Occasional underextrusion

-

This seems to happen mostly around more detailed areas and I suspected that it might have to do with the acceleration due to pressure advance. I lowered the extruder's acceleration and jerk with no change. I have also increased the amperage of the extruder motors from 800 to 1000 to 1400mA with the problem still seeming to appear at the same rate.

The extruder is an E3D titan in a flying extruder configuration with an ~180mm bowden tube to an E3D chimera with a .35mm nozzle.

This problem causes significant issue with the strength of functional parts.

Here is the config.g: config.g

Thanks -

@jim546 does it consistently do it in the same place, same Gcode, same filament or is it random?

-

@jumpedwithbothfeet

It does do it with different filaments. I'll need to see if I can recreate it intentionally. and see if its consistent is some spots or random.

thanks -

@jim546 trying t9 narrow down if there are repeatable features etc that cause it will definitely help.

One thing that springs to mind would be filament swell in the heatbreak. I've had this before when I used too high retraction and PA so it pulled the filament too far back and I got occasional clogs. Sometimes it would clear quickly (and just look like under extrusion). Related, it could be that you are getting heat creep up the heatbreak/filament on slower layers.

Once you've found a sample print you can repeat it on, try reducing your retraction amount, PA, and/or print temp

-

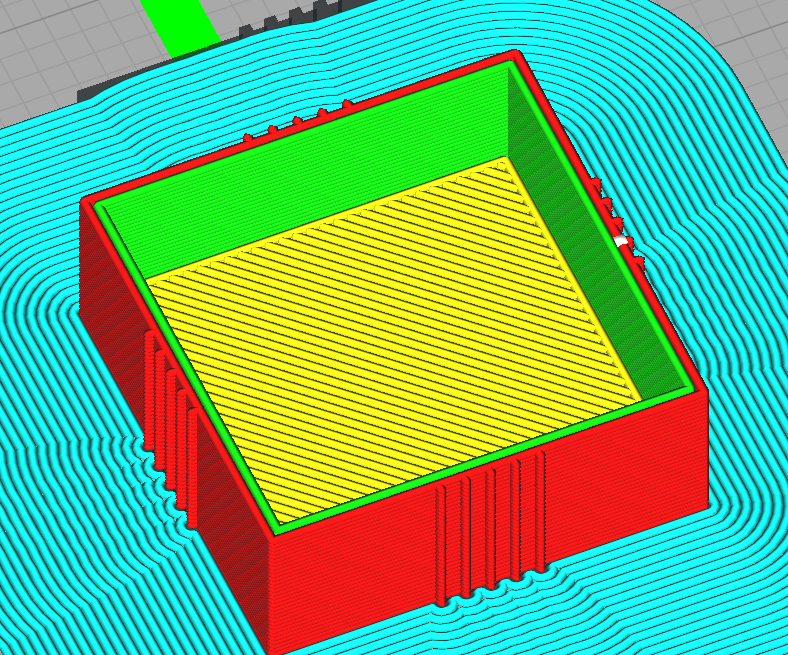

I've created a model that recreates the issue

When the extruder goes over the small surface details the filament retracts more than it extrudes. When I first saw this I thought it was a cut and dry case of skipping steps. I lowered the jerk and acceleration more and more until I could watch it accelerate slowly but it was still doing the same thing.

video link here.

extrusion_Trim.mp4

The ptfe tube is separated from the top of the extruder so I could more easily see how far its retracting.

I checked the gcode to make sure there were no problems there and printed the model with pressure advance disabled. I also reset the acceleration and jerk. The model printed normally but with the expected problems from no pressure advance. -

Have you checked the bearings on that titan extruder?

-

@phaedrux What am I looking for in the bearings? The gear seems to be solidly mounted with no way for the teeth to skip or for the gear to move around.

I'm going to try to print the model on the second extruder to see if it does the same thing.

-

The small bearings that hold the large gear in the assembly can become damaged. The can begin to jam on direction change. Sometimes you can hear it. If you remove the hobbed bolt you can sometimes see the bearings lubricant has leaked out and if you rotate by hand gently you can feel they are rough. This happens very easily if the bolt is over tightening.

-

@phaedrux

I took the extruder off of the motor and reassembled it. The gear spins freely within the bearings when under load.

I've switched to the other extruder and haven't noticed it yet but I haven't had time to tried to try and cause it yet.