Tevo Little Monster stepper motor move only in one direction

-

I just got a brand new TLM which I could not get running with MKS. Therefore rather than to dive deep into MKS I decided to purchase a Original Duet Wifi that arrived yesterday. After following the Tutorial on YOUTUBE " How to Install a DUET board on a Delta Style 3D Printer - The TEVO Little Monster" I was able to reach the DWC 3 and to upload the config and firmware.

However arriving at the HOME ALL "STEP", I noticed, that I do not have the Home x , y , z button only HOME ALL. After clicking HOME ALL the print head started moving very slowly with a wired noise and got stacked as the z-axis did not move and I switched of before I enter into more problems.

To find out what is going on, I followed a tutorial to check if the

different stepper motors even move. So I remove the belt and

by using G91 and G1 H2 X10 F1OO ...G1 H2 X-10 G1 H2 Y10 ....

I tried to check if the stepper motors were "moving". Well the result is for me wired noise joining the fact, that beside of a movement in only one direction for X10 and X-10 etc.. it gave

a sensation of vibration of the pulley.I would highly appreciate any hint to come out of the sh...

If for that one need files, just ask , as I do not know

what might be needed.For any help thank you very much.

linus

attached: DWC-TLM

-

@linus4200 said in Tevo Little Monster stepper motor move only in one direction:

I tried to check if the stepper motors were "moving". Well the result is for me wired noise joining the fact, that beside of a movement in only one direction for X10 and X-10 etc.. it gave

a sensation of vibration of the pulley.It sounds like the motors might not be connected properly, or somehow misconfigured.

Check your motor phases are wired correctly: https://duet3d.dozuki.com/Wiki/Choosing_and_connecting_stepper_motors#Section_Identifying_the_stepper_motor_phases

Please copy and paste your config.g, homedelta.g, bed.g files.

Also send M122 and M98 P"config.g" in the gcode console and copy and paste the results here.

This will give us some more insight into what is actually happening on your printer.For setting up a delta you should take a look at these guides as well.

https://duet3d.dozuki.com/Wiki/ConfiguringRepRapFirmwareDeltaPrinter

https://duet3d.dozuki.com/Wiki/Calibrating_a_delta_printer -

@phaedrux

Thank you very much for your prompt reply, please find below the

required information:config.g :

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.0 on Sun Aug 08 2021 03:13:57 GMT+0200 (Central European Summer Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"TLM" ; set printer name

M665 R155 L397.19 B155 H520 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S1 ; enable FTP

M586 P2 S1 ; enable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z80.00 E663.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2)

M906 X1400 Y1400 Z1400 E1400 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; set minimum Z; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S1 P"zstop" ; configure active-high endstop for low end on Z via pin zstop; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 R150 S45 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S1 H1 T45 ; set fan 2 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power losshomedelta.g:

; homedelta.g

; called to home all towers on a delta printer

;

; generated by RepRapFirmware Configuration Tool v3.3.0 on Sun Aug 08 2021 03:13:57 GMT+0200 (Central European Summer Time)

G91 ; relative positioning

;*** Slow homing has been configured. Change F180 to F1800 below when your configuration is working

G1 H1 X705 Y705 Z705 F180 ; move all towers to the high end stopping at the endstops (first pass)

G1 H2 X-5 Y-5 Z-5 F1800 ; go down a few mm

;*** Slow homing has been configured. Change F180 to F360 below when your configuration is working

G1 H1 X10 Y10 Z10 F180 ; move all towers up once more (second pass)

G1 Z-5 F6000 ; move down a few mm so that the nozzle can be centred

G90 ; absolute positioning

G1 X0 Y0 F6000 ; move X+Y to the centrebed.g;

; bed.g

; called to perform automatic delta calibration via G32

;

; generated by RepRapFirmware Configuration Tool v3.3.0 on Sun Aug 08 2021 03:13:57 GMT+0200 (Central European Summer Time)

M561 ; clear any bed transform

; Probe the bed at 3 peripheral and 3 halfway points, and perform 6-factor auto compensation

; Before running this, you should have set up your Z-probe trigger height to suit your build, in the G31 command in config.g.

G30 P0 X0 Y84.9 H0 Z-99999

G30 P1 X73.53 Y-42.45 H0 Z-99999

G30 P2 X-73.53 Y-42.45 H0 Z-99999

G30 P3 X0 Y42.4 H0 Z-99999

G30 P4 X36.72 Y-21.2 H0 Z-99999

G30 P5 X-36.72 Y-21.2 H0 Z-99999

G30 P6 X0 Y0 H0 Z-99999 S6

; Use S-1 for measurements only, without calculations. Use S4 for endstop heights and Z-height only. Use S6 for full 6 factors

; If your Z probe has significantly different trigger heights depending on XY position, adjust the H parameters in the G30 commands accordingly. The value of each H parameter should be (trigger height at that XY position) - (trigger height at centre of bed)M122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.3 (2021-06-15 21:44:54) running on Duet WiFi 1.02 or later

Board ID: 0JD0M-9P6B2-NJ4S8-6J1FJ-3S06S-T86UL

Used output buffers: 3 of 24 (11 max)

=== RTOS ===

Static ram: 23876

Dynamic ram: 74496 of which 0 recycled

Never used RAM 16044, free system stack 184 words

Tasks: NETWORK(notifyWait,13.6%,246) HEAT(delaying,0.0%,314) Move(notifyWait,0.1%,364) MAIN(running,85.6%,441) IDLE(ready,0.7%,29), total 100.0%

Owned mutexes: WiFi(NETWORK) HTTP(MAIN)

=== Platform ===

Last reset 00:02:28 ago, cause: power up

Last software reset at 2021-08-07 21:01, reason: User, GCodes spinning, available RAM 16044, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Step timer max interval 0

MCU temperature: min 17.1, current 23.9, max 24.3

Supply voltage: min 23.8, current 24.0, max 24.4, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Driver 0: position 70856, standstill, SG min/max not available

Driver 1: position 70856, standstill, SG min/max not available

Driver 2: position 70856, standstill, SG min/max not available

Driver 3: position 0, standstill, SG min/max not available

Driver 4: position 0, standstill, SG min/max not available

Driver 5: position 0

Driver 6: position 0

Driver 7: position 0

Driver 8: position 0

Driver 9: position 0

Driver 10: position 0

Driver 11: position 0

Date/time: 2021-08-08 11:58:59

Cache data hit count 4294967295

Slowest loop: 5.35ms; fastest: 0.17ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 4.0ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 83, maxWait 0ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is ready with "M122 " in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 80.32ms; fastest: 0.00ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8- WiFi -

Network state is active

WiFi module is connected to access point

Failed messages: pending 0, notready 0, noresp 0

WiFi firmware version 1.26

WiFi MAC address 24:a1:60:2d:ff:ff

WiFi Vcc 3.43, reset reason Turned on by main processor

WiFi flash size 4194304, free heap 23216

WiFi IP address 192.168.1.33

WiFi signal strength -65dBm, mode 802.11n, reconnections 0, sleep mode modem

Clock register 00002002

Socket states: 0 0 0 0 0 0 0 0

M98 P"config.g"

HTTP is enabled on port 80

FTP is enabled on port 21

TELNET is enabled on port 23This is with belts not mounted (as I tried if the stepper motor even turn, which they do in one direction only).

Thanks for the help.

linus

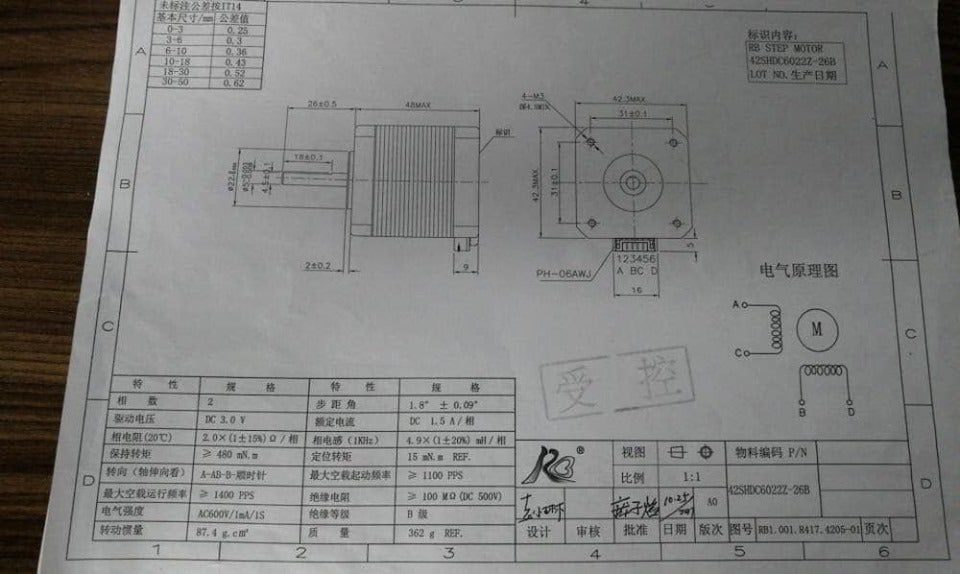

P.S. : Might it be a problem of the Stepper Motors ? Only info I have is whats written on them : RB STEP MOTOR 42SHDC6022-Z26B - LOT NO. 190402

- WiFi -

-

@linus4200 said in Tevo Little Monster stepper motor move only in one direction:

; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S1 P"zstop" ; configure active-high endstop for low end on Z via pin zstopYour endstop positions are incorrect for a delta. X1 Y1 Z1 means low end of travel. They should be X2 Y2 Z2 for the high end of the towers.

Once that is fixed your homing should produce the right results.

-

Thank you very much. One issue less. I changed it as per your instruction and pressed the home all button. Result the x+ y

motor slowly lowering their position while z did not move nothing and consequently by lowering the x and y axis without the z axis results in crashing against the z aluminum profile of the printer and trying to move even further.Moreover I manually moved the "print head" into the home position and pushed again home all and a small movement

and then stopped. Thereafter I used DWC to try if there is any

movement on x, y and z axis. Indeed it moved but only in one direction using x+ or x- .... . Any idea why?With reference to the motors themselves do I have the change the current? to get a "fluid" movement?

Thanks for your help, without that I would not know what to do.

linus

P.S.: Might it be that even being a new printer the stepper motors are broken ? How to check this? Attached a video

to better understand my problem. -

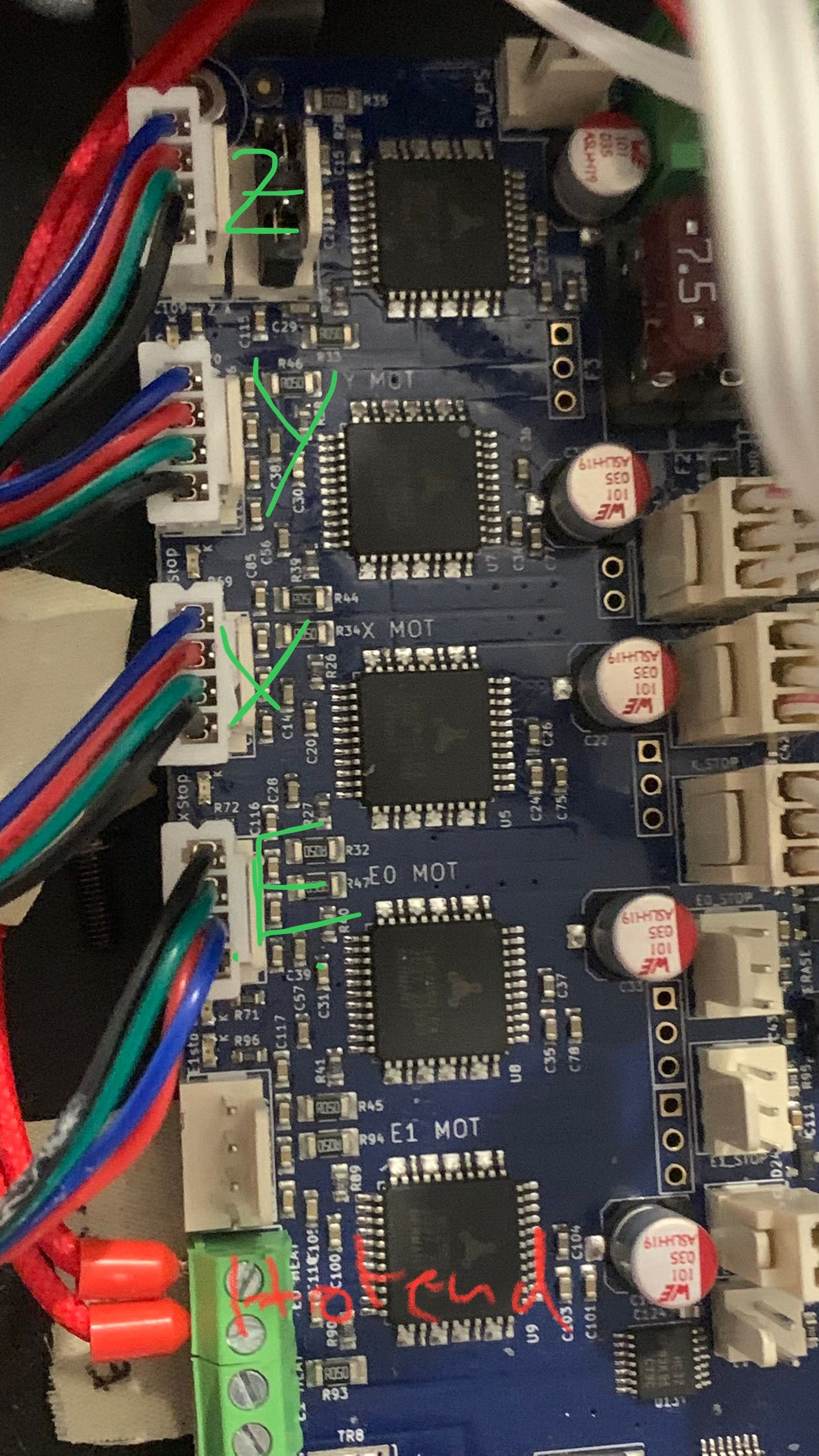

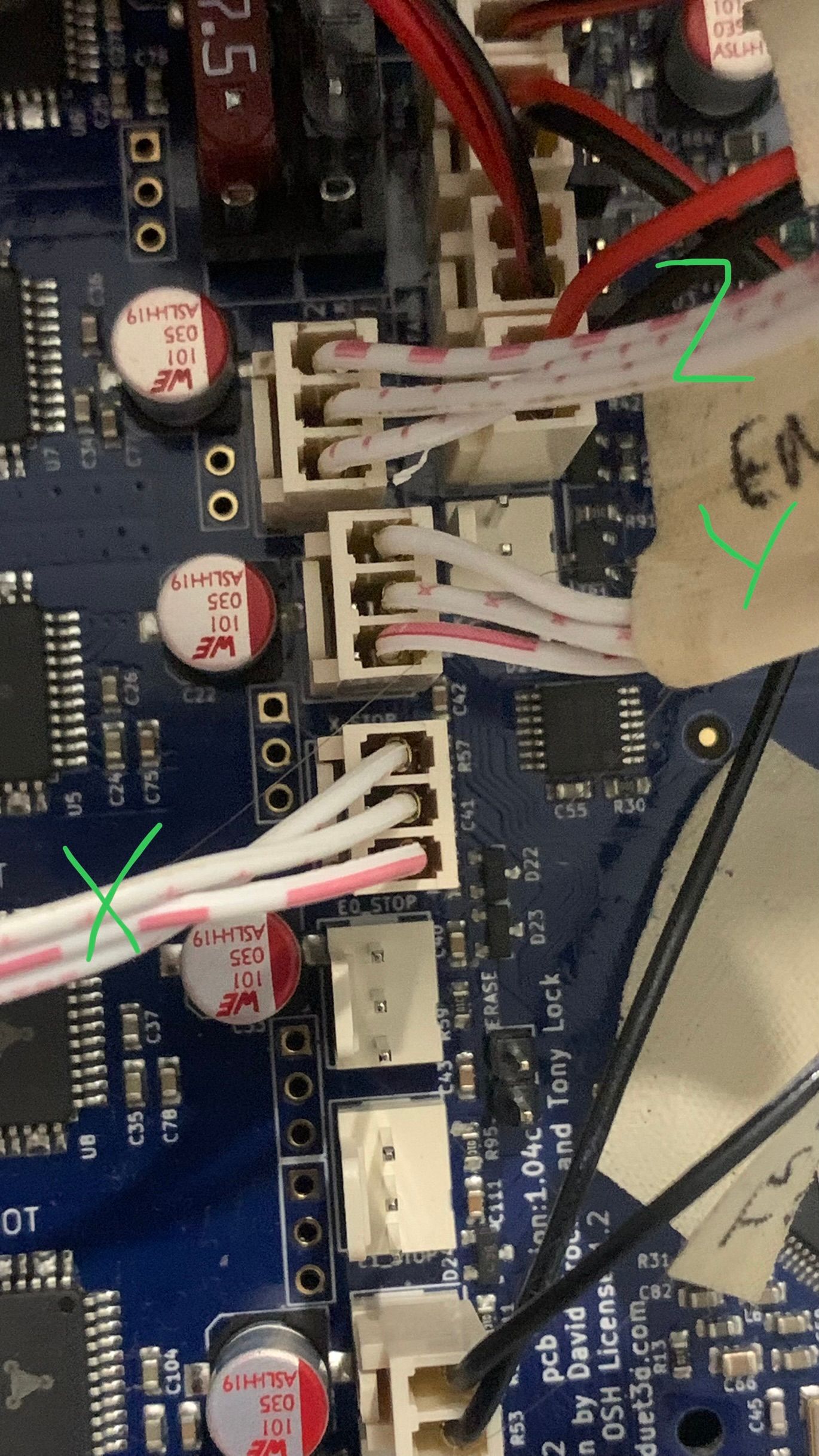

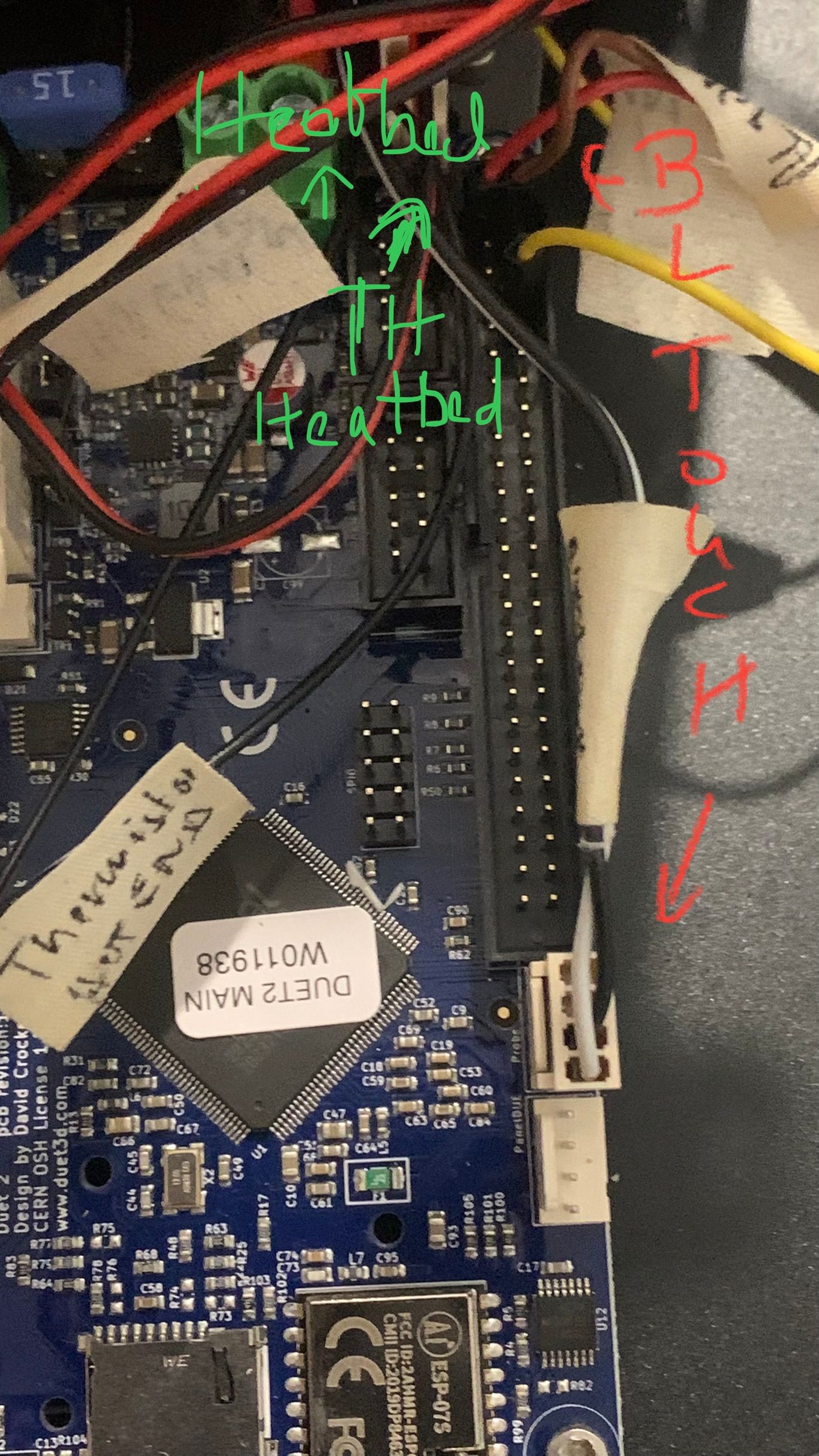

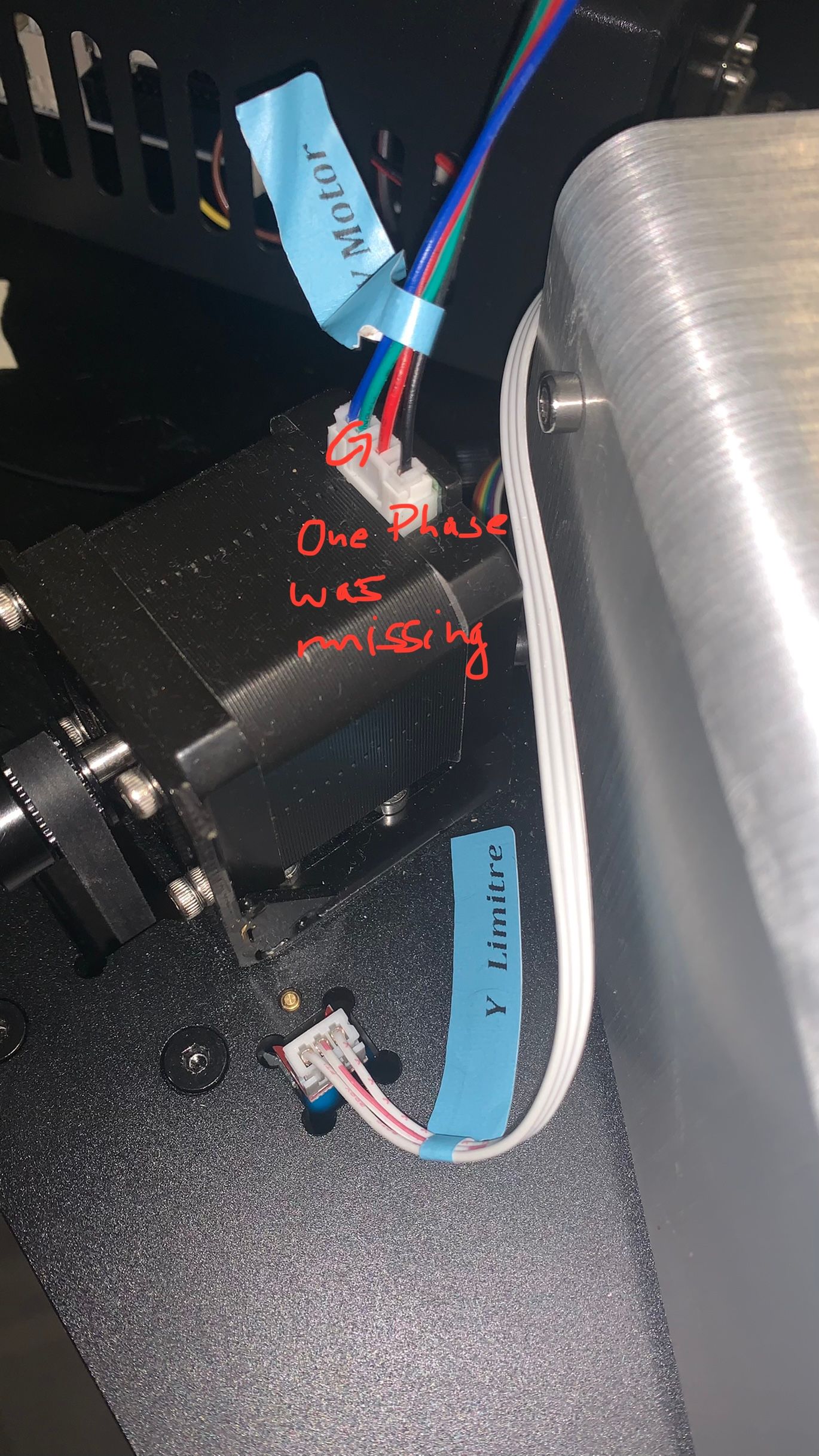

Dear @PHAEDRUX,

I thought with reference to eventual wiring mistakes it might come handy to make some photos. Therefore please find the photos attached. I hope it helps. Thank you very much.

Linus

-

I forgot

-

@phaedrux said in Tevo Little Monster stepper motor move only in one direction:

Check your motor phases are wired correctly: https://duet3d.dozuki.com/Wiki/Choosing_and_connecting_stepper_motors#Section_Identifying_the_stepper_motor_phases

Did you check the motor phase pairs?

Now with the endstop corrected if you remove the belts from the motor shafts and try to move the motors, does it spin correctly?

To see if you can get them to move without homing first, send G92 X100 Y100 Z100 and then try to issue movement commands for each motor individually by sending

G91

G1 H2 X10

G1 H2 X-10

G1 H2 Y10

G1 H2 Y-10

G1 H2 Z10

G1 H2 Z-10 -

Thanks for the reply. Following your advise I and lowering the current from 1000mA to 800mA and up to 1500mA by executing G92 X100 Y100 Z100 and then G91 H2 X10 I got a movement on down (attached files) and by using G91 H2 X-10 the exact same result and the same direction.

As far as I understand I should have had a movement in two directions up&down. How can it be that in my case all three motors move down x10 and x-10, y10 and y-10 and z10 and z-10 for both commands? Any hint ?Thanks

linus

P.S. : Attached Motor Info

[0_1628509204934_DUET TLM.zip](Uploading 100%) -

-

@linus4200 did you check your motor phases like @Phaedrux asked?

https://duet3d.dozuki.com/Wiki/Choosing_and_connecting_stepper_motors#Section_Identifying_the_stepper_motor_phasesMost likely you've got one of them switched. You need to use a multimeter to check them (as shown in the guide).

-

Thank you very much to both of you, as without your help, I would never ever have expected, that, purchasing a new printer, they deliver it, without wiring correctly the stepper motor and as consequence only one phase is working.

With reference to the Home All Button. Does the procedure HOME ALL has to be successfully be executed for the Home X,Y & Z Button to appear on the Dashboard? Once again, thank you for your assistance. I did not expected to get proven the proverb " someone is to poor to buy cheap" so soon. Thanks.

linus

-

@linus4200 I've seen the phases paired wrongly before but not that! Glad you fixed it though

For a delta, you only ever do homeall to home all towers at once. If you home one tower on its own while the others were at the bottom you'd rip your effector in two! Separate homex, homey, homez are for cartesian/corexy printers

-

By using the home all button x and y move towards the end-stop while z does not move, which could break the rods, if I do not switch off before. Is this still related to my former problem or

do I miss something?linus

-

@linus4200 well that means you have another issue...

First, follow @Phaedrux's previous advice and check if all three of your motors spin at all:

@phaedrux said in Tevo Little Monster stepper motor move only in one direction:

Now with the endstop corrected if you remove the belts from the motor shafts and try to move the motors, does it spin correctly?

To see if you can get them to move without homing first, send G92 X100 Y100 Z100 and then try to issue movement commands for each motor individually by sending

G91

G1 H2 X10

G1 H2 X-10

G1 H2 Y10

G1 H2 Y-10

G1 H2 Z10

G1 H2 Z-10From this you should see if they all move, and double-check they are spinning in the correct direction.

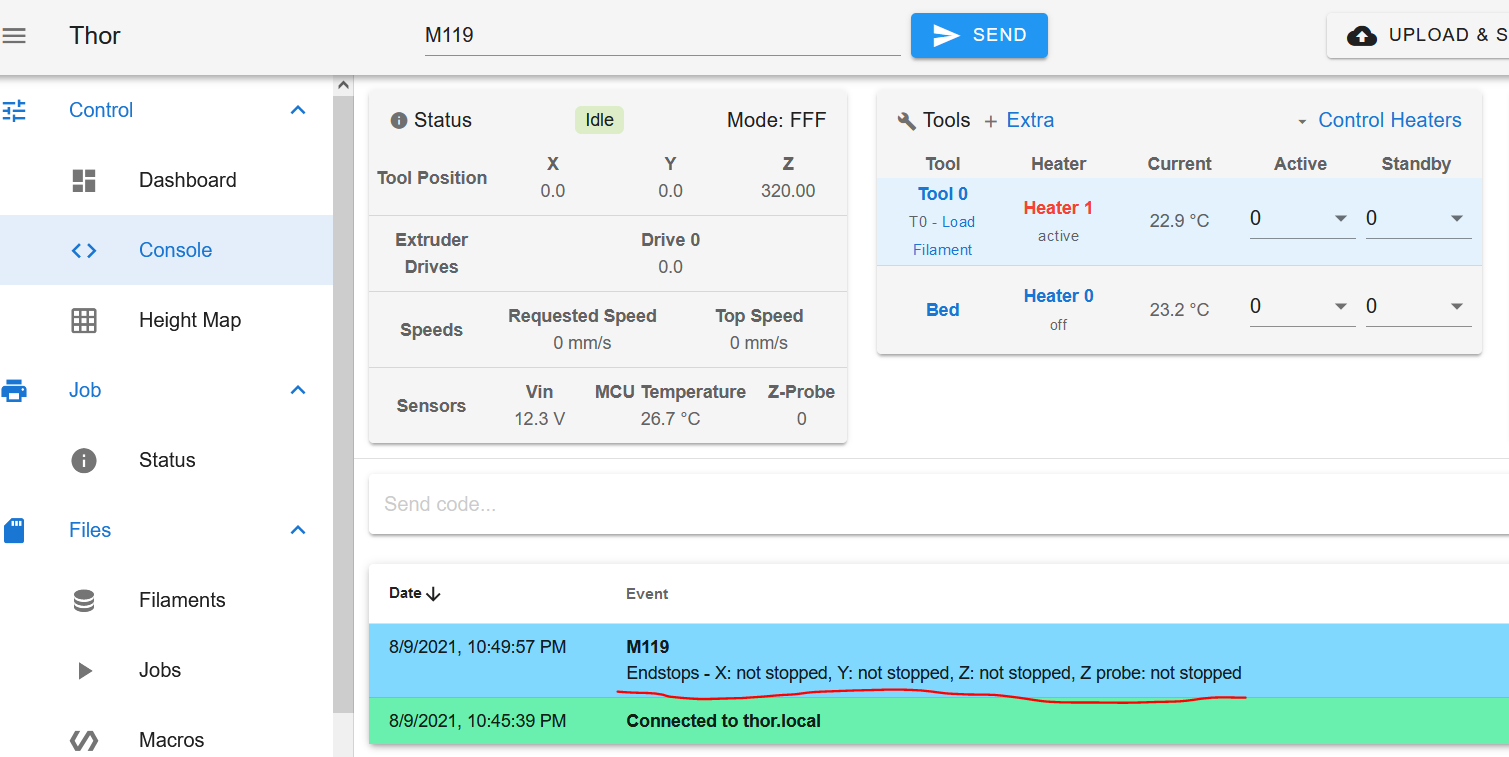

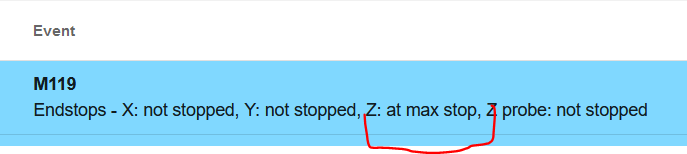

After you have done that, you can check if your endstops are working correctly. With the carriages away from the endstops (i.e. so the endstops aren't pressed), send M119 via the console in DWC. You should get a response like this, showing that the endstops are not pressed:

Now press & hold each of the endstop switches in turn and see if they react by sending M119 again. You should get something like this for each saying it's at the 'max stop' (in this one I'm pressing the Z endstop switch)

Do both of those sets of tests and let us know the results andwe can help you from there

-

@engikeneer said in Tevo Little Monster stepper motor move only in one direction:

G91

G1 H2 X10

G1 H2 X-10

G1 H2 Y10

G1 H2 Y-10

G1 H2 Z10

G1 H2 Z-10Dear @engikeneer please find attached the result of what I should try.

Moreover you find what happens clicking home all. I think the video

explains it better than I could do in writing. Thankslinus

-

I see your photos and video, but I don't have any context for them. What's happening exactly?

The video looks like you've got movement working in both directions now?

In your photos, it looks like you've tested the endstops.. And they respond appropriately to being triggered? Do they also match the towers as expected? See here: https://duet3d.dozuki.com/Wiki/ConfiguringRepRapFirmwareDeltaPrinter#Section_Testing_the_motors_and_endstops_individually

The big red error message in your photos. When does that pop up?

-

@linus4200 in both pictures, it says Z at max stop. If you weren't pressing the Z endstop in the first picture, that means you have a problem with the z endstop.

Check the wiring and repeat that test until you see the z endstop working properly. There's some more details in the guide page that @Phaedrux has posted

-

Dear @Phaedrux

The Fotos and Video correspond to the previous post of @engikeneer to check result

Of m119 and to execute G1H2 X10, G1 H2 C-10 then the same for Y&Z to check motor movement and the “home all” video shows what happened clicking the home all button, as you can see there, x and y carriage move up to the endstop while the z carriage does not move. I hope I checked correctly. Thank you very muchLinus

-

@linus4200 said in Tevo Little Monster stepper motor move only in one direction:

x and y carriage move up to the endstop while the z carriage does not move.

This would be explained by the endstop status always reading as triggered as @engikeneer mentioned. So check your endstops wiring for Z.