Mistake True bed levelling G32

-

@sgk files for other peoples reference

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by Ben Levi - BLV developer as a basic version ; ================ General preferences ============ G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"duet3-sgk008" ; set printer name M669 K1 ; select CoreXY mode ; ================ Network ======================== M552 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; ================ Drives mapping ================= M569 P1 S0 ; physical drive 0.1 goes forwards - X driver M569 P2 S0 ; physical drive 0.2 goes forwards - Y driver M569 P3 S1 ; physical drive 0.3 goes forwards - Z1 Right driver M569 P4 S0 ; physical drive 0.4 goes forwards - Z2 Left driver M569 P0 S1 ; physical drive 0.0 goes forwards - extruder driver M584 X1 Y2 Z3:4 E0 ; set drive mapping ; ================ Drives settings ================ M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X200.00 Y200.00 Z800.00 E917.444 ; set steps per mm - for Matrix extruder:E324.214 ;M566 X700.00 Y700.00 Z24.00 E2000.00 ; set maximum instantaneous speed changes (mm/min) ;M203 X35000.00 Y35000.00 Z1200.00 E5000.00 ; set maximum speeds (mm/min) M566 X500 Y500 Z800 E600 ; Set maximum instantaneous speed changes (Jerk) (mm/min) M203 X20000 Y20000 Z600 E3600 ; Set maximum speeds (mm/min) ;M201 X6000.00 Y6000.00 Z400.00 E2500.00 ; set accelerations (mm/s^2) M201 X1000 Y1000 Z100 E600 ; Set accelerations (mm/s^2) ;M906 X1600 Y1600 Z1600 E1000 I30 ; set motor currents (mA) and motor idle factor in per cent M906 X1350 Y1350 Z1200 E700 I10 ; Set motor currents (mA) and motor idle factor in per cent M84 S60 ; Set idle timeout ; ================ Independent Z leveling (original 2 z-axis) ================= ;M671 X369.75:-59.75 Y155:155 S5 ; Define positions of Z leadscrews for Independent Z leveling M671 X-45.0:364.0 Y165.0:165.0 S5.0 ;bed compensation ; ================ Axis Limits ==================== ;M208 X-35.5 Y0 Z0 S1 ; set axis minima ;M208 X320 Y326.8 Z340 S0 ; set axis maxima M208 X-3.50 Y0 Z0 S1 ; Set axis minima M208 X340 Y320 Z350 S0 ; Set axis maxima ; ================ Endstops ======================= M574 X1 S1 P"io0.in" ; configure active-high endstop for low end on X via pin io0.in M574 Y2 S1 P"io1.in" ; configure active-high endstop for low end on Y via pin io1.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; ================ Z-Probe ======================== M558 P8 C"io2.in" A5 B1 H5 F120 T15000 ; set Z probe type to unmodulated and the dive height + speeds (for Mini IR sensor M558 P8 C"io2.in" A2 H5 F120 T15000) ;G31 P50 X11.5 Y65.8 Z1.035 ; set Z probe trigger value, offset and trigger height Z1.023 G31 P50 X-1 Y-20 Z1.300 ; Set Z probe trigger value, offset and trigger height M556 S50 X0 Y0 Z0 ; set orthogonal axis compensation parameters ;M557 X30:270 Y30:270 P4 ; define mesh grid M557 X20:270 Y20:270 P3 ; Define mesh grid ; ================ Heaters ============================================== M308 S0 P"temp0" Y"thermistor" A"Bed" T100000 B3950 ; configure sensor 0 as thermistor on pin temp0 M950 H0 Q10 C"out1" T0 ; create bed heater output on out0 and map it to sensor 0 (if NOT using SSR - delete Q10) M307 H0 R0.291 K0.269:0.000 D12.75 E1.35 S1.00 B0 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S100 ; set temperature limit for heater 0 to 100C M308 S1 P"temp1" Y"thermistor" A"Hotend" T107537 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out2" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 R2.438 K0.550:0.123 D5.13 E1.35 S1.00 B0 V24.1 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; ================ Fans & Lights ================== M950 F0 C"out7" Q500 ; create fan 0 on pin out7 and set its frequency M106 P0 S0 H1 T35 ; set fan 0 value. Thermostatic control is turned on M950 F1 C"out8" Q500 ; create fan 1 on pin out8 and set its frequency M106 P1 S0 H-1 C"Layers Fan" ; set fan 1 value. Thermostatic control is turned off M950 F2 C"out9" Q500 ; create fan 2 on pin out9 and set its frequency (lights) M106 P2 S0.2 H-1 C"Lights" ; set fan 2 value. Thermostatic control is turned off (lights) ; ================ Tools ========================== M563 P0 D0 H1 F1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; ================ Miscellaneous ================== ;M575 P1 S1 B57600 ; enable support for PanelDue M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss; homez.g ; called to home the Z axis ; ; generated by Ben Levi - BLV developer as a basic version G91 ; relative positioning G1 H2 Z5 F6000 S2 ; lift Z relative to current position G90 ; absolute positioning G1 X152 Y166.4 F6000 ; go to first probe point G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioning; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by Ben Levi - BLV developer as a basic version M561 ; clear any bed transform G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G90 ; absolute positioning G28 ; home all M557 X20:270 Y20:270 P3 ; Define mesh grid G30 P1 X10 Y175 Z-99999 ; probe near a leadscrew, half way along Y axis G30 P0 X330 Y175 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors G29 S0 ; probe the bed and enable compensation M291 P"Leveling finished !" R"Probing.." S1 T2 -

@sgk there doesn't appear to be anything wrong with your config.

Can you confirm that the stepper motor attached to driver 3 is the one thats X-45 Y165 and that the other stepper motor connected to driver 4 is the one on the other side? -

@jay_s_uk

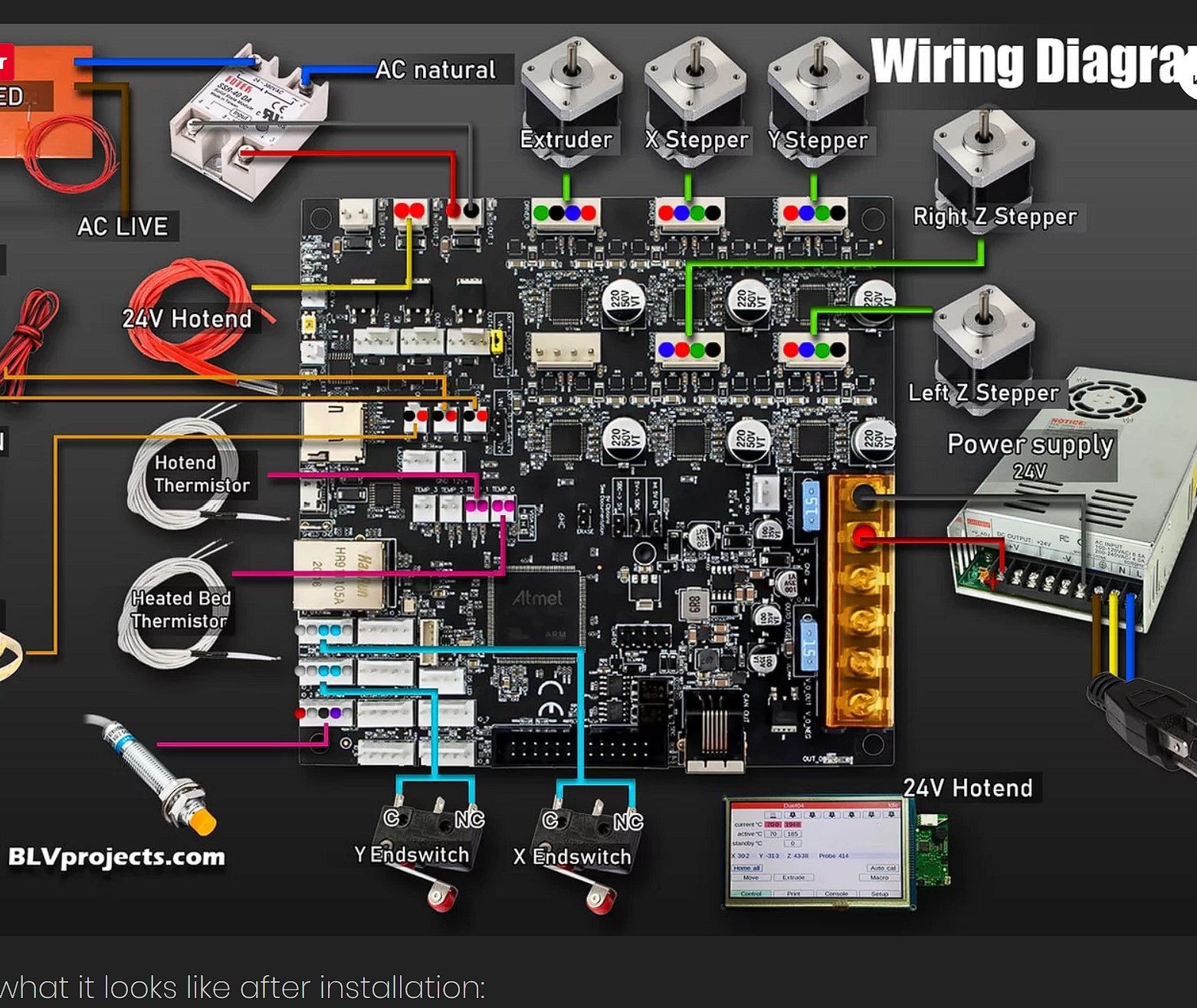

they are connected as in the photo though

-

@sgk is the left one the one closest to X0?

-

@jay_s_uk excuse me I don't understand questions?

-

@sgk well when the tool is at X0, is it nearest the motor called "left z stepper" or is it closest to the one called "right z stepper"?

-

@jay_s_uk to the left

-

@sgk which indicates that the firmware setup is correct then and its left to either be a mechanical issue, e.g. x axis twist or maybe the IR probe doesn't like being so close to the edge of the bed

-

@jay_s_uk

the impression that I have is that each time I do g32 the bed does not get level and it always goes down more and more on the side -

@jay_s_uk I could make a video to better understand

-

@sgk which is why i think you have the stepper motors the wrong way round

-

@jay_s_uk but when I do home all the 2 z motors go well together they are synchronized

-

@sgk if you have them mapped the wrong way round, RRF will adjust the wrong one

-

@jay_s_uk I could solve this problem how do you have an idea please

-

@sgk change your z mapping in M584 from Z3:4 to Z4:3

-

@jay_s_uk

ha ok i will try now thank -

@jay_s_uk I have this as an error

Error: Z probe readings not consistent -

-

@sgk says it all really. the z probe readings are the same within the tolerance band thats set. I'm not sure how good the IR probe is with PEI surfaces

-

@jay_s_uk with the duet 2 card I never had a problem with the pei