First Layer and Extrusion Problems

-

pla_unload.g pla_load.g pla_config.g Hello togehter,

i finished my first corexy build yesterday and wanted to tune the z offset for a good first layer with your tutorial for BLtouch and independent Z leveling.

But now i have the Problem that my z offset is way to high and i dont know where to put the new values in.

in my config is the following line for my BLtouch:

; Z-Probe

M950 S0 C"io7.out" ; create servo pin 0 for BLTouch

M558 P9 C"^io7.in" H5 F120 T6000 ; set Z probe type to bltouch

G31 P500 X-26 Y2 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X50:400 Y50:400 S50 ; define Mesh GridAfter Leveling the bed with a piece of paper and setting Z=0 with G92 Z0

then a single measurement with G30 S-1 where i get the value of x.xxx

when i am changing the Z value, i dont get it right. or is there something i am missing ?

The indipendent Z Leveling seems to work just Fine.

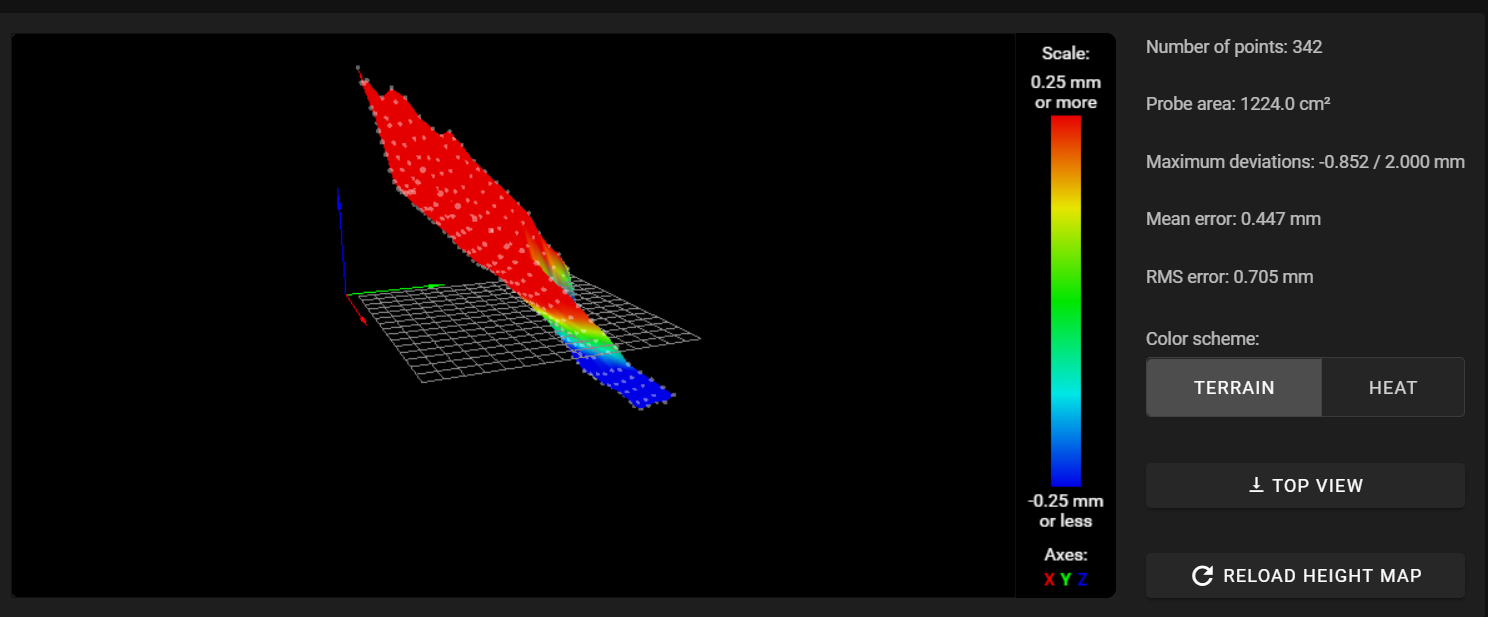

But my High Map is a Desaster

i tried Tue BEd Level First and then a Mesh Compensation.

i tried Tue BEd Level First and then a Mesh Compensation.The other Problem is that my Extruder seems to skip steps and is constantly feeding to less material. The E STeps are 830 for a Original Direct Drive BMG with a E3d Volcano with 0.4 Nozzle. When i am manual Extrudiong at 225° i cant go with the speed over 5 -15 mm bevor it starts making strange clicking noises.

Where can i set the Retractions Paramters etc. ?

I tried using the Filaments Macros with the load, unload and config files , but i dont know if it is correct .Reprap 3.1.1

Duet 3 + RPI 3b+

0.9° Pancake Stepper on the BMG

1.8° Z StepperTried printing PLA with 215 ° Nozzle and Bed 60°

config (1).g

homez.g

bed.g

pla_config.g

pla_load.g

pla_unload.gKindly Regards

Frederik -

I dont know where i can change the offset ?

Do i have to add a command after the BLTouch Lines or change the trigger height ?The dozuki only says to change the G31 , but how ?!?

-

in config.g :

G31 P500 X-26 Y2 Z2.5 <= modify the Z, increase value for reduce height of nozzle -

ok thanks , one moment i will try it

-

Is the Right way to do a bed leveling:

first G32

then G 28

and then adjusting for the right layer height ?This is my First Printer build

-

G29 S1 ; Load previously set bed map

this should not be in the config.g

the mesh should be loaded after you have established z=0

so a good place is the start of your slicer g code

for the offset see

https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe#Section_Calibrate_the_Z_probe_trigger_height -

when i run first a true bed level and then a bed mesh compensation i get the following heightmap:

RepRapFirmware height map file v2 generated at 2020-11-20 14:53

xmin,xmax,ymin,ymax,radius,xspacing,yspacing,xnum,ynum

0.00,340.00,0.00,370.00,-1.00,20.00,20.00,18,19

2.000, 1.878, 1.875, 1.890, 1.685, 1.642, 1.517, 1.442, 1.358, 1.253, 1.180, 1.145, 1.135, 1.138, 1.160, 1.177, 1.250, 1.333

1.715, 1.562, 1.735, 1.757, 1.603, 1.550, 1.423, 1.320, 1.240, 1.132, 1.075, 1.030, 1.020, 1.020, 1.048, 1.062, 1.105, 1.183

1.683, 1.645, 1.835, 1.725, 1.558, 1.397, 1.267, 1.160, 1.070, 1.010, 0.943, 0.925, 0.910, 0.922, 0.975, 1.005, 1.022, 1.100

1.635, 1.677, 1.760, 1.573, 1.440, 1.302, 1.163, 1.052, 0.970, 0.905, 0.847, 0.815, 0.802, 0.815, 0.855, 0.892, 0.930, 1.010

1.603, 1.555, 1.608, 1.442, 1.285, 1.150, 1.060, 0.953, 0.833, 0.755, 0.712, 0.690, 0.685, 0.695, 0.730, 0.770, 0.818, 0.927

1.483, 1.513, 1.510, 1.255, 1.155, 1.025, 0.943, 0.828, 0.795, 0.685, 0.597, 0.578, 0.573, 0.578, 0.613, 0.653, 0.722, 0.812

1.440, 1.442, 1.358, 1.160, 0.998, 0.858, 0.715, 0.642, 0.648, 0.542, 0.507, 0.507, 0.510, 0.533, 0.557, 0.610, 0.675, 0.775

1.478, 1.415, 1.267, 1.017, 0.917, 0.797, 0.743, 0.680, 0.615, 0.605, 0.432, 0.413, 0.420, 0.440, 0.455, 0.505, 0.573, 0.677

1.355, 1.205, 1.100, 0.875, 0.770, 0.672, 0.648, 0.590, 0.523, 0.417, 0.307, 0.300, 0.312, 0.333, 0.352, 0.392, 0.455, 0.555

1.212, 1.145, 0.953, 0.783, 0.632, 0.550, 0.560, 0.490, 0.360, 0.280, 0.203, 0.208, 0.225, 0.233, 0.238, 0.292, 0.352, 0.453

1.112, 1.010, 0.820, 0.632, 0.493, 0.390, 0.395, 0.347, 0.243, 0.158, 0.092, 0.100, 0.127, 0.120, 0.127, 0.163, 0.215, 0.333

1.005, 0.875, 0.705, 0.480, 0.358, 0.243, 0.212, 0.165, 0.115, 0.045, -0.010, 0.005, 0.010, 0.007, 0.012, 0.047, 0.097, 0.212

0.913, 0.750, 0.557, 0.318, 0.233, 0.108, 0.057, -0.002, -0.062, -0.110, -0.153, -0.148, -0.132, -0.137, -0.108, -0.068, 0.005, 0.095

0.797, 0.625, 0.425, 0.248, 0.127, -0.012, -0.097, -0.160, -0.220, -0.270, -0.283, -0.288, -0.270, -0.265, -0.227, -0.158, -0.105, -0.023

0.698, 0.483, 0.167, 0.115, -0.005, -0.145, -0.248, -0.302, -0.368, -0.440, -0.453, -0.475, -0.470, -0.430, -0.387, -0.315, -0.265, -0.182

0.500, 0.312, 0.070, -0.078, -0.193, -0.310, -0.408, -0.467, -0.552, -0.592, -0.575, -0.573, -0.578, -0.547, -0.495, -0.427, -0.350, -0.267

0.358, 0.160, -0.092, -0.172, -0.295, -0.415, -0.500, -0.573, -0.642, -0.665, -0.627, -0.595, -0.637, -0.640, -0.583, -0.515, -0.438, -0.347

0.265, 0.068, -0.240, -0.307, -0.420, -0.557, -0.640, -0.690, -0.735, -0.715, -0.660, -0.653, -0.730, -0.743, -0.698, -0.627, -0.542, -0.432

0.105, -0.070, -0.250, -0.320, -0.557, -0.677, -0.762, -0.797, -0.802, -0.773, -0.743, -0.795, -0.852, -0.833, -0.752, -0.670, -0.625, -0.517 -

That is the orresponding height map picture from my DWC

-

post the output of 3 consecutive G32.

most likely your motor order is wrong

-

1.G32

Leadjustments made: -2.618 -0.246 -0.521, points used 3, (mean, deviation) before (-0.997, 0.862) after (0.000, 0.000)2.G32

Leadscrew adjustments made: -0.054 1.112 0.200, points used 3, (mean, deviation) before (0.399, 0.459) after (-0.000, 0.000)3.G32

Leadscrew adjustments made: 0.044 0.756 -0.011, points used 3, (mean, deviation) before (0.228, 0.321) after (0.000, 0.000) -

i´ve checked the cabling.

left front spindle is connected to driver 2

back center spindle to driver 3

right front spindle to driver 4 -

Hi,

Do you lead screws really have pitch of 1.25?

Regards bed.g:

I'm not sure what having two P parameters is going to do to your bed leveling.

Why did you add the second P1.25?

Frederick

-

@fcwilt said in First Layer and Extrusion Problems:

Do you lead screws really have pitch of 1.25?

he has z400. where did you see 1.25 leadscrew?

M92 X160.00 Y160.00 Z400.00 E830.00 ; set steps per mm -

@Frederik said in First Layer and Extrusion Problems:

1.G32

Leadjustments made: -2.618 -0.246 -0.521, points used 3, (mean, deviation) before (-0.997, 0.862) after (0.000, 0.000)

2.G32

Leadscrew adjustments made: -0.054 1.112 0.200, points used 3, (mean, deviation) before (0.399, 0.459) after (-0.000, 0.000)

3.G32

Leadscrew adjustments made: 0.044 0.756 -0.011, points used 3, (mean, deviation) before (0.228, 0.321) after (0.000, 0.000)that seems to be converging. can you run a g29 now and post the picture

-

@Veti said in First Layer and Extrusion Problems:

@fcwilt said in First Layer and Extrusion Problems:

Do you lead screws really have pitch of 1.25?

he has z400. where did you see 1.25 leadscrew?

M92 X160.00 Y160.00 Z400.00 E830.00 ; set steps per mmSee his bed.g file.

He has two P parameters for each G30. Not sure if that is messing things up or not.

Frederick

-

good catch.

yes the second P1.25 parameter should be removed. this is not a valid parameter for G30

your pitch is 8mm btw. -

@Veti said in First Layer and Extrusion Problems:

your pitch is 8mm btw.

How can we be sure the pitch is 8mm? The config values might be wrong. Maybe the comment in bed.g is correct?

Clarification is needed from the OP.

Frederick

-

ok ,i have changed it.

is it possible to create a homez.g file where it automatically probes the bed on three points and enable compensation ?

perhaps like :

; homez.g

; called to home the Z axis

;

; generated by RepRapFirmware Configuration Tool v3.1.7 on Wed Nov 18 2020 18:04:17 GMT+0100 (Mitteleuropäische Normalzeit)G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G90 ; absolute positioning

G1 X240 Y220 F6000 ; go to first probe point

G32 ; home Z by True bed leveling 3 points in bed.gor do i have to include the three positions like

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G90 ; absolute positioning

G1 X240 Y220 F6000 ; go to first probe point

G30 P0 X330 Y240 Z-9999 ; Front Left

G30 P1 X150 Y0 Z-9999 ; Middle Back

G30 P2 X0 Y248 Z-9999 S3 ; Front Right and compensate 3mm -

create a macro that calls G28 and G32

-

@fcwilt said in First Layer and Extrusion Problems:

How can we be sure the pitch is 8mm?

i cant, but there is a very high chance that isnt a M8 metric lead screw.