Keep Motors energised when changing assignment

-

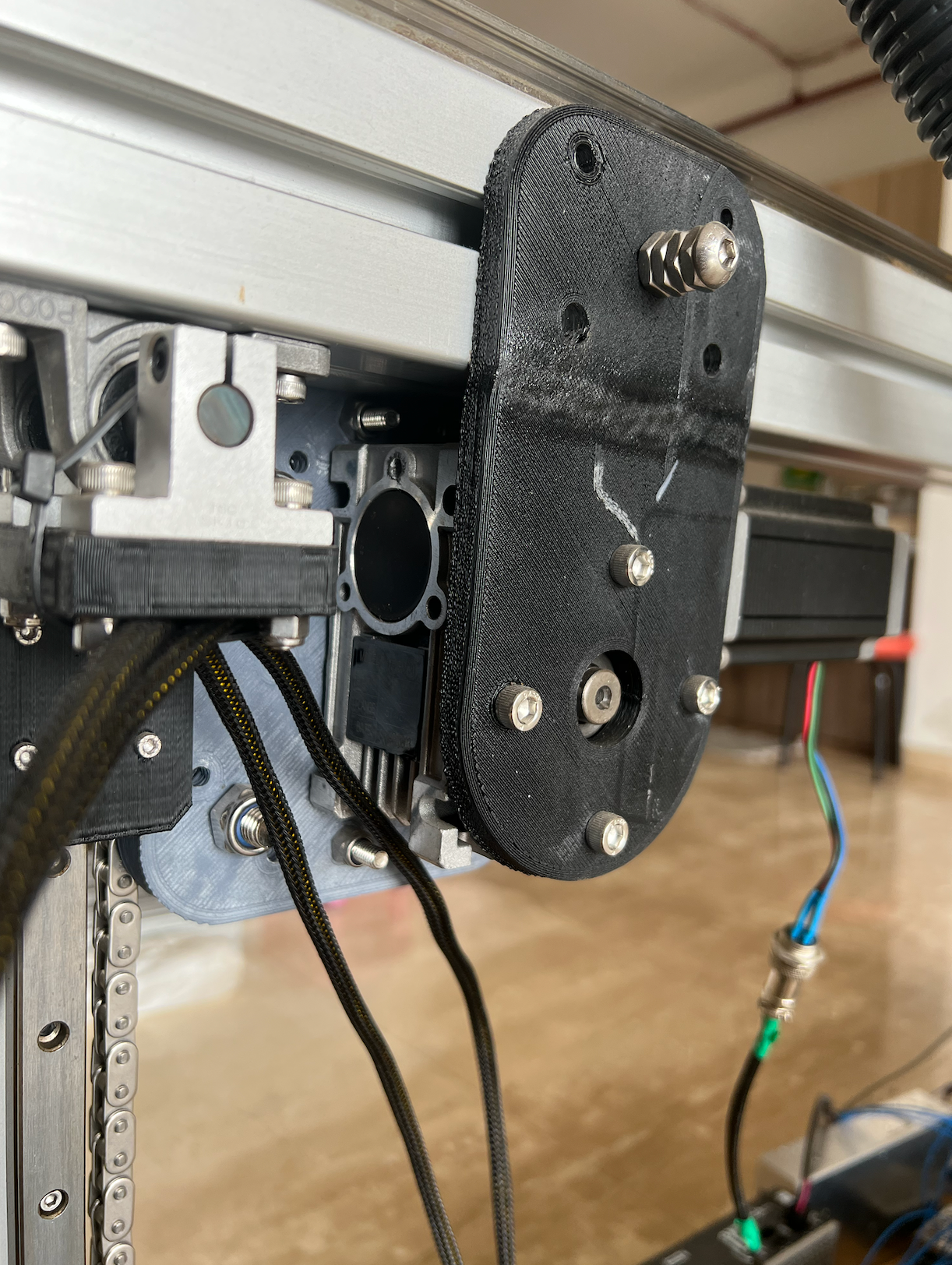

@deckingman I'm not using leadscrews, I've made a custom chain + sprocket assembly that the gantry runs up and down on.

There's a 10:1 worm gearbox between the sprocket and motor. I figured a worm gearbox would not be back-driven but I seem to have selected a lower ratio than required. My current solution to that is to switch the sprockets to smaller-diameter ones or switch the gearboxes to a higher ratio.

I'm leaning toward the latter.Even still assuming the gantry doesn't fall down, I'd like for it to be rock solid in place when the entire actuator-based leveling happens which takes us back to the previous issues.

P.S.: The mounts are only printed to test and will be CNC'd later on.

-

@sotpurk Sorry but there are too many contradictions for me to keep up. In your OP, you stated that when motors are de-energised, the 80 Kgs of mass falls and you want to prevent that happening. My point is that when power is lost for any reason, that 80Kgs of mass is still going to fall. So to my mind, this is a mechanical problem which requires a mechanical solution. Preventing the motors from de-energising when you re-map them isn't going to help if power is lost for some other reason.

-

@deckingman I apologize if my description was confusing.

I will fix the gantry falling by replacing the gearboxes so the gantry falling when power is lost isn't an issue.The problem is only when reassigning the axes while the machine is powered on do the motors lose energy. Now the axis won't fall when that happens even if the motors are not energized, but since it'll be probing the weight is going to be shifting and I would like to have no lost steps.

And since it's an industrial environment I can't rely purely on the worm gears when probing hence it's important that the motors are energized.TL;DR: What happens when power is lost is not the concern here, but keeping the motors energized while probing is.

-

@sotpurk Maybe it's as simple as adding a capacitor to the enable pins? Just to cover the short time gap between assigning and energizing...

IMHO the enable pins aren't time critical part of the motion planner, so adding a bit of delay won't harm.I remember having all drivers on my DIY Duet2 extension board permanently enabled and IIRC the DUEX5 only has one enable pin for all drivers as well.

@T3P3Tony am I right? -

-

@o_lampe Oo that's neat and would solve the issue. Thanks.

I just checked the schematics. All the enable inputs seem to be tied to a single pulled-up line from the MCU.I'll try this out as soon as I get a chance. Thanks again.

-

@sotpurk the enable/disable of individual drivers is done using SPI commands to them. The global enable pin is only used to prevent the drivers being enabled before they have been initialised and for emergency stop.

-

undefined Phaedrux moved this topic from General Discussion

undefined Phaedrux moved this topic from General Discussion

-

-

undefined T3P3Tony referenced this topic

undefined T3P3Tony referenced this topic

-

@o_lampe if the bed has to remain still during a firmware reset (different issue from what the OP was discussing with axis remapping) then the correct solution is to use brakes on the motors, or potentially in some situations geared motors.

-

@T3P3Tony @o_lampe

Yes, have ordered new gearboxes(worm) with higher ratios to mitigate this issue.

The problem with the motors de-energizing when changing assignments still remains though.

I messed around with the firmware but couldn't produce any results.

It seems to be a firmware limitation as was said before and to move forward I've ordered a 6XD with drivers so that I can control the enable and power separately; hopefully that should be enough to get the levelling logic working reliably. -

undefined sotpurk referenced this topic

undefined sotpurk referenced this topic