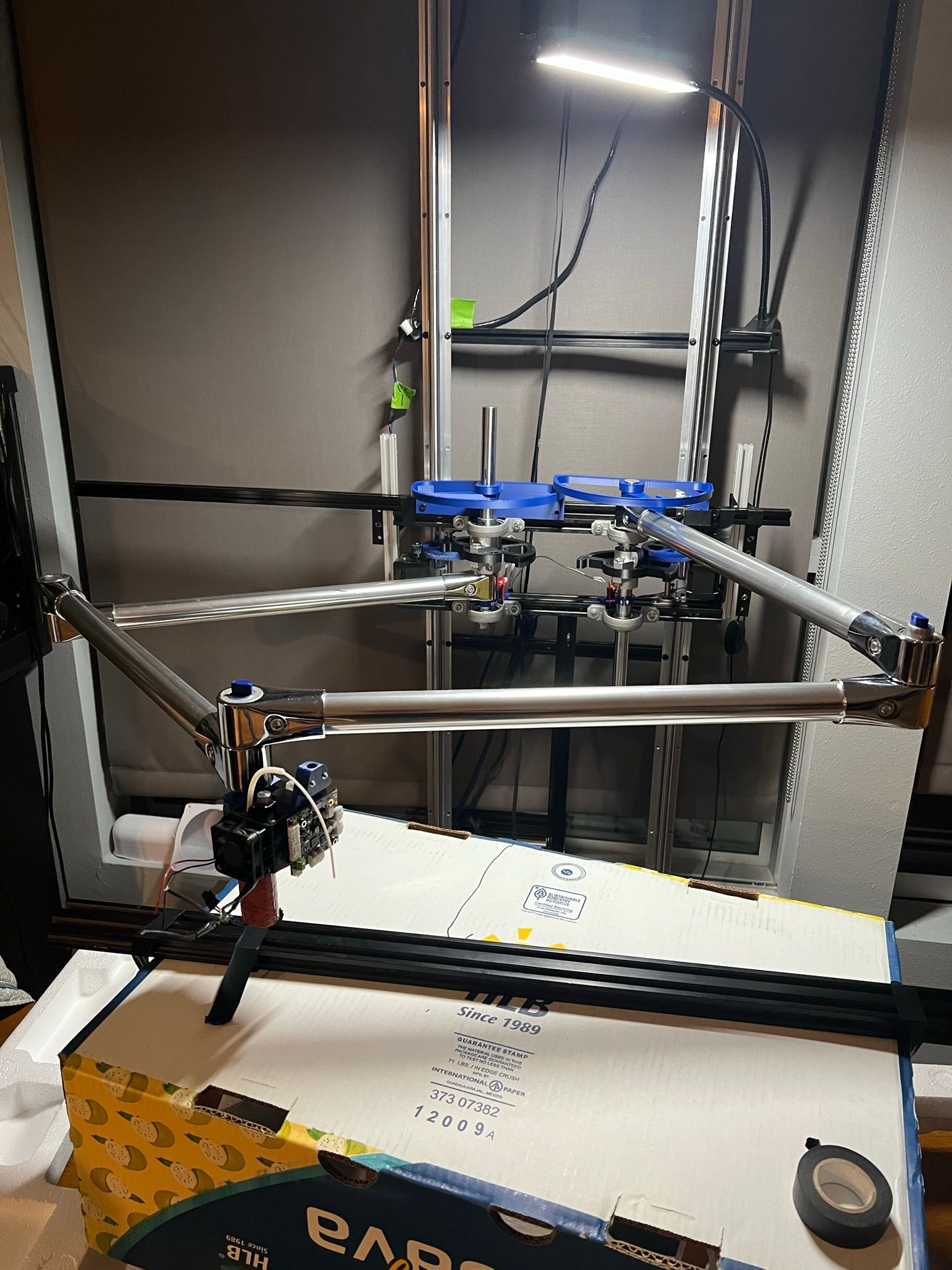

5 bar scara on duet3!

-

@JoergS5 I also thought of adapting the gearbox to 380 or 540/600 sized dc brushed motors. But that's a subject for a new thread.

-

looks good mate!

I'm currently working on calibration and while I think I'm closing in on getting a straight 600mm line X axis at Y600, I'm noticing there's still way to much wobble and inconsistency to use this as a printer.

I think my two options are to switch to this harmonic drive stepper motor (aliexpress link is $54 rather than $155 from amazon in the US):

I could either directly drive the 20mm shafts from the motor or try a 2:1 gear reduction. Either way, there's a lot less shafts and plastic gears in between the stepper and the output to add backlash and spring to the system.

otherwise I might try building a T-shaped core-XY first to see how that performs in comparison. Something with a long X axis and a shorter Y axis. I have some big printed projects I want to get moving for the summer so at this point I just want a motion system that can get the job done. I think there's a longer leadtime option for those motors that saves a bunch on shipping that I can order and have in a month or so.

-

@michaelr123 in my opinion you're simply using too long arms. Long arms multiply the errors. If you're using 10 cm arms, you'll get much better solution. You can use cantileved mode to place the hotend a bit away from the last hinge. Placing the XY actuator with bigger distance will also help (but this conflicts with the short arms). I have/had similar problems with 6 axis robot, so this is from my experience (better would be parallel arms vertically or parallelogram structure. Stability could be gained by overconstraining with tensegrity methods also).

But if your project requirement is a big print area and you have time pressure, using CoreXY (or Cartesian in Gantry style) will probably be a better option.