The nozzle scratches the part

-

@redax27 Nothing obvious sticks out to me with your print file.

When you start a print, do you start the file with the build plate cold? In your print file it appears as if you home the printer first, and then preheat your bed. I recommend changing your Cura profile to either preheat the bed and nozzle before homing, or re-home after the build plate and nozzle temperatures are reached.

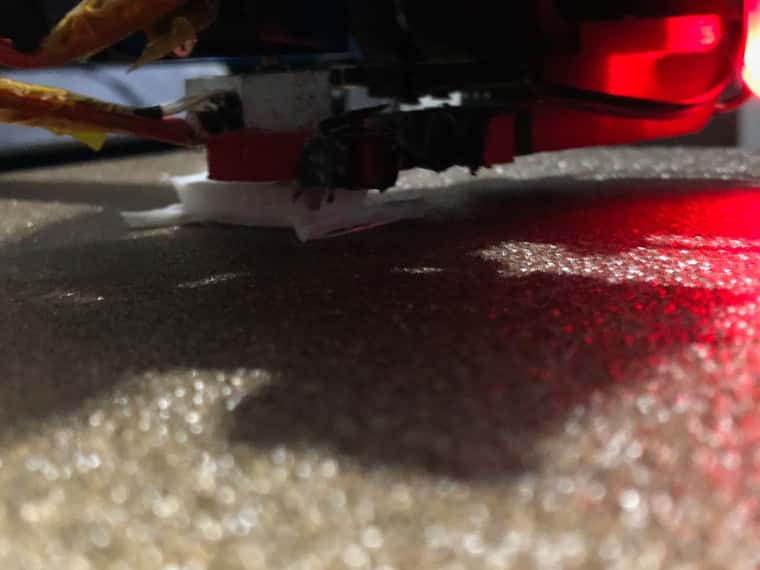

I ask because of this area (same as bottom right):

It looks as if the nozzle and build plate are coming closer together (or even the bed is not level/bent). This COULD happen if your bed, nozzle, frame, etc, are expanding as they increase in temperature. Although, 60°C isn't TOO hot. Could also be that your bed is not flat.

-

@sebkritikel Hi,

Thank you for your answer; the reason why I do it like that is an accuracy measurement problem.

As I let the bed heat during the bl-touch measurement causes a big error (more than 0.5/0.6mm).

If I have no heating and no fans, in this case I have a good measurement and always the same.

I can maybe begin to heat and stop the heating only during the short measurement.

Do you think it's a good idea? The best way is to solve the measurement mistake, but I have no idea how to solve that.

Regards -

@redax27 The accuracy problem - do you mean you see a big difference in the height map when the bed is cool vs. when the bed is hot (for example, you measure when cold, then later measure when hot)? Or do you mean that the BL touch homing may vary/error by .5 / .6mm?

Do you do a height map? If so, can you upload one?

-

@sebkritikel As you say, I think it's an interference when heating. If I do G30-S-1 alone or G30 S-1 with the heating, I have a big measurement difference (around 0,5/0,6). I will add B term as proposed to M558 . For information, see enclosed my map. I have done it by heating the bed @60°C and cut it during the process. It's not perfect because the bed cools down but better than nothing.

heightmap.csv -

@sebkritikel Hi, after some week-end tests, I go ahead but not completely cancelled my problem.

Adding B1 to M558 during measurement cycle is appropriate and cut the heating during measures.

After applying this new feature, G29 seems correct and the printing of the first layer is better. But after several layers the extruder forces again and stops the material feeding.

I begin to be really disappointed because it’s difficult to print something simple.

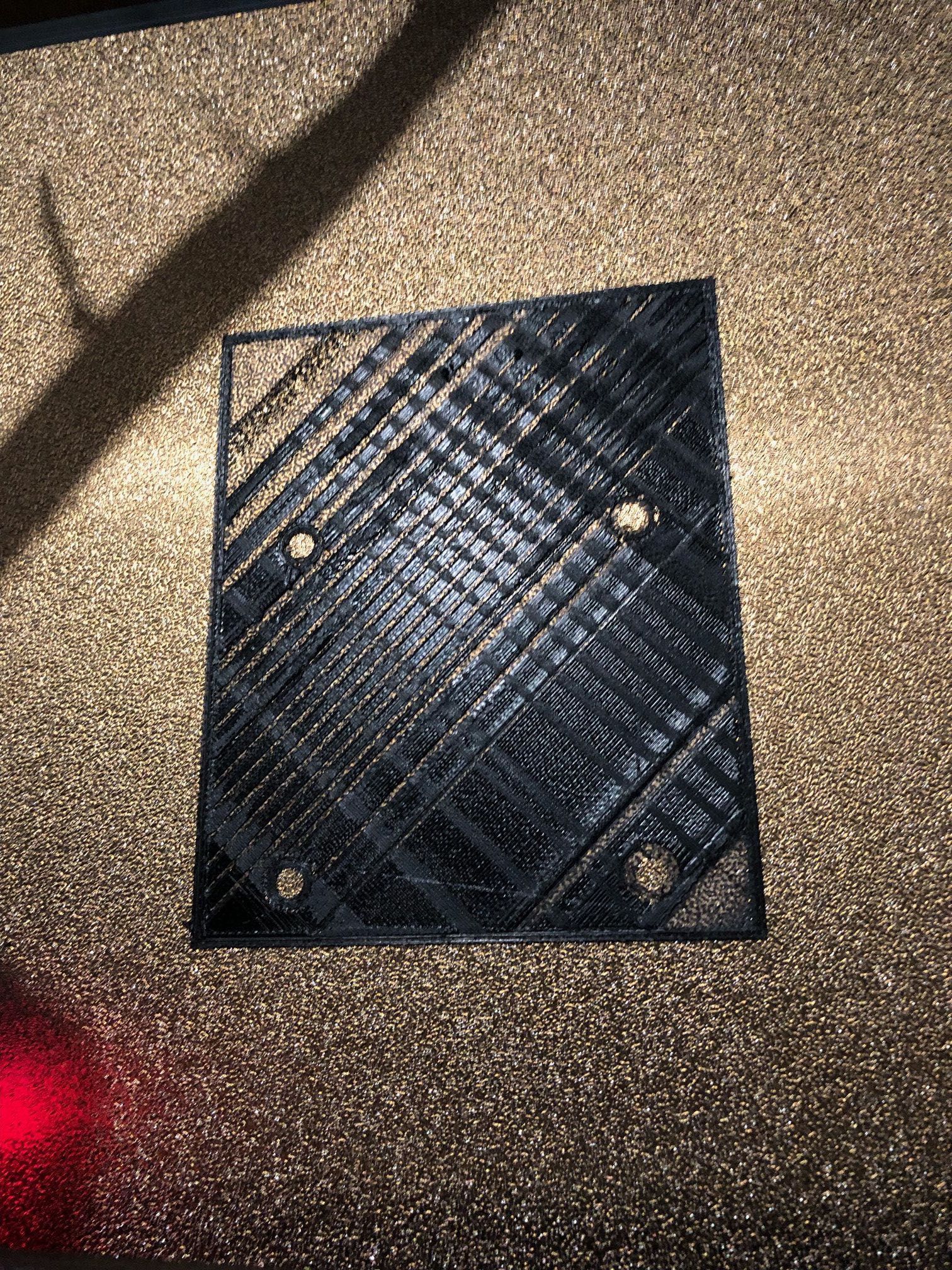

Below my last test. Could it be the atmosphere moisture?

-

Below my last test.

Don’t know much about your printer, the filament you use and the parameters you apply to a print, but your "cabriolet" benchy reminds me of what I get from a (partially) clogged nozzle.

The potential reasons are manyfold and difficult to spot, maybe you can give us some hints:

- filament type (I assume: PLA?)

- wattage of the heater

- heater temperature

- nozzle diameter

- print speed

- retraction settings

- setup of your customised print head

The last item from my list is aimed at a possible heat-creep which may block the filament flow over time. That depends largely on the cooling of your hotend (fan1) and the retraction settings.

-

@infiniteloop, Hi, thank you for your interest.

My last post follows the beginning of the post; at a moment, the nozzle finishes by scratching the part and blocks the material feeding. Below some additional requested information :- filament type: PLA+

- wattage of the heater: 40W

- heater temperature: 210 °C

- nozzle diameter: 0,4

- print speed: 100mm/s

- retraction settings 3mm - no Z hop - no combing mode - 40mm/s

- setup of the customised print head: Bowden head designated to be twice. Running at the moment with a single head (as it’s difficult to make it run, I prefer to begin with a single head). The fan 0 pipe is a weak point, I know it and I have to print a new part. It could be an explanation but I have also the same problem with long time layers (on other parts) where the cooling is less important. But, not 100% sure that it’s not the reason of the problem…

-

@redax27 Thx for the data points. Most of them are quite plausible and unsuspicious to cause nozzle clogging due to heat creeping up to the cold part of the hotend. So, everything looks fine, but …

I don’t wanna adress the part cooling fan (that’s fan 0?) at this stage, although stringing deserves a second thought. To avoid said heat-creep, it is essential to effectively cool the upper part of your hotend - in my understanding of your config.g, that’s the task of fan 1?

Well, whatever fan takes this task - try to verify its operation. In your config, the F parameter in all of your

M106GCodes puzzles me: it should no longer be valid with RRF 3.x. Better to remove that.A second thing to try: halve print speed. I don’t want to doubt the capabilities of your printer, it’s just better to start low.

Then, print a benchy. If you still encounter the same problem, reduce retracts to <0.8 mm: if that works, you have a strong indicator of insufficient hotend cooling. Else, I’m on the wrong path.

-

@infiniteloop first of all, thanks for your last message, it was a good basis for me to investigate and debug my config. I found mistakes, wrong fan numbers, inverting printing fan and nozzle fan. I finally also exchange the mounting of the nozzle fan direction which blowed out and not in.

I had long time ago calibrated the bed heating but not the nozzle heater. It’s now done and, and… I have always the same problem. The last thing not done (as I don’t know how to do it) is the thermistor calibration but really not sure it’s the reason of my problem.

Which method to choose to calibrate my thermistor? And do you have other idea?

I will post later my updated config and the last benchy G-code used at the end.Regards

-

…inverting printing fan and nozzle fan.

Hm, which is what? Commonly, the fan to cool the upper part of the heater is called the "hot end fan", the one which cools the filament after it has left the nozzle is called "print (or part) cooling fan".

In your OP you told us that the print head is completely customised - it might be helpful to post a snapshot so that I can better imagine that thing.

Which method to choose to calibrate my thermistor?

None? TBH, I just checked if my thermistor’s values looked somehow plausible at room temperature

You can find an in-depth tutorial here: Temperature calibration and ADC tuning.

And do you have other idea?

A lot: with 3D printers, there is barely anything that can’t get wrong

Currently, the contributors to this thread stare at the prints you posted. I’ve put my focus on the filament flow and a potential blocking - if you confirm that a nozzle clogging can be ruled-out, I’d propose, as a next step, to print a temperature calibration tower.

-

@infiniteloop Hi, thanks for your last comments, it's really interesting.

Sorry to answer after a so big time; unfortunately, I haven't always enough time to proceed on my tests and try solving this problem.

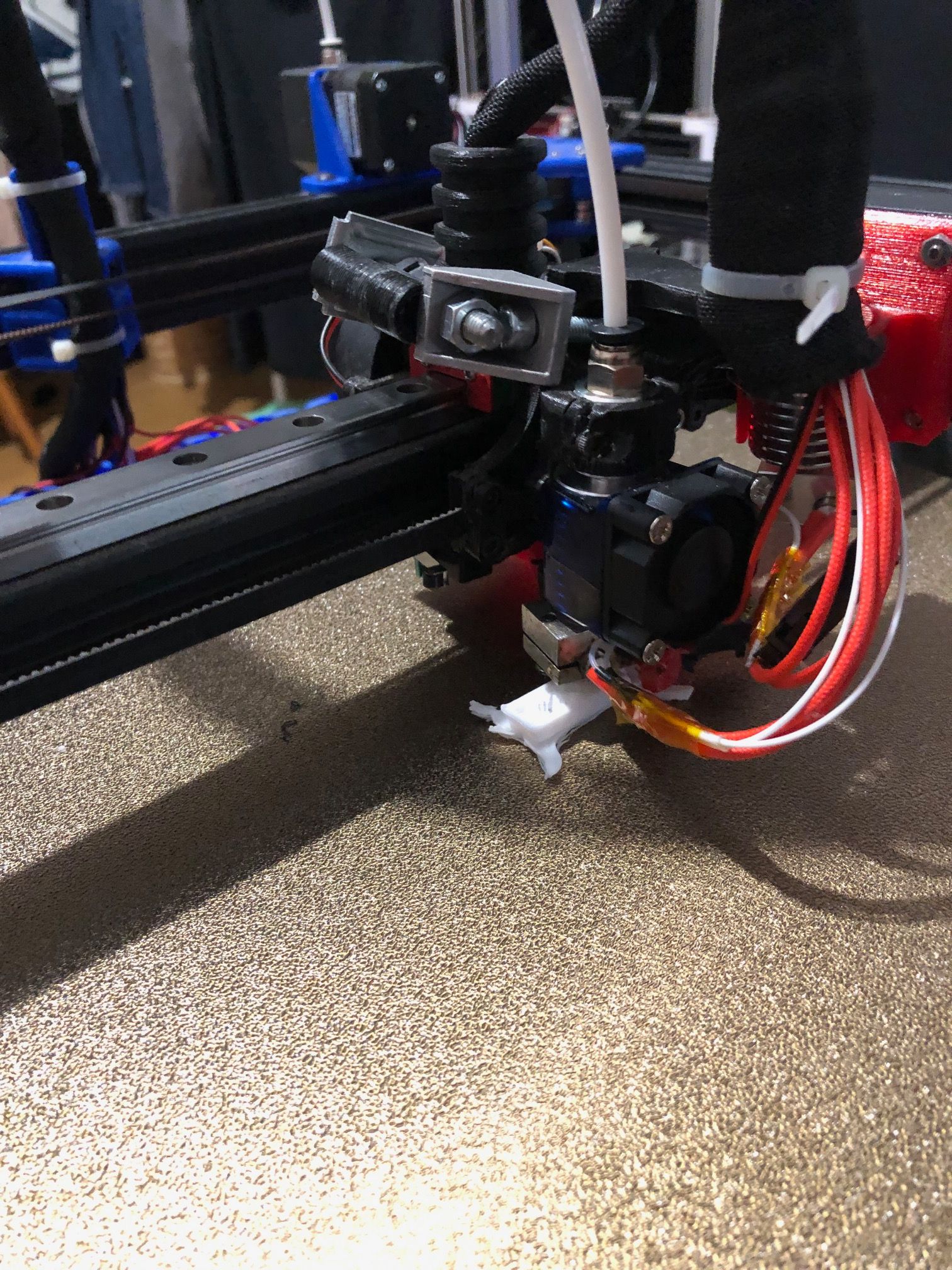

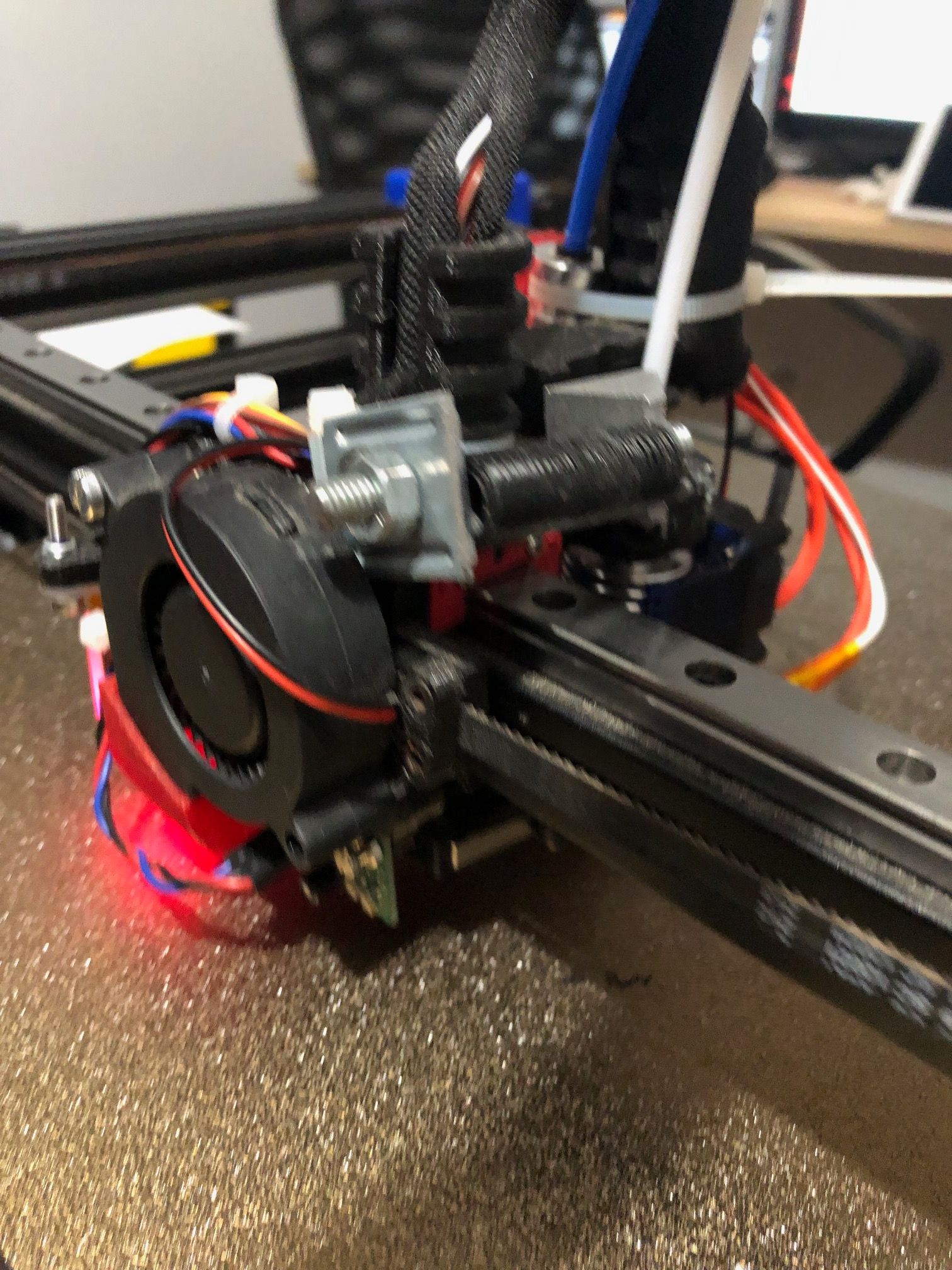

Enclosed some pictures; the head is really not finished and I would like to print new parts with this new printer because the old one is also difficult to run correctly. But my problem is close to the story of the egg and the hen.

I make a little test tonight, completely stop the part cooling fan and what a surprise, the part continue to grow up. It hasn't been finished because of a first layer badly fixed on the bed but nothing I can't solve. I will continue my tests in this direction but I think the main problem is the part cooling fan blowing out on the hot end and not on the part.

I come back asap with news. I hope at the end close this thread!!

-

Thank you for the imagery.

I think the main problem is the part cooling fan blowing out on the hot end and not on the part.

That's a damn good explanation for the clogging. Great you've spotted it. +1 for this.

However, I'm not sure if the part cooling fan is to blame for the irregular extrusion in this print:

As @sebkritikel commented above, there might be a problem with nozzle height and/or bed levelling. You can find some related links under the topic Z Probe, maybe Using the Manual Bed Levelling Assistant is worth a first look?

At this stage of commissioning, I would recommend not to use mesh bed compensation, as it might obfuscate mechanical inconsistencies (e.g. some non-rectangular geometry). To start with, simply probe the nozzle height in the center and at all corners of the bed with a sheet of paper. This should result in a decent first layer - not perfect, but of reasonable quality.

Whatever you get, feel free to post the results so that we can have a look

-

@redax27 the lower part (back end) of the benchy looks OK but the upper parts look as though the extrusion temperature is too high or the print cooling fan had stopped.

-

@dc42 Thank you for this comment, I think I had a little problem with my part cooling which wasn’t piloted at the good moment. It’s solved now.

-

@infiniteloop Hi, regarding my previous comment about the part cooling fan, I have finally changed my calibration by calibrating the tool. Like that the calibration is done with both fans. The part cooling is not so bad, but the nozzle always scratches the part… I begin to have less and less hairs…

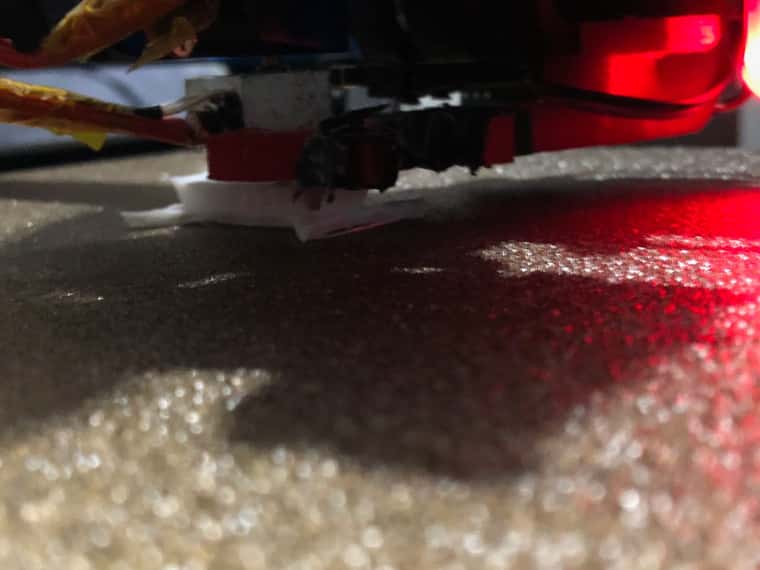

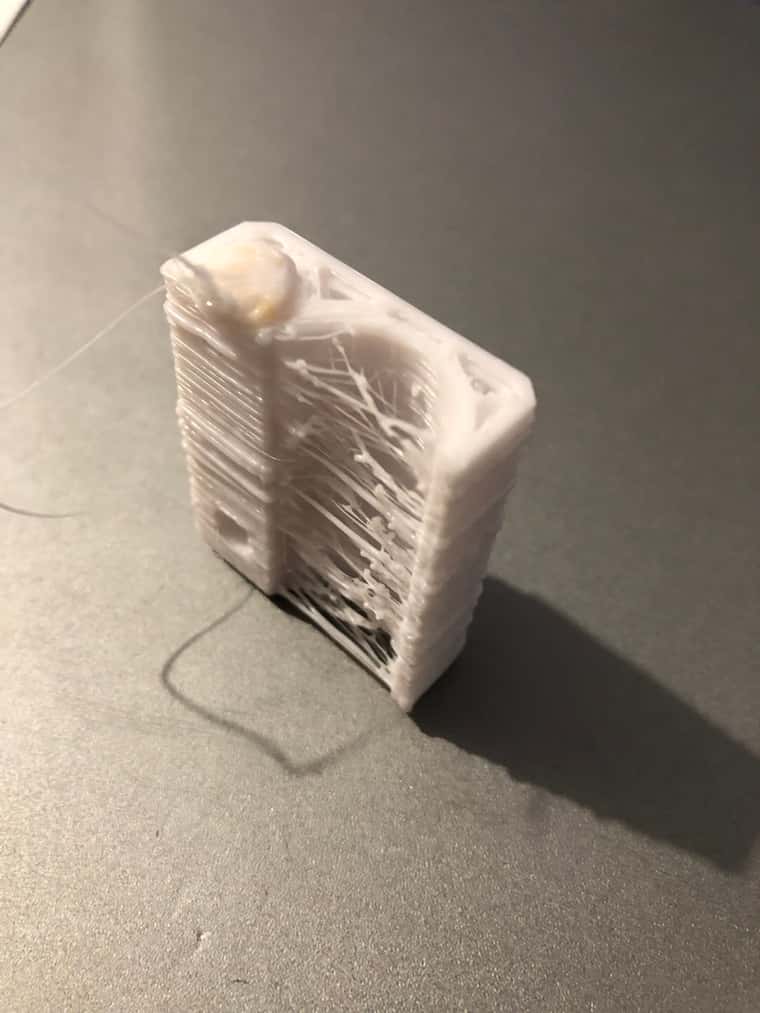

See below an amazing picture.

There is really a big material bubble. My Bowden extruder has a long pipe (around 500mm). I suspect to have too much pressure with a too long pipe. I will try to install a shorter pipe this week-end. Only to verify if it’s the reason of my problem. I have tried maybe not everything but almost… and begin to loose my mind! -

@redax27 Did you set your slicer to use relative E distances?

-

There is really a big material bubble.

Staring at your "amazing picture", I’m not quite sure of the enormous blob on top: is this a) at the final position of the nozzle after the print was terminated, or b) did you kill the job mid-print due to the blob?

We could ignore case a) for the moment, but TBH, I can’t imagine any reason for case b) to occur.

Apart from this monster blob, the result of your test doesn’t look hopeless. But before my critics, I’d like to confess that I’m no genius at all. That’s why I always try to break down complex phaenomina into manageable parts (which, BTW, is a neat job description for a programmer) - in other words: we should take one step at a time.

Step 1: You had some problem with a (partially) blocked filament flow: can we safely assume this being solved by disabling the part cooling fan? (Else, it’s worthless to focus on other problems.)

OK, in that case, you will have to re-design the air duct of the part cooling fan so that it no longer cools the tip of the nozzle. Until then, you cannot avoid stringing.

Step 2: Your test demonstrates excessive stringing. This cannot be avoided as long as the part cooling fan issue is unresolved. Other counter-measures (reduced temperature of the hotend, retraction settings) need to be taken as well, but for the moment, you should only try to reduce the temperature in steps of 5°C per test print. If this leads to nozzle clogging, go up again.

Step 3: From the beginning of this thread, you keep telling us that „the nozzle scratches the part“. To me, that’s not really obvious from the prints you’ve provided, but this picture

lets me think that there might be some parts of the air duct from your part cooling fan reaching down below the nozzle’s tip. It’s all black in black, so I can’t be sure of that. Maybe you can have a quick look at that?Step 4: Judging from your latest print, I tend to think that the layers are not well aligned in both X and Y. This can indicate a problem with positional reproducibility, in other words: double check the joints of your printer’s frame, tighten the v-rollers and/or the belts, have a look at all moving parts, check proper seating of the screws …

– Admittedly, there’s another explanation for what I observe: you could have printed the object at an insane speed, multiple 100 mm/s at least

- Sorry, just kidding.

- Sorry, just kidding.Step 5: After resolving my initial question (the blob) and after verifying proper filament flow (step 1), determining a reasonable extruding temperature (step 2), checking the ride height of the fan duct (step 3), and a strong inspection of your printer’s frame and its moving parts (step 4), so after you’ve resolved these basic issues, it’s time to deal with retraction settings and pressure advance, to fine-tune the first layer (mesh bed levelling?) and to fight stringing.

General recommendations: Within each step, only change one parameter at a time. Else, at least I no longer know which measure affected what. And, please stick with a single print model (maybe the benchy) so that you can compare the results. But there’s no rule without exception: to test the quality of a first layer, the object should cover a major area of the print bed, and to test temperature settings for the given combination of hotend and filament, a temperature tower is the model of choice.

Final advice: Don't panic! We've all gone through this, although …

I begin to have less and less hairs…

Absolute beginner! I've advanced to the premium league: don't need no barber any more

-

@ctilley79 Thank you for your comment; this parameter wasn't accessible from my Cura fitted for my core xy printer. I'm not a specialist but when I forced it by replacing M82 by M83 in my start G-Code, the result was catastrophic with strange noises in the extruder and material strange bubbles... I stop it before the end of the first layer. Not sure but I think this change isn't applicable to a core xy printer.

-

@infiniteloop said in The nozzle scratches the part:

Staring at your "amazing picture", I’m not quite sure of the enormous blob on top: is this a) at the final position of the nozzle after the print was terminated, or b) did you kill the job mid-print due to the blob?

it wasn't the last layer. After this bubble appeared, the hot end clogged and I had to stop it. We have case b).

OK, in that case, you will have to re-design the air duct of the part cooling fan so that it no longer cools the tip of the nozzle.Until then, you cannot avoid stringing.

For sure, I have to work to redesign the air duct. In this case the stringing was awaited; I reduce the retraction to let the part building. Before the bubble, the result was what I was looking for. Before having a new fan duct, I'll try to remove completely the part cooling and reduce the retraction (0.8)

lets me think that there might be some parts of the air duct from your part cooling fan reaching down below the nozzle’s tip. It’s all black in black, so I can’t be sure of that. Maybe you can have a quick look at that?

After a quick check, I'm sure my problem doesn't come from the fan duct scratching the part. The scratching comes from the nozzle as I listen to it but not always during the printing.

multiple 100 mm/s at least - Sorry, just kidding.

The printing is not so quick. I have printed it at 50mm/s. Regarding the quality, you're right, I have to tighten the belts again.

Thanks a lot for your advises, I'll come back when I have some other results...

-

After this bubble appeared, the hot end clogged and I had to stop it. We have case b).

That’s not good, because then, the part cooling fan (better: the air duct) is only part of the problem. Something else helps blocking the filament flow over time. At 50 mm/s, it won’t be due to the sheer volume being extruded…

Hm, what about the hotend fans? They are tiny, so that unhindered air flow is mandatory. I can’t determine that from your pictures, but it’s a thing to examine. An additional problem might occur when the hotend fan of tool 1 is triggered at 45°C: If this happens, both fans operate against each other.