Help with apparently too hot printing

-

@engikeneer said in Help with apparently too hot printing:

@jens55 Would definitely agree with the others that 80deg is probably too hot for PLA bed temp. Hairspray my friend! Either that or get a PEI sheet

I hate hate hate putting any goo of any kind on my print bed. It isn't necessary, makes a mess and usually you can see it on the print surface that touched the bed.

The current print is sticking well at 90C for the first layer ad then dropping to 60C. Actually that print, which is still running, is doing very well and I decided to let it run for the entire job rather than aborting it half way through.Have you checked how much your cooling fan is actually running during the print? If it's not at 100% when doing those overhangs then probably worth bumping up the slicer settings! I made this mistake when setting up my delta, then realised my fan was only running at 20% when I needed 100%...

I verified that the blower was turning but don't know how to verify that it's at 100% (Duet reports 100%)

Also, have you tried using smaller layer heights (for the overhang bit at least?) . Lower layer heights generally allow better overhangs because the overhang each layer does (in mm) is less.

Good idea, I will keep that in mind!

Also on layer adhesion, I've found most PLA's work even down to 180deg, so wouldn't be too scared of going lower.

It will be interesting to see how a190C print turns out.

Thanks!

-

@jens55 Fair points!

RE the fan setting, I was meaning check what your slicer is setting it to (PrusaSlicer will colour the model with the fan speed for each layer to show you, guessing others will do the same). If DWC says 100%, then probably is 100% though!

-

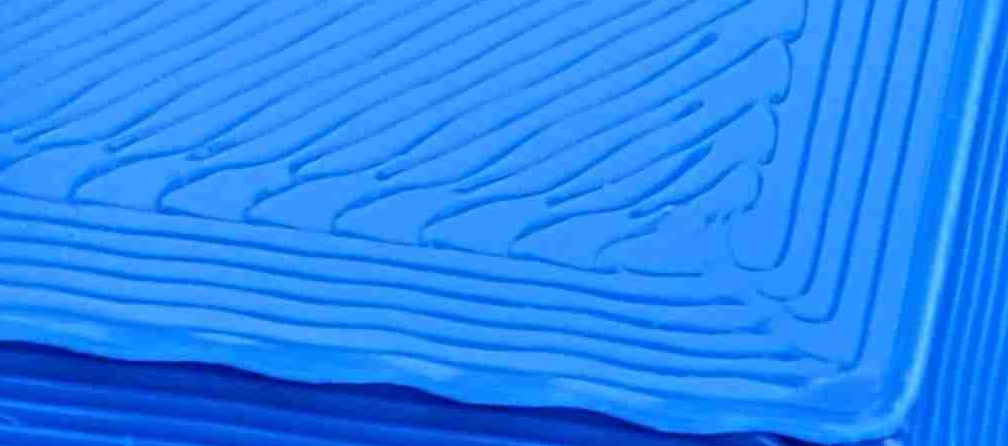

The next print sample is finished. The outcome is MUCH better than before but one out of the four edges is still dud.

Here is the bad edge and you can see just a hint of the edge lifting (remember this is printed upside down so 'lifting' here means 'edge pulling down' in this picture.

This is one of the other edges

In my mind, these results confirm that things were printed too hot but I am surprised that even 190C seems too high.

Next I will print at 185C to see if I can get the last edge 'fixed'

-

@jens55 i don't understand why you ask for help and then do the same mistakes after everyone told you that 90°c is too high for PLA. You might check out what glass transition temperature is and how much it is for PLA.

However remember that your cooling fan is not cooling every edge the same way. Turing the nozzle temperature too low will not help with that because the bed will keep the part too hot. Try putting a fan in front of your printer pushing fresh air: maybe your part will be brittle but you will see how much the surface finish will improve and use it as reference for further tuning.

If you don't have it buy a pei sheet or use blue masking tape and print the same gcode with 30°c bed (or also cold). We all faced that type of issues and the problem is always that PLA is not a material that likes 60°C temperature and high speed print.

-

@mikes said in Help with apparently too hot printing:

We all faced that type of issues and the problem is always that PLA is not a material that likes 60°C temperature and high speed print.

Curious.

I have always printed regular PLA on a 60 degree bed and never had an problems.

But I do print the first layer at a slow speed (15 mm/s) then moving up to 60 or better.

Frederick

-

@jens55 my guess I that that bad corner is your seam? Looks like there I bit of over extrusion at the very start of the first line of the first layer, then some of ripples at the end. Might be worth trying to tune PA and retraction a bit more, or use the P1 jerk policy.

Or alternatively, put the seam in the middle of one of the edges and/or set hour slicer to print the outer perimeters last? -

@mikes said in Help with apparently too hot printing:

@jens55 i don't understand why you ask for help and then do the same mistakes after everyone told you that 90°c is too high for PLA. You might check out what glass transition temperature is and how much it is for PLA.

Somebody seems to have a bad day .... sorry, hope it improves!

For the record, I have taken all the advise people have given me and adjusted my print accordingly. I was printing at 200, went down to 190 (this last set of pictures) and am presently printing at 185

I am not sure were the 90C comes from that you are talking about but the only place that comes in is for the bed temperature for the first layer and this is nowhere near where the issue occurs.However remember that your cooling fan is not cooling every edge the same way. Turing the nozzle temperature too low will not help with that because the bed will keep the part too hot. Try putting a fan in front of your printer pushing fresh air: maybe your part will be brittle but you will see how much the surface finish will improve and use it as reference for further tuning.

I did a print with 60C bed temp (all but the first layer) - no difference.

If you don't have it buy a pei sheet or use blue masking tape and print the same gcode with 30°c bed (or also cold). We all faced that type of issues and the problem is always that PLA is not a material that likes 60°C temperature and high speed print.

As I said, there was no difference in the nature of the problem when I dropped the bed temperature to 60C. There was a large improvement in the issue when I went from 200C to 190C nozzle temperature!

-

@engikeneer said in Help with apparently too hot printing:

@jens55 my guess I that that bad corner is your seam? Looks like there I bit of over extrusion at the very start of the first line of the first layer, then some of ripples at the end. Might be worth trying to tune PA and retraction a bit more, or use the P1 jerk policy.

Or alternatively, put the seam in the middle of one of the edges and/or set hour slicer to print the outer perimeters last?Now that is a really interesting thought and one well worth digging into. It would certainly explain why 3 edges are good and one is bad!

Thank you, I will look into that ! -

@jens55 60°C is still high for normal PLA. If you need these type of temperature try using some filament that is composite for take the glass transition temperature higher which is around 60°C for PLA. If you keep the part over that temperature overhangs will be a lot harder to print.

I've found some cheap PLA that cost around 11€/kg and it is much more prone to curling that for example colorfabb PLA/PHA.

10 degress less on the nozzle would change the curling behaviour only a little because the real heat reservoir in this case is the bed.Also as already suggested try randomize the seam position to, at least, know if also it is making the edge worse. If that is the case so try to check retraction settings and PA.

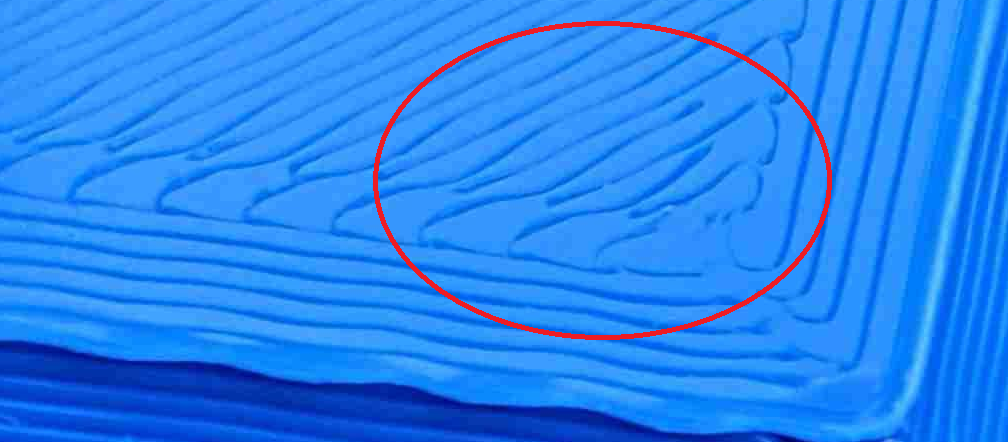

Just for debugging it i see a lot of wobbling on your print. Are you sure you are not printing too fast/too much acceleration?

-

@mikes said in Help with apparently too hot printing:

Just for debugging it i see a lot of wobbling on your print. Are you sure you are not printing too fast/too much acceleration?

It's a 500x500 bed slinger printer and the artifacts come gratis with the massive bed

-

Of course but i think that bottom layer is not due only to the bed slinger style...there is no uniform laying also on straight lines.. It could be the 90°C of the first layer being too high or also a mechanical problem on the extruder. Have you checked if it is extruding the correct amount of filament?

If you can't lay the first layer correctly i think you'll have hard times on overhang. Maybe we need to investigate deeper.

-

@mikes said in Help with apparently too hot printing:

I've found some cheap PLA that cost around 11€/kg and it is much more prone to curling that for example colorfabb PLA/PHA.

10 degress less on the nozzle would change the curling behaviour only a little because the real heat reservoir in this case is the bed.That would be reasonable if you are seeing the problems in the first few layers but if you are 20 mm or so up, the bed temperature should have little bearing on things.

-

@mikes said in Help with apparently too hot printing:

Of course but i think that bottom layer is not due only to the bed slinger style...there is no uniform laying also on straight lines.. It could be the 90°C of the first layer being too high or also a mechanical problem on the extruder. Have you checked if it is extruding the correct amount of filament?

If you can't lay the first layer correctly i think you'll have hard times on overhang. Maybe we need to investigate deeper.

Hmmm, interesting to see the photo magnified like that. The very obvious wobbly layer that jumps out at you is actually the edge of the brim of the print but I do see wobbles in the non-brim section as well. I have never noticed that before. I wonder what that coud be all about ....

-

I'm talking about that part there should be straight lines there. Just in the direction change you could get some blobs if PA is not tuned, but the infill part should be straight....

Here's an example...in this part i was still tuning PA (here it is a little too high) but you can clearly see that the lines are equally spaced and they are not "melted" like the ones in your pic:

-

Ahh, I misunderstood what wobbly lines you were talking about.

I wasn't concerned about those lines at all because the first layer has a 90 degree bed and is printed at 210C so way too hot ... but it has always given me good adhesion (without any chemicals on my glass bed) and a nice surface.

While I would agree that what we see here could certainly affect other aspects of the print, I am hesitant to link the two issues and would be afraid of getting sidetracked.I just pulled the latest print of the bed and the results are not pretty. I had printed all but the first layer at 185C nozzle temperature but brought the bed temp back up from 60C to 80C. I got all the crap like in the very first picture, only a bit worse.

Either the 190C/60C results were a fluke or thermal radiation from the hot bed is indeed affecting the print way more than I would have ever suspected.I think the next iteration should be 185/60C with the seam moved to somewhere in the middle of a flat area. I will run that tomorrow.

Edit: I am not clear on what I currently use for pressure advance (if any at all) .... there is a possibility that the wobbles in the first layer of the print are related to flow issues at the end of a line. IE, pa would sharply reduce flow as it gets to the reversal point. This is just a wild guess though ....

-

@mikes, nice first layer in that picture - seems pretty much perfect !

-

@jens55 so my suggestion is to start check from the bottom and fix everything that could increase the final defect. For example if you look at your photo you can clearly see that the "vertical perimeters" are straight, instead the "horizontal" ones (bottom of the photo) are wobbly. I can assume that the right vertical lines are aligned with the Y axis of the printer (the one that is parallel to the bed swinging) and the bottom horizontal ones are aligned with the X axis. To me it seems that there is some mechanical issue in the bed, maybe too much acceleration or jerk. Also it could be a too loose belt or a loose screw...

I would try to fix that before proceeding to test the temperature of print head and bed. Also to test temperature you can try run some temperature calibration tower (maybe something like this) that will reduce the time and amount of filament used, also giving you more information than a standard print

-

@mikes said in Help with apparently too hot printing:

I would try to fix that before proceeding to test the temperature of print head and bed. Also to test temperature you can try run some temperature calibration tower (maybe something like this) that will reduce the time and amount of filament used, also giving you more information than a standard print

Thanks Mike! I am working on setting up the temp tower now.

-

Well, this was an interesting exercise .... I printed the temperature tower in two goes since it popped off the build plate at the 200C mark but a reasonable print happened from 205C downward. The interesting bit was that it still printed fine at 170C (!!!). This got me to thinking that maybe my thermistor was reading wrong so I checked that and it was reading slightly off showing 170 when it was actually 175C.

The next interesting thing was that even at an actual temperature of 175C, the thin edge on the temperature tower showed upward curling! This was totally unexpected.

Here is a picture ... the top section was the one printed at 170C (actual 175C)

The left corner appears bent down slightly and the right corner is bent up a bit but in actual fact the entire edge and both corners are slightly bent up.

Looking at the underside of those edges seems to show that the printer can't properly print that last section that is supposad to be at about 60 degrees. The section before that is 45 degrees and that seems to print fine.

The left underside edge seems to have something else going on with it that is related to a seam.

I would appreciate some opinions on what I am seeing here.Edit: Even at 175 actual print temperature, layer bonding is excellent.

-

I have started another print job of the original model with 170C nozzle temperature and 60C bed temperature and with random seam location.