Magnetic sensor reads sensitivy wrong.

-

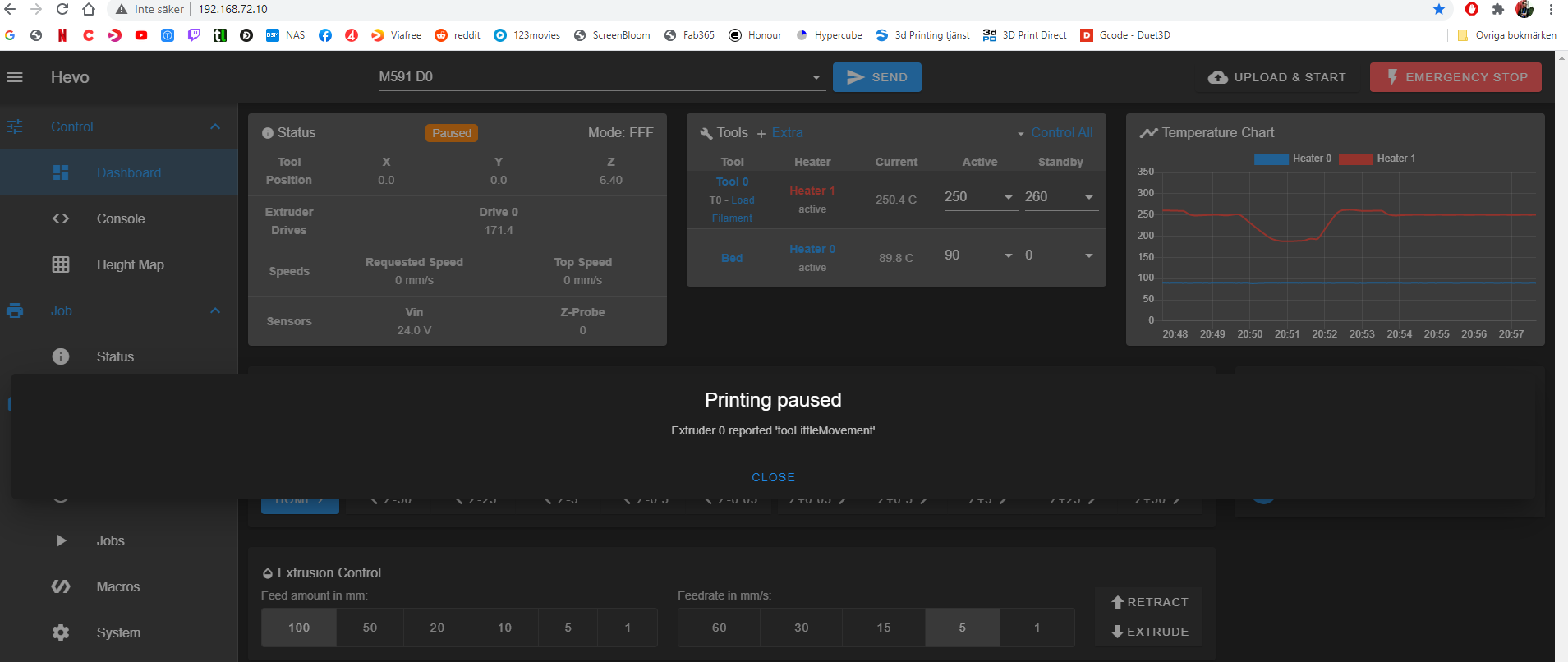

I have some problems calibrating my magnetic sensor. During normal prints i have 25.5 but when it slows down it measures 59.85. Why is it that different?

-

Seeing that your AGC value is 128, I think your magnet is too far from the sensor.

- Values for 'agc' of 85 to 105 are considered normal. If the value is higher, up to 128, the distance between the magnet and the sensor is likely to be too large (target is 0.25mm). Check that the screws holding the PCB down are not loose (caution: they are screwed into the plastic, so don't over-tighten them). If they are already tight, you could remove the 2 long screws to separate the two plastic parts and very slightly sand down the bottom surface of the top one (the one with the PCB attached) to move the sensor closer to the magnet.

From: https://duet3d.dozuki.com/Wiki/Duet3dFilamentMonitor_RotatingMagnetVersion#Section_Calibration

-

@alankilian how can that be? I use the duet housing. It cannot get closer.

-

They do explain how to make sure the screws are tight, and if they ARE tight, how to disassemble the housing and make a change so the magnet is moved closer to the sensor:

@alankilian said in Magnetic sensor reads sensitivy wrong.:

If they are already tight, you could remove the 2 long screws to separate the two plastic parts and very slightly sand down the bottom surface of the top one (the one with the PCB attached) to move the sensor closer to the magnet.

-

This post is deleted! -

@alankilian even if agc is correct it has no affect on my issue sadly.

It seems like the magnet is hitting the pcb so it is not spinning now. So something is wrong. Since agc is correct could it be a defective sensor? It should not be hitting the sensor if agc is within spec right?

-

@Alucardi said in Magnetic sensor reads sensitivy wrong.:

the magnet is hitting the pcb

Try adding small pieces of paper between the PCB and the case now to get the magnet a little farther away from the sensor.

I think you ALMOST have it working.

-

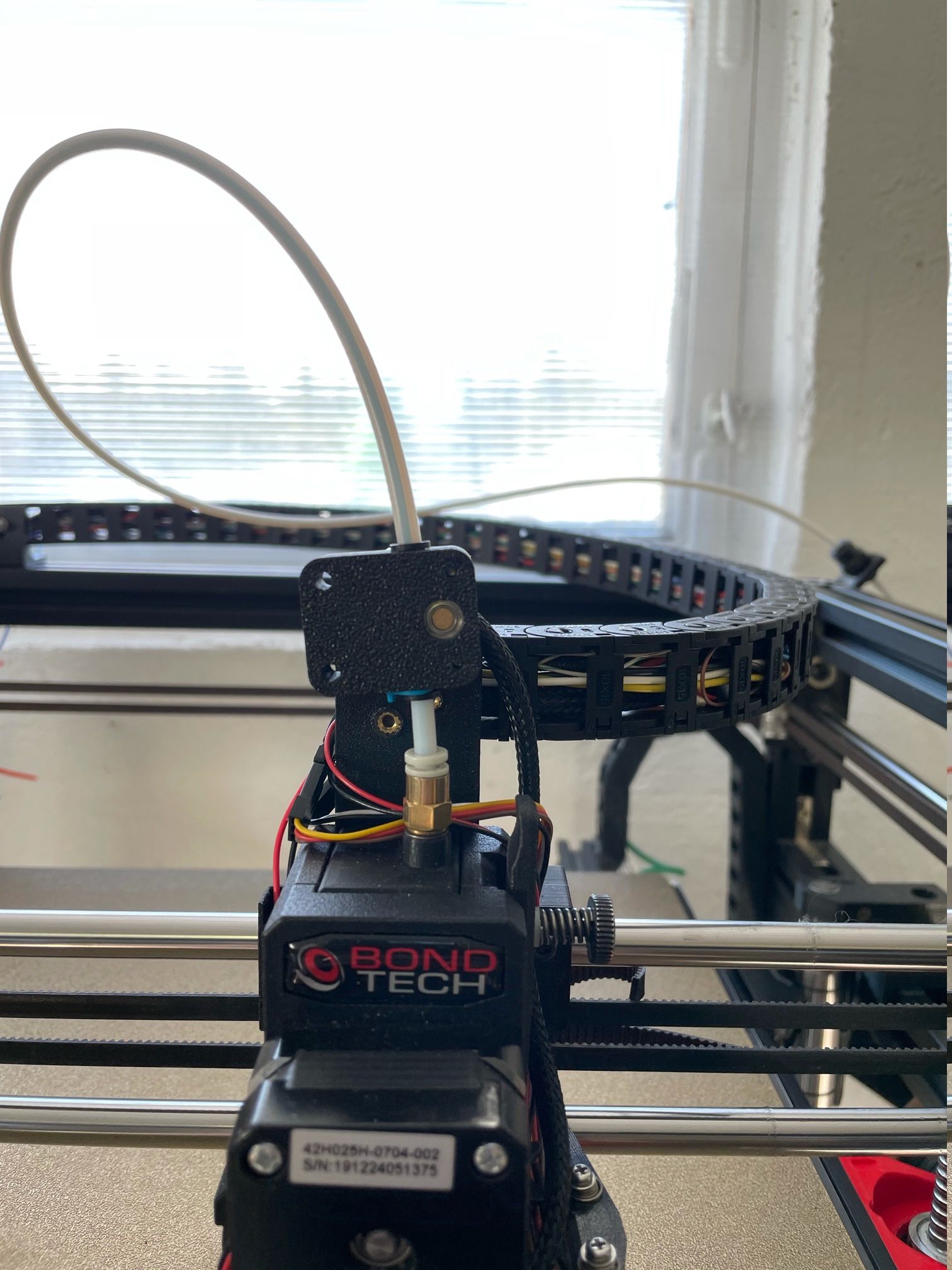

@alankilian i there is another issue with sensor. Look how it looks. This can’t be normal.

-

What looks wrong to you?

It looks just like mine.

-

@alankilian top of the axel looks rough but seems to be ok.

-

You said it was grinding against the sensor a little bot. That probably make it look different from mine.

Just add some paper strips here until the magnet turns freely, reassemble it and see if it works.

-

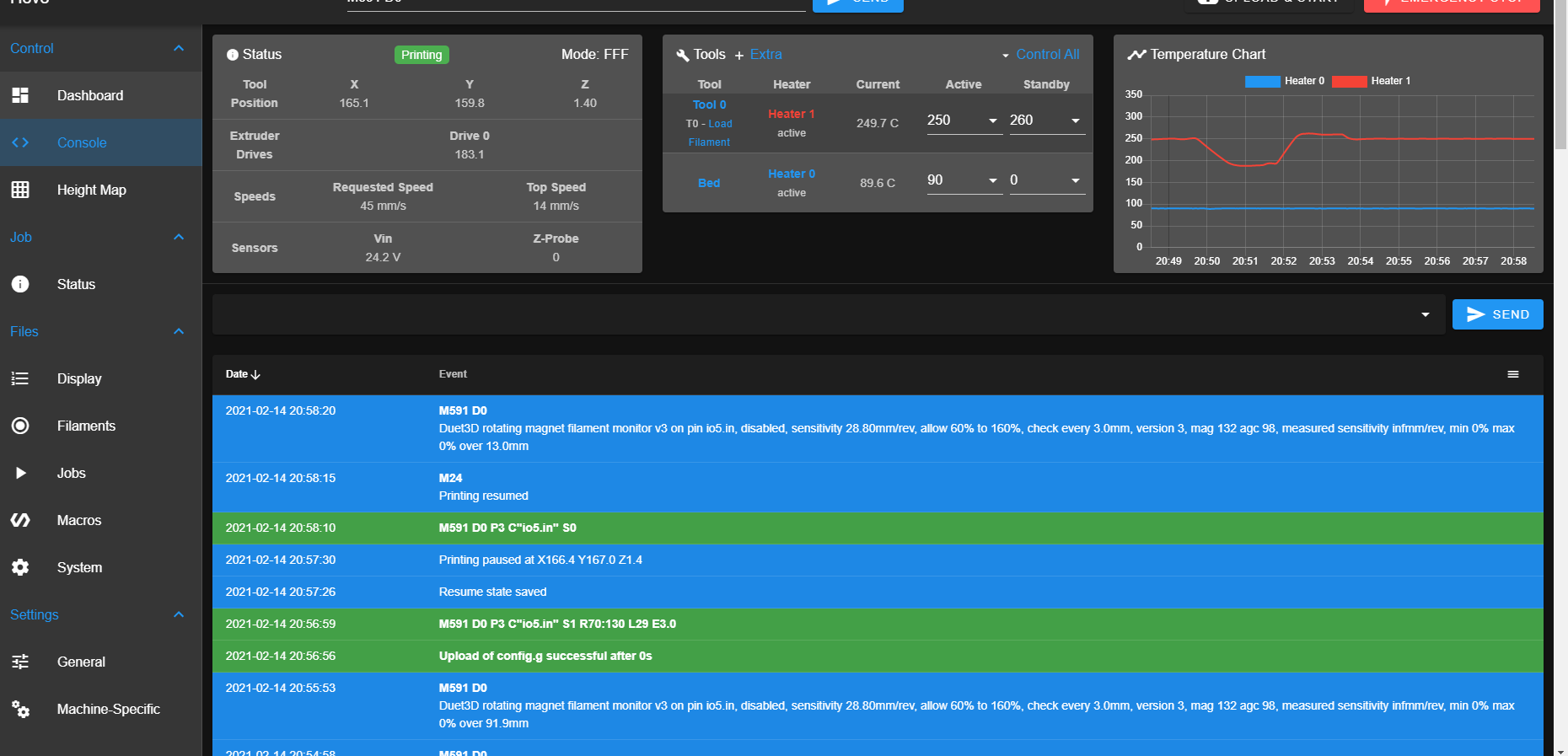

@alankilian added paper between the housings and that seem to have done the trick.

You happen to know if it is possible to calibrate e-steps with this?

-

added paper between the housings and that seem to have done the trick

HEY! That's great news!

You happen to know if it is possible to calibrate e-steps with this?

Hmm.....

What are you thinking?

The sensor measures how many times the wheel goes around.

How would you go from the sensor output of mm/rev to total mm extruded?

Could you measure the diameter of the wheel and use that?I calibrate eSteps using the "Measure 120mm, extrude 100mm, measure the leftovers and see how close to 10mm it is" and it's been fine for me.

-

@alankilian i do it like that to. but i thought this would be a more precise tool to use. It says "measured sensitivity 25.43mm/rev, min 97% max 103% over 410.6mm" i assume that means over 410.6mm of filament.