Extruder motor doesn't move

-

@phaedrux After I click Home X or Y or Z, the system would move down a little bit, then stop, not moving in the homing direction at all.

-

@phaedrux G28 X, failed to enable endstops.

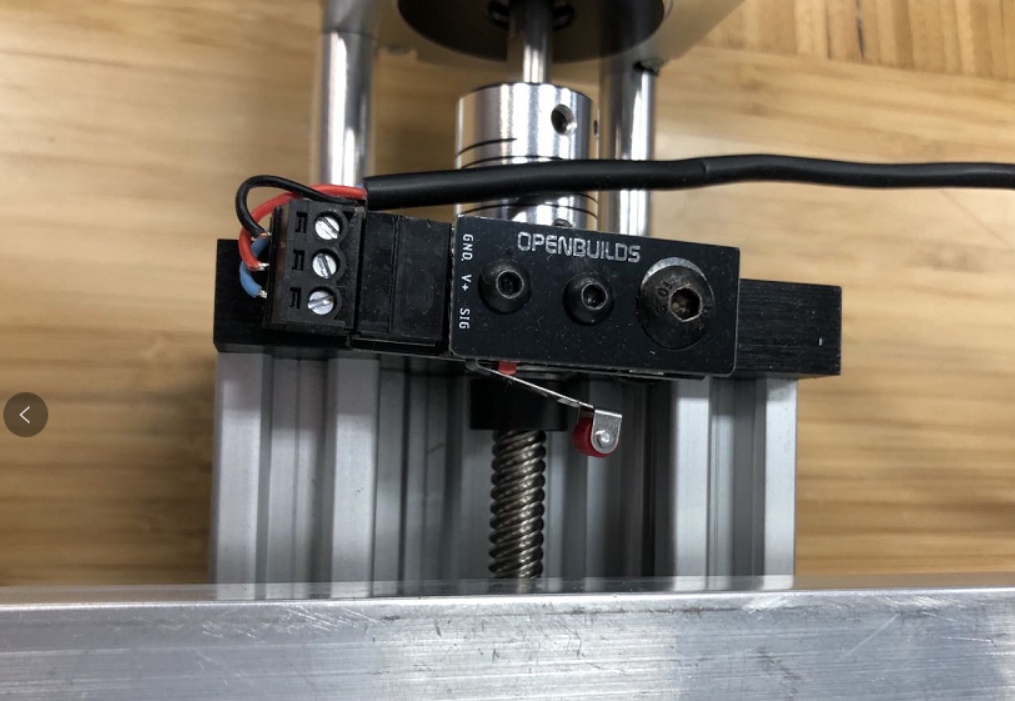

This is the type of endstop I'm using. It worked before I upgrading the firmware.

-

@phaedrux ; homex.g

; called to home the X axis

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Wed Jun 09 2021 18:36:12 GMT-0400 (Eastern Daylight Time)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-235 F1800 ; move quickly to X axis endstop and stop there (first pass)

G1 H2 X5 F6000 ; go back a few mm

G1 H1 X-235 F360 ; move slowly to X axis endstop once more (second pass)

G1 H2 Z-5 F6000 ; lower Z again

G90 ; absolute positioning -

And if you click the switch does it change the LED at the board?

-

@phaedrux Yes clicking switch changes LED light on the board.

-

@zfeng said in Extruder motor doesn't move:

G1 H2 X5 F6000 ; go back a few mm

Can you remove the H2 from that line and test again? Does it still move slightly?

If you send M119 what does it report for the status of the endstops? Does it change when the endstop is depressed?

Can you try removing the

!from the pin name and doing the same tests? -

@phaedrux Before I change anything today, the xyz homing all went fine... I don't know why. But the issue of extrude/retract not active still the same.

-

@phaedrux ; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Thu Jun 10 2021 17:46:43 GMT-0400 (Eastern Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X230 Y210 Z200 S0 ; set axis maxima; Endstops

M574 X1 S1 P"!xstop" ; configure active-high endstop for low end on X via pin !xstop

M574 Y1 S1 P"!ystop" ; configure active-high endstop for low end on Y via pin !ystop

M574 Z1 S1 P"!zstop" ; configure active-high endstop for low end on Z via pin !zstop; Z-Probe

M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M557 X15:215 Y15:195 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

-

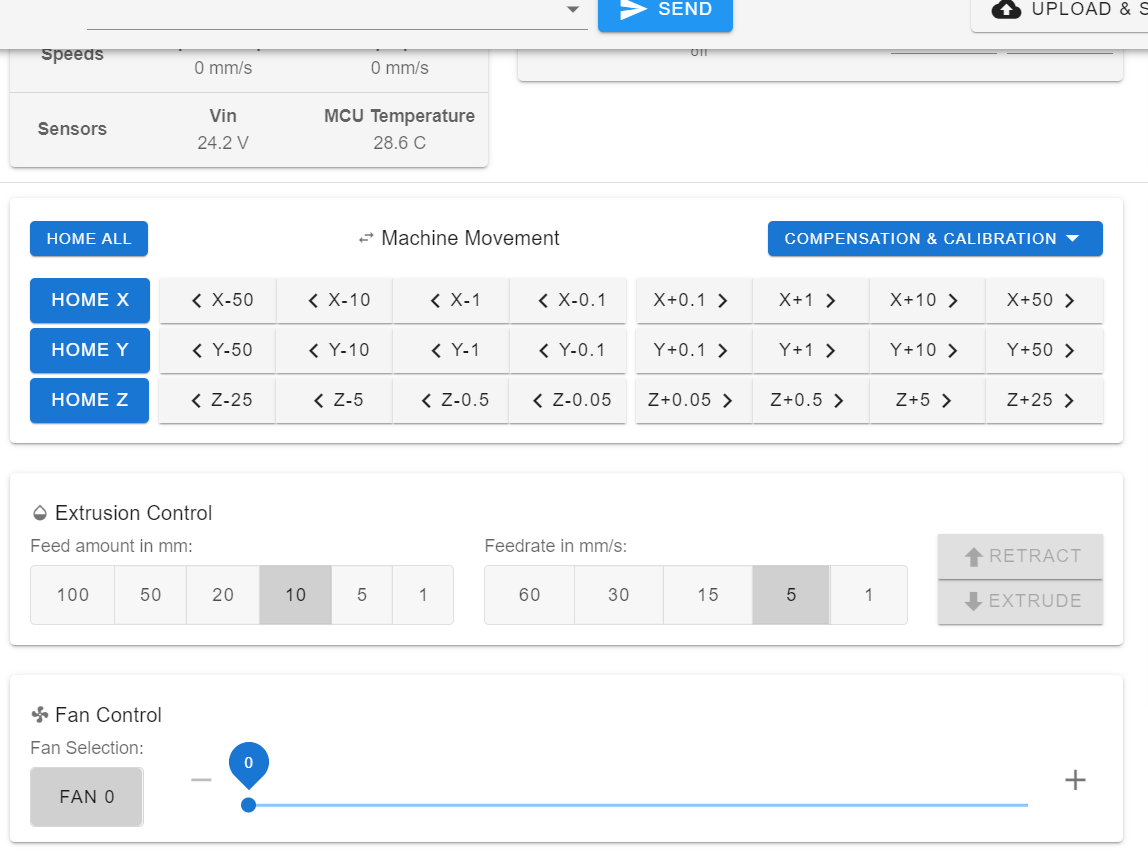

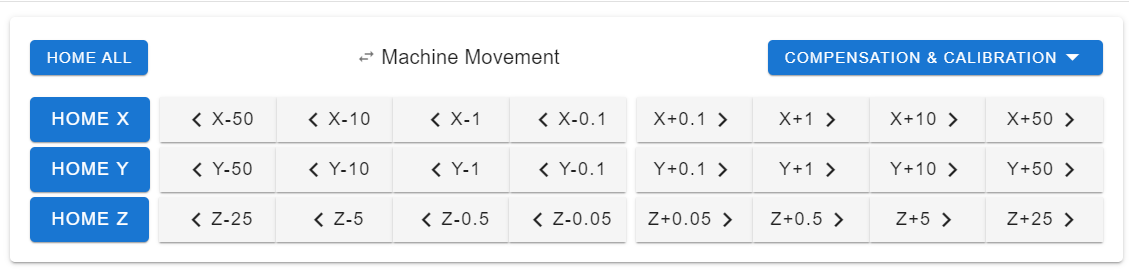

@phaedrux Another question I have is: what is the unit of the numbers in the machine movement control? Is it mm?

-

Yes that is movement in millimeters.

-

Add this

T0

M302 P1 ; Allow cold extrusionto the end of your config.g and see if you're able to activate the extruder then.

If that doesn't work, Since this is a tool that will be using an external heater controller you could follow the advice in the cold extrusion wiki entry to define the tool without a heater associated at all.

https://duet3d.dozuki.com/Wiki/Gcode#Section_M302_Allow_cold_extrudes

Note: One limitation of M302 is that it requires a thermistor to be present for the temperature to be monitored. If your system does not have a thermistor or heater to be monitored, you can define your tool in M563 without a heater to disable cold extrusion protection on that tool. ex: M563 P0 S"Pump" D0 F0 Note the lack of H parameter.

So in your case

; Tools M563 P0 D0 H1 F0 ; define tool 0You would remove the H1 entirely.

-

@phaedrux I want to send the temperature signal from PID to the Duet board, do I need adapters to do it? I saw online there's some kind of daughter board for thermocouple. I'm using Duet 2 ethernet, which daughter board should I purchase?

-

Can you give more info on your external temperature controller?

-

@phaedrux It's a very common Inkbird PID controller. The thermocouple from the extruder head is a K-type thermocouple.

-

If the thermocouple is already going to the PID controller how do you hope to connect it to the Duet as well?

Do you have a link for that unit?

-

@phaedrux I plan to use a dual thermocouple connector to split the thermocouple signal, so that one goes to the PID and the other goes to the Duet board.

-

Ok, yes if you've got a dual thermocouple with two junctions with their own wires then yes, you could run one to the controller and one to the Duet. You would need the Duet Thermocouple Daughterboard to be able to read the temp.

https://duet3d.dozuki.com/Wiki/Thermocouple_daughter_board

https://duet3d.dozuki.com/Wiki/Connecting_thermocouples -

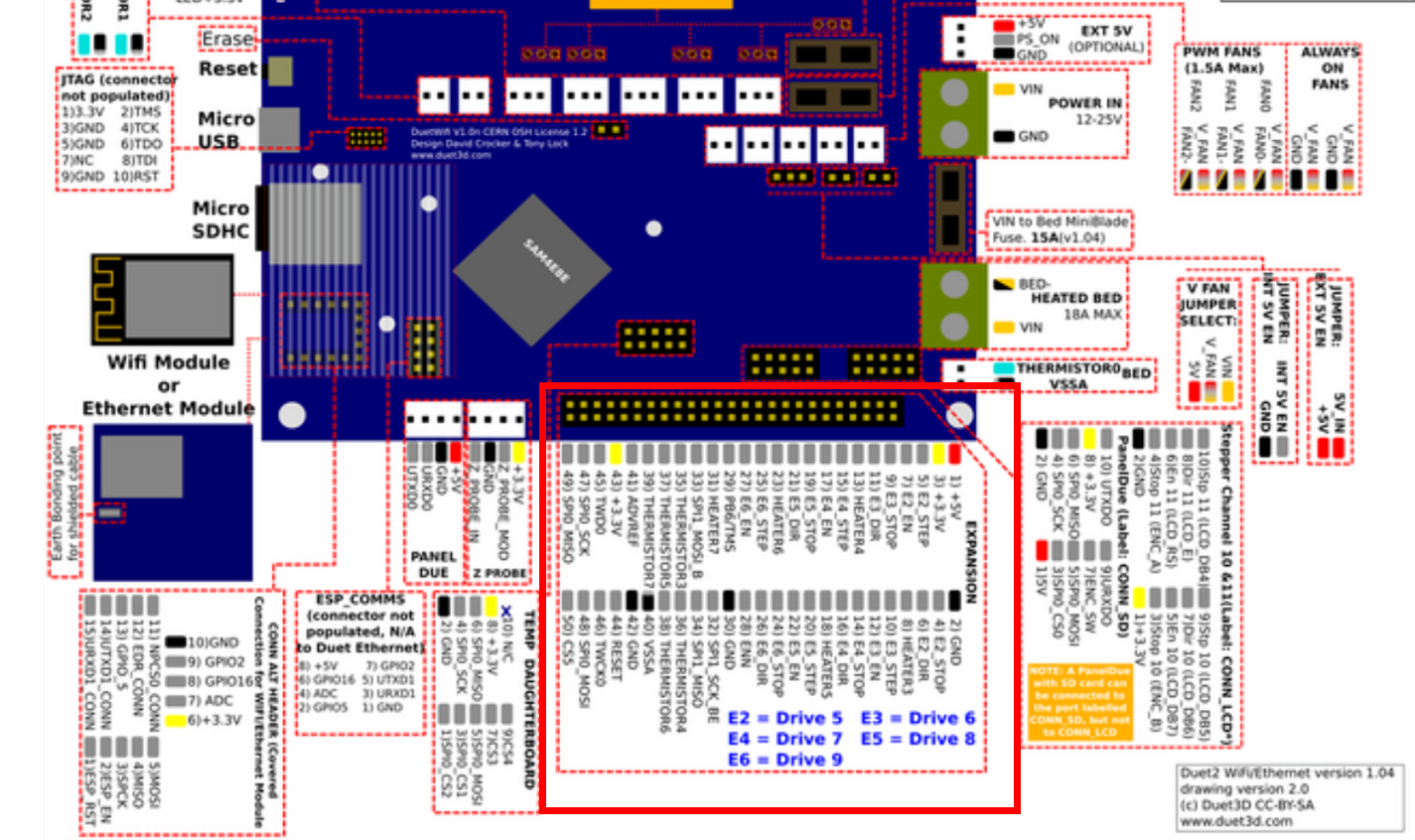

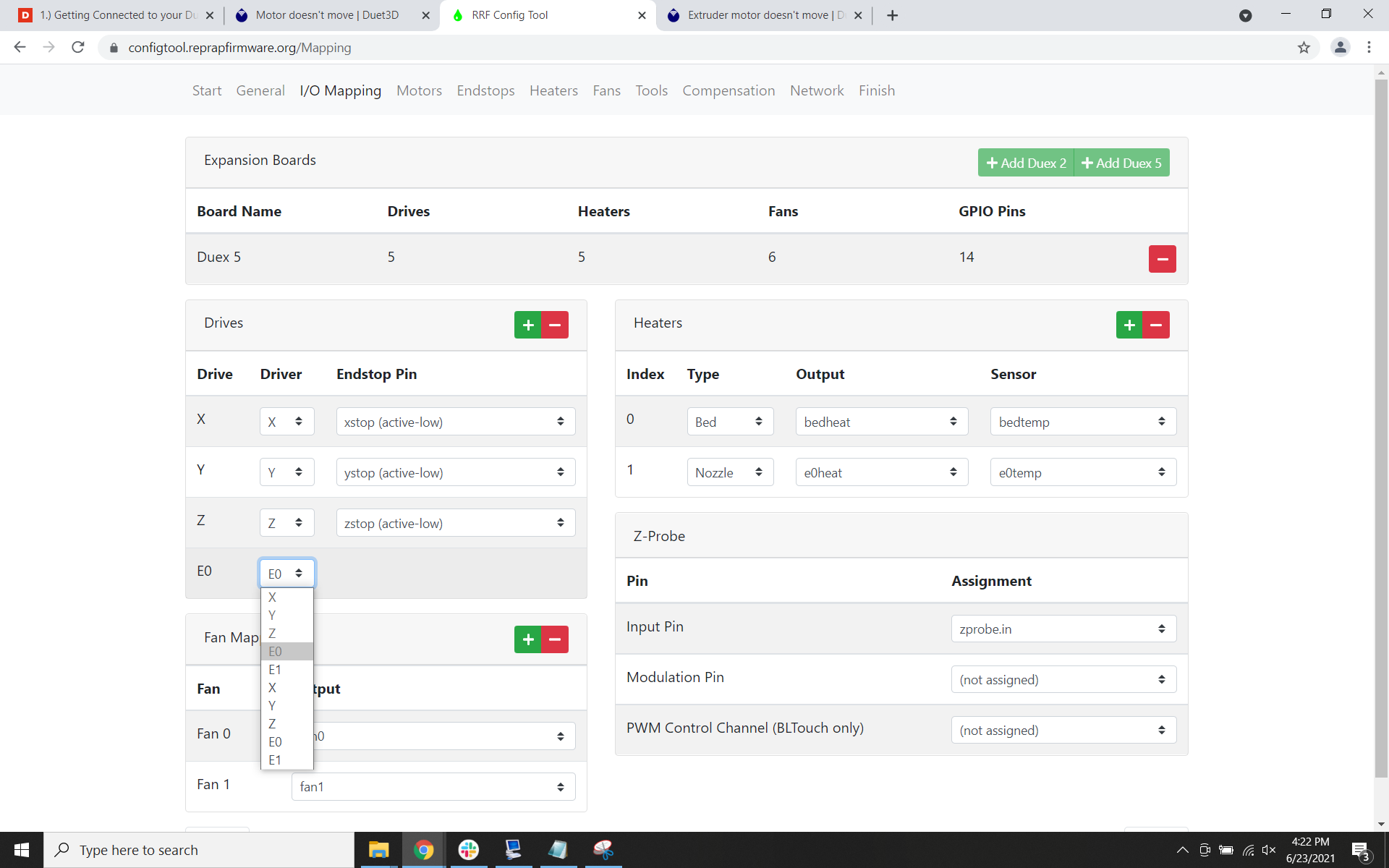

Hi, now the temperature is all set, but I have some problems with the extruder motor. I used the expansion portion (highlighted in the red square shown below) of the board for extruder signals. The channels I connected are E2, but I couldn't setup the config file to use the E2 motor because it isn't listed.

-

You'll need to alter the config manually to add non-standard mappings.

-

@phaedrux Could you please explain how to do that?