I could use some help

-

@fcwilt @droftarts Do you see what I did wrong? With all 4 motors?

Mac

-

@mac said in I could use some help:

@fcwilt @droftarts Do you see what I did wrong? With all 4 motors?

Mac

No I don't.

Based on the diagram you posted the yellow/brown pair are connecting to one phase of the stepper and the red/black pair are connecting to the other phase.

And the connections to the Duet seem correct.

What do you think is wrong?

Frederick

-

@fcwilt this is why I’m not an electrical engineer. I decided to try shorting the two phases to make sure my “discovery” was correct. As you have indicated, post’s 1 and 3 (bottom and 3rd up) are a phase, and post’s 2 and 4 are the other phase. So that means red and yellow go together, and brown and black go together. Whew, my head is spinning!

Thanks for commenting. Your affirmation is helping, a lot.

Mac

-

@mac said in I could use some help:

@fcwilt this is why I’m not an electrical engineer. I decided to try shorting the two phases to make sure my “discovery” was correct. As you have indicated, post’s 1 and 3 (bottom and 3rd up) are a phase, and post’s 2 and 4 are the other phase. So that means red and yellow go together, and brown and black go together. Whew, my head is spinning!

Thanks for commenting. Your affirmation is helping, a lot.

Mac

On the Stepper and the Duet A+ and A- are one phase, B+ and B- are the other phase.

Frederick

-

@fcwilt it’s hard for me to understand this because what I always see is A+, A-, B+, B-. I don’t know which wire of each phase is minus, or plus for that matter. That’s what’s hanging me up on this issue. If it doesn’t water, (I’ve heard that), why is the wiring of the motors presented that way? Why does Duet3D label their pins that way? You know?

-

@mac said in I could use some help:

@fcwilt it’s hard for me to understand this because what I always see is A+, A-, B+, B-. I don’t know which wire of each phase is minus, or plus for that matter. That’s what’s hanging me up on this issue. If it doesn’t water, (I’ve heard that), why is the wiring of the motors presented that way? Why does Duet3D label their pins that way? You know?

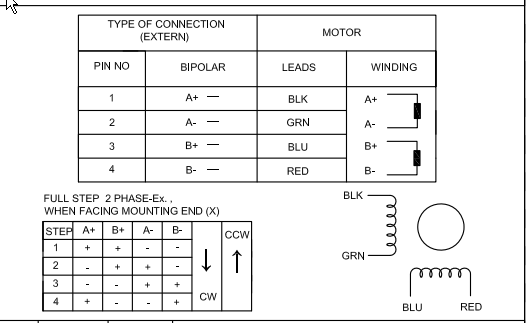

Here is a fairly typical stepper diagram showing how applied signals translate into steps:

Down on the lower left, notice the chart that has STEP 1,2,3,4 in the left column.

Notice that for Step 1 the + and - symbols under the columns for A+, B+, A- and B-.

That tells you when you apply a positive voltage to A+ and B+ and the corresponding negative voltage to A- and B- the stepper will move to Step 1.

As the board changes the voltages applied to the coils, so they match the chart, the stepper will move from Step 1 to Step 2 to Step 3 to Step 4.

And while it may not be obvious if the polarity applied to one of the coils happens to be the opposite of what the chart calls for the only thing that happens is the stepper turns in the reverse direction.

So, as long as you connect the A terminals for the Duet to the one of the coils and the B terminals of the Duet to other coil you can control the direction of rotation with the S parameter of the M569 commands.

Frederick

-

@fcwilt it truly is a magic borne of human ingenuity.

The motors didn’t show up today. Bummer. I’m hope for mail on Sunday now.

So could you talk about 24volts versus 12 volts. I know the change would cost me, but what are the hardcore benefits?

Mac

-

@mac said in I could use some help:

@fcwilt it truly is a magic borne of human ingenuity.

The motors didn’t show up today. Bummer. I’m hope for mail on Sunday now.

So could you talk about 24volts versus 12 volts. I know the change would cost me, but what are the hardcore benefits?

Mac

I already addressed that question in my post of 30th June. Scroll up and read the last bit again. Essentially you could get more torque out of the motors and use more powerful heaters. But if 12V gives you enough torque and enough heater power for your printer, you'll not see any benefit.

-

@fcwilt the motors arrived at 8:55 PM.

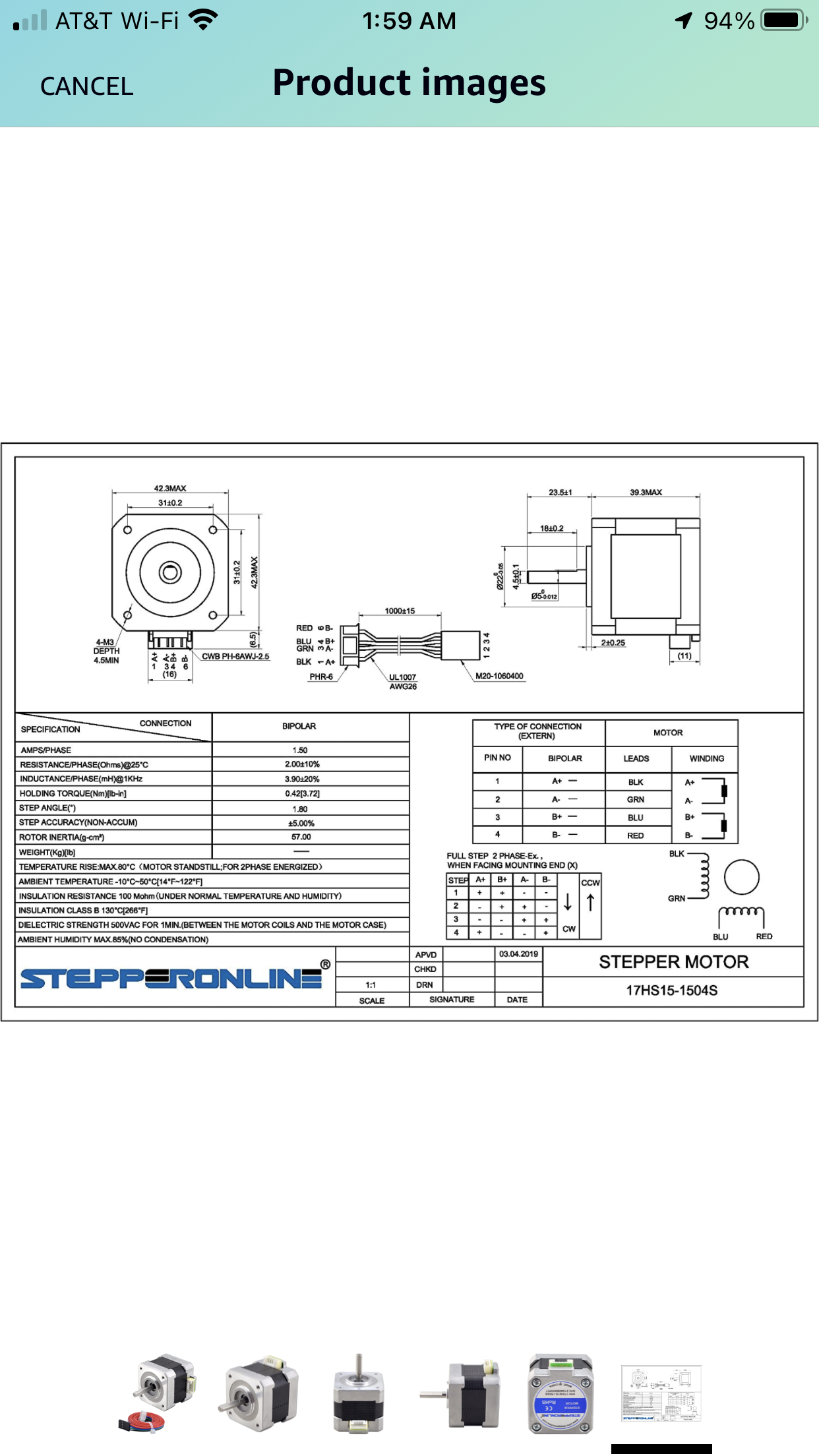

What, exactly, does RRF want to know about these motors?

What line of the config.g file needs to be edited, and how should it appear with the correct info?

Mac

-

@mac Motor current is all. A good setting is about 85% of the rating. So around 1.2 to 1.3 amps (1200 to 1300 mA) for those motors which are rated at 1.5Amps.

-

@deckingman just finished installing them. It all went well.

-

@mac said in I could use some help:

@deckingman just finished installing them. It all went well.

Once you are ready to test the new steppers remember to:

- execute M564 H0 S0 so you can jog each axis without homing or worrying about axis limits.

- use the jog buttons to verify each axis is moving in the correct direction

In the homing code I posted for you there was an absolute move at the end of each file.

Comment those absolute moves out for now, until we know the homing moves are working.

Frederick

-

@fcwilt my clock says 10:45; I've been up since 2 AM.

I just plugged the power into the machine.

My plan is to use RRF to tell the config.g file about these new motors. I'm still UNCLEAR as to what I should tell it. I'm also unclear about how to code it.

You referred to some code you wrote? Recently, or before?

I'm going to take this one step at a time, and try not to jump forwards without knowing where I'm going.

Mac

-

@mac There is an old adage which goes something like, "catch a man a fish and he'll feed himself for a day, but teach a man how to catch fish and he'll feed himself for life". Now I'm not trying to be disrespectful in any way, and I'll continue to help when I can, but if we carry on like this, you will have an endless list of questions and especially with the time differences due to geographic locations, you are going to have to wait for the answers. That's only going to add to your frustrations.

I'd like to teach you how to fish rather than keep feeing you now and then. So might I respectfully suggest, that you start looking at the documentation https://docs.duet3d.com/. Ian ( @droftarts ) has put a lot of time and effort into it and it really is very user friendly. Just start typing something in the search box at the top (e.g. "stepper motors") and it'll return a host a relevant topics which in turn will give you the information you need - often with actual code examples.

If you get used to doing this, you'll find you get all the answers you need much more quickly. Of course, we fellow users are on the whole a friendly bunch and we'll continue to help as a when our commitments allow. But we only know what we know from reading the documentation (and asking the odd question now and again).

-

@mac Okay, I found the "code." (It was back at 510.)

First, I feel like I have to tell my config.g that these new motors are X, where X is 1.2 - 1.3 amps / 1200 - 1300 mA.

I just set all the the motors to 1200 mA.

NOTE: I keep looking at the Z motor / Steps per mm; it's set at 4000? The Max. Speed Change (mm/s) is set at 1, the Max. Speed (mm/s) is set at 10, and the Acceleration (mm/s-squared) is set at 200? Is that right?

-

@deckingman thanks, contrary to what people believe, I do read the documentation. As for fishing, never caught a fish in my life, but my middle son was a commercial fisherman for 10 years? Fish is way too expensive for my budget.

-

@mac said in I could use some help:

NOTE: I keep looking at the Z motor / Steps per mm; it's set at 4000? The Max. Speed Change (mm/s) is set at 1, the Max. Speed (mm/s) is set at 10, and the Acceleration (mm/s-squared) is set at 200? Is that right?

Don't worry about most of those settings right now.

The only one of initial importance is the steps / mm.

It's easy enough to determine by testing what the value should be. Like before, you command a move of a known length, say, 50mm and measure with a ruler/scale how far it actually moved. From that you can determine the actual value or very close to it.

Frederick

-

@fcwilt I'll put that on the list of checks I'm making.

After I changed the information on the motors (from 600 mA to 1200 mA), and loaded a new config.g to DWC, surprise surprise, the "!^'s" are back on the endstops (05, 06, and 02).

I deleted them, and saved the config.g, and rebooted the machine.

All the motors are 1200 mA now, and the endstops are P"io5.in", P"io6.in" and P"io2.in".

That DO - something command that Ian suggested is gone. I'm going to put it back in (after I find in it in the thread).

Mac

-

@mac

; Drives M569 P0.0 D3 V0 S1 ; physical drive 0.0 goes forwards M569 P0.1 D3 V0 S1 ; physical drive 0.1 goes forwards M569 P0.2 D3 V0 S1 ; physical drive 0.2 goes forwards M569 P0.3 D3 V0 S1 ; physical drive 0.3 goes forwardsThe D3 V0 commands were suggested by Ian.

-

@mac Okay, TEST No. 1: M119 SEND.

Result: Endstops - X: not stopped, Y: not stopped, A: not stopped, Z probe: not stopped.

TEST No. 2: M119 SEND with each endstop depressed (one at a time).

Result: Endstops - X: at max stop, Y: not stopped, Z: not stopped, Z probe: not stopped.

Result: Endstop - X: not stopped, Y: at max stop, Z; not stopped, Z probe: not stopped.

Result: Endstops - X: not stopped, Y: not stopped, Z; at min stop, Z probe: not stopped.TEST No. 3: Execute M564 H0 S0 to jog each axis, are they going in the correct direction?

M564 H0 S0 executed.

Change to Dashboard.

All jog buttons are available.TEST X: I tried to jog right and left 10mm. Nothing happened.

TEST Y: I tried to jog Y-10. The bed shuddered in place.

TEST Z: I tried to jog Z-5 and Z+5. Z did not move.NOTE: I had to extend the X and Z endstops because I printed out a box for the board, and mounted it on the right Z rail. I don't know if this is possible, or not, but the wire I used to extend the endstops was slightly larger than the original wire.

There is also the possibility that the extensions are shorting out. I'll have to check that.

I'll also check the board to see if I made an error plugging the endstops in.

Given that the M119 tests worked, it seems like the endstops should be working?

RESULTS: X, Y, and Z failed to perform as expected.

TEST No. 4

G91 (sets relative movement, G1 H1 Y-10 F3600 what happens?

G1 H1 Y-10 F3600 SENT

RESULT: Bed shuddered in place.

At this point, I'm going to suspend the test.

Mac