3d Benchy Question

-

@engikeneer

That may very well be... the bracket im using was just from thingiverse.

-

Yeah that does seem dangerously low. Time to cad up a new bracket?

-

ya i can do that i suppose. Can work on that this week I suppose.

-

Maybe instead of the mount being above the bltouch it could hold it from underneath like a hangar and raise it up a couple mm. Doesn't need to be much.

-

@phaedrux

"it could hold it"You lost me on that one... the bl touch can not go up any further without modification to the current bracket to make it slightly shorter.

-

@wingtip

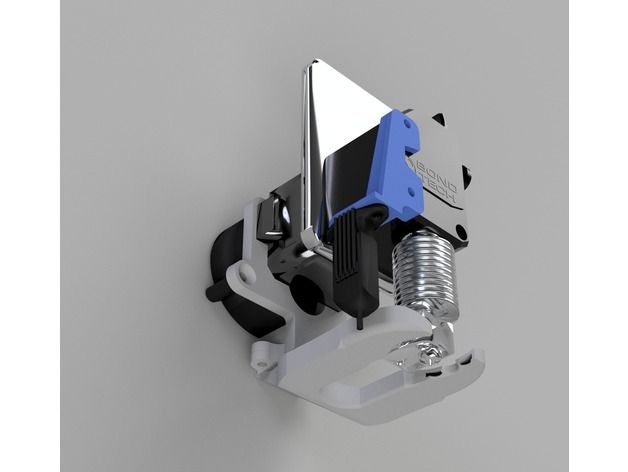

New probe bracket installed and much better clearance now. Dialing in babysteps again then i think i'll try one of my larger prints.

-

Just started a 68 hour print.. go big or go home lol... First layer goin down

-

Good luck! Can't print little cubes and boats forever.

-

So im about 29 hours into this print and i have a slow leaky hotend (i switched to that .5 nozzle remember) that im having to remove blobs now and then so they dont come off sticking to the print. Being this is my first duet, can I use the pause function, raise the gantry, check the nozzle tightness, then just hit resume and expect it to go right back where it left off without failing the print from pausing?????

-

@wingtip said in 3d Benchy Question:

can I use the pause function, raise the gantry, check the nozzle tightness, then just hit resume and expect it to go right back where it left off without failing the print from pausing?

Yup. If you have powerloss recovery configured you could even turn it off and come back later. (as long as it stays stuck to the bed anyway). though keep in mind if you force it out of position when playing with the nozzle or change the effective Z height of the nozzle that might show up on the layer.

-

@phaedrux

Mother F*&ng hell.... FFFFFuK my life33 hours in..... paused it. Removed the fang cooler temporarily, tightened up the now very loose hotend. cleaned up the mess as best i could. put on a new sock as the old one was torn pulling it off the hotend.

Went back to the panel due to resume and saw this error:

Error Heater 1 fault temperature excursion exceeded 15C (target 236, actual 220.4, Cancelled print, print time 32h 31 min.I frantically hit the nozzle temp button and tried to adjust the temp but it wasnt working, then I must have hit something cause all of a sudden the gantry started heading back towards the bed... and i watched it go back down and drive itself into the print hard... no choice but to hit the emergency F*&&ing stop which reset the paneldue. An entire spool and a half of material just wasted. Im not even sure what made it start its way back down when i was only hitting the nozzle temp buttons but there it was moving towards the bed at well below temp...

All the axis are not homed. I still have the print button at the bottom but when you press it there are no options... It was on layer 45, and the pause was on x271.9 y100.4 z11.2. But i highly F*&^ing doubt i can salvage this since the axis are now not homed. Im so F)&*^ing pissed right now. 1 and a 1/2 rolls of filament gone. Mainly due to having set the infill percentage to high at 40% and it was eating up material fast...

F*&k me. Im going to bed, its 4am

-

@wingtip check whether there is a resurrect.g file in /sys that was created when the heater fault occurred.

-

It did create one. However, i do think i could re home x and y but z will be an issue. Even if i could do a single g30 hit somewhere in a corner away from the part... Im not sure how i would do the side to side leveling that adjusts my two z motors independently.....

; File "0:/gcodes/LowerHullOnePiece.gcode" resume print after print paused at 2021-06-02 03:17 G21 M140 P0 S90.0 G29 S1 T-1 P0 G92 X271.933 Y100.414 Z11.290 G60 S1 G10 P0 S236 R0 T0 P0 M98 P"resurrect-prologue.g" M116 M290 X0.000 Y0.000 Z-0.040 R0 T-1 P0 T0 P6 ; Workplace coordinates G10 L2 P1 X0.00 Y0.00 Z0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 G10 L2 P9 X0.00 Y0.00 Z0.00 G54 M106 S0.10 M106 P1 S1.00 M116 G92 E3273.61646 M82 M23 "0:/gcodes/LowerHullOnePiece.gcode" M26 S6429748 G0 F6000 Z13.250 G0 F6000 X271.933 Y100.414 G0 F6000 Z11.250 G1 F3000.0 P0 G21 M24 -

@wingtip you may not need to do the side-to-side levelling. The Z motors typically jump by up to +/- 2 full steps during a power cycle. So they only get out of sync if they jump different ways, and only by a maximum of 4 full steps per power cycle. Depending on your Z steps/mm, that may not matter if you only power down and up once.

-

but your forgetting it drove itself into the part and started skipping steps.. I would think the best option would be to get z fully homed properly somehow

-

@wingtip you could remove any filament attached to the nozzle, then lower the nozzle so that it just touches the print, and use a G92 command to set Z to the same value as indicated in resurrect.g.

-

@dc42

true, but what about my side to side leveling that is certainly now screwed up? This is why i said i knew i could do a single probe hit but that wont adjust the gantry to the offset of side to side level.... Otherwise if you dont do that the nozzle would fine say at y10 and be driving into the print at y300.... I think im going to just have to scrap this and start over when i get more filament. -

@wingtip said in 3d Benchy Question:

true, but what about my side to side leveling that is certainly now screwed up?

If the print is wide enough, you could use M584 to map Z to just one of the motors temporarily so that you can adjust them individually to get the nozzle just touching the print at both sides.

Your chances of resuming the print accurately enough to get a good finished print are not good, but by trying you may learn more about your printer.

-

As long as the part is still attached to the bed there's always a decent chance of recovery.

Do you have a machinist block or some other block of metal that you could set on either side of the printed part and use that as a gauge on whether the Z motors have gone out of sync? Just touch the nozzle to it and then compare to the other side. With the Z motor disabled you could even turn them by hand to adjust if needed. With G92 Z you can force Z as homed to whatever height you need. So if you can verify that the motors are even you can set the height at the top of the print and resume.

Was the nozzle leaking because it wasn't hot tightened?

I assume the temp excursion was from taking the nozzle sock and cooler off suddenly.

-

I do not have any precision blocks. I have already removed the part from the bed.. it gives me a chance to inspect the support material as well... i think i want to tweak it a bit as well to release better. I have already re leveled, done a new heightmap to make sure everything is at least close to being right as can be. gonna do a support test and experiment with those settings and also maybe try printing a new part cooler to solve the other issue of having to set the fan speed extremely low to not upset the thermistor.

In a day or so my shipment of 3 more rolls of white filament should be here.