Sorry it's been a while since I last posted. Ive been busy trying to find a job, doing interviews and had a death in the family recently as well.

As for the hot end not getting up to temp, it has been resolved by reprinting that fang and making a better cut this time. Once that was resolved i was able to attempt a first print, which of course was a calibration cube so i could start dialing in e step accuracy, acceleration and jerk settings etc etc.

Well, before that could happen i had to dial in the z offset of the bl touch to get it to lay down a first layer... I really wish the babystep UI would give you more options for adjustment like the move UI gives. Having just one option at .02 takes forever to get close. In any case its printing but im still squishing a bit much so im still trying to dial that in as each cube was being printed...

After messing with the printer for about 14 hours straight that day i had 4 cubes printed. I was dialing in extrusion multiplier, the e steps, the offset, some ringing... and was getting closer but i went to bed.

The next day i fired the printer up, fired up another cube after making some more tweaks. I had my face down near the glass to observe the first few layers to adjust the babystepping more precisely when i heard a bang that startled me and I watched the glass crack from one side to the other. I was able to let the print continue and did get a completed cube from it but the glass (my 2nd one) is toast. The first glass has an extremely small barely noticeable crack and could be used again but i've decided on something different. I am just guessing here, but from a cold state to 90c on cheap annealed glass was destined for failure. I had planned on dialing back on bed temps once i started getting consistent prints but 90 is where it was sticking good for just glass at that moment.

After this i just decided to custom order some borosilicate glass. The first place i found for my custom sized bed they provided a quote of well over $600. They said boro is stupid expensive but for $40 dollars they could sell me tempered glass and should be fine... reluctantly i said ok and ordered it not wanting to spend over $600. The tempered glass would be about 7 days to have made.

The more i thought about it the more it was bothering me as ive seen boro glass offered for smaller printers dirt cheap so i decided to keep looking. I found another place online that is located about 2 hours away in another state but their site said they have many sizes in stock. I called them up and asked for a quote giving them the same dimensions i gave the first place. He asked what thickness. Having noticed some of the smaller printers were using 3.2mm boro i opted for the 3.8. He came back with a quote of $125! I ordered it and immediately called the other place back and cancelled the tempered glass order and told them about the quote differences for the boro.

So, im sitting here dying to dial this printer in more and i have to wait 7-10 days for this order at which time i have to drive over and get it mind you 2 hours away. Shipping was out of the question since ups is charging by size now and not just weight, not that id trust them with a sheet of glass anyways.

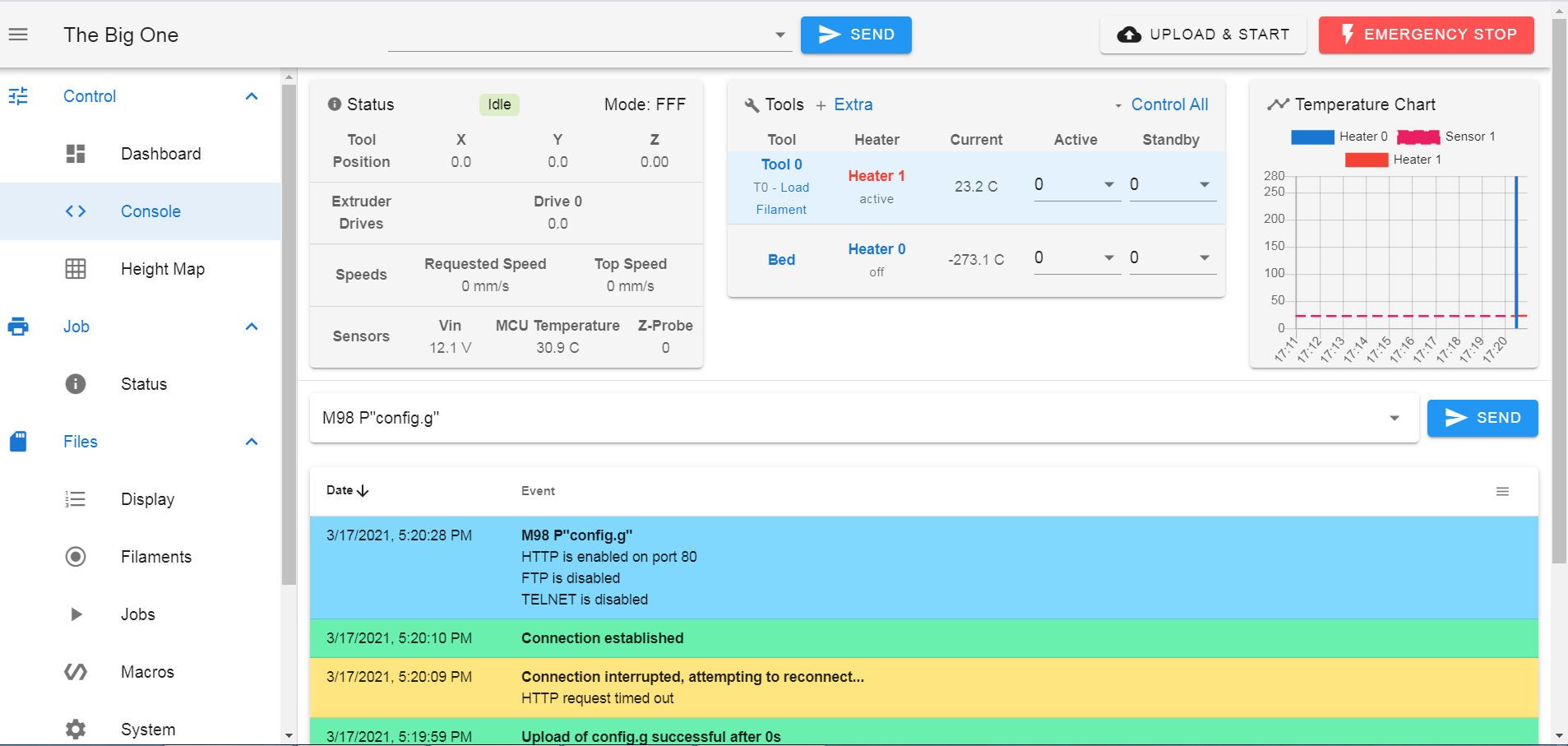

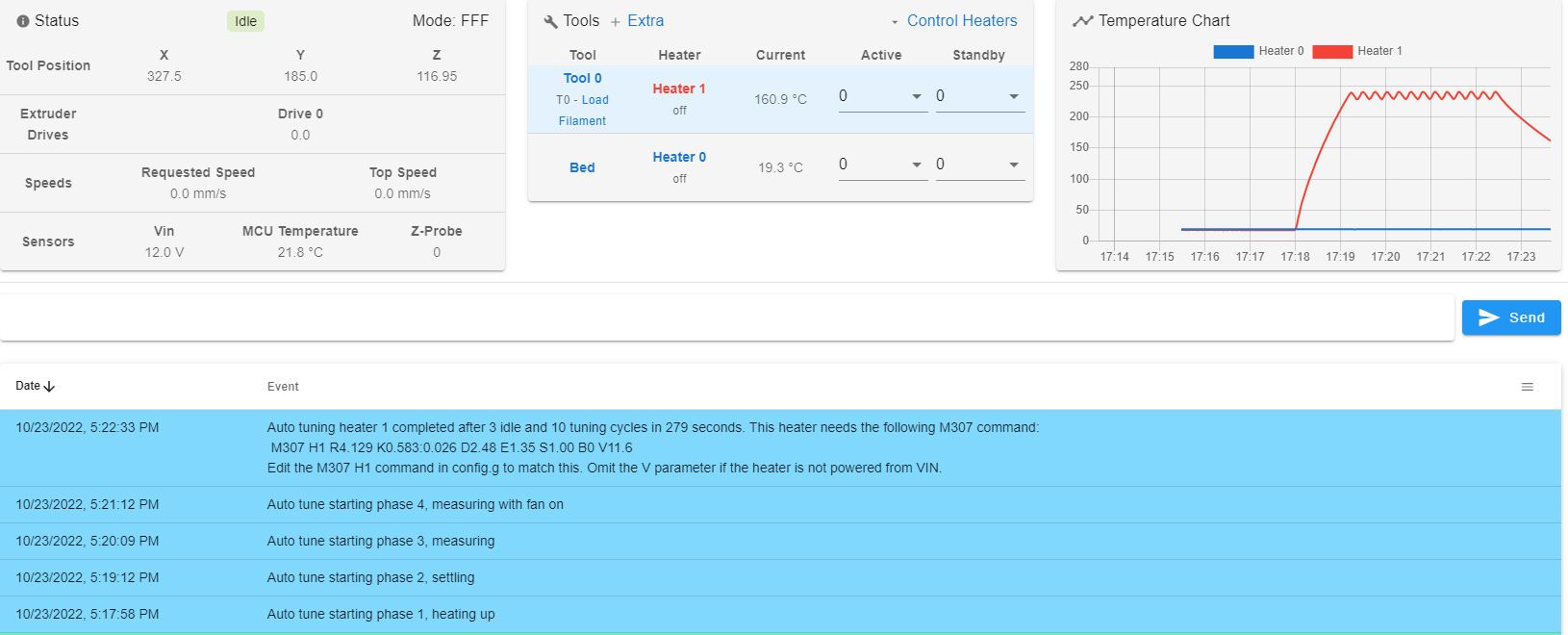

I have to give a HUGE HUGE shout out to @fcwilt who helped me completely re-write all my gcode and sort out bed leveling with my setup and mesh compensation , breaking out functions to separate files rather than shove everything into the config file. We spent lots of time on the phone, answering questions and emailing back and forth. Huge thank you to him. I believe once the boro glass is installed the rest will be easy peazy (knock on wood).