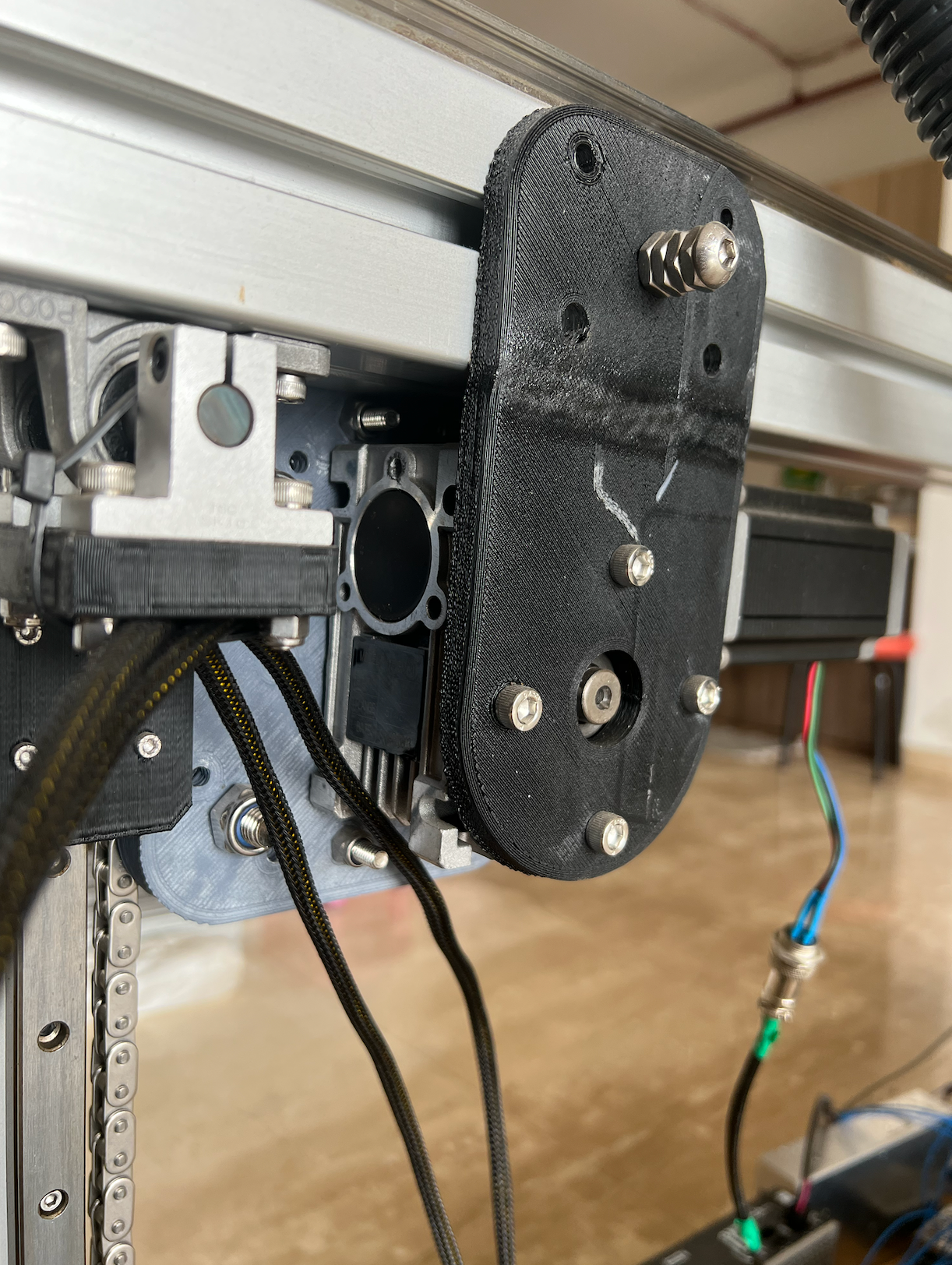

@DrDFlo I got a bit occupied with another project so it still roughly looks the same, but I've changed the Y and X printed mounts to CNC ones and doing the same for Z.

It's producing decent prints now apart from the entire frame oscillating at heights (which is expected since I'm going to support it externally later on)

Because the gantry is rather heavy, It's a lot of wasted energy to level/mesh the bed so I came up with remapping an actuator that has an end-stop at one end as Z when probing. That way only the actuator moves instead of the entire gantry moving in Z; but the 6HC doesn't allow the motors to remain energized when changing assignments so I'm waiting for a 6xd board to be delivered where I can do this externally. (there's no reseller in my country so importing takes too much time) (https://forum.duet3d.com/topic/31694/keep-motors-energised-when-changing-assignment?_=1680794473398)

Also installing a vacuum loop from the extruder for feeding pellets (the momentary exposure to moisture in the air isn't a big deal since the primary storage is isolated and it's only fed when being printed so no long-term exposure.)

Swapping the current worm gears as well, I was under the impression that worm gears can't be back-driven but seems like that's only the case when certain conditions are met. So have ordered new gearboxes with higher ratios (will use the old ones on another build) but man, imports.

Ideally, the extruder doesn't need to move beyond 120mm/s to achieve its maximum output but I've tested the machine to reliably move at 800mm/s which was scary fast.

Here's my most recent print: