SuperSlicer and multiple printers

-

If you have multiple printers, how is your workflow arranged in/with SuperSlicer?

Do you start multiple instances of the program or is there another suggested way of going? I am primarily concerned with two issues:- SuperSlicer has a habit of randomly crashing. Am I risking too much with having multiple instances of SS open?

- Am i asking for file corruption if I run multiple instances? Does SS properly lock files that are open by each instance?

If you run a print farm, what do you do? One computer per instance of SS? Multiple instances of SS on one computer? Other tricks? One could work on one project, send that off to the printer, start a new project for a new printer (ie only ever have one project on the go) ? If you have more than one printer and print small projects, it gets a bit tedious to keep track of all the tiny special details that are configured for each project although using .3mf files helps in this regard ... it still can get confusing especially if you tweak thinks iteratively and print a project multiple times while tweaking settings for optimum results.

How do you deal with this? -

@jens55

Simple solution = uninstall and run Prusa untill SS solves their issues.This is what I have done

-

@jens55 What version of SS are you using? I've got 2.3.57 on Windows 10 and not had any crashing issues. I get an occaisional graphics glitch, but nothing switching tabs doesn't fix. I don't think it's the very latest, but might be the latest confirmed stable. I quite often also have multiple instances open too as I tend to prepare multiple prints in a batch, or if I'm re-printing something several times over with tweaks in-between printing other things - no issues to report, though you'll have to open a new instance to get any updated configurations you have saved in another instance (thing that might answer your second question too).

Saving the projects also helps a lot as you can always pick up from where you left off later! You can also open them up in PrusaSlicer too and it will pull through all your settings (temporarily). Not tried it the other way round

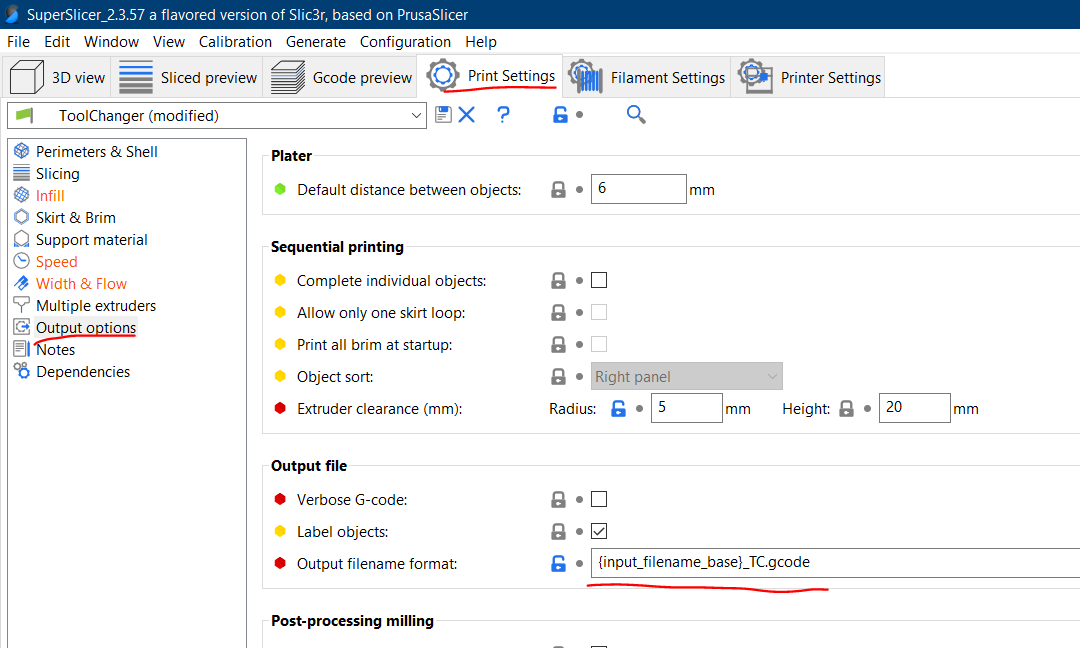

I tend to use SS for my toolchanger, and Prusa Slicer for my other three printers so can't comment too much on handling multiple printers... One trick I have found is you can get it to auto-append names onto the files, so all my toolchanger jobs have _TC on the end so I can keep track of multiple gcode files of the same object for multipe machine.

-

@engikeneer, thanks! I use a much later version and now that you mention it, I recall a warning about occasional crashing. I believe it is 2.5.59 although it is on a different computer and I can't verify at the moment. In any case, it is bleeding edge so I can't complain about the occasional crash. It sounds like you are doing much the same as I am which gives my some confidence that I am doing things the way they were intended.

How do you do the auto append? That seems like a handy feature.

May I inquire why you are using SS for one printer and PS for the others rather than standardizing on one or the other?

When you have multiple instances open, do you have a trick for keeping track which instance is which printer so you don't have to tab through multiple instances until you find the right one? I use Ubuntu so whatever you might use in a Windows setup might not apply but then it might be similar too. -

@engikeneer, found the setting on how to re-name the output file - thanks

-

@jens55 Sorry was out this afternoon... for other people who come across this, it's under 'Print Settings', 'Output options'

Reason for using SS & PS is longwinded... In general I have used Prusa Slicer for my three (different) printers for a while and have somewhat tuned the settings for them. I then got a toolchanger last year and in setting it up and doing some googling I found that Superslicer handles the multi-tool setup a little better/cleaner, so I started using SS for the toolchanger and have now tuned my profiles for that a bit. And I've just been too lazy to commonise the rest

I will admit, it does help keeping track of multiple different printers' slicing when the software is different... but it is nice that they're basically the same under the hood! Also, all my printers are different (delta, prusa clone, TC, 300mm cube corexy), so you can tell what session/printer your using just by looking at the plater. If the were more similar, I guess you could have multiple profiles and use the bed stl thing to number them or something similar?