Help with apparently too hot printing

-

@jens55 60°C is still high for normal PLA. If you need these type of temperature try using some filament that is composite for take the glass transition temperature higher which is around 60°C for PLA. If you keep the part over that temperature overhangs will be a lot harder to print.

I've found some cheap PLA that cost around 11€/kg and it is much more prone to curling that for example colorfabb PLA/PHA.

10 degress less on the nozzle would change the curling behaviour only a little because the real heat reservoir in this case is the bed.Also as already suggested try randomize the seam position to, at least, know if also it is making the edge worse. If that is the case so try to check retraction settings and PA.

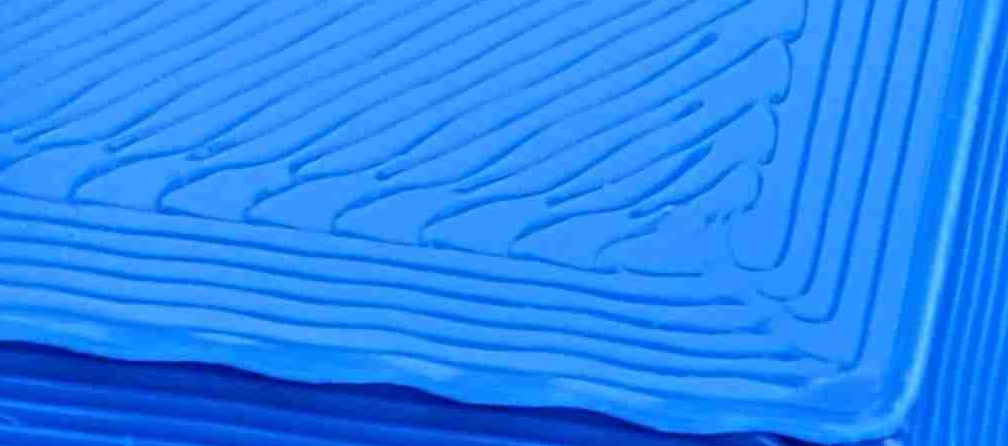

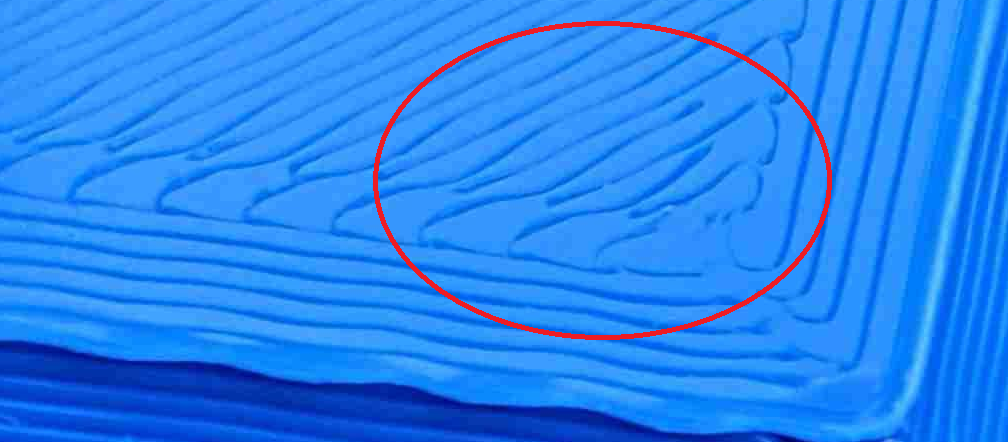

Just for debugging it i see a lot of wobbling on your print. Are you sure you are not printing too fast/too much acceleration?

-

@mikes said in Help with apparently too hot printing:

Just for debugging it i see a lot of wobbling on your print. Are you sure you are not printing too fast/too much acceleration?

It's a 500x500 bed slinger printer and the artifacts come gratis with the massive bed

-

Of course but i think that bottom layer is not due only to the bed slinger style...there is no uniform laying also on straight lines.. It could be the 90°C of the first layer being too high or also a mechanical problem on the extruder. Have you checked if it is extruding the correct amount of filament?

If you can't lay the first layer correctly i think you'll have hard times on overhang. Maybe we need to investigate deeper.

-

@mikes said in Help with apparently too hot printing:

I've found some cheap PLA that cost around 11€/kg and it is much more prone to curling that for example colorfabb PLA/PHA.

10 degress less on the nozzle would change the curling behaviour only a little because the real heat reservoir in this case is the bed.That would be reasonable if you are seeing the problems in the first few layers but if you are 20 mm or so up, the bed temperature should have little bearing on things.

-

@mikes said in Help with apparently too hot printing:

Of course but i think that bottom layer is not due only to the bed slinger style...there is no uniform laying also on straight lines.. It could be the 90°C of the first layer being too high or also a mechanical problem on the extruder. Have you checked if it is extruding the correct amount of filament?

If you can't lay the first layer correctly i think you'll have hard times on overhang. Maybe we need to investigate deeper.

Hmmm, interesting to see the photo magnified like that. The very obvious wobbly layer that jumps out at you is actually the edge of the brim of the print but I do see wobbles in the non-brim section as well. I have never noticed that before. I wonder what that coud be all about ....

-

I'm talking about that part there should be straight lines there. Just in the direction change you could get some blobs if PA is not tuned, but the infill part should be straight....

Here's an example...in this part i was still tuning PA (here it is a little too high) but you can clearly see that the lines are equally spaced and they are not "melted" like the ones in your pic:

-

Ahh, I misunderstood what wobbly lines you were talking about.

I wasn't concerned about those lines at all because the first layer has a 90 degree bed and is printed at 210C so way too hot ... but it has always given me good adhesion (without any chemicals on my glass bed) and a nice surface.

While I would agree that what we see here could certainly affect other aspects of the print, I am hesitant to link the two issues and would be afraid of getting sidetracked.I just pulled the latest print of the bed and the results are not pretty. I had printed all but the first layer at 185C nozzle temperature but brought the bed temp back up from 60C to 80C. I got all the crap like in the very first picture, only a bit worse.

Either the 190C/60C results were a fluke or thermal radiation from the hot bed is indeed affecting the print way more than I would have ever suspected.I think the next iteration should be 185/60C with the seam moved to somewhere in the middle of a flat area. I will run that tomorrow.

Edit: I am not clear on what I currently use for pressure advance (if any at all) .... there is a possibility that the wobbles in the first layer of the print are related to flow issues at the end of a line. IE, pa would sharply reduce flow as it gets to the reversal point. This is just a wild guess though ....

-

@mikes, nice first layer in that picture - seems pretty much perfect !

-

@jens55 so my suggestion is to start check from the bottom and fix everything that could increase the final defect. For example if you look at your photo you can clearly see that the "vertical perimeters" are straight, instead the "horizontal" ones (bottom of the photo) are wobbly. I can assume that the right vertical lines are aligned with the Y axis of the printer (the one that is parallel to the bed swinging) and the bottom horizontal ones are aligned with the X axis. To me it seems that there is some mechanical issue in the bed, maybe too much acceleration or jerk. Also it could be a too loose belt or a loose screw...

I would try to fix that before proceeding to test the temperature of print head and bed. Also to test temperature you can try run some temperature calibration tower (maybe something like this) that will reduce the time and amount of filament used, also giving you more information than a standard print

-

@mikes said in Help with apparently too hot printing:

I would try to fix that before proceeding to test the temperature of print head and bed. Also to test temperature you can try run some temperature calibration tower (maybe something like this) that will reduce the time and amount of filament used, also giving you more information than a standard print

Thanks Mike! I am working on setting up the temp tower now.

-

Well, this was an interesting exercise .... I printed the temperature tower in two goes since it popped off the build plate at the 200C mark but a reasonable print happened from 205C downward. The interesting bit was that it still printed fine at 170C (!!!). This got me to thinking that maybe my thermistor was reading wrong so I checked that and it was reading slightly off showing 170 when it was actually 175C.

The next interesting thing was that even at an actual temperature of 175C, the thin edge on the temperature tower showed upward curling! This was totally unexpected.

Here is a picture ... the top section was the one printed at 170C (actual 175C)

The left corner appears bent down slightly and the right corner is bent up a bit but in actual fact the entire edge and both corners are slightly bent up.

Looking at the underside of those edges seems to show that the printer can't properly print that last section that is supposad to be at about 60 degrees. The section before that is 45 degrees and that seems to print fine.

The left underside edge seems to have something else going on with it that is related to a seam.

I would appreciate some opinions on what I am seeing here.Edit: Even at 175 actual print temperature, layer bonding is excellent.

-

I have started another print job of the original model with 170C nozzle temperature and 60C bed temperature and with random seam location.

-

It's a 500x500 bed slinger printer and the artifacts come gratis with the massive bed

That's not true unless you're exceeding accelerations that the setup can handle. Every machine has its limits to "good" prints, bedslingers just have a disadvantage even with similar construction/constraint. If you're exceeding what the setup can handle, slow down the accels. Check that your belts are tight enough.

My two guesses - Pressure advance, or uncalibrated extrusion multiplier/esteps.

How did you verify your thermistor? Heat it up to X temperature, yoink the cable and read resistance quick?Please ensure that both are sorted. (pressure advance is M572, try tuning it using some of the scripts posted on the forum. I've seen this kind of behavior with very out-of-sorts PA before.)

The photo of the bottom of the print looks like either A) overextrusion or B) too close of a nozzle to the bed, squishing out too far and spilling into the next tracks as it extrudes, or C) both.

As a side note - what brand/resin of PLA?

-

@jens55 Can you please post a photo of your filament cooler setup?

-

@luke-slaboratory said in Help with apparently too hot printing:

It's a 500x500 bed slinger printer and the artifacts come gratis with the massive bed

That's not true unless you're exceeding accelerations that the setup can handle. Every machine has its limits to "good" prints, bedslingers just have a disadvantage even with similar construction/constraint. If you're exceeding what the setup can handle, slow down the accels. Check that your belts are tight enough.

While that is basically true, so is the fact that shoving something like a 5kg bed back and forth causes vibration unless you are going REAL slow

As it sits, max acceleration is 3000 in x and 300 in y, max jerk is 600 in x and 300 in y. I don't recall what the actual Cura settings were for acceleration and jerk. Speed btw was 70 mm/secMy two guesses - Pressure advance, or uncalibrated extrusion multiplier/esteps.

Extrusion calibration is likely adjusted correctly but pressure advance was a wild guess at 0.4 for an BMG LGX feeding a Dragon hot end.

How did you verify your thermistor? Heat it up to X temperature, yoink the cable and read resistance quick?

I used a digital (contact) thermocouple instrument.

Please ensure that both are sorted. (pressure advance is M572, try tuning it using some of the scripts posted on the forum. I've seen this kind of behavior with very out-of-sorts PA before.)

I might be off slightly on PA - nothing dramatic though.

The photo of the bottom of the print looks like either A) overextrusion or B) too close of a nozzle to the bed, squishing out too far and spilling into the next tracks as it extrudes, or C) both.

This is not the first layer - nozzle to bed distance is irrelevant, Z axis is calibrated.

Seeing that this is only an issue with the overhang and that there is no over extrusion otherwise, I am not sure why you think it to be over extrusion rather than material falling off the edge where it is not supported. I must admit, it DOES look like over extrusion but how can it be if the rest of the print showes no sign of over extrusion?As a side note - what brand/resin of PLA?

It's a house brand from Filaments.ca .... I will look it up and post the proper name in a bit.

Edit: Ecotough PLA

-

@cosmowave said in Help with apparently too hot printing:

@jens55 Can you please post a photo of your filament cooler setup?

-

Make your PA 0 and test - for a direct drive feeding a Dragon, i would expect it to be below .1 - for reference, my most recent print using a volcano hotend with a hemera is ~.01 with PLA. Per Duet's documents - .4 is where they'd expect a medium-length bowden setup would be. https://duet3d.dozuki.com/Wiki/Pressure_advance

This stands out as the primary issue - PA is something that needs to be tuned, not guessed, and is unique to the filament and sometimes even the colorIf overextruding - Overhangs would exhibit "drooping" behavior because there's more material to droop - I've seen that behavior on my own prints, and corrected it by dialing back the multiplier a few %.

Re: vibrations

Sorry to sound so abrasive - I run a bedflinger that has a 5kg bed assembly and I am now running 5k accel for production prints. My extrusion toolhead moves are 330+mm/s (.25mm height, .48width track, ~35mm3/s) If you want to remove the defects, slow your accel or stiffen your motion. I use two linear rails for the bed, 9mm belt, and a huge nema 17 to accomplish accurate and beautiful prints at these speeds+feeds. All I'm trying to say is that its not inevitable that you'll have vibrations or issues with large beds or "high speeds" - every machine has its limits somewhere. I can't print on this machine 15k accel like my corexy platform can, but its nowhere near "slow"

-

@luke-slaboratory said in Help with apparently too hot printing:

Make your PA 0 and test - for a direct drive feeding a Dragon,

done

Sorry to sound so abrasive - I run a bedflinger that has a 5kg bed assembly and I am now running 5k accel for production prints. My extrusion toolhead moves are 330+mm/s (.25mm height, .48width track, ~35mm3/s) If you want to remove the defects, slow your accel or stiffen your motion. I use two linear rails for the bed, 9mm belt, and a huge nema 17 to accomplish accurate and beautiful prints at these speeds+feeds. All I'm trying to say is that its not inevitable that you'll have vibrations or issues with large beds or "high speeds" - every machine has its limits somewhere. I can't print on this machine 15k accel like my corexy platform can, but its nowhere near "slow"

My printer is a CR10 S5 V rollers and not a very rigid frame. I have trouble relating to a bed slinger with a rigid frame.

-

The next print is done and it's not a pretty picture.

A temperature of 170C appears to be the lowest possible temperature. There appears to be a bit of a reduction in model strength and there is considerable (but very thin) spider webbing inside the model. Based on that, the print temp should be in the 180, 185C, 190 range.

The bad news, while the crap on the outside is reduced, it is still there. Also, the random seam location didn't help.The only thing I have left is the change to the PA (from 0.4 to 0). Beyond that the next thing is to add support to the edges.

Next print will be with the PA changed and support added. I will have to fix my z probe first though.

-

For further info, Cura has acceleration set to 500 and jerk is 8