printing issues with model

-

So im trying to improve this model and i've adjusted the temp, speed, acceleration, jerk, and flow as well as the retraction with only a small improvement. Every time its gets to the middle of the print there are bad corners and sometimes blobs form. I'm hoping someone here can help me figure out why it looks the way it does and what should i adjust. using duet 3+pi and firmware 3.2

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name ; Drives M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.0 S0 ; physical drive 0.0 goes forwards M569 P0.2 S0 ; physical drive 0.2 goes forwards M569 P0.3 S0 ; physical drive 0.3 goes forwards M569 P0.4 S0 ; physical drive 0.3 goes forwards M569 P20.0 S1 ; physical drive 0.3 goes forwards M584 X0.1 Y0:4 Z2:3 E20.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X3200.00 Y3200.00 Z3200.00 E873.00 ; set steps per mm M566 X400.00 Y400.00 Z5.00 E1000.00 ; set maximum instantaneous speed changes (mm/min) M203 X1500.00 Y1500.00 Z70.00 E5000.00 ; set maximum speeds (mm/min) M201 X560.00 Y560.00 Z5.00 E5000.00 ; set accelerations (mm/s^2) M906 X3900 Y3900 Z1800 E1300 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; s9t axis minima M208 X890 Y925 Z780 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io0.in" ; configure active-high endstop for low end on X via pin !io8.in M574 Y1 S1 P"io1.in" ; configure active-high endstop for low end on Y via pin !io2.in M574 Z0 S1 ; configure Z-probe endstop for low end on Z ; Z-Probe M558 P8 C"20.io0.in" H5 F90 T100000 ; set Z probe type to unmodulated and the dive height + speeds G31 P500 X0 Y0 Z0.1 ; set Z probe trigger value, offset and trigger height M557 X0:885 Y0:985 S80 ; define mesh grid ; Heaters M308 S0 P"20.temp0" Y"pt1000" ; configure sensor 0 as thermistor on pin 20.temp0 M950 H0 C"20.out0" T0 ; create nozzle heater output on 20.out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ;M308 S1 P"temp0" Y"thermistor" T100000 B3950 ; configure sensor 1 as thermistor on pin temp0 ;M950 H1 C"out0" T1 ; create bed heater output on out0 and map it to sensor 1 ;M307 H1 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit ;M140 H1 ; map heated bed to heater 1 ;M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"out8" Q500 ; create fan 0 on pin out8 and set its frequency M106 P0 S0 H0 T45 ; set fan 0 value. Thermostatic control is turned on M950 F1 C"out9" Q500 ; create fan 1 on pin out9 and set its frequency M106 P1 S0 H0 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 S"Titan Aqua 1.75" D0 H0 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined

-

M92 X3200.00 Y3200.00 Z3200.00 E873.00 ; set steps per mm

Those are some high steps per mm. What kind of a printer is this? Provide some more details please?

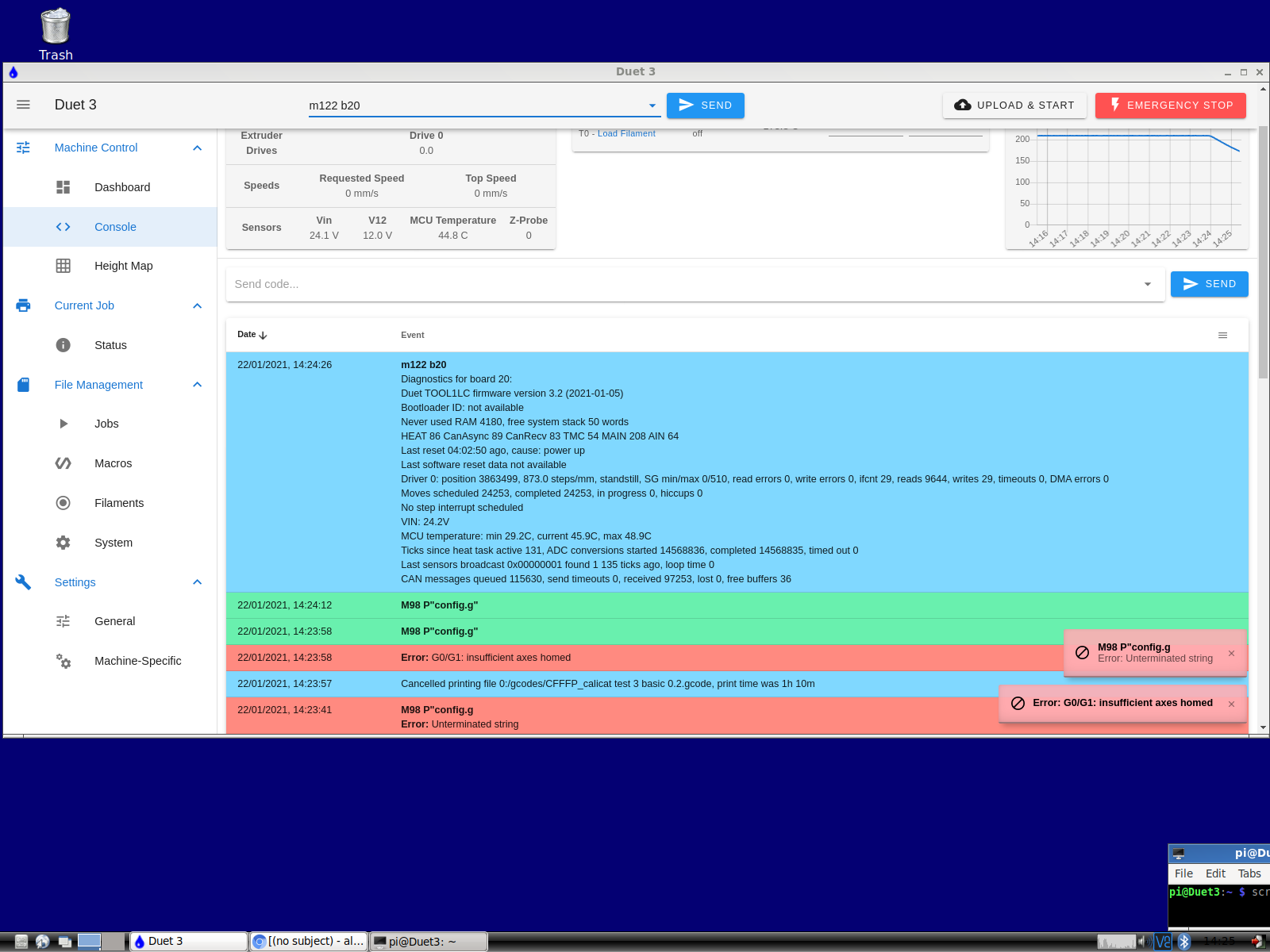

Results of M122? And M122 B1 etc if you have expansions.

Also send M98 P"config.g" to check for any syntax errors.Have the heaters been PID tuned?

Extruder calibrated? -

Its a cartesian printer its about 800mmx800mm. it has a nema 23 0.9 degree for the all axis because its all metal and i wasn't able to get it to move faster than 20mm/s with nema 17 which were 1.8 degree. I'm not sure if the steps per mm/ are correct but I used prusa steps per mm calculator and that's what got. as for the heaters, i haven't done a PID tune yet. I did calibrate the extruder.

-

The unterminated string error is because you're missing the closing quote "

PID tuning might help with the banding actually. thermal expansion of the bed or heater flex could be part of it. Same for the hotend.

Is it a lead screw based axis?

-

yes its dual lead screw for y-axis and single lead screw for the x-axis. im using two motors for the y-axis and single motor for the x-axis. as for the bed heater, i haven't connected it so that's not working now. what do you mean by heater flex?

-

@1997alex

Why is H1 commented out? -

Basically bang-bang can make it move up and down a small amount.

-

@DIY-O-Sphere said in printing issues with model:

@1997alex

Why is H1 commented out?it's the bed, but not connected

-

@Phaedrux oh i see, so should i leave it as bang or change it to PID.

-

Well once you PID tune it and save the results it will use PID once those results are loaded again. So you don't have to change anything in config.g

M303 T0 S200will tune the hotend associated with tool0Normally the bed is heater0 and tools come after.

-

@Phaedrux ok thanks ill give it try and see if that helps.

-

I tried auto tuning and it gives me an Error:M303: remote auto tuning not implemented

-

Ah yes you're using a tool board. Can't auto tune yet. If you can connect to the main board temporarily you can auto tune.

-

@1997alex said in printing issues with model:

800mmx800mm

thats a big printer. is it bowden or direct drive?

-

@Veti its direct drive and going to enclose it to keep the temp consistent.

-

We recently identified some issues in synchronizing moment over CAN that affect some prints, and fixed them in the RRF 3.3beta. As you are using a tool board, I suggest you try the beta.

-

@dc42 ok will give it try, thanks for the help.