I could use some help

-

@mac said in I could use some help:

@fcwilt you're not going to like this, but here goes:

G1 H1 Y-10 F3600 would NOT move the bed. I tried twice, and I clicked multiple times each time.

Then I changed H1 to H2.

The command sent the bed back to the endstop 10 mm's at a time. When it was at -220 I looked to see what's what. There was another 10mm's to go, so I clicked on the send button. The bed went back that 10mm's, and depressed the endstop.

Then I clicked on the Y+50 joy button at the far right of Home Y. Instead of going 50mm's, the bed went all the way to the front of the printer, and stopped without pounding on the adjustment cap.

This machine has a mind of it's own. My apologies for such bad news.

You did re-boot the printer after editing the config.g file?

I have no idea why H2 would work and not H1. Perhaps because H2 is not checking for the endstop to be activated and H1 is.

But you cannot use H2 to home, it has to be H1.

Here is a set of steppers that might fit - they are 39mm instead of 38mm and their specs are much better in regards to resistance and inductance:

How much longer then 38mm could you fit? The larger ones tend to have more power and better specs.

Frederick

-

@mac said in I could use some help:

@fcwilt you're not going to like this, but here goes:

G1 H1 Y-10 F3600 would NOT move the bed. I tried twice, and I clicked multiple times each time.

Then I changed H1 to H2.

The command sent the bed back to the endstop 10 mm's at a time. When it was at -220 I looked to see what's what. There was another 10mm's to go, so I clicked on the send button. The bed went back that 10mm's, and depressed the endstop.

Then I clicked on the Y+50 joy button at the far right of Home Y. Instead of going 50mm's, the bed went all the way to the front of the printer, and stopped without pounding on the adjustment cap.

This machine has a mind of it's own. My apologies for such bad news.

Here is a thought. Did you run M119 to check the endstop status first?

If the Y endstop were already activated then the G1 H1 would not move.

Frederick

-

@fcwilt these motors are 42 X 42 X 37. The screw spacing is 33. I’m going to need the same size motors to fit this printer. But I want to get motors that are up to Duet’s abilities. My budget is up to a Hundred dollars for 4 motors.

-

@fcwilt my master taught me to Always M119 first.

-

-

@mac said in I could use some help:

@fcwilt my master taught me to Always M119 first.

And what did it report?

Inquiring minds want to know!

Frederick

-

@mac said in I could use some help:

@fcwilt these motors are 42 X 42 X 37. The screw spacing is 33. I’m going to need the same size motors to fit this printer. But I want to get motors that are up to Duet’s abilities. My budget is up to a Hundred dollars for 4 motors.

So even the extra 2mm of the ones I linked to is too much?

Drat.

Frederick

-

@mac said in I could use some help:

@fcwilt @droftarts what do you think of this motor?

https://www.mybotonline.com/download/17HS15-1704S.pdf

https://www.mybotonline.com/download/17HS15-1704S_Torque_Curve.pdf

Mac

Well the specs are better in several ways.

And the price is right.

How long to get them?

Frederick

-

@fcwilt I’m trying to get them from stepper online

-

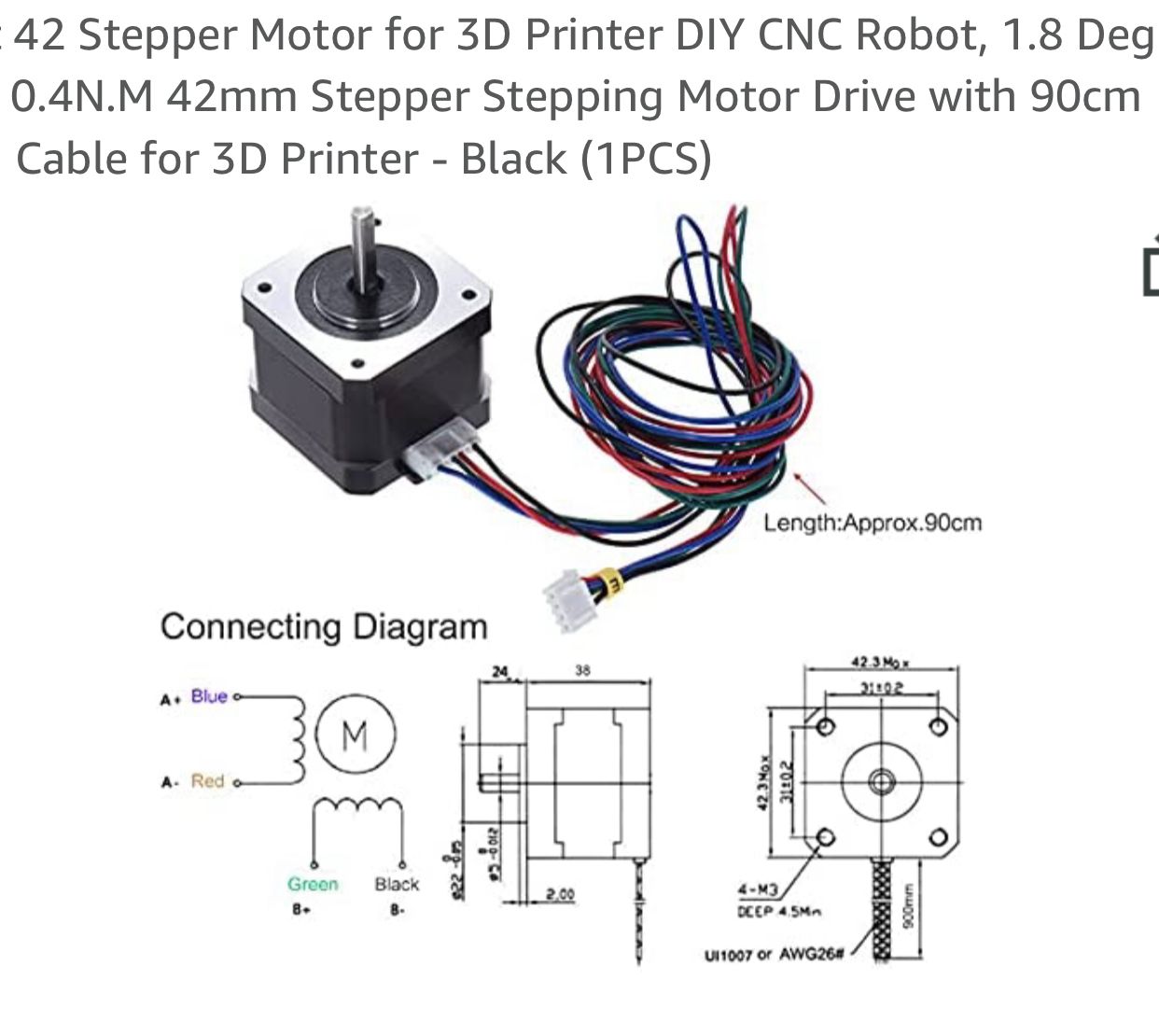

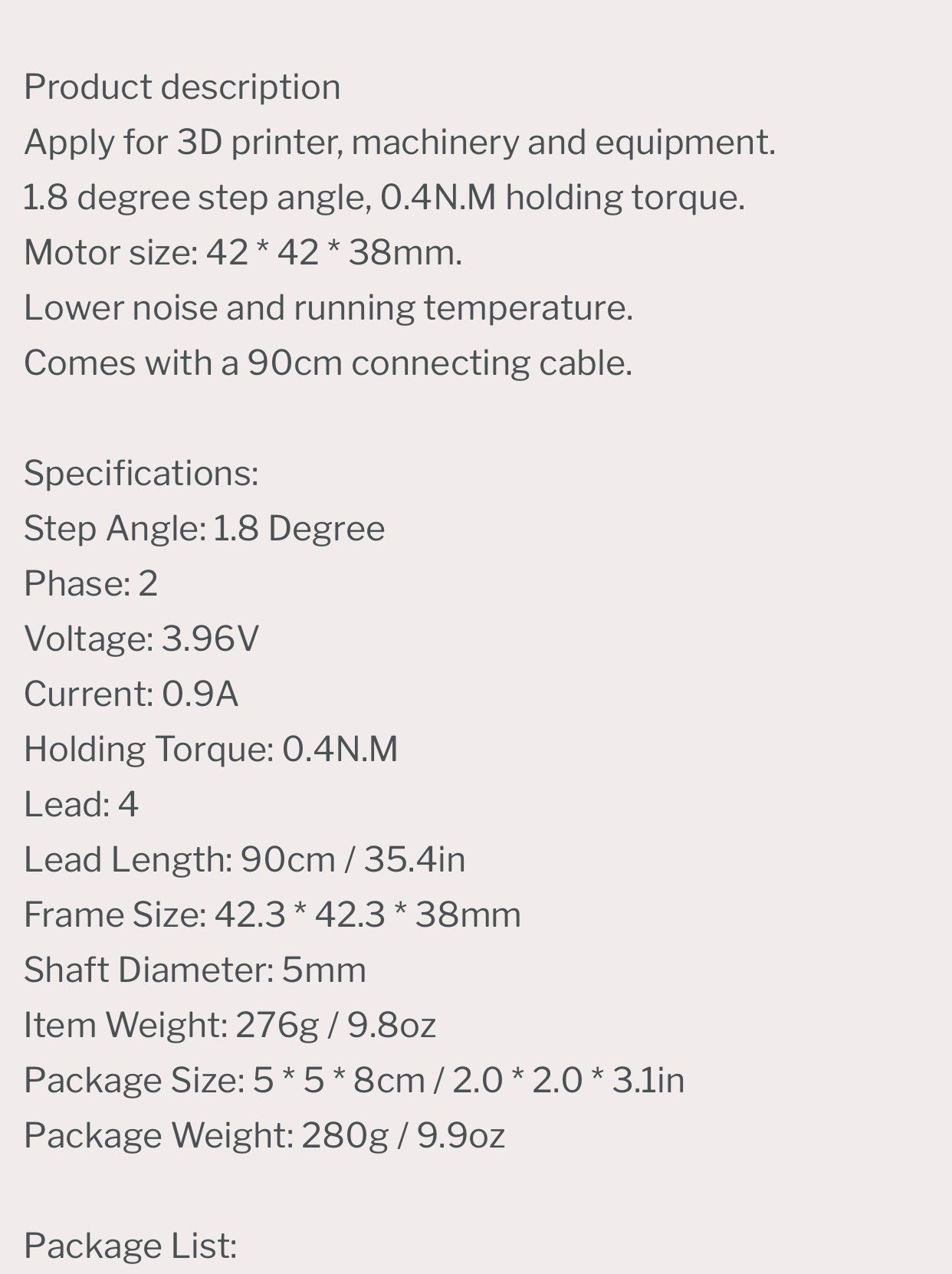

@fcwilt @droftarts I’d like to know what you think of the motor specs in the picture below. Would this motor play nice with the Duet3D Mini 5+? Would it be better than the motors in the XVico? It matches up perfectly with those motors.

-

-

@mac

No, those don't look good at all.

You really cannot fit the 39mm ones I linked to?

Frederick

-

@fcwilt the 42X39 for the X-motor works. It works for the Extruder also, and it will work for the Y-motor, but it will be super close to the bed’s back right adjustment wheel. The problem is the Z-motor. I’m going to have to raise the Z-screw 2mm’s. I’m just not looking forwards to that. But okay, here goes. I’ll order the motors right now.

Mac

-

@fcwilt end of July.

-

@fcwilt how am I going to deal with those Amazon motors being 24volts? Am I going to have to buy a 24 volt power supply?

-

-

This post is deleted! -

@fcwilt here's my power supply.

-

@mac 12V or 24V doesn’t matter too much. Motors work better with 24V, and can usually run faster (it’s like having more water in a dam; there’s more potential energy) but 12V is fine for most cases. If you switch to 24V you’ll have to change your bed and hot end heaters heaters too. 24V may or may not work better with your current motors and the Duet Mini 5+, I’m not sure.

Can you post a link for the actual motors you have purchased? I’m not quite sure which ones you got in the end.

One thing I’m still slightly concerned about is the quality of your crimping. Did you do all the motor crimps? Did you use the tool you posted a picture of, which is for ferrules rather than crimps? Poor connections could be causing some of the issues, too.

Lastly, it’s also possible that a lot of the problems is down to the endstops being wired NO. The endstop wires run next to the motor wires, and may well be picking up interference and registering false activations. I’d suggest running the endstop wires separately from the motor wires, or changing the connections on micro switches to NC.

Ian

-

@droftarts well, that’s a lot to think about. If I can find 12v motors maybe that’s a better solution. But then I’ll still have a problem with my bed not passing the pid tests. Thanks for the input.