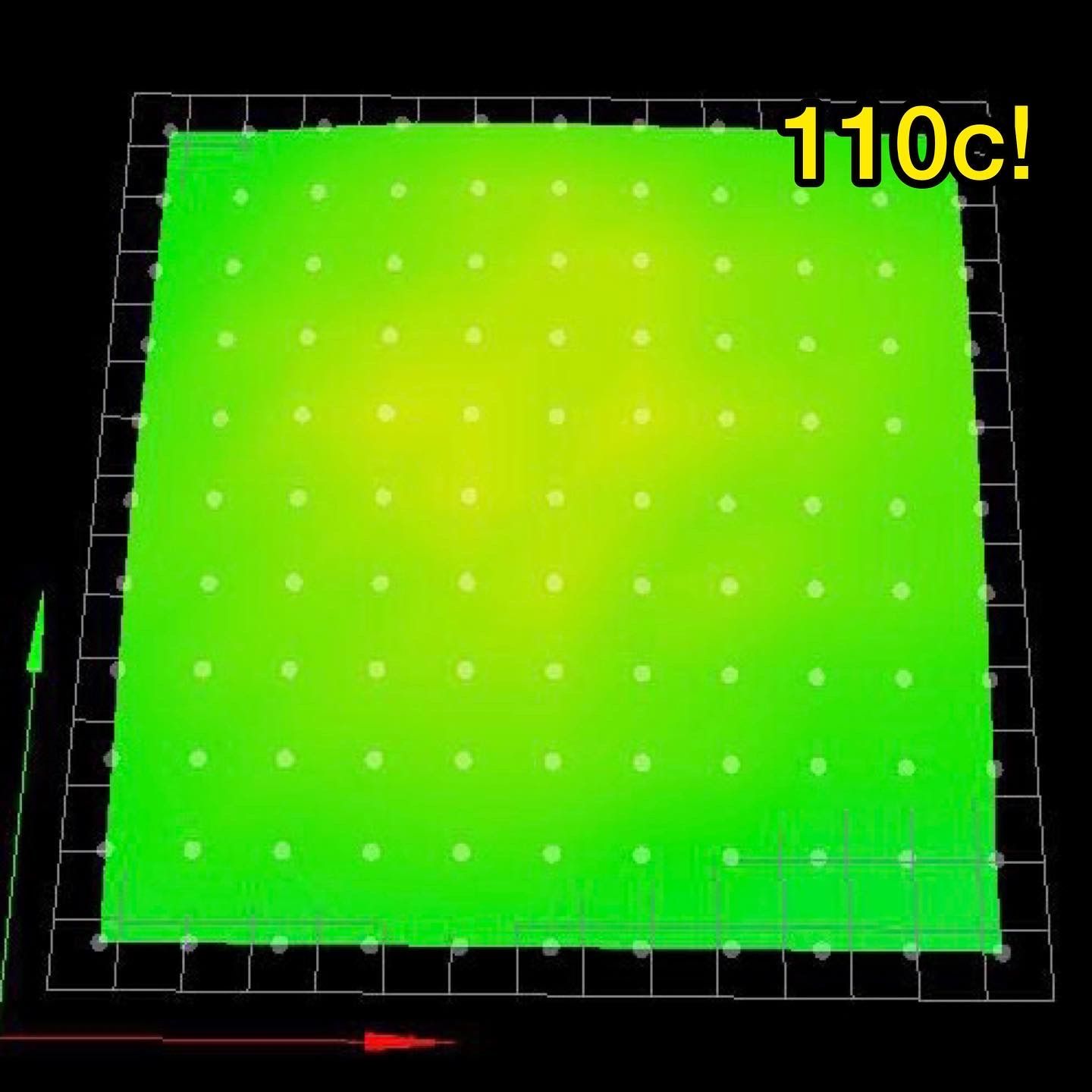

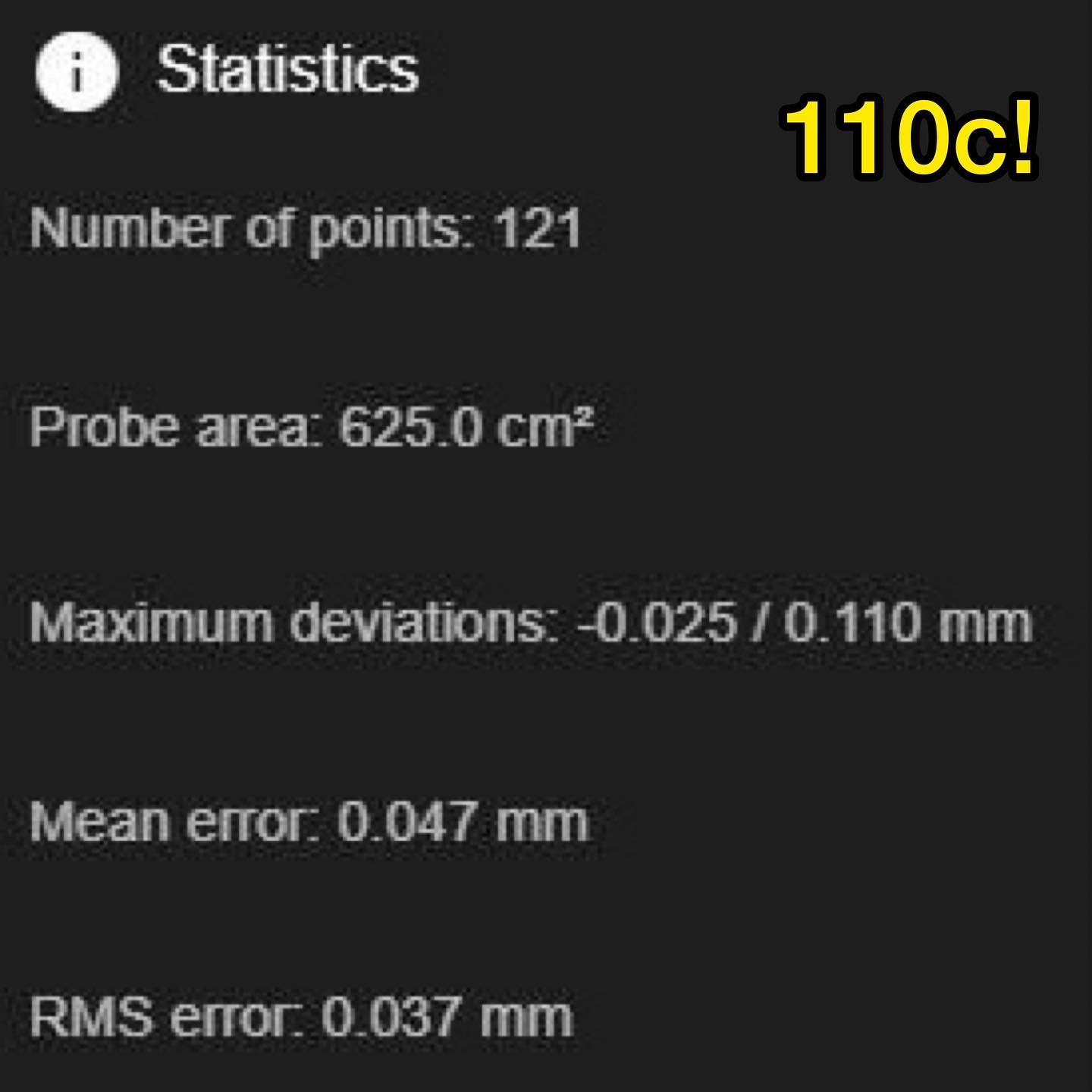

More photos of the new build plate after cleaning it up and getting it installed. We are very pleased but there will be some additional design tweaks. I’ve got to say, I’m really impressed with the mesh bed leveling results..!

-

The wham bam pex surface works good but I have had problems with it coming apart if the material I'm printing with tries to pull up ruining the surface. Seems like the top layer of it comes apart.

-

@JamesM so far, we’ve had good luck with it after sanding.. but it’s just one of many surfaces we are testing. However, I do understand what you are pointing out about it and will be watching for it..

-

We have completed the motion system for the oozeBot ele^gant with all testing complete. It can sustain 400mm/s in X&Y and 250mm/s in Z!

Check out a quick video of it in motion here: https://vimeo.com/515410723

-

Beautiful machine! It's looking really great.

-

Well done. Looking forward to seeing more.

-

Hi,

Your height map is obscenely good - are you just trying to make the rest of us feel inadequate?

What I wouldn't give to have a bed that flat.

And why doesn't your machine try to shake itself apart at those speeds?

I've never tried speeds like that but I'm pretty sure my printers would disassemble themselves in protest.

What printing speeds are you aiming for?

Thanks.

Frederick