An "hardware" advice for linear rails

-

@fcwilt said in An "hardware" advice for linear rails:

@thedragonlord

Hi,

Well you could put it on top if you designed and created new brackets for supporting the pulleys.

Or you can put it on the side.

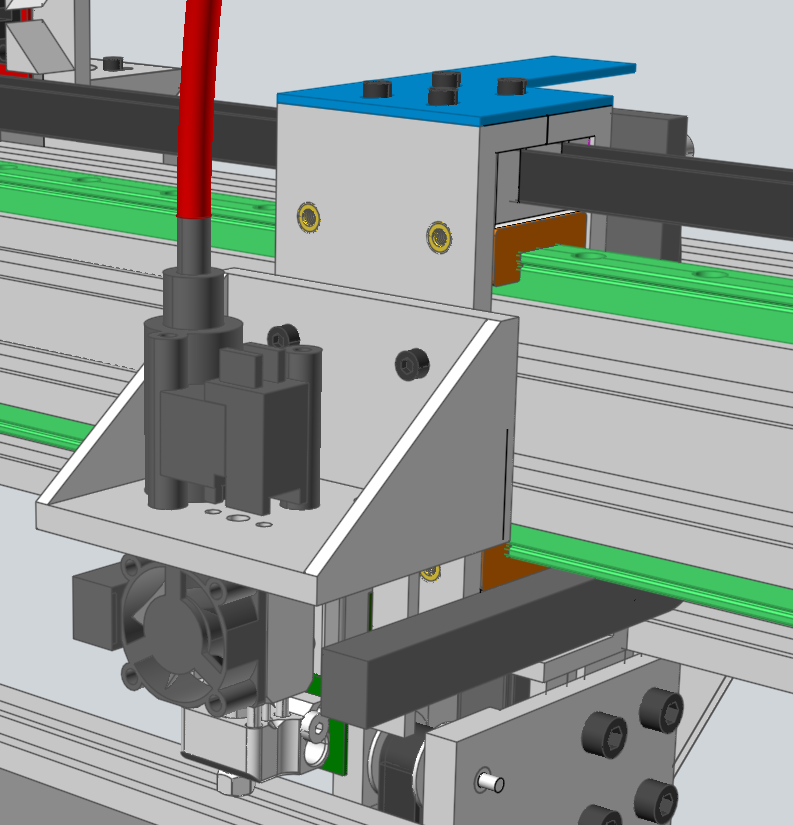

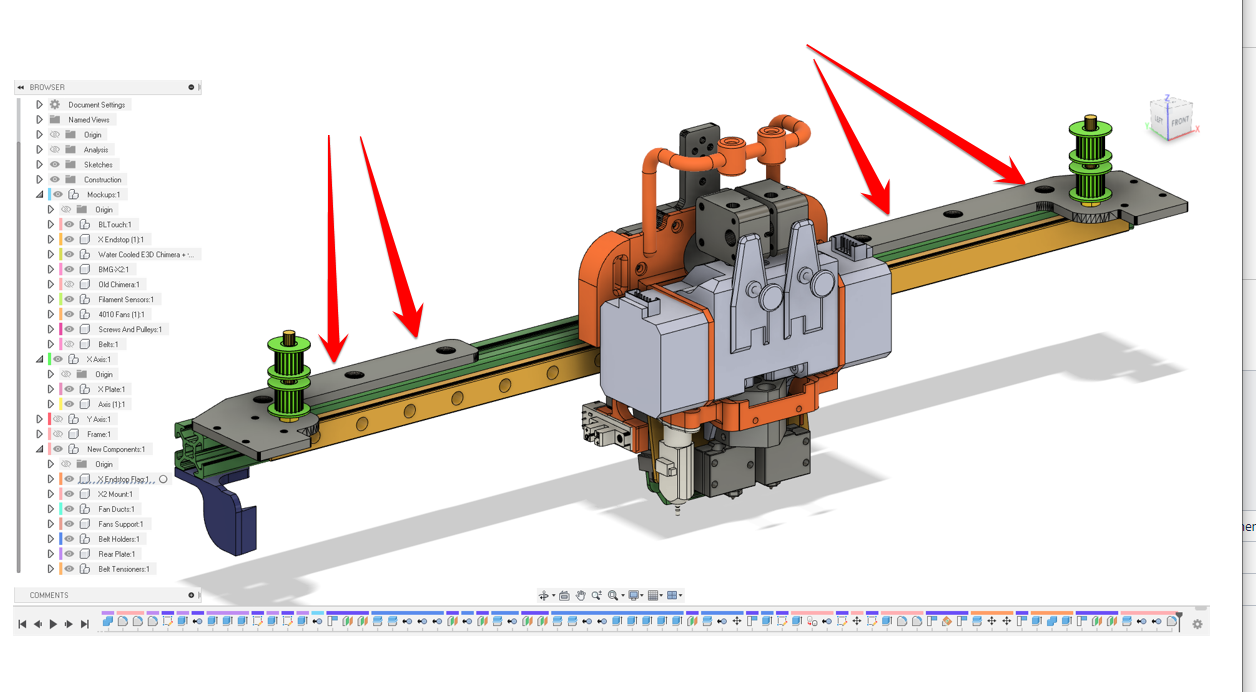

I have a printer with two rails mounted on a 20x40 extrusion, carrying the hotend mount. I have colored them green in the image below:

Frederick

as you can see unfortunately I can't mount it on the top of the X 2020 because in the sides there are the flanges to attatch the axis to the Y linear rails

-

@thedragonlord

Why not add a second rail to the other side and mount the second Bondtech there? Like a saddlepack.

You'll win some printarea in one direction, but also loose some in the other direction. Frame and bed shape might need changes too

But the weight distribution is even. (think: torsional forces for the 2020 extrusion) -

@thedragonlord said in An "hardware" advice for linear rails:

as you can see unfortunately I can't mount it on the top of the X 2020 because in the sides there are the flanges to attatch the axis to the Y linear rails

I'm sure that's true but I don't see the flanges you are talking about.

In any case mounting a second rail is fine, as long as you make sure there is no binding.

In my case the hotend mount is tall and the Nimble Drive cable exerts a certain amount of force on the mount. Without the bottom rail the hotend mount "rocked" a bit in the Y direction.

Frederick

-

@o_lampe said in An "hardware" advice for linear rails:

@thedragonlord

Why not add a second rail to the other side and mount the second Bondtech there? Like a saddlepack.

You'll win some printarea in one direction, but also loose some in the other direction. Frame and bed shape might need changes too

But the weight distribution is even. (think: torsional forces for the 2020 extrusion)What second Bondtech? The X2 is a single piece

-

@fcwilt said in An "hardware" advice for linear rails:

@thedragonlord said in An "hardware" advice for linear rails:

as you can see unfortunately I can't mount it on the top of the X 2020 because in the sides there are the flanges to attatch the axis to the Y linear rails

I'm sure that's true but I don't see the flanges you are talking about.

In any case mounting a second rail is fine, as long as you make sure there is no binding.

In my case the hotend mount is tall and the Nimble Drive cable exerts a certain amount of force on the mount. Without the bottom rail the hotend mount "rocked" a bit in the Y direction.

Frederick

Thanks! Here are the flanges (I'm not sure it's a correct technical name for the pieces):

-

@thedragonlord

OK then nevermind. I've also seen mirrored single Bondtech drives...

In you case you could use two standard BMGs and mount the BLTouch between them (below the 2020 rail)

Still talking about saddlepack fashion... -

As you probably already know the Voron 2 still has (it's changing) two MGN9H rails. One on the front and the other one underneath. That's working good if you can align them properly and if your extrusion isn't twisted or curved.

But with a toolhead of 700g hanging on one side I'm really more concerned with the torsional rigidity of the 2020 extrusion. I guess it might be a bit flexy?

-

@gixxerfast said in An "hardware" advice for linear rails:

As you probably already know the Voron 2 still has (it's changing) two MGN9H rails. One on the front and the other one underneath. That's working good if you can align them properly and if your extrusion isn't twisted or curved.

But with a toolhead of 700g hanging on one side I'm really more concerned with the torsional rigidity of the 2020 extrusion. I guess it might be a bit flexy?

with 700gr? i hope not..

-

@thedragonlord said in An "hardware" advice for linear rails:

@gixxerfast said in An "hardware" advice for linear rails:

As you probably already know the Voron 2 still has (it's changing) two MGN9H rails. One on the front and the other one underneath. That's working good if you can align them properly and if your extrusion isn't twisted or curved.

But with a toolhead of 700g hanging on one side I'm really more concerned with the torsional rigidity of the 2020 extrusion. I guess it might be a bit flexy?

with 700gr? i hope not..

If you do the maths, it might surprise you. A lot depends on the length of the beam. You need to know the modulus of elasticity of the material and the moment of inertia which depends on the cross sectional shape of the beam. A quick rough and ready calculation using the modulus of elasticity for 6063-T5 and the moment of inertia for 2020 as used by Open Builds for their extrusion, and assuming a length of 1 metre (to keep the maths simple), supported at both ends would deflect by 2.04mm if 700 gms was placed in the centre of such a beam.

Of course, you'd need to do the same calculations for the linear guide itself as this would add some stiffness to the composition. But I generally find it's best to do the maths in order to avoid what might be an expensive mistake.

-

@deckingman said in An "hardware" advice for linear rails:

@thedragonlord said in An "hardware" advice for linear rails:

@gixxerfast said in An "hardware" advice for linear rails:

As you probably already know the Voron 2 still has (it's changing) two MGN9H rails. One on the front and the other one underneath. That's working good if you can align them properly and if your extrusion isn't twisted or curved.

But with a toolhead of 700g hanging on one side I'm really more concerned with the torsional rigidity of the 2020 extrusion. I guess it might be a bit flexy?

with 700gr? i hope not..

If you do the maths, it might surprise you. A lot depends on the length of the beam. You need to know the modulus of elasticity of the material and the moment of inertia which depends on the cross sectional shape of the beam. A quick rough and ready calculation using the modulus of elasticity for 6063-T5 and the moment of inertia for 2020 as used by Open Builds for their extrusion, and assuming a length of 1 metre (to keep the maths simple), supported at both ends would deflect by 2.04mm if 700 gms was placed in the centre of such a beam.

Of course, you'd need to do the same calculations for the linear guide itself as this would add some stiffness to the composition. But I generally find it's best to do the maths in order to avoid what might be an expensive mistake.

wow...

-

@thedragonlord said in An "hardware" advice for linear rails:

wow...

A man of few words.

Would it be possible to redesign to use a 20x40 extrusion?

Frederick

-

@fcwilt said in An "hardware" advice for linear rails:

@thedragonlord said in An "hardware" advice for linear rails:

wow...

A man of few words.

Would it be possible to redesign to use a 20x40 extrusion?

Frederick

mmhh... not a bad idea! I'm using few words because I'm using my cell phone and I hate to write using the phone....

-

@thedragonlord You should also do your own maths and not trust an old fart who posts on a forum.

Having re-checked my rough and ready calcs, it looks like I was out by a factor of about 10. So (according to my latest back of an envelope calcs) the deflection of 1 metre length of 2020 with 700gms applied to the centre would actually be 0.29mm. That's still fairly significant but not as bad as 2.04mm. The addition of stiff linear rails will help but you'd need to do the maths to be sure if it's enough.

Having re-checked my rough and ready calcs, it looks like I was out by a factor of about 10. So (according to my latest back of an envelope calcs) the deflection of 1 metre length of 2020 with 700gms applied to the centre would actually be 0.29mm. That's still fairly significant but not as bad as 2.04mm. The addition of stiff linear rails will help but you'd need to do the maths to be sure if it's enough.On the other hand, 4020 extrusion (with the 40mm side being vertical) has a moment of inertia roughly 7 times greater than 2020, which according to my second back of an envelope calcs would give a deflection of 0.043mm with the same 700gms applied to the entre of a a 1 metre length.

-

@thedragonlord said in An "hardware" advice for linear rails:

I'm using few words because I'm using my cell phone and I hate to write using the phone....

I watch folks speeding along using two thumbs. I never got the hang of it. I make enough mistakes using one finger which appears to be a very stupid finger. That's why the phone is rarely on my person.

Frederick

-

@deckingman said in An "hardware" advice for linear rails:

The addition of stiff linear rails will help but you'd need to do the maths to be sure if it's enough.

Isn't it the purpose of the extrusion to support the rail and not vice versa?

I know that you know, just wanted to point out the dilemma. -

@o_lampe said in An "hardware" advice for linear rails:

@deckingman said in An "hardware" advice for linear rails:

The addition of stiff linear rails will help but you'd need to do the maths to be sure if it's enough.

Isn't it the purpose of the extrusion to support the rail and not vice versa?

I know that you know, just wanted to point out the dilemma.Yes, as a general rule. But if the guide is bolted to the extrusion at multiple points along its length, then the resultant composite beam will be stiffer than either the aluminium extrusion, or the linear guide alone.

-

If you're worried about rigidity, why not use square aluminum tube instead of 2020 t-slot? T-slot, especially 2020, is like spaghetti. 20mm square tubing is more rigid and probably lighter.

T-slot is useful stuff if you have to mount a lot of stuff and keep moving it around. In this case, you're putting one or two linear rails on it and you won't be moving them around.

-

@deckingman said in An "hardware" advice for linear rails:

Having re-checked my rough and ready calcs, it looks like I was out by a factor of about 10. So (according to my latest back of an envelope calcs) the deflection of 1 metre length of 2020 with 700gms applied to the centre would actually be 0.29mm.

Deflection os a simply supported beam with point load at mid span is proportional to cube of span, so 'simplifying' the span to 1m introduces quite a large error if the span isn't actually that.

Taking an I value I find on the internet for 20x20 of 6988mm^4, assuming a 500mm span (I scaled bolt holes assuming 25mm pitch in the rail), 700g (ie 7N) midpsan load, E value of 70GPa (typical alu alloy), the deflection is about 0.04mm, which is more palatable.

Plus, as noted, this ignores the stiffening effect of the rail. If that's 8mmx12mm that's an I of about 1460mm^4, but the E will be 200GPa ish, so the stiffness of the rail is about two-thirds of the 2020. (That's ignoring bolt holes, but they'll probably only reduce it by 1% or so on average.) That makes the composite section 65% stiffer, brings deflection down to around 0.02mm.

This ignores sel;f-weight of the 2020 and the rail. Call it 0.03mm.

-

Hi,

just adding my 2 cents;

IIRC the Voron community is battling the bimetallic effect of a steel rail bolted to an aluminium extrusion, affected by the build volume temperature elevation due to the heated bed. This would also be alleviated by having steel rails on opposing sides of the alu extrusion, either top/bottom or front/back.

Another thing worth mentioning, especially cheaper linear rails might not be 100 % stiff, so adding a second rail will greatly limit tilting around the longitudinal axis of the linear rail. Just make sure to make the mounting of the second linear bearing adjustible in both directions, because you might introduce binding forces otherwise.

...because you know what they say, if you can't make it precise, make it adjustable hehe

-

@achrn said in An "hardware" advice for linear rails:

Deflection os a simply supported beam with point load at mid span is proportional to cube of span, so 'simplifying' the span to 1m introduces quite a large error if the span isn't actually that.

True - but if you want to be pedantic, the OP didn't specify a beam length.

Taking an I value I find on the internet for 20x20 of 6988mm^4,.....

I hope you mean 6988 * 10^-12.

assuming a 500mm span (I scaled bolt holes assuming 25mm pitch in the rail),

But now you are making assumptions to ascertain the beam length, so your calculations could equally introduce a large error

700g (ie 7N) midpsan load,

As we are being pedantic, 700g is actually 6.867N

E value of 70GPa (typical alu alloy)

I used 68.9GPa which is the true value for 6063-T5 but of course, we could both be wrong as the OP hasn't specified the extrusion type.

Anyway I'm done. Hopefully the OP will see through the pedantic criticism of my efforts to help him, and realise the value of doing his own calculations.