Some Novice Questions

-

HI Guys,

FIRMWARE_NAME: RepRapFirmware for Duet 3 MB6HC FIRMWARE_VERSION: 3.4.2 ELECTRONICS: Duet 3 MB6HC v1.01 FIRMWARE_DATE: 2022-09-13 15:17:43

I'm starting to get somewhere now with the kind help, assistance and guidance from

@Norder @PhaedruxI'm still doing/on the calibration of the Duet Docs, and just part printed the test calibration rounded cube, but noticed something's and also have a few novice questions.

When I run the G32 to probe the bed (in the 4 corners in my case), followed with G29 (9 x 9 probe points), do I enter M500 P10:G31 or anything after doing this before I print, so the printer remembers the lay of my bed?

When I ran the G29 command I noticed that the Blue Send Button on the DWC occasionally had a rotating arrow (like the spinning beach-ball), when it finished probing I would get a network error and it would automatically start the probe sequence again. The printer/Duet's only 2m meters away, in the same room and separated by nothing except for myself and the chair I'm sat on?

I had to use -0.10 baby-steps to get the correct squish for my 1st layer. Should I add this/change this in my G31 config.g, or can this be automatically saved in some way?

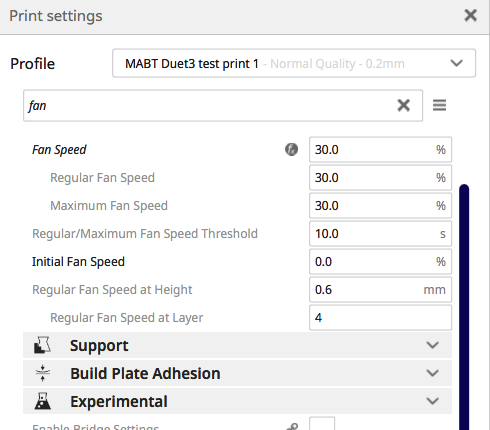

I used Cura to slice the Rounded Cube test print, but I noticed that the part cooling fan never switched on. I had enabled print cooling, fan speed 100%, initial fan speed 0%, but it didn't come in the 100 layers I printed?

I'd also like to ask if you could recommend any decent endstop switches. The microswitches I'm using are standard ones shipped with my Tronxy x5sa pro. Boy do the metal lever arms rattle. Can you recommend some that don't have this issue, or better alternatives?

I'd be grateful for you feedback.

; Configuration file for Duet 3 MB 6HC (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.13 on Mon Sep 19 2022 16:04:20 GMT+0100 (British Summer Time) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name M669 K1 ; select CoreXY mode ; Bed Adjustment Screw Positions M671 X5:278:278:5 Y5:5:302:302 P0.5 ; front left, front right, back right, back left ; Drives M569 P0.0 S0 ; physical drive 0.0 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P0.3 S1 M569 P0.4 S0 ; physical drive 0.3 goes forwards M584 X0.0 Y0.1 Z0.2:0.3 E0.4 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E330.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X900 Y900 Z900 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X-2 Y-8 Z0 S1 ; set axis minima M208 X330 Y330 Z400 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin !io1.in M574 Y1 S1 P"!io2.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin !io2.in ; Z-Probe M574 Z1 Z1 S2 ; set endstops controlled be probe M558 P5 C"^!io3.in" H5 F120 T6000 ; set Z probe type to switch and the dive height + speeds G31 P500 X-46 Y-19 Z1.56 ; set Z probe trigger value, offset and trigger height M557 X19:244 Y-2:304 P9 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 R0.187 K0.192:0.000 D1.89 E1.35 S1.00 B0 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 R2.498 K0.275:0.349 D6.79 E1.35 S1.00 B0 V24.0 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"out7" Q500 ; create fan 0 on pin out4 and set its frequency M106 P0 C"Part Cooling" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"out8" Q500 ; create fan 1 on pin out5 and set its frequency M106 P1 C"Extruder Cooling" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on ; Tools M563 P0 S"Hemera" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Emergency Stop M950 J1 C"io4.in" M851 P1 T0 S0 R0 ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss T0 M501; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v3.3.13 on Mon Sep 19 2022 16:04:20 GMT+0100 (British Summer Time) ;M561 ; clear any bed transform ;G29 ; probe the bed and enable compensation G28 ; home M401 ; deploy Z probe G30 P0 X5 Y5 Z-9999 ; probe front left G30 P1 X278 Y5 Z-9999 ; probe front right G30 P2 X278 Y302 Z-9999 ; probe rear right G30 P3 X5 Y302 Z-9999 S4 ;probe rear left M402 -

@dizzwold said in Some Novice Questions:

When I run the G32 to probe the bed (in the 4 corners in my case), followed with G29 (9 x 9 probe points), do I enter M500 P10:G31 or anything after doing this before I print, so the printer remembers the lay of my bed?

No M500 needed. The G32 and G29 are active as soon as they are finished running.

@dizzwold said in Some Novice Questions:

When I ran the G29 command I noticed that the Blue Send Button on the DWC occasionally had a rotating arrow (like the spinning beach-ball), when it finished probing I would get a network error and it would automatically start the probe sequence again. The printer/Duet's only 2m meters away, in the same room and separated by nothing except for myself and the chair I'm sat on?

This is strange. Is your DWC also on 3.4.2?

@dizzwold said in Some Novice Questions:

I had to use -0.10 baby-steps to get the correct squish for my 1st layer. Should I add this/change this in my G31 config.g, or can this be automatically saved in some way?

You can modify the G31 yes. Have you already tuned your extruder? That's the other half of the first layer equation.

@dizzwold said in Some Novice Questions:

I used Cura to slice the Rounded Cube test print, but I noticed that the part cooling fan never switched on. I had enabled print cooling, fan speed 100%, initial fan speed 0%, but it didn't come in the 100 layers I printed?

Show the first 50 lines or so of a sliced gcode file. Does the part cooling fan work if you adjust the slider?

@dizzwold said in Some Novice Questions:

M401 ; deploy Z probe

You can remove M401 and M402 from bed.g. Not needed.

-

Hi @Phaedrux,

Thank you for you reply.

@phaedrux said in Some Novice Questions:No M500 needed. The G32 and G29 are active as soon as they are finished running.

Does that include if I power down and reboot?

Just check the web control, and that 3.4.2 also.

@phaedrux said in Some Novice Questions:

Have you already tuned your extruder? That's the other half of the first layer equation.

My extruder, a Matrix (I couldn't afford a Hemera at the time), was skipping a 7mm/s so backed it off to 6.5mm/s and tested 100mm of filament and it was fine with that.

Heres the Gcode of the test print. I've just actually spotted a possible cause. I've ot the flavour set to Marlin. It should be Reprap if I'm not mistaken?

;FLAVOR:Marlin ;TIME:12881 ;Filament used: 12.48m ;Layer height: 0.2 ;MINX:107.2 ;MINY:107.2 ;MINZ:0.2 ;MAXX:222.8 ;MAXY:222.8 ;MAXZ:100 ;Generated with Cura_SteamEngine 4.10.0 M82 ;absolute extrusion mode ; X5SA Pro Start Code G21 G90 M82 M107 T0 M140 S55.0 M104 S205.0 T0 M190 S55.0 M109 S205.0 T0 G28 G92 E0 G92 E0 G92 E0 G1 F300 E-0.6 ;LAYER_COUNT:500 ;LAYER:0 M107 P1 G0 F2700 X114.94 Y115.757 Z0.2 ;TYPE:SKIRT G1 F300 E0 G1 F1800 X115.759 Y114.938 E0.03897 G1 X116.09 Y114.625 E0.05429 G1 X116.959 Y113.852 E0.09342 G1 X117.308 Y113.559 E0.10875 G1 X118.222 Y112.837 E0.14794 G1 X118.577 Y112.573 E0.16282 G1 X119.529 Y111.905 E0.20195 G1 X119.917 Y111.649 E0.21759 G1 X120.907 Y111.039 E0.25671 G1 X121.295 Y110.815 E0.27179 G1 X122.32 Y110.262 E0.31097 G1 X122.733 Y110.055 E0.32651 G1 X123.786 Y109.565 E0.36559 G1 X124.193 Y109.39 E0.38049 G1 X125.276 Y108.959 E0.41971 G1 X125.705 Y108.802 E0.43508 G1 X126.809 Y108.436 E0.47421 G1 X127.251 Y108.304 E0.48973 G1 X128.374 Y108.004 E0.52883 G1 X128.807 Y107.902 E0.5438 G1 X129.948 Y107.666 E0.583 G1 X130.395 Y107.587 E0.59827 G1 X131.546 Y107.418 E0.63741 G1 X132.002 Y107.364 E0.65286 G1 X133.161 Y107.263 E0.692 G1 X133.61 Y107.237 E0.70713 G1 X134.772 Y107.203 E0.74624 G1 X135 Y107.2 E0.75391 G1 X195.003 Y107.2 E2.77262 G1 X195.231 Y107.203 E2.7803 G1 X196.394 Y107.237 E2.81944 G1 X196.843 Y107.263 E2.83457 G1 X198.002 Y107.364 E2.87371@phaedrux said in Some Novice Questions:

Does the part cooling fan work if you adjust the slider?

Yes it does. I don't know if this is correct, but I was printing had 2 sliders, 1 titled "Tool", I cant remember to other, but they both moved together.

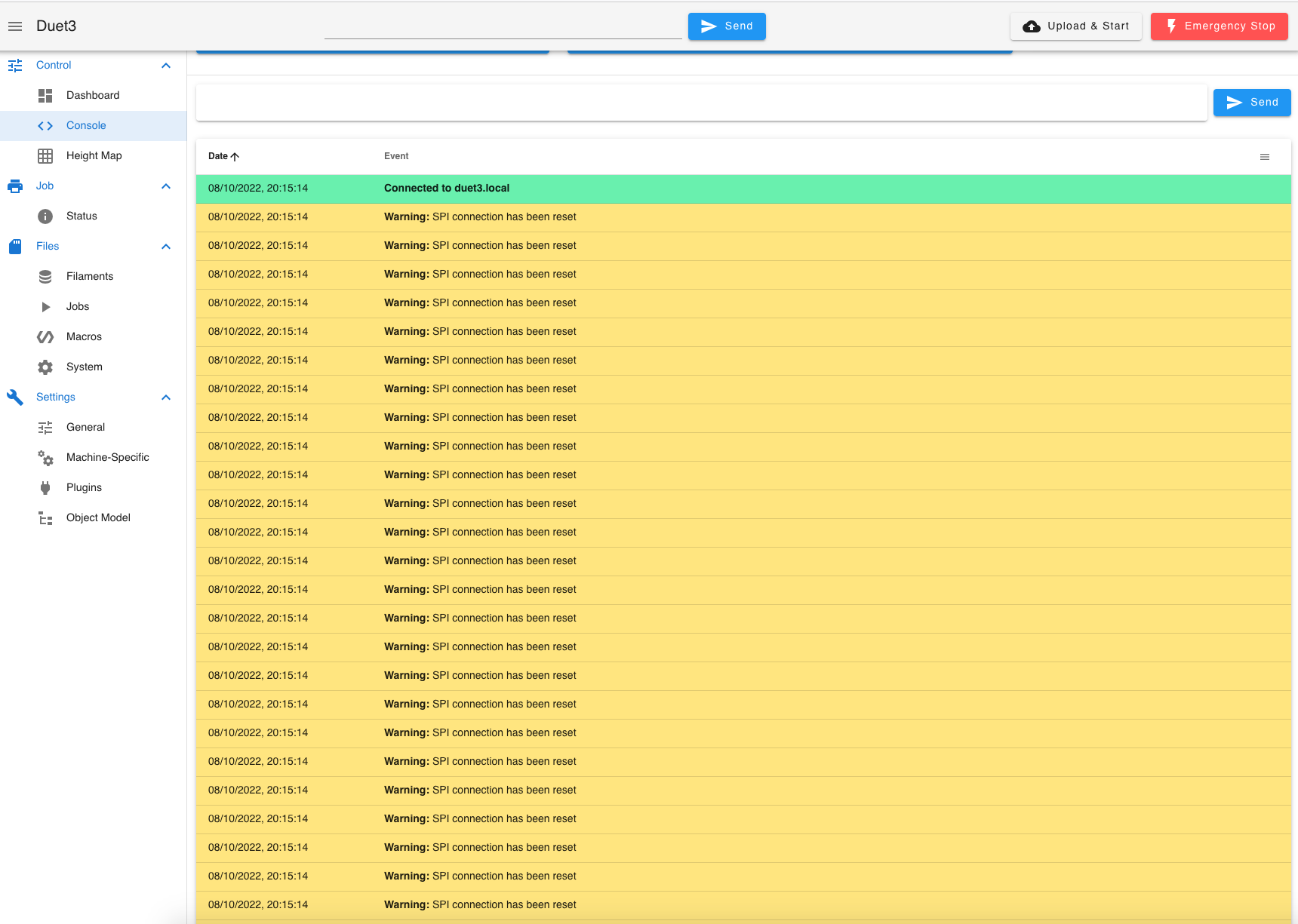

Wow, I've just found 100's if not 1000's of warnings in the console;

Warning : SPI Connection has been reset

What one earth is that about. I'd powered down the Duet and pi when I posted the above and just fired it up now to check things to repost/reply.I'll retry printing again tomorrow with the flavour set to Reprap. I can't now as it's night. I live i a very poorly, or shall we say, the lack of soundproofing between neighbours in flats. The printer has disturbed them before, hence the need for new microswitches and my post questioning Drylin.

-

@dizzwold said in Some Novice Questions:

Does that include if I power down and reboot?

For G32 doing leveling you'd need to run that again because when the motors are unpowered they lose position.

For G29, you can either re-run it each time, or save and load a heightmap with G29 S1.

@dizzwold said in Some Novice Questions:

It should be Reprap if I'm not mistaken?

Yes it should be RepRap flavour.

All I can see from your gcode file is M107 P0 and P1 to turn off fans. Do you see any M106 commands in the full file? You may need to configure Cura to use the right fan.

@dizzwold said in Some Novice Questions:

had 2 sliders, 1 titled "Tool", I cant remember to other, but they both moved together.

Yes, the Tool Fan slider will control the part cooling fan of the currently selected tool. And the other slider is likely the same fan.

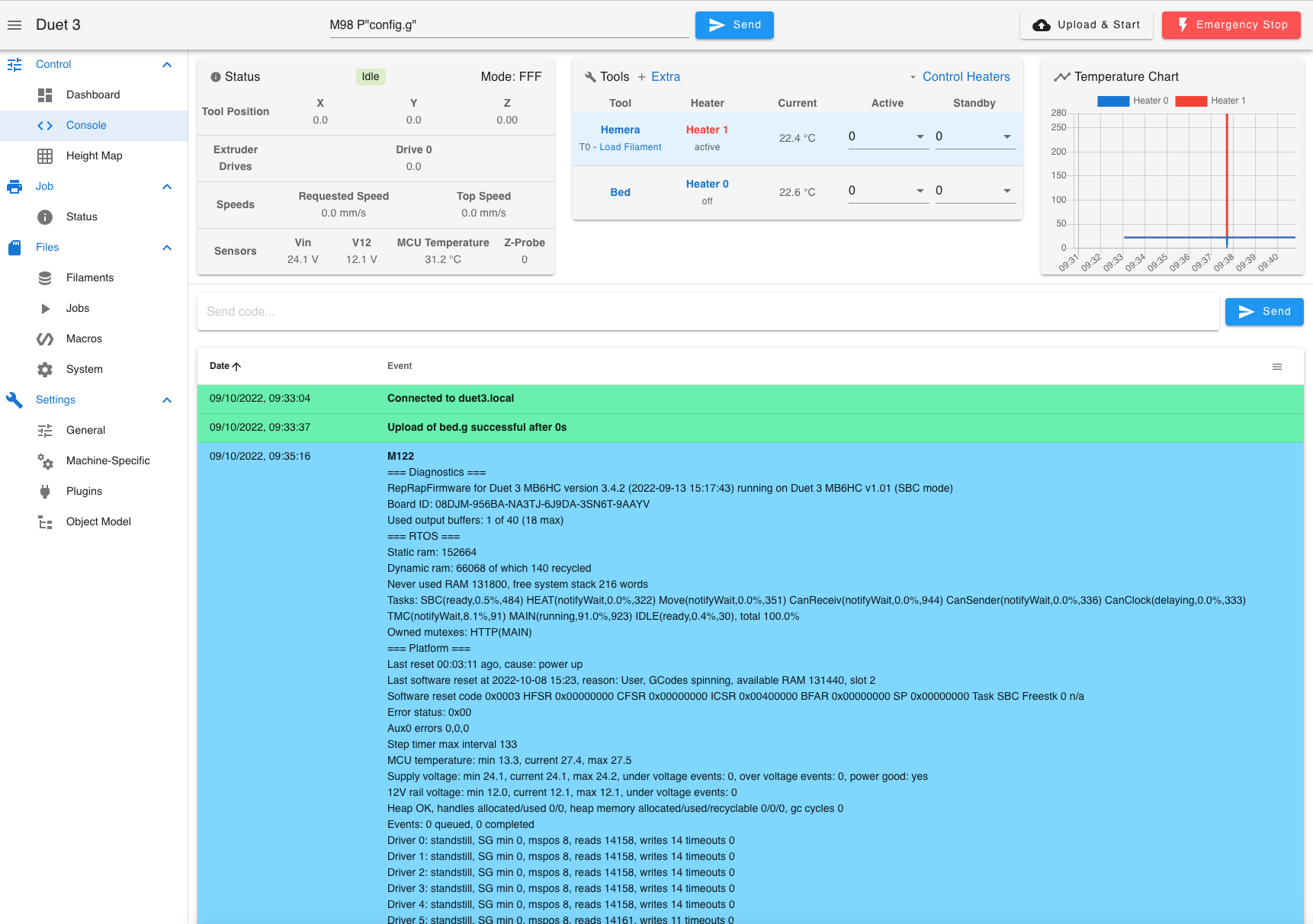

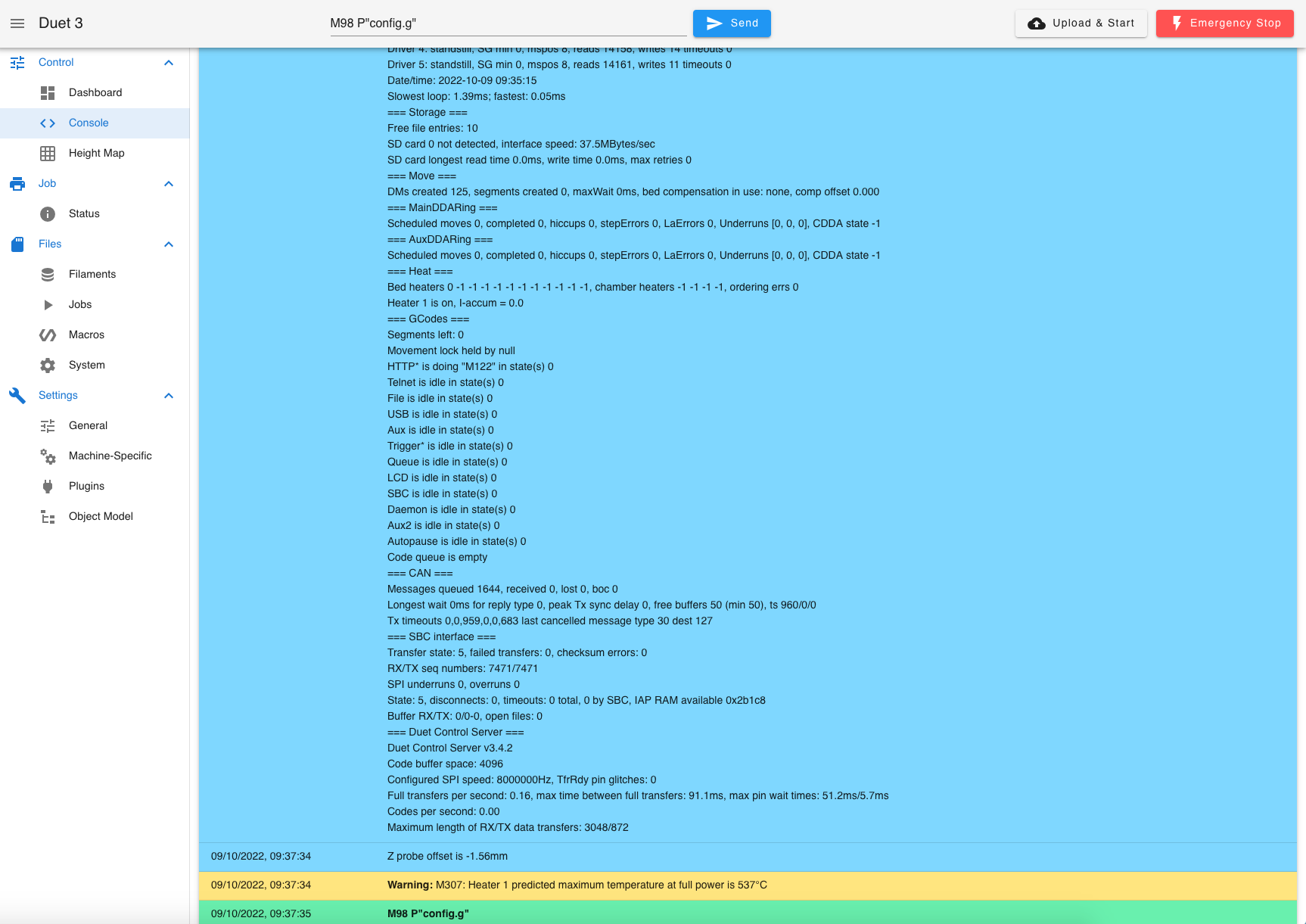

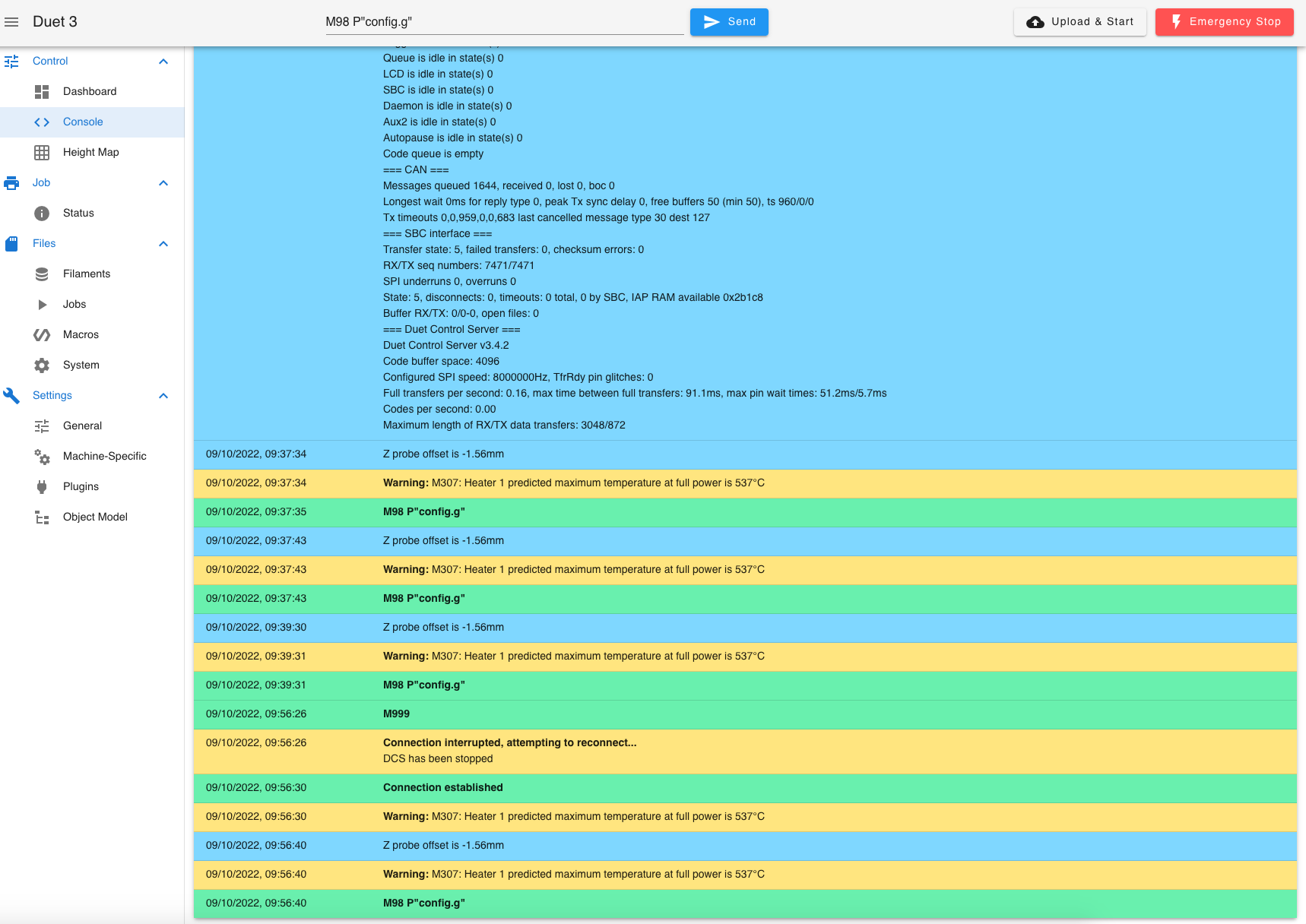

Can you send M122 and M98 P"config.g" in the gcode console and copy and paste the results here?

-

@dizzwold

Fan control in Cura...

There is the Regular Fan Speed and the Maximum Fan Speed.

If Regular Fan Speed is 0 and the Maximum Fan Speed is 100, then the fan only rotates when the time falls below a certain level, which is specified in Regular/Maximum Fan Speed Threshold.If the Regular/Maximum Fan Speed Threshold is 10 seconds, the fan will only start if the layer is printed in less than 10 seconds.

So be sure to check the entry in Regular Fan Speed.

Two fan speed sliders in DWC...

I always had two sliders for the same fan that moved at the same time.

I think... after I gave the fan its own name, the second slider was gone.

In the following line, give the fan a different name, such as "Component Fan" or something.

M106 P0 C"Part Cooling" S0 H-1Report if it worked because I'm only 70% sure it works.

Do you still have Cura 4.10 ?

If yes, then you should update it.

The current version is 5.10 -

Here's the results of M122, I've also added screenshots.

09/10/2022, 09:33:04 Connected to duet3.local 09/10/2022, 09:33:37 Upload of bed.g successful after 0s 09/10/2022, 09:35:16 M122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.4.2 (2022-09-13 15:17:43) running on Duet 3 MB6HC v1.01 (SBC mode) Board ID: 08DJM-956BA-NA3TJ-6J9DA-3SN6T-9AAYV Used output buffers: 1 of 40 (18 max) === RTOS === Static ram: 152664 Dynamic ram: 66068 of which 140 recycled Never used RAM 131800, free system stack 216 words Tasks: SBC(ready,0.5%,484) HEAT(notifyWait,0.0%,322) Move(notifyWait,0.0%,351) CanReceiv(notifyWait,0.0%,944) CanSender(notifyWait,0.0%,336) CanClock(delaying,0.0%,333) TMC(notifyWait,8.1%,91) MAIN(running,91.0%,923) IDLE(ready,0.4%,30), total 100.0% Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:03:11 ago, cause: power up Last software reset at 2022-10-08 15:23, reason: User, GCodes spinning, available RAM 131440, slot 2 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task SBC Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 Step timer max interval 133 MCU temperature: min 13.3, current 27.4, max 27.5 Supply voltage: min 24.1, current 24.1, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.0, current 12.1, max 12.1, under voltage events: 0 Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min 0, mspos 8, reads 14158, writes 14 timeouts 0 Driver 1: standstill, SG min 0, mspos 8, reads 14158, writes 14 timeouts 0 Driver 2: standstill, SG min 0, mspos 8, reads 14158, writes 14 timeouts 0 Driver 3: standstill, SG min 0, mspos 8, reads 14158, writes 14 timeouts 0 Driver 4: standstill, SG min 0, mspos 8, reads 14158, writes 14 timeouts 0 Driver 5: standstill, SG min 0, mspos 8, reads 14161, writes 11 timeouts 0 Date/time: 2022-10-09 09:35:15 Slowest loop: 1.39ms; fastest: 0.05ms === Storage === Free file entries: 10 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === DMs created 125, segments created 0, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === CAN === Messages queued 1644, received 0, lost 0, boc 0 Longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 50 (min 50), ts 960/0/0 Tx timeouts 0,0,959,0,0,683 last cancelled message type 30 dest 127 === SBC interface === Transfer state: 5, failed transfers: 0, checksum errors: 0 RX/TX seq numbers: 7471/7471 SPI underruns 0, overruns 0 State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x2b1c8 Buffer RX/TX: 0/0-0, open files: 0 === Duet Control Server === Duet Control Server v3.4.2 Code buffer space: 4096 Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 0 Full transfers per second: 0.16, max time between full transfers: 91.1ms, max pin wait times: 51.2ms/5.7ms Codes per second: 0.00 Maximum length of RX/TX data transfers: 3048/872 09/10/2022, 09:37:34 Z probe offset is -1.56mm 09/10/2022, 09:37:34 Warning: M307: Heater 1 predicted maximum temperature at full power is 537°C 09/10/2022, 09:37:35 M98 P"config.g" 09/10/2022, 09:37:43 Z probe offset is -1.56mm 09/10/2022, 09:37:43 Warning: M307: Heater 1 predicted maximum temperature at full power is 537°C 09/10/2022, 09:37:43 M98 P"config.g"With typing

M98 P"config.g"in console, I get no return, nothing;

I've found some M106 commands;

4446: M106 S85 P1 4682: M106 S170 P1 4918: M106 S255 P1 127443: M106 S0I've just tried the

M98 P"config.g"again after callingM999, but still no return.Here's a shot of the Cura fan settings I have;

I'll try changing the fan name and running some tests when I get back, I've got to go out.

Being that I'm still learning and calibrating I dare not leave the printer unattended.I'm really grateful for your time and patience.

-

@dizzwold said in Some Novice Questions:

M106 S85 P1

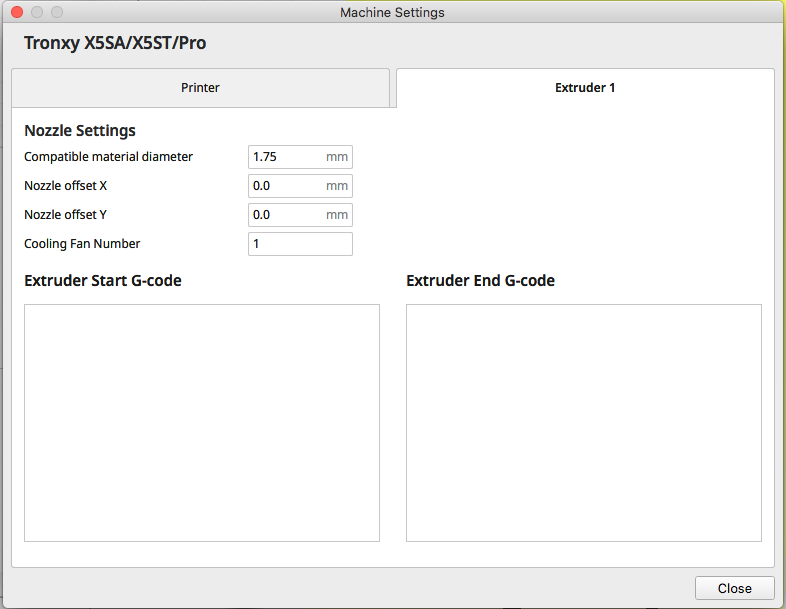

Check your Cura machine configuration. It looks like it's set to use Fan1 instead of Fan0.

-

-

@dizzwold said in Some Novice Questions:

I can't upgrade to Cura 5.1. I only have an old Mac computer (2011). Believe me it's a nightmare, I can't update fusion or many other things either.

That seems familiar to me.

I always lag behind the others in terms of hardware.

Sometimes I have the feeling I could open a technology museum.

Better days are coming, @dizzwold.

-

Can I move my Cura profiles (retraction, Esteps, etc) direclty into the Duet, or will they be different and have to re-test all my filaments?

-

@Dizzwold

Cura Profiles cannot be loaded in Duet.

What exactly are you planning? -

@Norder

Hi Gunter,Sorry, I think was confusing myself with read to many things at once (filaments/Macros). I need to slow down.

I have some settings in Cura like retraction distance and speed, and different filaments use different Esteps. So do I crate a Filament, and then create a macro for that filament that contains the relevant Esteps, retraction, etc?

I've done my first print (a mounting plate for a toolboard (not yet configured)), and still yet to finish calibrating (Speeds,Jerk,Acceleration), even so, this is a game changer compared to the Tronxy/Chitu. I couldn't do things like Baby Step. Basically with the Tronxy, once you pressed print, that was it, except for pressing Stop.

Also in Cura, I had start and end gcodes. Should I bring them over to the Duet, or just keep them in Cura?

Can I ask what slicer you use?

Sorry, lots of questions and I have "SO" much to learn.

I'm thinking once I've got things better organised I'm going to connect it via Ethernet as I still keep getting network errors, mainly when running the mesh compensation, but I'm yet to find a write-up or guide on how this is done with the duet 3 and RPi4 SBC and on a Apple Mac.

I'm really grateful for all the help you've given me. I really appreciate it.

-

@Dizzwold said in Some Novice Questions:

I have some settings in Cura like retraction distance and speed, and different filaments use different Esteps. So do I crate a Filament, and then create a macro for that filament that contains the relevant Esteps, retraction, etc?

Yes, you can put all relevant datas into the filament-files

@Dizzwold said in Some Novice Questions:

Also in Cura, I had start and end gcodes. Should I bring them over to the Duet, or just keep them in Cura?

That's up to you. You can leave it in your slicer, or put it in start.g / end.g in the sys folder.

Note: The start.g is running before any slicer startcode... -

@Dizzwold said in Some Novice Questions:

Can I ask what slicer you use?

I use PrusaSlicer. But I also set up Cura in case there should be any problems with the PrusaSlicer. But it has only happened once so far.

In config.g you set the speeds as high as your printer can handle or the maximum speeds that you do not want to exceed.

In the slicer you then set the speeds you want for your component or for your filament.Printer settings in the slicer can make the speeds entered in config.g slower, but not faster.

For example, if config.g says 20000mm/min for the maximum speed and 10000mm/min in the printer settings in the slicer, then 10000mm/min is used.

But if there are 30000mm/min in the printer settings in the slicer, then it stays with the 20000mm/min from the config.gThere are two camps on how to manage your filaments.

Some do it with the DWC.

The others manage their filaments in the slicer.

You have to find out what works best for you.

I manage all my filaments in the slicer (if the slicer can).I also have a custom GCode for each filament in PrusaSlicer, e.g. the Pressure Advance value is in there, since each type of filament (PLA, ABS, Nylon etc.) should have its own Pressure Advance value.

So a pressure advance value in config.g that is valid for all filaments can work well... but doesn't have to.There is also a text field for comments that I can make about the filament, for example, it says what oversize I would have to print with the filament in order to get true-to-size components.

Each filament shrinks to a different extent when it cools down to room temperature.

I then transfer this value to the slicer, for example when I print a component from different filaments, so that later everything fits together and I only have to rework a little.This is my start code in the slicer (please do not copy 1:1)

T0 ; set tool #0 G21 ; set units to millimetres G90 ; set to absolute positioning M106 S0 ; set fan speed to zero (turned off) G28 ; home M116 H1 S2 ; warten bis das hotend +-2 grad celsius der erwarteten temperatur erreicht hat G1 Z5 F1000 ; hotend 5mm heben G1 X165 Y143 F7000 ; zur druckbett-mitte fahren G30 ; z-hoehe aus bettmitte holen G1 X100 Y-15 Z1 F7000 ; zum startpunkt fahren G92 E0 ; zero the extruded length G1 E30 F200 ; nozzle fluten G92 E0 ; zero the extruded length again G29 S1 ; mesh ladenThis is the end code in the slicer (please do not copy 1:1)

G91 ; set to relative positioning G1 E-2 F1200 ; filament retraction 2mm G1 Z10 F1000 ; hebe die nozzle um 10mm G90 ; set to absolute positioning M104 S0 ; turn off nozzle heater M140 S0 ; turn off bed heater G1 E-8 F250 ; retract the filament slightly G28 X0 ; move to the X-axis origin (Home) G0 Y230 F800 ; bring the bed to the front for easy print removal M84 ; turn off stepper motors M107 ; turn fan off M106 P2 S0 ; led beleuchtung aus G4 P1000 ; 1 Sekunde Pause M106 P2 S1 ; led beleuchtung an G4 P1000 ; 1 Sekunde Pause M106 P2 S0 ; led beleuchtung aus G4 P1000 ; 1 Sekunde Pause M106 P2 S1 ; led beleuchtung an G4 P1000 ; 1 Sekunde Pause M106 P2 S0 ; led beleuchtung aus G4 P1000 ; 1 Sekunde Pause M106 P2 S1 ; led beleuchtung an G4 P1000 ; 1 Sekunde Pause M106 P2 S0 ; led beleuchtung aus G4 P1000 ; 1 Sekunde Pause M106 P2 S1 ; led beleuchtung anIt doesn't matter if commands already given by the Duet are repeated here.

T0 is also at the end of config.g, for example.The important thing is... what is in the Slicer Start GCode is done, so if T1 were there I would have a problem because I only have one print head, i.e. only T0. The print could not be started because the Duet would report a problem.

I hope I could help you.

Google Translate

-- Original Text --Ich nutze den PrusaSlicer. Aber ich habe auch Cura eingerichtet, falls es mal Probleme mit dem PrusaSlicer geben sollte. Es ist bis jetzt aber nur einmal vorgekommen.

In der config.g stellst Du die Geschwindigkeiten so hoch ein wie Dein Drucker es schafft bzw die maximalen Geschwindigkeiten die Du nicht überschreiten möchtest.

Im Slicer stellst Du dann die Geschwindigkeiten ein die Du für Dein Bauteil oder auch für Dein Filament möchtest.Drucker Einstellungen im Slicer können die Geschwindigkeiten die in config.g eingetragen sind, langsamer machen aber nicht schneller.

Steht in der config.g zB 20000mm/min für die maximale Geschwindigkeit und 10000mm/min in den Drucker Einstellungen im Slicer, dann wird die 10000mm/min genommen.

Stehen dort aber 30000mm/min in den Drucker Einstellungen im Slicer, dann bleibt es bei den 20000mm/min aus der config.gEs gibt da zwei Lager wie man seine Filamente verwaltet.

Die einen machen das mit dem DWC.

Die anderen verwalten ihre Filamente im Slicer.

Du musst für Dich heraus finden wie es für Dich am besten passt.

Ich verwalte alle meine Filamente im Slicer (wenn der Slicer das kann).Ich habe im PrusaSlicer auch einen benutzerdefinierten GCode für jedes Filament, da steht zB der Pressure Advance Wert drin, da jede Art von Filament (PLA, ABS, Nylon etc.) seinen eigenen Pressure Advance Wert haben sollte.

Also einen Pressure Advance Wert in der config.g der für alle Filamente gültig ist, kann gut funktionieren... muss aber nicht.Es gibt auch ein Textfeld für Anmerkungen die ich zu dem Filament machen kann, dort steht bei mir zB mit welcher Übergröße ich mit dem Filament drucken müsste um maßgerechte Bauteile zu erhalten.

Jedes Filament schrumpft wenn es auf Zimmertemperatur abgekühlt ist, unterschiedlich stark.

Ich übertrage diesen Wert dann in den Slicer, wenn ich zB ein Bauteil aus verschiedenen Filamenten drucke, damit später auch alles zusammen passt bzw ich nur wenig nacharbeiten muss.Das ist mein Startcode im Slicer (Bitte nicht 1:1 übernehmen)

GCode siehe obenDas ist der Endcode im Slicer (Bitte nicht 1:1 übernehmen)

GCode siehe obenEs ist hier nicht schlimm wenn Befehle die bereits vom Duet vorgegeben wurden, hier wiederholt werden.

Das T0 steht zB auch am Ende der config.g.Wichtig ist... das was im Slicer Start GCode steht, wird gemacht, würde da also T1 stehen hätte ich ein Problem weil ich nur einen Druckkopf habe, also nur T0. Der Druck könnte nicht gestartet werden weil das Duet ein Problem melden würde.

Ich hoffe ich konnte Dir etwas helfen.