S3D users, how do you setup for Duet?

-

What kind of setups do you guys use to adapt S3D for seamless use in Duet?

-

@tecno I design with OnShape, slice with S3D, upload to the Duet over Ethernet and hit the print button.

-

360 > S3D * where do you set fan parameters * > upload via WiFi > DWC and hit print.

-

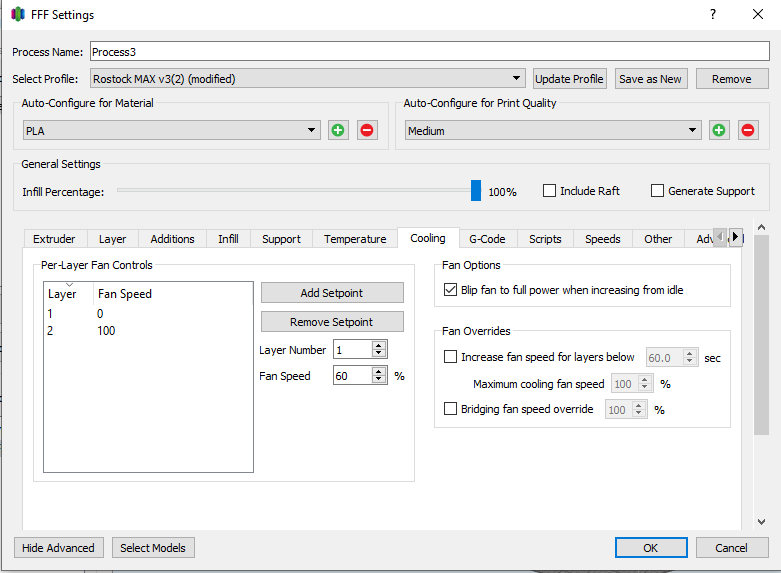

@tecno I set cooling fans in the cooling tab.

Here's my Factory file.

(Rename it .fff)

Rostock MAX v3(2).gcode -

I am bad to explain what I want to know.

M106 handles the part fan that way, I have 2 fans one for tool that needs to be at 100% all the time andpart fan set to needed cooling depending of material to be printed. So I need to set both separately

; Fans

M950 F0 C"121.out1" Q500 ; create fan 0 on pin out5 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Part-Layer fan

M950 F1 C"121.out2" Q500 ; create fan 1 on pin out6 and set its frequency

M106 P1 S1 H1 T45 ; Set tool fan to start at 45°CAs it is now with only one M106 set 20% (Petg) for the Part-Layer fan it command the tool fan also.

You see why I need help

-

@tecno I'm sorry, I don't understand yet what you need.

You have two fans configured:

- F0 is a "Part-Layer" fan.

-- I assume this is for cooling the part. - F1 is a thermostatically-controlled "tool fan"

-- I assume this is the hotend cooling fan.

I have my fans and tool defined like this in RepRap-3

; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0Do you have an M563 that maybe somehow defines tool 0 using both fans?

Post your full config.g and I'll take a look.

The M106 commands in my S3D-produced GCODE look like this:

In the start code at the top: M106 S0 Then a layer of GCODE, then ; layer 2, Z = 0.200 M106 S255 Then LOTS of GCODE and at the end: ; layer end M106 S0 ; turn off cooling fan M104 S0 ; turn off extruder M140 S0 ; turn off bed - F0 is a "Part-Layer" fan.

-

No M563

Your gcode is like mine, works for you but not for me as I need to controll 2 fans separetely.

One way to solve my problem is to edit gcode file but that is not so good as you can forget to do it

-

You have two fans configured:

- A hotend fan

- A part cooling fan.

They are controlled separately.

- One with a temperature controller so it turns on if the sensor is greater than 45C

- The other is controlled by the M106 command.

Do you have a THIRD fan somewhere you want to control?

-

@tecno said in S3D users, how do you setup for Duet?:

I have 2 fans one for tool that needs to be at 100% all the time

If you have a fan that needs to be on 100% of the time, plug it in to the connector for the "Always-on fan"

Which Duet board do you have?

I'll show you the connector location. -

Mini 5+ WiFi

That is not an option to have the fan always on, It is on a port that can be controlled and need to control that toolfan. These fans are connected to Toolboard as you can see on the port numbers.

3rd is always on blowing over the Duet board = Big Silent Noctua.

-

@tecno I'm sorry that I still don't understand your problem.

You have a hotend fan that's controlled by a thermostat.

- Does that fan work?

You have a fan that is a part cooling fan controllable with the M106 command.

- Does that fan turn off when you type M106 S0

- Does it turn on when you type M106 S255

What fan does not work the way you need it to?

You say "As it is now with only one M106 set 20% (Petg) for the Part-Layer fan it command the tool fan also."

That sounds like you are saying if you type M106 S50 (To set your cooling fan to 20%) that your hotend fan also changes speed?

Is that right?Will you please post your full config.g ?

-

@alankilian

I think I have sorted out my problem, been cleaning up the code in config.g

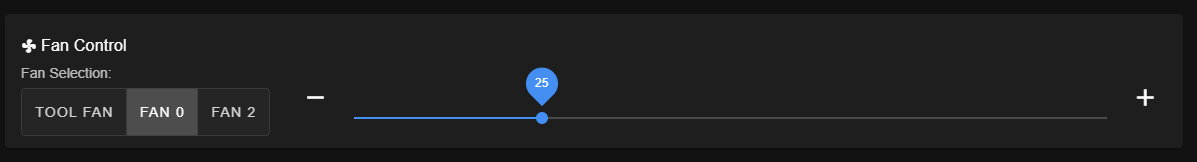

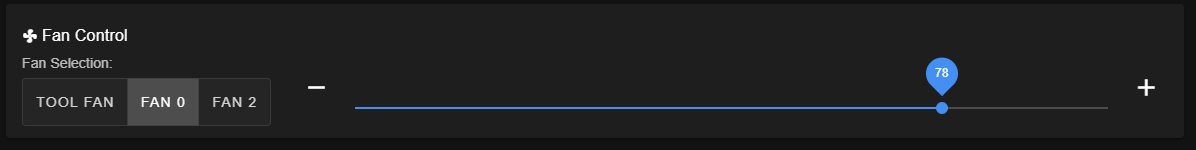

Had earlier a problem that Toll Fan and Fan 0 was ganged in this fan control panel

Wasa typo obviously as it seems to work now as I want

; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out1" T0 ; create bed heater output on out1 and map it to sensor 0

M307 H0 R0.211 C620.5 D1.28 S1.00 V24.1 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120CM308 S1 P"121.temp0" Y"thermistor" T100000 B3950 ; configure sensor 1 as thermistor on pin temp1

M950 H1 C"121.out0" T1 ; create nozzle heater output on out2 and map it to sensor 1

M307 H1 B0 R3.712 C153.4 D6.29 S1.00 V24.3 ; PID values after tuninh

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"121.out1" Q500 ; create fan 0 on pin out5 and set its frequency // PART FAN

M106 P0 S0 H-1 ; P0 = fan0 S0 = Speed 0 H-1 = Disable Termostatic modeM950 F1 C"121.out2" Q500 ; create fan 1 on pin out6 and set its frequency // TOOL FAN

M106 P1 S1 H1 T45 ; P1 = fan1 S1 = Speed 100% H1 = Enable Thermostatic mode T45 = start at 45°CM950 F2 C"out3" Q500 ; create fan 2 on pin out3 and set its frequency // Main Board Fan

M106 P2 S1 H-1 ; P2 = fan2 S1 = speed 100% H-1 = Disable Termostatic mode; Tools

M563 P0 D0 H1 F1 ; P0 = tool0 D0 = ext drive H1 = heater1 F1 = fan1

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0CWhen it was bad I did not know how to get correctly posted gcode to controll fans, but now I think it will work.

Cheers

Bengt -

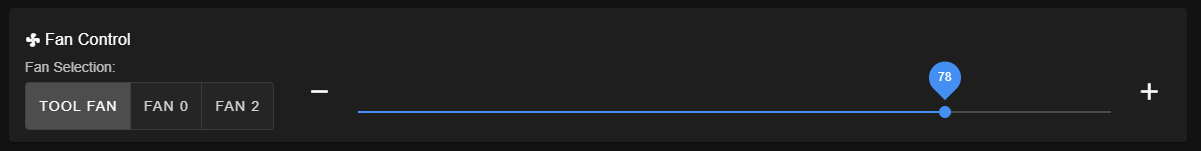

@tecno The "Tool Fan" on that slider will control the fan associtated with whichever tool is currently selected. So it will indeed the tied to one of your fans. Based on your gcode you have a problem though.

Fan0 you have set up as a gcode controlled part cooling fan and fan1 is the thermostatically controlled heatsink fan. But your tool has fan1 associated with it, but it should have Fan0.

Change M563 P0 D0 H1 F1 to M563 P0 D0 H1 F0

-

-

When you say tool fan, do you mean heat sink fan?

Tool fan should mean part cooling fan.

Fan1 is thermostatically controlled so it would be for the heatsink. In which case it should not be assigned to that tool with F1

-

Look at the picture above of fan controll panel.

Tool Fan = F1 Fan0 = Fan0 = partlayer cooling F2 = boardcooling.

It was this fu that got me nowhere and got ganged in the panel >> toolfan and f1 that is not logical and not very clear for the user.

It is working now (as far as can see) so I will not touch it

Cheers

Bengt -

Yes I see your picture and I see your gcode.

I'm telling you that "tool fan" in that picture is meant to control the part cooling fan associated with that tool. If you had more than one tool, it would control the part cooling fan for whichever tool was selected.

Your gcode has associated a thermostatically controlled fan has the part cooling fan. This is not correct. If it's working fine now, just wait until it's not.

You can disagree with what I'm telling you, but it's only because you don't understand what I'm saying.

I think the root of the misunderstanding is that you are taking "tool fan" to mean the heat sink fan. This is not the meaning of "tool fan" in a 3d printer context.

// TOOL FAN should say Heat sink fan.

M563 P0 D0 H1 F1 should be M563 P0 D0 H1 F0 which is your Part fan.

Trust me. This is a common misunderstanding.

Let's look at it this way.

-

@phaedrux It's also possible that he thinks his part cooling fan is plugged in to fan0, but it's really plugged in to fan1.

(I know this because I made the same mistake and couldn't get my fans running right for a half of a day.)

-

First of all this is a language confusion for me, 70+ and Finn living in Sweden, my apologies.

Why is both Tool Fan and Fan 0 in this panel as they are the same and no Fan1?

Tool Fan only shows when T0 is active.Seems to work as intended just a bit confusing for me and probably for others too.

Cheers

Bengt -

@tecno said in S3D users, how do you setup for Duet?:

just a bit confusing for me and probably for others too.

Yes I agree, but it does make more sense when you have more than 1 tool. If you have 4 tools, each with their own part cooling fan, the tool fan slider will always work with whichever tool is currently selected.