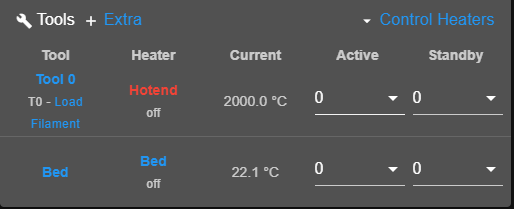

PT1000 on toolboard showing 2000c

-

@jay_s_uk

okay. I moved the heater to the 6HC so its working. -

@jay_s_uk I disagree. I have my hotend heater connected to my Duet 3 and my thermistor connected to my tool board and it works fine.

-

@dhusolo it was a restriction in 3.3.0

-

@jay_s_uk said in PT1000 on toolboard showing 2000c:

@dhusolo it was a restriction in 3.3.0

To expand on that, it is a restriction on all "3"series firmware versions up to and including 3.3.0 and affects all expansion boards, not just tool boards.

-

I understand that but what I'm saying is that I'm running 3.3.0 and I have my hotend heater on my Duet 3 and the hotend thermistor is on the toolboard.

M308 S0 P"0.temp0" Y"thermistor" A"Bed" T100000 B4725 C0.0000000706 ; configure sensor 0 as thermistor on pin temp0 M308 S1 P"20.temp0" Y"thermistor" A"Hotend" T100000 B4680 C6.455513e-8 ; configure sensor 1 as thermistor on pin temp1-Matrix M950 H0 C"0.out1" T0 ; create bed heater output on out0 and map it to sensor 0 M950 H1 C"0.out2" T1 ; create nozzle heater output on out1 and map it to sensor 1 -

@dhusolo https://duet3d.dozuki.com/Wiki/Duet_3_firmware_configuration_limitations

According to the above, it's a permanent limitation for safety reasons. Maybe the rationale has changed but the documentation hasn't caught up?

-

@deckingman The documentation on the limitation says:

A heater on an expansion or tool board can only be controlled by a temperature sensor on the same expansion board. This is a safety precaution.

@dhusolo said:

I have my hotend heater connected to my Duet 3 and my thermistor connected to my tool board and it works fine.

So it's the other way around from the firmware limitation, and (apparently) works.

Ian

-

Soooo.....Should I create another post so we can get back on topic?

I have my heater and my PT1000 currently attached and mapped to my Duet36HC, so they are working, when I have attached to my toolboard1LC:

P1000:

Connected and Mapped to Toolboard1LC Temp0 - Does not work

Connected and Mapped to Toolboard1LC Temp1 - Does not workHotend:

Connected and Mapped to Toolboard1LC Out0 - Does not workFan 1:

Connected and Mapped to Toolboard1LC Out1 PH4 - Does not workFan 2:

Connected and Mapped to Toolboard1LC Out2 PH3 - Does not workBLTOUCH:

Connected and Mapped to Toolboard1LC IO0 PH4 - WorksExtruder:

Connected and Mapped to Toolboard1LC Driver0 PH4 - WorksX Endstop:

Connected and Mapped to Toolboard1LC IO2 PH3 - Works -

@practac can you post your current config and an output of

M122 B20 -

@jay_s_uk that was sent yesterday along with another M122 . Here is the output from the M122 B20

M122 B20

Diagnostics for board 20:

Duet TOOL1LC firmware version 3.3 (2021-06-15 16:12:58)

Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1)

Never used RAM 3660, free system stack 2789 words

Tasks: Move(notifyWait,0.0%,153) HEAT(delaying,0.0%,117) CanAsync(notifyWait,0.0%,65) CanRecv(notifyWait,0.0%,76) CanClock(notifyWait,0.0%,65) TMC(delaying,2.8%,57) MAIN(running,92.2%,424) IDLE(ready,0.0%,27) AIN(delaying,4.9%,142), total 100.0%

Last reset 00:01:01 ago, cause: power up

Last software reset time unknown, reason: AssertionFailed, available RAM 3392, slot 2

Software reset code 0x0120 ICSR 0x00000000 SP 0x2000415c Task Freestk 129 bad marker

Stack: 00000544 00022ffc 00019b65 20003134 00016cff 20003134 000163d1 20000ed0 00000000 00000001 00008275 200071c8 200071c8 200071e0 00000000 20000f50 00011647 000223b8 00022474 00021ac8 00019b05 200071c8 200071c8 20000f50 000083ed 200071d8 000009c7

Driver 0: position 0, 675.3 steps/mm, standstill, SG min/max 0/0, read errors 0, write errors 0, ifcnt 12, reads 30754, writes 12, timeouts 0, DMA errors 0, steps req 0 done 0

Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0

Peak sync jitter 0/5, peak Rx sync delay 195, resyncs 0/0, no step interrupt scheduled

VIN: 24.3V

MCU temperature: min 17.5C, current 22.8C, max 22.8C

Ticks since heat task active 64, ADC conversions started 61558, completed 61557, timed out 0, errs 0

Last sensors broadcast 0x00000000 found 0 69 ticks ago, loop time 0

CAN messages queued 182, send timeouts 0, received 470, lost 0, free buffers 37, min 37, error reg 110000

dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0

Accelerometer detected: no

I2C bus errors 0, naks 3, other errors 0 -

@practac your config yesterday doesn't reference the toolboard for the PT1000. so can you confirm that thats definitely the one you're using?

-

@jay_s_uk yes sir it it the same toolboard.

-

This post is deleted! -

@practac no, I meant is the config you posted yesterday definitely the version you are trying to use? Because if it is I'm not surprised it doesn't work. I'm asking because you've mentioned changing things to try and get it to work

-

This post is deleted! -

@practac said in PT1000 on toolboard showing 2000c:

M308 S1 P"0.temp1" Y"pt1000" A"Hotend" T100000 B4680 C6.455513e-8 ; configure sensor 1 as pt1000 on pin 20.temp0

You should leave off the T, B and C parameters for a PT1000. Although I doubt whether it will help. This may be a case of ESD damage to the series resistor on the toolboard.

Can you reconfigure your setup to use the PT1000 on the toolboard with those parameters removed?

-

@phaedrux

remapped temp probe to this:M308 S1 P"20.temp0" Y"pt1000" A"Hotend" ; configure sensor 1 as pt1000 on pin 20.temp0

Still showing Hotend at 2000c

Tried the other temp port on the toolboard with this:

M308 S1 P"20.temp1" Y"pt1000" A"Hotend" ; configure sensor 1 as pt1000 on pin 20.temp0Same results

-

Please send an email to warranty@duet3d.com and CC your reseller. Include a link to this forum thread and the details of your original purchase. You'll receive a reply with a form to fill out.

-

@phaedrux said in PT1000 on toolboard showing 2000c:

Done. Thank you and thank you to all the others that assisted.