@Phaedrux ok, sorry about that confusion. I wasn’t sure what part of the code to input into my homez file at first but it works now. Thanks.

Best posts made by aprz

-

RE: z probe not displaying under sensor status web controllerposted in General Discussion

-

RE: Trouble with first test printposted in Tuning and tweaking

its saying that my g code is spam. I don't know why it doesn't want to submit? i tried submitting portions of it but still says the same thing.

-

Future changes to limitations for filament sensor configurationposted in Firmware wishlist

Somethings I would like to be able to do using a basic filament runout sensor.

I'm looking into having a duet Magnetic filament sensor( M591 D0 P3 C"20.io1.in" S1) near the extruder connected to the tool board mainly for detecting precise filament movement and the other one, a Dyzen filament sensor(M591 D0 P1 C"0.io3.in" S1) that only detects filament runout as a back up sensor at the other end of the long Bowden tube. The dozuki page of limitations show that this option will not be supported. I understand that "Filament monitors must be connected to the same board as the corresponding extruder motor. This use so that the firmware can correlate the measured filament movement and the commanded extruder movement in real time." to avoid any miss reading but I just need the filament runout sensor at the other end of the Bowden tube to alert me if the filament just runs out(nothing to do with filament movement readings) that's what i would have the duet magnetic sensor for mainly. I understand the Duet magnetic sensor could do the same and i could run the Dyzen runout sensor wires to the tool board but id like to avoid having so many wires running from inside to outside the printers chamber.

If i can just configure a simple sensor to detect runout on an extruder running on a separate board that uses P1 that would be great. besides that the duet hardware and software is great. Thanks for all the help aswell.

-

RE: New firmware issue - temp not readingposted in General Discussion

ok thanks i thought i just had to do one single update after sending the sudo apt-get update and sudo ad-get upgrade. well, problem is fixed.

-

RE: duet 3 connecting z probe inductive sensorposted in Duet Hardware and wiring

Ok never mind the resistors, I’ll try that out later but I just ordered another probe that is a npn swapped it out. It works just had to fix a couple wiring issues but anyone out there wanting to use a inductive sensor make sure it’s a npn inductive sensor, also the sensor works with the 3.3v power in the io5 pin and didn’t need to wire it to the vin or 12v. I have the brown going to 3.3v, the blue going to ground and the black going to “io5.in”. Well thanks for the help problem solved.

-

Trouble with first test printposted in Tuning and tweaking

So I’m ready to print or at least I think I am. Calibrated the extruder, set the mesh compensation, and all axis home as they should.

Issue is as it homes the x y and z axis, heats up the nozzle, and z goes back down it begins to extrude the Filament but it doesn’t move the x or y axis. I’m not sure what to do.

I’m using the cura slicer and using a level bed test print and cube.

Duet 3 board and 3.3.1 rrf

Here’s the link to the print

-

Faulty heater from manufacturer/supplierposted in General Discussion

Warning to anyone considering purchasing a heater from a Chinese company to (save money) be cautious about buying from there as it’s not UL rated(from my research). I purchased a very large heater from a supplier in China and I had a licensed electrician come install everything needed to run it( he was skeptical about the heater and only helped with the circuit breaker and outlet). Then two months later after running the heater up to 100c (because the build plate is a 1/4 inch thick and heat transfer is low) the heater started smoking by the wire leading out of the base of the heater. Photos attached..... lesson learned and could have led to a fire. I won’t be buying a heater from that specific Chinese company again. Now I’m looking for a US manufacturer that can make a heater so it’s gonna be pricey but you get what you pay for($180).

BTW the heater is “rated” for 120c max and the configuration was 120v at 3000w at 30a which was doable and the electrician confirmed it but recommended a 240v when using that much power next time to reduce the amps. So I won’t be cheap when it comes to heaters and high powered units like this from now on.

BTW the heater is “rated” for 120c max and the configuration was 120v at 3000w at 30a which was doable and the electrician confirmed it but recommended a 240v when using that much power next time to reduce the amps. So I won’t be cheap when it comes to heaters and high powered units like this from now on.

Latest posts made by aprz

-

monitor the filament sensor through the status windowposted in Duet Web Control

Is there a way to monitor the filament sensors movement/status, similar to how the z probe sensor is monitored and displayed in the status window. Id like to be able to glance at the monitor instead of always having to look at the printer/filament sensor. If its not available I think it would be a nice addition.

-

RE: Heater fault issue while tool 0 fan is onposted in Tuning and tweaking

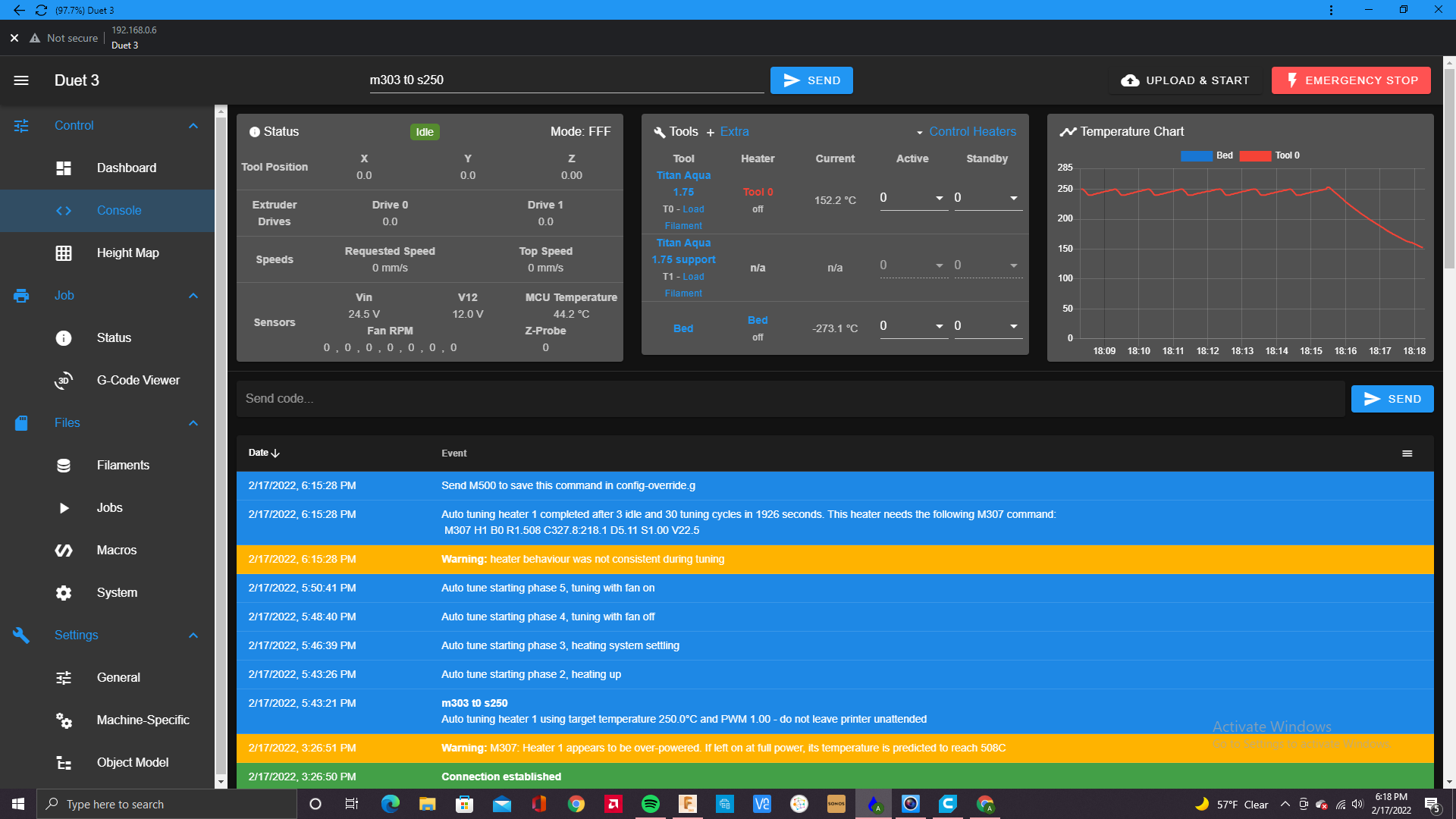

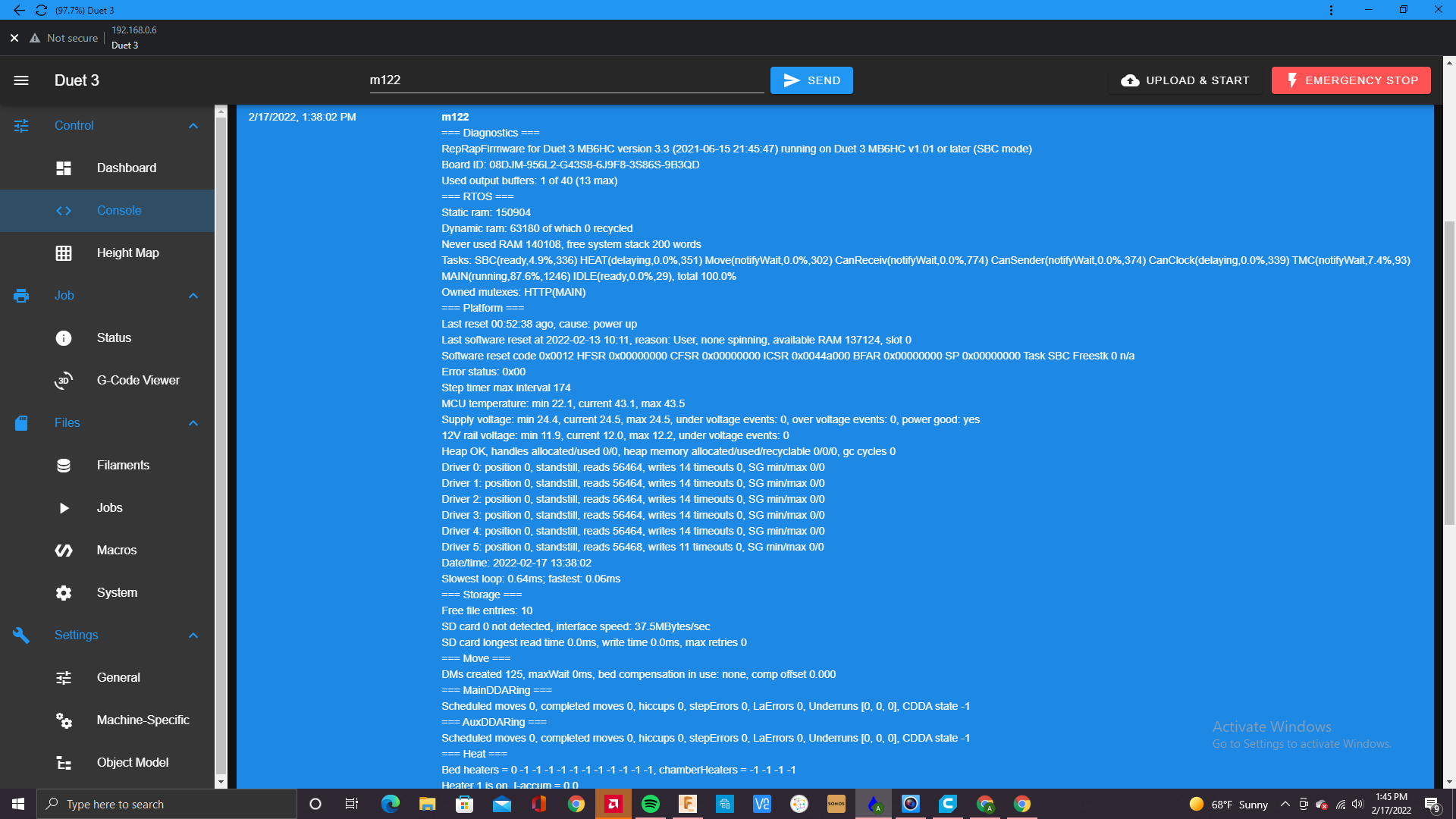

@phaedrux I ran the M303 H0 S250 twice and the message I got in the event log, below is a screen shot. I'm not sure what is causing that warning. I've changed the heater as well but didn't seem to fix the issue, what else could it be? Again thanks for the help.

-

RE: Heater fault issue while tool 0 fan is onposted in Tuning and tweaking

@phaedrux Thanks. I'll recalibrate with the M303 T0 S250 instead of the other, that may be why the fault keeps occurring.

-

Heater fault issue while tool 0 fan is onposted in Tuning and tweaking

I've been having an issue recently with the heater faulting while the part cooling fan is on during a print. I'm assuming its a gcode error but would appreciate any help and suggestions. Also, after doing a heater calibration I noticed the voltage for the heater is 22.2, (M307 H1 R1.683 C322.300:307.700 D4.10 S1.00 V22.2 B0) is that normal.

Thanks.Here's my config file:

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name ; Wait a moment for the CAN expansion boards to start G4 S2 ; Network ;M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP ;M586 P0 S1 ; enable HTTP ;M586 P1 S0 ; disable FTP ;M586 P2 S0 ; disable Telnet ; Drives M569 P0.4 S1 ; X axis right motor physical drive 0.4 goes forwards M569 P2.2 S1 ; X axis left motor physical drive 2.2 goes forwards M569 P2.0 S1 ; Y axis physical drive 2.0 goes forwards M569 P2.1 S1 ; Y axis physical drive 2.1 goes forwards M569 P1.1 S0 ; Y axis physical drive 1.1 goes forwards M569 P1.0 S0 ; Y axis physical drive 1.3 goes backwards M569 P0.0 S1 ; Z axis physical drive 0.0 goes forwards M569 P0.1 S1 ; Z axis physical drive 0.1 goes forwards M569 P0.2 S1 ; Z axis physical drive 0.2 goes forwards M569 P0.3 S1 ; Z axis physical drive 0.3 goes forwards M569 P20.0 S0 ; Tool 1 physical drive 20.0 goes forwards M569 P21.0 S1 ; Tool 2 physical drive 21.0 goes forwards M584 X0.4:2.2 Y2.0:2.1:1.1:1.0 Z0.0:0.1:0.2:0.3 E20.0:21.0 ; Four Z motors connected to driver outputs Z axis M671 X-30:-30:890:890 Y-30:890:890:-30 S2 ; leadscrews at rear left, front left, front right, rear right (connected to Z) M208 X0:820 Y0:820 Z0:800 ; X axis moves from 0 to 845, Y axis goes from 0 to 840, Z Moves from 0 to 800, C moves from -45 to 360 M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation M92 X52.49 Y104.99 Z3200.00 E837.00:837.00 ; set steps per mm M566 X420.00 Y420.00 Z270.00 E7000.00:7000.00 ; set maximum instantaneous speed changes (mm/min) M203 X7250.00 Y7250.00 Z350.00 E10000.00:10000.00 ; set maximum speeds (mm/min) M201 X300.00 Y300.00 Z270.00 E8000.00:8000.00 ; set accelerations (mm/s^2) M906 X3600 Y2900 Z2500 E1100:1100 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits ;M208 X0:845 Y0:890 Z0:800 ; X axis moves from 0 to 845, Y axis goes from 0 to 840, Z Moves from 0 to 800, C moves from -45 to 360 ; Filament sensors M591 D0 P3 C"20.io1.in" S1 R82:131 L27.47 E90.0 ; Duet3D rotating magnet sensor for extruder drive 0 is connected to E0 endstop input, enabled, sensitivity 24.8mm.rev, 80% to 135% tolerance, 5mm detection length ;M591 D1 P1 C"21.io1.in" S1 ; filament monitor connected to pin 21.io1.in ;M591 D0 P1 C"0.io0.in" S1 ; filament monitor connected to pin 3.io3.in ;Extra sensor M308 S10 Y"mcu-temp" A"MCU" ; Endstops M574 X1 S1 P"2.io2.in" ; configure active-low endstop for low end on X via pin 2.io2.in M574 Y1 S1 P"1.io2.in" ; configure active-low endstop for low end on Y via pin 1,io2.in M574 C0 Z0 ; No C Z endstop ; Z-Probe M558 P8 C"!21.io0.in" H3 F150 ; set Z probe type to unmodulated and the dive height + speeds G31 P500 X0 Y0 Z1.62 ; set Z probe trigger value, offset and trigger height M557 X0:800 Y0:800 S50 ; define mesh grid X/Y and probe spacing ; Heaters M308 S0 P"temp0" Y"thermistor" A"Bed" T100000 B3950 ; configure Bed sensor 1 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 1 M307 H0 R0.224 C219.6 D7.78 S1.00 V24.1 ; PID auto tune results for Tool 1 bed heater M140 H0 ; map heated bed to heater 1 M143 H0 S120 ; set temperature limit for heater 1 to 120C M308 S1 P"20.temp0" Y"pt1000" A"Tool 0" ; configure sensor 0 as thermistor on pin 20.temp0 M950 H1 C"20.out0" T1 ; create nozzle heater output on 20.out0 and map it to sensor 0 M307 H1 B0 R1.572 C361.9 D4.16 S1.00 V22.4 ;M308 S2 P"21.temp0" Y"pt1000" A"Tool 1" ; configure sensor 0 as thermistor on pin 20.temp0 ;M950 H2 C"21.out0" T2 ; create nozzle heater output on 20.out0 and map it to sensor 0 ;M307 H2 B0 R1.717 C105.7:98.6 D2.95 S1.00 V23.9 ; PID auto tune results for Tool 0 Titan Aqua 1.75 ;fan M950 F0 C"out8" Q250 ; create fan 0 on pin out8 and set its frequency M106 P0 T115 S0.10 C"Radiator Fan" ; set fan 0 value. Thermostatic control is turned on M950 F1 C"20.out2+out2.tach" Q250 ; create fan 1 on pin 20.out2 and set its frequency M106 P1 H-1 R1 C"Titan Aqua 1.75 T1" ; set fan 1 value. Thermostatic control is turned on M950 F2 C"21.out2" Q250 ; create fan 2 on pin 21.out2 and set its frequency M106 P2 T205 S0.10 H2 C"Titan Aqua 1.75 T2 support material Fan" ; set fan 2 value. Thermostatic control is turned on M950 F3 C"1.out3+out3.tach" Q450 ; create fan 1 on pin 20.out2 and set its frequency M106 P3 H-1 R1 C"Motor Fan 1" ; set fan 1 value. Thermostatic control is turned on M950 F4 C"1.out4+out4.tach" Q450 ; create fan 1 on pin 20.out2 and set its frequency M106 P4 H-1 R1 C"Motor Fan 2" ; set fan 1 value. Thermostatic control is turned on M950 F5 C"1.out5+out5.tach" Q450 ; create fan 1 on pin 20.out2 and set its frequency M106 P5 H-1 R1 C"Motor Fan 3" ; set fan 1 value. Thermostatic control is turned on M950 F6 C"2.out3+out3.tach" Q450 ; create fan 1 on pin 20.out2 and set its frequency M106 P6 H-1 R1 C"Motor Fan 4" ; set fan 1 value. Thermostatic control is turned on M950 F7 C"2.out4+out4.tach" Q450 ; create fan 1 on pin 20.out2 and set its frequency M106 P7 H-1 R1 C"Motor Fan 5" ; set fan 1 value. Thermostatic control is turned on M950 F8 C"2.out5+out5.tach" Q450 ; create fan 1 on pin 20.out2 and set its frequency M106 P8 H-1 R1 C"Motor Fan 6" ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 S"Titan Aqua 1.75" D0 H1 F0:1 ; define tool 0 ;M567 P0 E1.00:1.00 ; Mix drive E0 and drive E2 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 1 active and standby temperatures to 0C M563 P1 S"Titan Aqua 1.75 support" D1 H2 F0:2 ; define tool 1 G10 P1 X-15.4 Y0 Z0 ; set tool 2 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ; Custom settings are not defined T0 ; select first tool M501 ;read stored parameters

-

RE: Issue with filament monitor too little movementposted in Filament Monitor

@phaedrux ok thanks will try that.

-

RE: Issue with filament monitor too little movementposted in Filament Monitor

@dc42 ok thanks, what could be causing the "too little movement" fault to appear?

-

Issue with filament monitor too little movementposted in Filament Monitor

Machine pauses due to “too little movement” fault.

Duet 3 DWC 3.3.0

Filament ptfe tube is long so it’s causing a bit of resistance but was working for 3 layers of the print and I was able to print a small object just fine, then this happened. I’m not sure what’s going on or what is causing this, I just finished calibrating the filament sensor before I began the print job so it wasn’t the calibration I think.

I did send a new m591 to update the old one during the print and then sent a “m591 d0” to verify the change which is in the screenshot.

I’m not sure what the over 11131mm means in the console message?

Here’s my gcode

Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name ; Wait a moment for the CAN expansion boards to start G4 S2 ; Network ;M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP ;M586 P0 S1 ; enable HTTP ;M586 P1 S0 ; disable FTP ;M586 P2 S0 ; disable Telnet ; Drives M569 P1.2 S1 ; X axis physical drive 0.4 goes forwards M569 P2.2 S1 ; X axis physical drive 0.5 goes forwards M569 P2.0 S1 ; Y axis physical drive 2.0 goes forwards M569 P2.1 S1 ; Y axis physical drive 2.1 goes forwards M569 P1.1 S0 ; Y axis physical drive 1.1 goes forwards M569 P1.0 S0 ; Y axis physical drive 1.3 goes backwards M569 P0.0 S1 ; Z axis physical drive 0.0 goes forwards M569 P0.1 S1 ; Z axis physical drive 0.1 goes forwards M569 P0.2 S1 ; Z axis physical drive 0.2 goes forwards M569 P0.3 S1 ; Z axis physical drive 0.3 goes forwards M569 P20.0 S0 ; Tool 1 physical drive 20.0 goes forwards M569 P21.0 S1 ; Tool 2 physical drive 21.0 goes forwards M569 P0.4 S0 ; Tool 2 physical drive 0.4 goes forwards M569 P0.5 S0 ; Tool changer coupler Physical drive 0.5 goes forwards M584 X1.2:2.2 Y2.0:2.1:1.1:1.0 Z0.0:0.1:0.2:0.3 C0.5 E20.0:21.0:0.4 ; Four Z motors connected to driver outputs Z axis M671 X-30:-30:890:890 Y-30:890:890:-30 S3 ; leadscrews at rear left, front left, front right, rear right (connected to Z) M208 X0:820 Y0:820 Z0:800 C0:360 ; X axis moves from 0 to 845, Y axis goes from 0 to 840, Z Moves from 0 to 800, C moves from -45 to 360 M350 X16 Y16 Z16 C16 E16:16:16 I1 ; configure microstepping with interpolation M92 X80.00 Y160.00 Z3200.00 C91.022 E837.00:837.00:760.00 ; set steps per mm M566 X200.00 Y200.00 Z270.00 C2 E7000.00:7000.00:7000.00 ; set maximum instantaneous speed changes (mm/min) M203 X7250.00 Y7250.00 Z350.00 C5000 E10000.00:10000.00:10000.00 ; set maximum speeds (mm/min) M201 X90.00 Y90.00 Z270.00 C500 E8000.00:8000.00:8000.00 ; set accelerations (mm/s^2) M906 X3500 Y2100 Z2300 C600 E990:990:500 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits ;M208 X0:845 Y0:890 Z0:800 C0:360 ; X axis moves from 0 to 845, Y axis goes from 0 to 840, Z Moves from 0 to 800, C moves from -45 to 360 ; Filament sensors M591 D0 P3 C"20.io1.in" S1 R82:131 L27.47 E30.0 ; Duet3D rotating magnet sensor for extruder drive 0 is connected to E0 endstop input, enabled, sensitivity 24.8mm.rev, 80% to 135% tolerance, 5mm detection length ;M591 D1 P1 C"21.io1.in" S1 ; filament monitor connected to pin 21.io1.in ;M591 D0 P1 C"0.io0.in" S1 ; filament monitor connected to pin 3.io3.in ;Extra sensor M308 S10 Y"mcu-temp" A"MCU" ; Endstops M574 X1 S1 P"2.io2.in" ; configure active-low endstop for low end on X via pin 2.io2.in M574 Y1 S1 P"1.io2.in" ; configure active-low endstop for low end on Y via pin 1,io2.in M574 C0 Z0 ; No C Z endstop ; Z-Probe M558 P8 C"!21.io0.in" H3 F150 ; set Z probe type to unmodulated and the dive height + speeds G31 P500 X0 Y0 Z1.28 ; set Z probe trigger value, offset and trigger height M557 X0:800 Y0:800 S65 ; define mesh grid X/Y and probe spacing ; Heaters M308 S0 P"temp0" Y"thermistor" A"Bed" T100000 B3950 ; configure Bed sensor 1 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 1 M307 H0 R0.224 C219.6 D7.78 S1.00 V24.1 ; PID auto tune results for Tool 1 bed heater M140 H0 ; map heated bed to heater 1 M143 H0 S120 ; set temperature limit for heater 1 to 120C M308 S1 P"20.temp0" Y"pt1000" A"Tool 0" ; configure sensor 0 as thermistor on pin 20.temp0 M950 H1 C"20.out0" T1 ; create nozzle heater output on 20.out0 and map it to sensor 0 M307 H1 B0 R1.519 C243.6 D3.15 S1.00 V22.7 ; PID auto tune results for Tool 0 Titan Aqua 1.75 ;M308 S2 P"21.temp0" Y"pt1000" A"Tool 1" ; configure sensor 0 as thermistor on pin 20.temp0 ;M950 H2 C"21.out0" T2 ; create nozzle heater output on 20.out0 and map it to sensor 0 ;M307 H2 B0 R1.717 C105.7:98.6 D2.95 S1.00 V23.9 ; PID auto tune results for Tool 0 Titan Aqua 1.75 ;fan M950 F0 C"out8" Q250 ; create fan 0 on pin out8 and set its frequency M106 P0 T115 S0.10 H1:2 C"Radiator Fan" ; set fan 0 value. Thermostatic control is turned on M950 F1 C"20.out2" Q250 ; create fan 1 on pin 20.out2 and set its frequency M106 P1 T205 S0.10 H1 C"Titan Aqua 1.75 T1 Hot end Fan" ; set fan 1 value. Thermostatic control is turned on M950 F2 C"21.out2" Q250 ; create fan 2 on pin 21.out2 and set its frequency M106 P2 T205 S0.10 H2 C"Titan Aqua 1.75 T2 support material Fan" ; set fan 2 value. Thermostatic control is turned on M950 F3 C"out5" Q250 ; create fan 3 on pin out5 and set its frequency ; Tools M563 P0 S"Titan Aqua 1.75" D0:2 H1 F0:1 ; define tool 0 M567 P0 E1.00:1.00 ; Mix drive E0 and drive E2 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 1 active and standby temperatures to 0C M563 P1 S"Titan Aqua 1.75 support" D1 H2 F0:2 ; define tool 1 G10 P1 X-15.4 Y0 Z0 ; set tool 2 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C image url)

image url) -

RE: printer doesn't pause when there is a heater faultposted in General Discussion

@phaedrux ok thanks for the help. I'll order a duet filament sensor to monitor filament issues for now until this is fixed.

-

printer doesn't pause when there is a heater faultposted in General Discussion

My printer was almost done with a print and the heater fault was displayed but continued printing with out filament extruding because the heaters were at 0 Celsius. I was trying to figure out how to activate the auto pause when heater fault is displayed but could not figure out what was needed. Any help would be appreciated. I'm currently recalibrating heater so will update that but heater fault should cause printer to pause right? Thanks for the help in advance.

Duet 3 and DWC 3.3.0

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name ; Wait a moment for the CAN expansion boards to start G4 S2 ; Network ;M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP ;M586 P0 S1 ; enable HTTP ;M586 P1 S0 ; disable FTP ;M586 P2 S0 ; disable Telnet ; Drives M569 P1.2 S1 ; X axis physical drive 0.4 goes forwards M569 P2.2 S1 ; X axis physical drive 0.5 goes forwards M569 P2.0 S1 ; Y axis physical drive 2.0 goes forwards M569 P2.1 S1 ; Y axis physical drive 2.1 goes forwards M569 P1.1 S0 ; Y axis physical drive 1.1 goes forwards M569 P1.0 S0 ; Y axis physical drive 1.3 goes backwards M569 P0.0 S1 ; Z axis physical drive 0.0 goes forwards M569 P0.1 S1 ; Z axis physical drive 0.1 goes forwards M569 P0.2 S1 ; Z axis physical drive 0.2 goes forwards M569 P0.3 S1 ; Z axis physical drive 0.3 goes forwards M569 P20.0 S0 ; Tool 1 physical drive 20.0 goes forwards M569 P21.0 S1 ; Tool 2 physical drive 21.0 goes forwards M569 P0.4 S0 ; Tool 2 physical drive 0.4 goes forwards M569 P0.5 S0 ; Tool changer coupler Physical drive 0.5 goes forwards M584 X1.2:2.2 Y2.0:2.1:1.1:1.0 Z0.0:0.1:0.2:0.3 C0.5 E20.0:21.0:0.4 ; Four Z motors connected to driver outputs Z axis M671 X-30:-30:890:890 Y-30:890:890:-30 S3 ; leadscrews at rear left, front left, front right, rear right (connected to Z) M208 X0:820 Y0:820 Z0:800 C0:360 ; X axis moves from 0 to 845, Y axis goes from 0 to 840, Z Moves from 0 to 800, C moves from -45 to 360 M350 X16 Y16 Z16 C16 E16:16:16 I1 ; configure microstepping with interpolation M92 X80.00 Y160.00 Z3200.00 C91.022 E837.00:837.00:760.00 ; set steps per mm M566 X70.00 Y70.00 Z270.00 C2 E7000.00:7000.00:7000.00 ; set maximum instantaneous speed changes (mm/min) M203 X7250.00 Y7250.00 Z350.00 C5000 E10000.00:10000.00:10000.00 ; set maximum speeds (mm/min) M201 X90.00 Y90.00 Z270.00 C500 E8000.00:8000.00:8000.00 ; set accelerations (mm/s^2) M906 X3200 Y1800 Z2300 C600 E990:990:500 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits ;M208 X0:845 Y0:890 Z0:800 C0:360 ; X axis moves from 0 to 845, Y axis goes from 0 to 840, Z Moves from 0 to 800, C moves from -45 to 360 ; Filament sensors M591 D0 P1 C"20.io1.in" S1 ; filament monitor connected to pin 20.io1.in ;M591 D1 P1 C"21.io1.in" S1 ; filament monitor connected to pin 21.io1.in ;M591 D0 P1 C"0.io3.in" S1 ; filament monitor connected to pin 3.io3.in ;Extra sensor M308 S10 Y"mcu-temp" A"MCU" ; Endstops M574 X1 S1 P"2.io2.in" ; configure active-low endstop for low end on X via pin 2.io2.in M574 Y1 S1 P"1.io2.in" ; configure active-low endstop for low end on Y via pin 1,io2.in M574 C0 Z0 ; No C Z endstop ; Z-Probe M558 P8 C"!21.io0.in" H3 F150 ; set Z probe type to unmodulated and the dive height + speeds G31 P500 X0 Y0 Z1.28 ; set Z probe trigger value, offset and trigger height M557 X0:800 Y0:800 S65 ; define mesh grid X/Y and probe spacing ; Heaters M308 S0 P"temp0" Y"thermistor" A"Bed" T100000 B3950 ; configure Bed sensor 1 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 1 M307 H0 R0.224 C219.6 D7.78 S1.00 V24.1 ; PID auto tune results for Tool 1 bed heater M140 H0 ; map heated bed to heater 1 M143 H0 S120 ; set temperature limit for heater 1 to 120C M308 S1 P"20.temp0" Y"pt1000" A"Tool 0" ; configure sensor 0 as thermistor on pin 20.temp0 M950 H1 C"20.out0" T1 ; create nozzle heater output on 20.out0 and map it to sensor 0 M307 H1 B0 R1.858 C109.4 D2.96 S1.00 V23.6 ; PID auto tune results for Tool 0 Titan Aqua 1.75 ;M308 S2 P"21.temp0" Y"pt1000" A"Tool 1" ; configure sensor 0 as thermistor on pin 20.temp0 ;M950 H2 C"21.out0" T2 ; create nozzle heater output on 20.out0 and map it to sensor 0 ;M307 H2 B0 R1.717 C105.7:98.6 D2.95 S1.00 V23.9 ; PID auto tune results for Tool 0 Titan Aqua 1.75 ;fan M950 F0 C"out8" Q250 ; create fan 0 on pin out8 and set its frequency M106 P0 T115 S0.10 H1:2 C"Radiator Fan" ; set fan 0 value. Thermostatic control is turned on M950 F1 C"20.out2" Q250 ; create fan 1 on pin 20.out2 and set its frequency M106 P1 T205 S0.10 H1 C"Titan Aqua 1.75 T1 Hot end Fan" ; set fan 1 value. Thermostatic control is turned on M950 F2 C"21.out2" Q250 ; create fan 2 on pin 21.out2 and set its frequency M106 P2 T205 S0.10 H2 C"Titan Aqua 1.75 T2 support material Fan" ; set fan 2 value. Thermostatic control is turned on M950 F3 C"out5" Q250 ; create fan 3 on pin out5 and set its frequency ; Tools M563 P0 S"Titan Aqua 1.75" D0:2 H1 F0:1 ; define tool 0 M567 P0 E1.00:1.00 ; Mix drive E0 and drive E2 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 1 active and standby temperatures to 0C M563 P1 S"Titan Aqua 1.75 support" D1 H2 F0:2 ; define tool 1 G10 P1 X-15.4 Y0 Z0 ; set tool 2 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ; Custom settings are not defined T0 ; select first tool -

RE: Issue with Duet 3 6hcposted in General Discussion

@dc42 thanks for the help, that fixed my problem. If I need more fans connected for example to cool the steppers, is it ok to connect them to the expansion boards?