RRF3 PID TUNING HOTEND ¨warning as result¨

-

Hi guys..

Trying to do PID TUNING of my e3d v6 with E3D cartridge type Semitec 104Gt and standard cartridge with my DUET 2 WIFI.

But the result of the pid is this =Warning: heater behaviour was not consistent during tuningAuto tuning heater 1 completed after 3 idle and 25 tuning cycles in 1251 seconds. This heater needs the following M307 command:

M307 H1 R1.897 C235.5 D6.73 S1.00 V12.1

Edit the M307 H1 command in config.g to match this. Omit the V parameter if the heater is not powered from VIN.Some idea ?

-

-

It means that the heating and cooling rates didn't settle down to consistent values after several cycles. One possible reason is noise n the temperature sensor readings, which would be apparent in temperature graph.

Try tuning using the tool target instead of heater target.

M303 T0 S190

-

do i need to heat the bed before send M303 T0 S190 ?

and when finished do i need to send M307 ?

-

You can heat the bed if you think the ambient temps will have an effect on the hotend, but generally no, you don't.

After tuning has finished you can either send M500 to save the results to config-overide.g (and add M501 and the end of config.g to load them at startup) or copy and paste that M307 line into config.g itself.

-

I keep getting a warning ...

-

What does the heater graph look like?

Is your heater block making contact with the cold end heat sink or something?

-

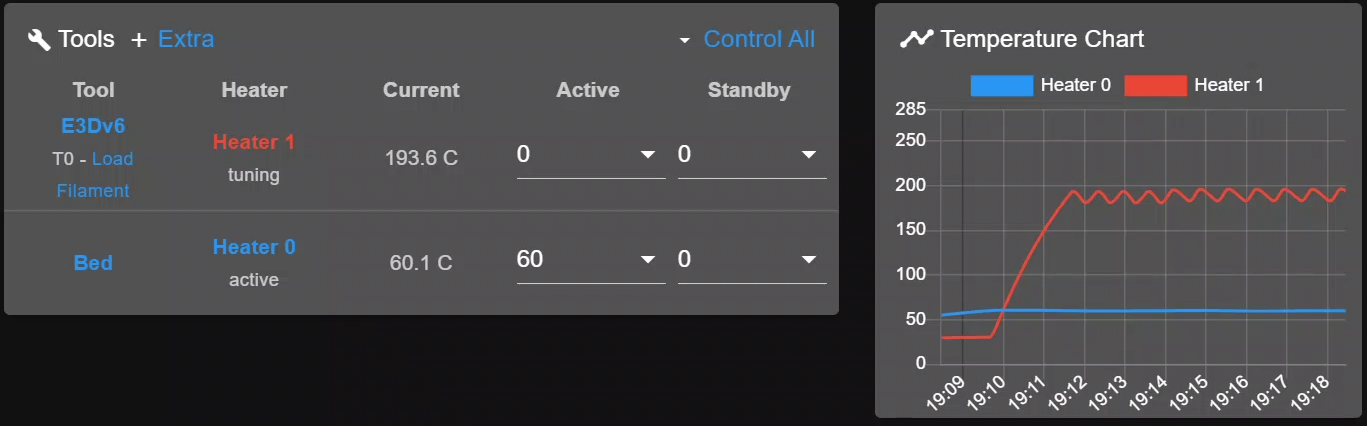

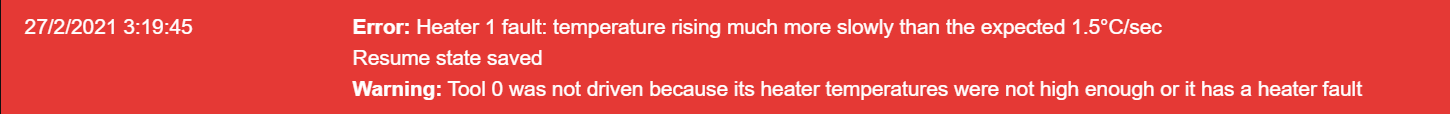

I recorded the moment..

-

Today i try to print cube from https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s179

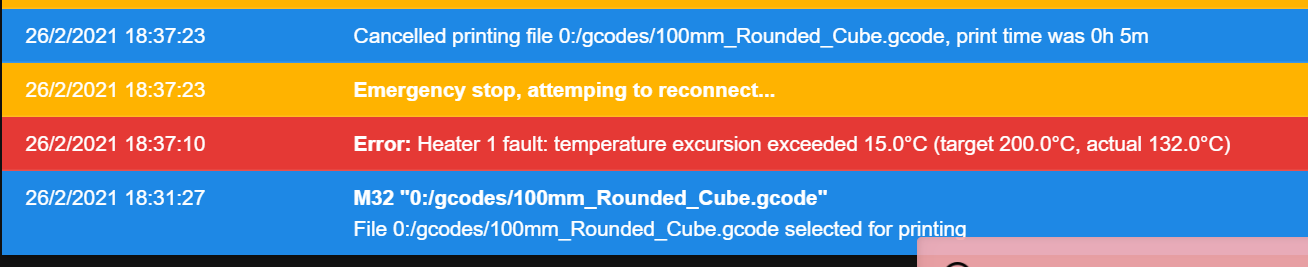

and i get this error message

really need help

-

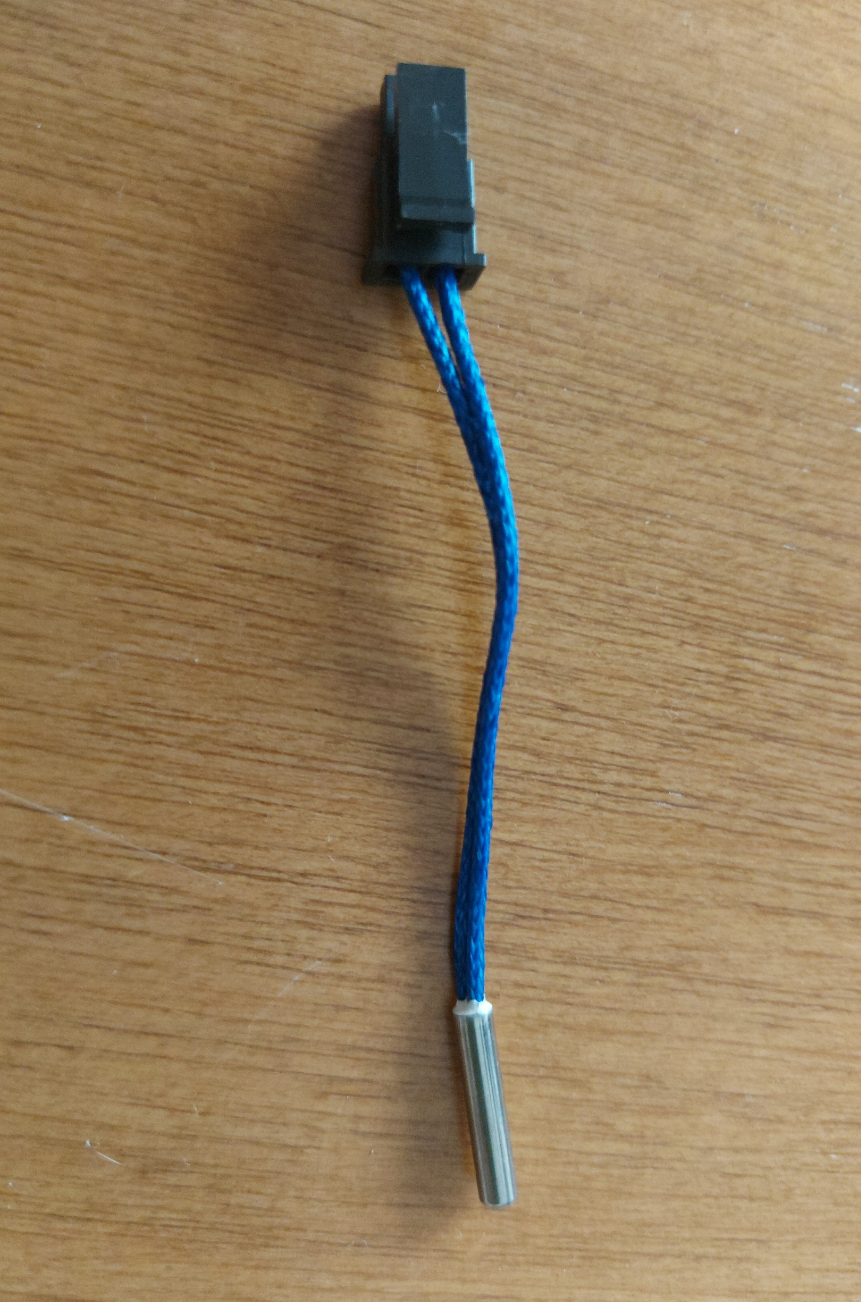

Can you post a photo of your hotend? It sounds like something isn't quite right with the hotend.

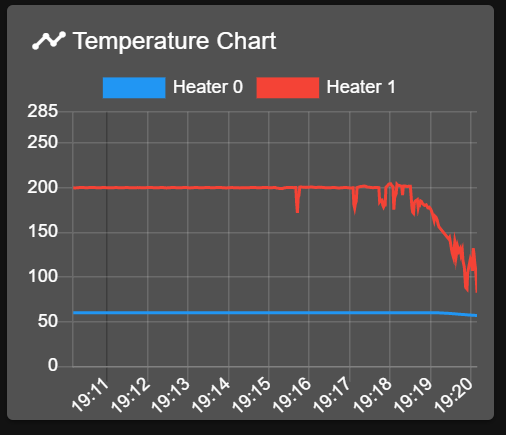

What did the heater graph look like on that print?

-

Could be possible about power supply not working well ?

-

That graph looks more like interference on the thermistor wires or a bad connection. It wasn't apparent in the previous graph from the tuning operation, but it's definitely apparent there.

-

bad crimp ? bad cable ?

im using cat5e and terminals crimped

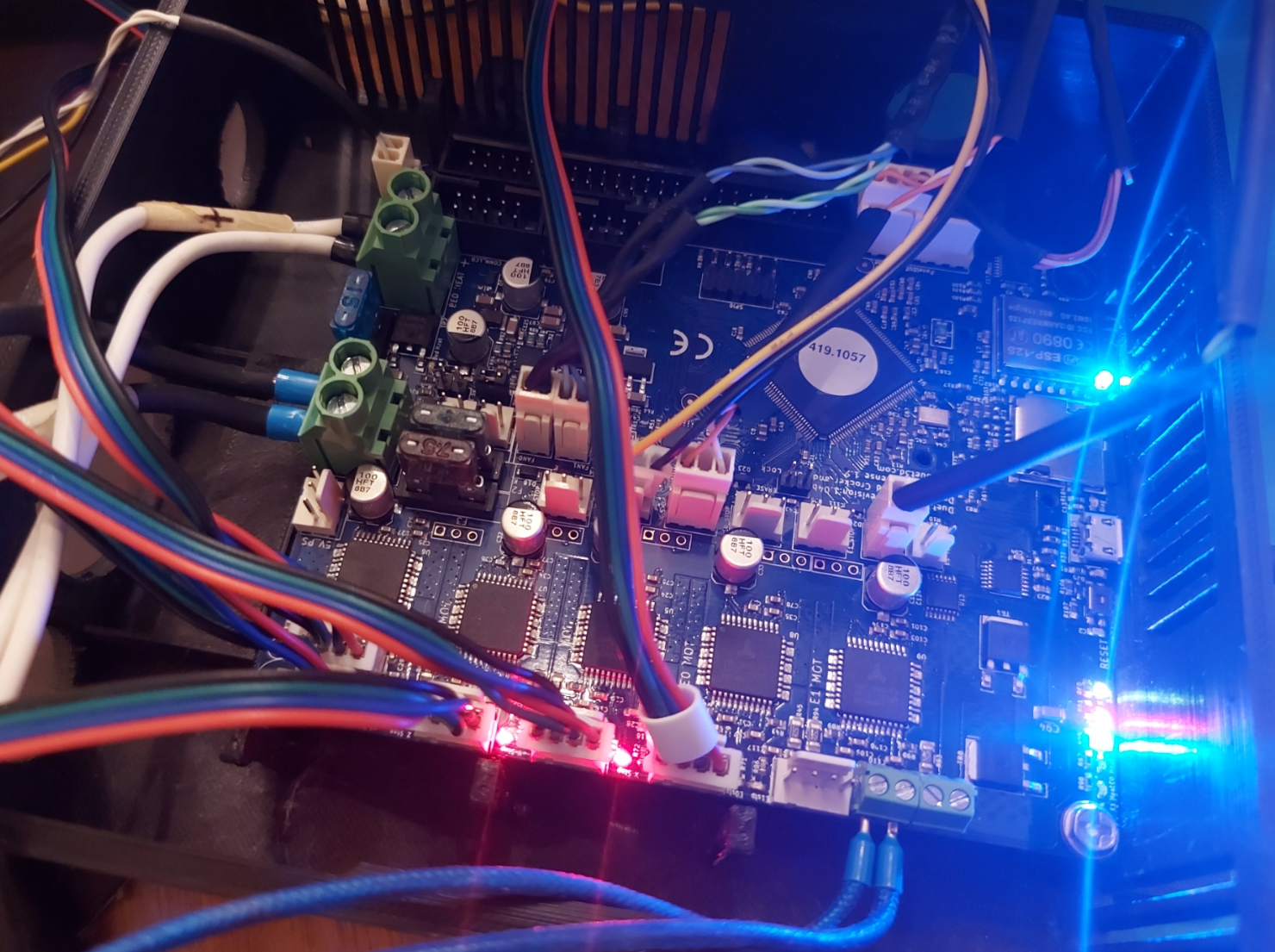

i will upload photos -

-

Are the thermistor wires running through the same cat5 cable as a stepper or heater? That could be causing some interference. I would try running some external test wires for the thermistor and see if it's better.

-

I did it.. and i get same result.

-

@ezemaff You have a noisy thermistor signal. It's either the wiring, the connectors, or the thermistor itself. If you are absolutely sure there is nothing wrong with the wiring, then change the thermistor.

-

@deckingman Could any other wire be making noise? because the thermistor is new, and the wiring its from stock on this moment.

-

@ezemaff said in RRF3 PID TUNING HOTEND ¨warning as result¨:

@deckingman Could any other wire be making noise? because the thermistor is new, and the wiring its from stock on this moment.

In general, 100k thermistors are less sensitive to external noise than say pt100s but it's not impossible that another cable run parallel to the thermistor might be causing the noise. It's also not impossible for new thermistor cartridges to be faulty.

It's also quite possible that E3D's awful method of clamping the thermistor cartridge with a grub screw, has meant that you've inadvertently crushed the cartridge and/or cracked the ceramic potting compound which is causing an intermittent short circuit.

Edit. What are those wago style connectors shown above. Are they being used in the thermistor wiring? If so, ditch them.

-

I will try changing the thermistor for a new one ! Thanks for the help and your time !! I keep you updated