Milling motor control - Duet3/PWM Converter

-

@Nightowl could you not add an extra relay to control the power and then add another output on the M950? like you have your mikita

-

That's what I was thinking. As I see it, any M3 command would need to 'operate' the relay (as it currently does for the Makita) and the Snnnn part to control the speed.

I'm just not sure how to incorporate the code to make that happen.

-

@Nightowl said in Milling motor control - Duet3/PWM Converter:

; Spindle configuration

M950 R0 C"vfd" L0:25000 Q1000 ; create spindle with index 0

M563 P0 S"Sorotec" R0 ; create tool 0 with spindle 0 and name it "Sorotec"

T0add another output to the M950, i.e.

M950 R0 C"vfd+out1" L0:25000 Q1000 ; create spindle with index 0

and wire the relay to out1 (you can adjust that as well).

M3 should activate that relay and M5 should turn it off. -

@Nightowl see the section on configuring spindles at https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m950-create-heater-fan-spindle-or-gpioservo-pin for an explanation of the suggestion by @jay_s_uk.

-

I see! Thank you, @jay_s_uk

Of course, that makes sense. It's the same idea as for the Makita (apart from the pins) so if I used this, to configure the motor:; Spindle configuration M950 R0 C"vfd+out7" L0:25000 Q1000 ; create spindle with index 0 M563 P0 S"Sorotec" R0 ; create tool 0 with spindle 0 and name it "Sorotec" T0 ; select tool 0...that would get me to where I want to be, whilst keeping the relay on the existing pins.

That's brilliant, thank you so much!

-

Thanks, @dc42, I'll check it out

-

Just out of curiosity, how do I find out what the Q setting should be?

Is this information relative to the PWM controller, which is advertised as being 1kHz to 3kHz?

Thanks

-

@Nightowl its more relative to VFD

-

@Nightowl said in Milling motor control - Duet3/PWM Converter:

Just out of curiosity, how do I find out what the Q setting should be?

Is this information relative to the PWM controller, which is advertised as being 1kHz to 3kHz?Yes, use between 1000 and 3000.

-

Some progress!

Using the code below, I can now start/stop the motor with M3 Sn and M5 respectively, but I can't change the speed: it is constant at 4,000RPM, which suggests to me that the voltage required to change the speed isn't there. Possibly a fault with the PWM converter?

Here's the code:

; Milling motor and relay configuration M950 R0 C"vfd+out7" L0:25000 Q1000 ; enable router relay on out7 M563 P0 S"Sorotec" R0 ; assign spindle 0 to tool 0 and name it Sorotec T0 ; select tool 0 M5 ; ensure motor is turned off -

@Nightowl have you adjusted the variable resistor on the top? have you set the VFD up for PWM control? I had to change some of the registers on my VFD to use PWM rather than RS485

-

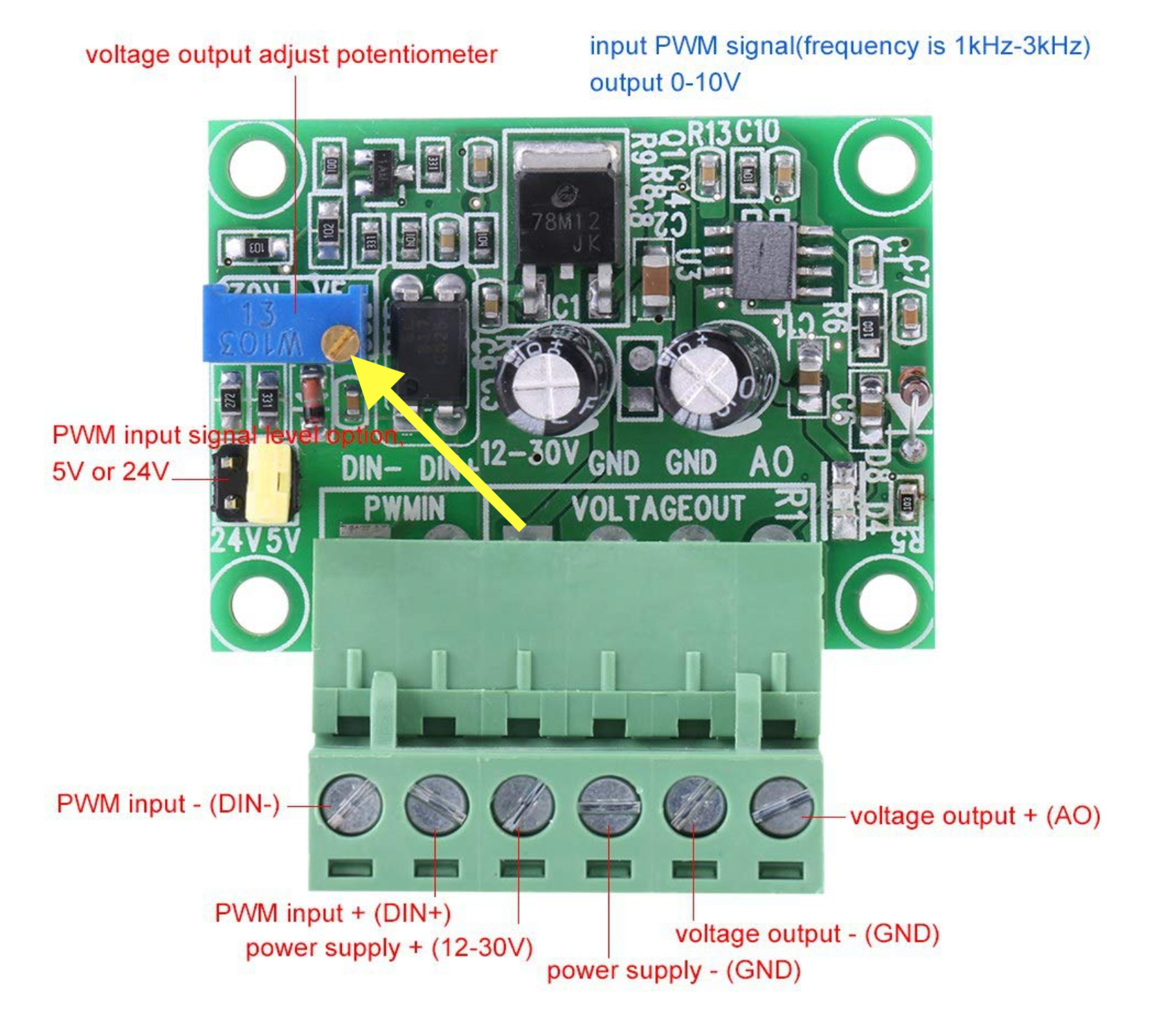

If you mean this one (arrowed), no I haven't:

I'm not using a VFD, though. Just following the instructions from the Ooznest website, the M950 guide and this document.

I've just noticed point 2 indicates the "5V/24V PWM input signal level option" should be set to 5V, so I'll need to check that...

-

One thing I've checked - very carefully, is the voltage across the 12V and GND connectors, adjacent to the 5V PWM connectors, on the Duet control board, and they're only providing 6V.

Also, the voltage across terminals GND and AO on the PWM board doesn't change when I adjust the motor speed (without the cable connected to the motor, so there's no load) from M3 S1000 to M3 S25000

That can't be right, surely?

Also, the jumper on the PWM board is set to 5V.

-

@Nightowl can you just confirm where the PWM is wired to on the duet board?

-

Certainly. The pins on the PWM board are connected to the Out9 VFD\Laser\Servo Drive header:

Port 1 (PWM in -ve) to 5V_Ext

Port 2 (PWM in +ve) to Out9

Port 3 (Power Supply 12-30V) to 12V

Port 4 (Power Supply GND) to GND

Port 5 (Voltage Out GND) to GND

Port 6 (Voltage Out +ve AO) to the motor plugThere is a loop between Ports 4 and 5, and this is also connected to the GND wire on the motor plug.

The third wire from the motor plug is connected to the PSU 24V +ve of the PSU.

-

@Nightowl thats where you'll be going wrong then as the header you're using is always on (i think). change numbers 3 and 4. it'll also probably explain why its always on at power up without that relay. i would just wire them to an out connector and switch your M950 accordingly.

-

-

@Nightowl ah bugger, you're right. i looked at the diagram wrong

-

All sorted, thank you gentlemen!

It was in fact down to way the PWM converter was connected to the Duet board.

I'll amend my diagram and publish it here (and delete the earlier one!

-

undefined dc42 marked this topic as a question

undefined dc42 marked this topic as a question

-

undefined dc42 has marked this topic as solved

undefined dc42 has marked this topic as solved

-

Here's the updated connection diagram:

...and this is the code from the config.g file:

; Milling motor and relay configuration M950 R0 C"vfd+out7" L4000:25000 Q1000 ; enable router relay on out7 M563 P0 S"St George" R0 ; assign spindle 0 to tool 0 and name it St George T0 ; select tool 0 M5 ; ensure motor is turned offNote: I have used this relay to provide mains power to the milling motor, which is activated from Out7 in this case. I guess any Out could be used, but the code would need to be changed accordingly.

Many thanks to @dc42 and @jay_s_uk for helping me resolve this, and I hope this diagram will be of use to others.

-

undefined Nightowl referenced this topic

undefined Nightowl referenced this topic