Understanding Height Maps

-

@jsinicro here is a picture of the printer, the two wooden pieces are of the exact height and were used to measure and adjust the lead screw to the same height at both ends of the X axis, the I ran the height map routine.

-

Have you seen this?

https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors

-

@jsinicro said in Understanding Height Maps:

@fcwilt OK, not sure what you mean by "lead screws/adjusting screws" lead screws are different from adjusting screws right. The lead screw is the screw that the motor turns -in this case the Z axis right?

The firmware supports auto bed leveling and manual bed leveling.

Auto bed leveling requires multiple Z steppers.

Manual bed leveling can make use of "thumb screws" that you turn by hand to make the needed adjustments to level the bed.

Now as to determining the X and Y coordinates to enter with the M671 command.

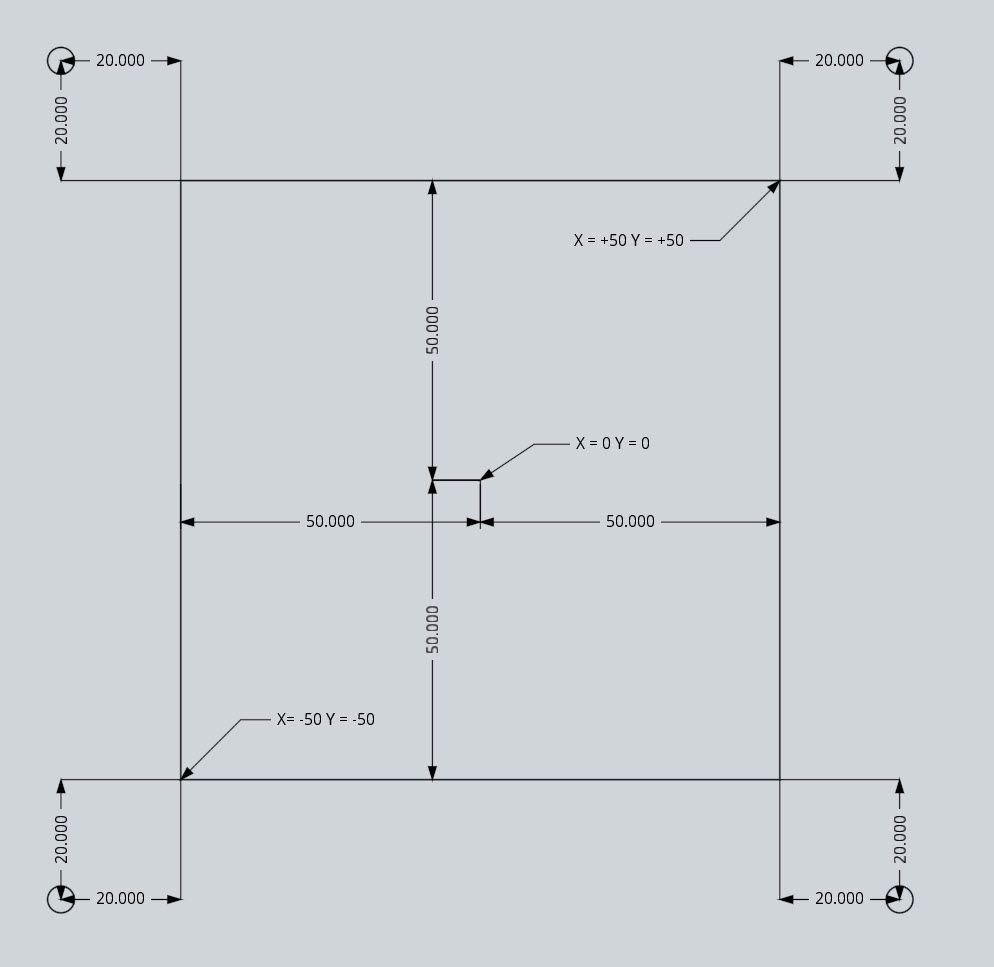

Consider this image of a imaginary printer bed arrangement:

The M208 command would be M208 X-50:50 Y-50:50 which means the printable area is 100 x 100 and X=0 Y=0 is at the center of the bed.

The four lead screws are 20 x 20 off each corner.

Lets assume that the Z steppers are assigned in the M584 command in this order:

- left front

- left rear

- right rear

- right front

So for the M671 we must specify the lead screw positions in the same order:

- left front

- left rear

- right rear

- right front

So that gives us M671 X-70:-70:70:70 Y:-70:70:70:-70

All the measurements are taken from the X=0 Y=0 point at the center of the bed.

Does that make it clear?

-

@fcwilt Yes, that's awesome thankyou. I will comeback this evening to do this.

-

@jsinicro OK so I think I understand the auto probing, I've set up the bed.g with 5 points 4 corners and the the center of the bed. should I execute the G29 to enable compensation at the end after the probing?

-

@jsinicro OK, so this is the new bed.g:

; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Apr 18 2021 23:08:09 GMT-0400 (Eastern Daylight Time) M561 ; clear any bed transform G30 K0 P0 X0 Y0 Z-9999 G30 K0 P1 X0 Y500 Z-9999 G30 K0 P2 X500 Y500 Z-9999 G30 K0 P3 X500 Y50 Z-9999 G30 K0 P4 X300 Y300 Z-9999 undefinedHowever when I execute this it runs into the X endstop eventually it stops don't understand why I home all first then in the home all after the homez I put the G32 command. Why is it running into the endstop?

-

-

@fcwilt here's my current config.g, also I tried a test print including the one Phaedrux posted above the bedlevel_nozzle stl file I used Cura the latest version and used the default settings to slice it. The print started but it was sitting there at the beginning not doing anything, but the web interface was showing that it was processing the print -time percentage was incrreasing, did not get any errors.

I then used a previous print and it seems that the nozzle keeps going too close to the bed even after I used a G92 Z0 to set a new position -moved the nozzle up and then used the G92 cmd.

FYI I decided to put the M999 at the end of the config file so that it would reset my U axis travel direction automatically however that's not something to do as then once printer turned back on I could no longer establish a network connection so this has been removed.

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Apr 18 2021 23:08:09 GMT-0400 (Eastern Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"jsinicro_1" ; set printer name ; Network M551 P"tinisa1125" ; set password M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Set Kinematics type and kinematics parameters M669 K0 ;X1:0:0 Y0:1:0 Z0:0:1 U1:0:0 ; ; Drives S = motor direction 0 is backwards/reversed direction based on motor orientation ; M569 P0.0 S1 ; physical drive 0.0 goes forwards z xxis 1 motor 1 M569 P0.1 S1 ; physical drive 0.1 goes forwards z axis 2 motor 1 M569 P0.2 S1 ; physical drive 0.2 goes forwards y axis 1 motor 1 M569 P0.3 S1 ; physical drive 0.3 goes forwards y axis 1 motor 2 M569 P0.4 S1 ; physical drive 0.4 goes forwards z axis 2 motor 2 M569 P0.5 S1 ; physical drive 0.5 goes forwards z axis 1 motor 2 M569 P1.0 S1 ; physical drive 1.0 goes forwards x axis 2 motor 1 M569 P1.1 S0 ; physical drive 1.1 goes forwards x axis 2 tool 1 motor M569 P3.0 S0 ; physical drive 3.0 goes forwards x axis 1 motor 1 M569 P3.1 S0 ; physical drive 3.1 goes forwards x axis 1 tool 2 motor ; mapping 2 motors on separate X axis and 2 motors each on 2 separate Z axis Y has just 2 motors ;M584 R0 S0 X1.0 U3.0 Y0.2:0.3 Z0.0:0.5:0.1:0.4 E1.1:3.1 P4 M584 R0 S0 X1.0 U3.0 Y0.2:0.3 Z0.0:0.5:0.1:0.4 E1.1:3.1 P4 M350 X16 Y16 Z16 U16 E16:16 I1 ; configure microstepping with interpolation M92 X80.00 Y395.72 Z400.00 U80.00 E840.99:840.99 ; set steps per mm M566 X300.00 Y300.00 Z60.00 U300.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min) M203 X900.00 Y900.00 Z180.00 U900.00 E900.00:900.00 ; set maximum speeds (mm/min) M201 X150.00 Y200.00 Z20.00 U150.00 E150.00:150.00 ; set accelerations (mm/s^2) M906 X800 Y1200 Z1200 U800 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M671 X139.21:-120.26:139.21:-120.26 Y-101:-101:-101:-101 ; lead screws offsets from X0,Y0 homed nozzle position remember to dimention right tower later ; currently we are only using left tower which controller 1 and 4 where 4 is the back motor when facing power supply ; Axis Limits starting with Left tower M208 X20:520 Y20:520 Z0:500 ; set axis max/min ; Endstops M574 X1 S1 P"!1.io0.in" ; configure 2 active-low "!" in name endstop for low end on X M574 Y1 S1 P"!1.io1.in" ; Y M574 Z2 S1 P"!1.io3.in" ; Z M574 Z2 S1 P"!3.io3.in" ; Z M574 U1 S1 P"!3.io0.in" ; configure 2 active-low "!" in name endstop for low end on X ; Z-Probe M558 P9 C"^1.io4.in" X0 Y0 Z1 H20 F120 K0 T6000 ; disable Z probe but set dive height, probe speed and travel speed M950 S0 C"1.io4.out" G31 X42 Y0 Z0.75 K0 P25 M558 P9 C"^3.io4.in" U0 Y0 Z1 H20 F120 K1 T6000 ; disable Z probe but set dive height, probe speed and travel speed M950 S1 C"3.io4.out" G31 U-44 Y0 Z2.648 K1 P25 ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 main board M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 ; disable bang-bang mode for the bed heater and set PWM limit M307 H0 B0 R0.348 C629.5 D2.14 S1.00 ; pid tuning parameters M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"1.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin and CAN #3.temp0 M950 H1 C"1.out0" T1 ; create nozzle heater output on 1.out0 and map it to sensor 1 M307 H1 B0 R2.209 C212.4 D5.61 S1.00 V24.2 ; pid tuning parameters M143 H1 S280 ; set temperature limit for heater 1 to 280C M308 S2 P"3.temp0" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin and CAN # 1.temp0 M950 H2 C"3.out0" T2 ; create nozzle heater output on 2.out0 and map it to sensor 2 M307 H2 B0 R2.248 C149.8 D4.97 S1.00 V24.3 ; pid tuning parameters M143 H2 S280 ; set temperature limit for heater 2 to 280C ; Fans ;M950 F0 C"1.out3" Q500 ; create fan 0 on pin 1.out3 and set its frequency ;M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off ;M950 F1 C"1.out4" Q500 ; create fan 1 on pin 2.out3 and set its frequency ;M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off ;M950 F2 C"3.out3" Q500 ; create fan 2 on pin 1.out4 and set its frequency ;M106 P2 S1 H1-1 T45 ; set fan 2 value. Thermostatic control is turned off ;M950 F3 C"3.out4" Q500 ; create fan 3 on pin 2.out4 and set its frequency ;M106 P3 S1 H1-1 T45 ; set fan 3 value. Thermostatic control is turned off ; Tools M563 P0 S"Z2-Axis" D0 H1 ;F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 S"Z1-Axix" D1 H2 X3 ;F2 ; define tool 1 X3 maps X movements to the U axis G10 P1 U0 Y0 Z0 ; set tool 0 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ; Create a tool that prints 2 copies of the object using both carriages M563 P2 D0:1 H1:2 X0:3 ; tool 2 uses both extruders, hot end heaters, and maps X to both X and U G10 P2 X50 Y0 U-50 S0 R0 ; set tool offsets and temperatures M567 P2 E1:1 ; set mix ratio 100% on both extruders ; Fillament sensor M591 D0 P7 C"0.io5.in" L7 R50:200 E15 S0 ;Bigtree smart filament moniter v2 set to moniter between 55%-150% of 7 counts over a distance of 22mm M591 D1 P7 C"3.io5.in" L7 R50:200 E15 S0 ;Bigtree smart filament moniter v2 set to moniter between 55%-150% of 7 counts over a distance of 22mm M581 P"1.io5.in" T2 C0 M581 P"3.io5.in" T3 C0 ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M501 undefined -

@jsinicro said in Understanding Height Maps:

M671 X139.21:-120.26:139.21:-120.26 Y-101:-101:-101:-101 ; lead screws offsets from X0,Y0 homed nozzle position remember to dimention right tower later ; currently we are only using left tower which controller 1 and 4 where 4 is the back motor when facing power supply

I don't understand what you are doing.

What kind of printer have you created?

Perhaps a photo would clarify.

Thanks.

Frederick

-

@fcwilt I finally see a light at the end of the tunnel. One spot I did not have enough glue however for the most part it looks good. I had to manually adjust the the bed with the bed springs as I was noticing almost touching the bed in some areas here is a pic of the leveling_nozzle stl. Its a custom build printer with OpenBuilds structural parts.

![IMG_2287[1].jpg](/assets/uploads/files/1625932568701-img_2287-1-resized.jpg)

![IMG_2288[1].jpg](/assets/uploads/files/1625932578402-img_2288-1-resized.jpg)

-

@jsinicro This is a prototype.

-

@jsinicro The idea came from the Zydex youtube video but I needed something much larger.

-

@jsinicro said in Understanding Height Maps:

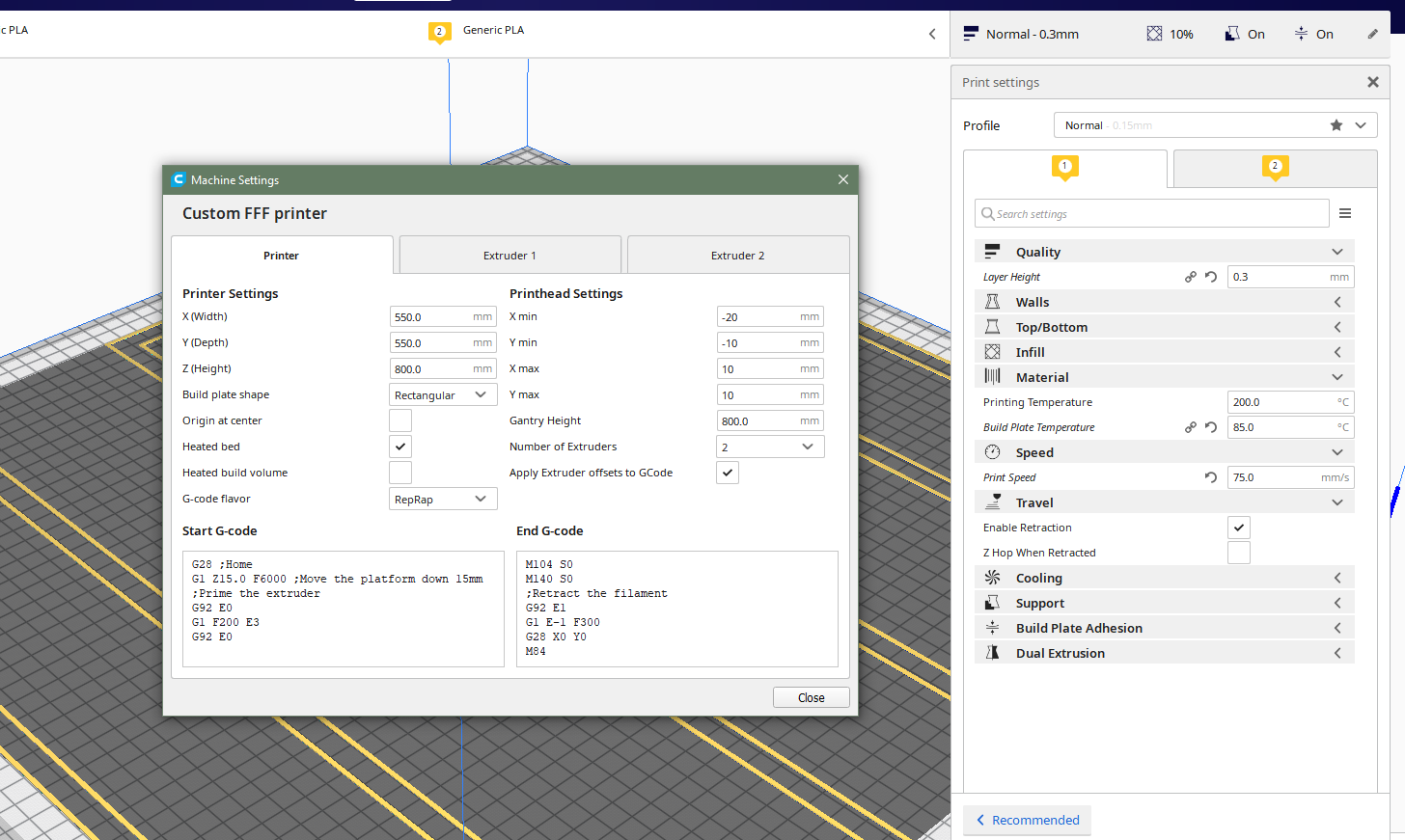

I used Cura the latest version and used the default settings to slice it. The print started but it was sitting there at the beginning not doing anything

Check your cura start gcode for any commands that set speed, accel, and jerk values. If they are there, remove them, and make sure you're set to use reprap gcode flavor.

-

@phaedrux You mean like M203,M205,M220,M566, OK you said in Cura, Like remove print speed or set it to 0? G-code flavor is set to RepRap.

Is there a better slicer program that is more specific to Duet 3 boards or RepRap ?

-

Interesting.

So you have two sets of Z towers with two steppers?

Can the Y axis move enough so both X and U can reach the entire bed?

Never tried to configure such a printer.

I think you will need to setup auto level for X and Y and run the process, then setup for U and Y and run the process.

Frederick

-

@jsinicro said in Understanding Height Maps:

Is there a better slicer program that is more specific to Duet 3 boards or RepRap ?

No, Cura is fine. Depending on the starting printer profile it will be setup for marlin and might have some speed commands specific to a different printer. Looks like yours is fine though.

-

@phaedrux The print was going so well but then looked like it was printing over the same extruded line and on one side the extruded plastic lifted up so it messed up. I'll try again

-

@jsinicro Maybe I needed more glue. This is a glass top I've bee using glue stick. the nozzle is set to 200 the bed is set to 85 for PLA. The nozzle is cooled via the Aqua cooled, however I do not have a blower yet for the extruded plastic That's what I am trying to print first. I've seen a bunch of videos that printing with a blower or with out one there isn't much difference.

-

Is the glass right on top of the bed heater?

Is it getting evenly hot? 85c is pretty hot for PLA.

Have you run a recent G29? What does the heightmap look like?

-

@phaedrux The bed gets really hot, I could probably cook on it, the heat gets distributed evenly but its definitely hotter towards the middle. Its one peace directly on the glass with cork under it. Its the same type of glass used on stoves, custom cut.

I ran the G29 after I created the bed auto level macro in the bed.g I issue the G32 at the end of the homeall.g and then the G29. I posted that map in my other post the third one. It did not make that much difference. The pic in that post that I was seeing the light at the end of the tunnel came out decent in the beginning but then I had to pause the print as one side started becoming loose. To get to that print as the pic showed in the other post I was adjusting the nozzle height manually as I was watching it move. Not doing so the nozzle would get way to close to the bed and only extrude like a spider web. I did not load the map with that print. The map showed about 1mm difference on the points not sure why it comes out almost on a 60degree. I will run the G29 again and see if there's any difference.