Constant Speed Stepper

-

Hi All,

Is there a recommended way to set a stepper motor running at a constant Speed continuously until you command it to stop.I thought perhaps sending a G1 command and just use Damon.g to reset the axis position to prevent it getting to the target value?

Or am I missing something obvious...?

Any constructive thoughts would be much appreciated.

All the best

Barry M -

The stepper isn't the same as a DC motor you can just turn on, you have to send it steps. So it depends how long you need to to run for. You could make it a very long axis and command it to move the entire length.

What exactly are you trying to do?

-

@CNCModeller Part of the problem is stopping the motor when you want to. If you use a series of moves, there will always be a slight pause between one move ending and the next starting. You can mitigate that somewhat by using longer length moves but then you can only stop the motor when one move finishes which might not be desirable depending on what you are trying to do. One possibility might to use an external pulse generator built around a 555 timer or some such and feed to output of that into an external stepper driver. You could then use an io pin to start and stop the pulse generator. All in all, it'd be a lot simpler to use a DC motor.

-

@Phaedrux said in Constant Speed Stepper:

What exactly are you trying to do?

It's to drive a mechanical mixing shaft on a custom mixing extruder based on the papers here

https://www.reprap.org/wiki/Mixer_extruder

I could just use a DC motor but I really wanted to have accurate speed control so I have repeatable control over the extrusion conditions.

After thinking more I'm also guessing that any gcode based control would prevent other motion until the long mixing "move" was completed.

Many thanks

Barry M -

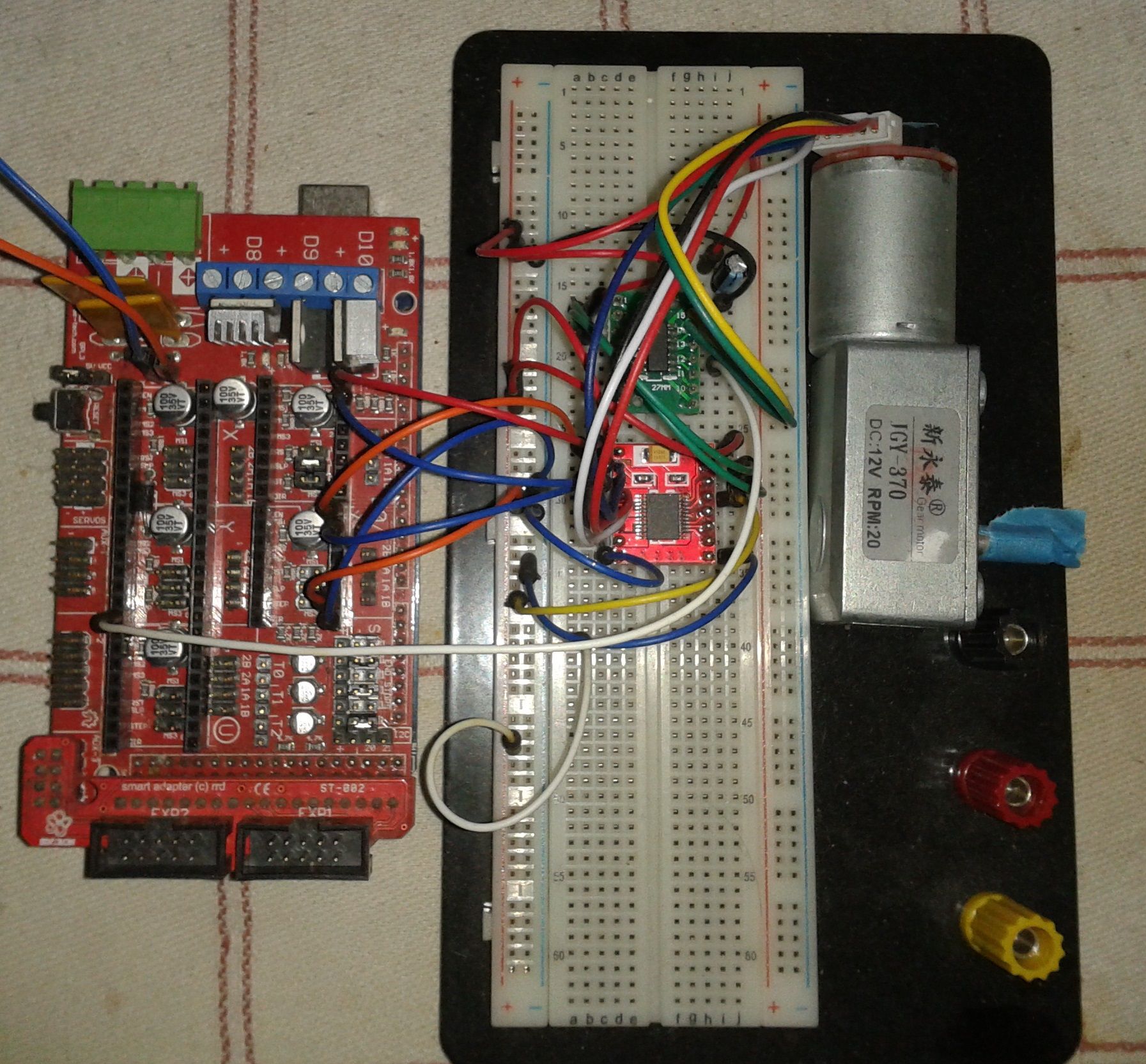

@deckingman, thanks, yes I'm gravitating towards an external Arduino setup that monitors a speed variable over the panel due interface if that's possible...

-

@CNCModeller said in Constant Speed Stepper:

It's to drive a mechanical mixing shaft on a custom mixing extruder based on the papers here.......................

Before you go too far down this road, I'd like to offer a word of caution if I may. As someone who has spent years developing multi-input hot ends, I feel qualified to do so. You'll note that the papers you referred to are from 2014 and earlier - some 9 years ago and yet there are no successful commercially available designs. Some claim to be but when you delve into things, you'll discover that they only work with continuous printing - i.e with no travel moves and usually at constant extruder speed such as vase mode. The biggest challenge that you will face (and which nobody mentions), is how to stop extrusion for non-print moves. We currently do this by retracting filament which works fairly well with current hot end designs. But when you introduce a complex mixing chamber in between the extruder and the nozzle, that retraction of filament at the input to the mixing chamber, does not lead to a simultaneous reduction in pressure at the nozzle. So you'll need to find some other way of preventing the filament from oozing during travel moves. The second biggest problem is related to the first and it is that small extruder moves on the inlet side may result in an increase in pressure at the entrance to the mixing chamber, but that increase in pressure does not instantly translate to the nozzle tip. For want of a better description, the volume of molten filament and the complexity of the geometry within the mixing chamber act as a sponge and damp out any small extruder moves. So parts with any sort of detail, become almost impossible to print.

So unless you can overcome those two challenges, you'll be restricted to producing things like vases or other parts that lack detail and/or which have no "non-print" travel moves.

I have thought that the retraction problem could possibly be overcome by shaping the end of the mixing shaft such that it would form a pintle valve. This would of course involve using a linear vertical movement as well as rotary movement. The lack of detail issue would involve using some form of "squirting" filament out of the nozzle other than varying the flow of filament entering the mixing chamber which is a much more complex problem to solve.

So just a word of caution before you spend too much time, effort and cash (as I have done).

-

@CNCModeller we are planning to implement this feature in RRF 3.6. Meanwhile it would be possible to use daemon.g to turn a stepper constantly using the second motion system, but the response time to a command to stop turning might be poor.

-

@CNCModeller A long time back, I have used a few DC motors with encoder to mimic a stepper controlled by a ATtiny arduino and a DCDC- halfbridge.( not L298..but L6201?)

Using those encoder motors for closed loop speed control is much easier.

-

@dc42 said in Constant Speed Stepper:

@CNCModeller we are planning to implement this feature in RRF 3.6. Meanwhile it would be possible to use daemon.g to turn a stepper constantly using the second motion system, but the response time to a command to stop turning might be poor.

Thanks @dc42 useful information

-

@deckingman thanks for sharing your experience.

It sounds like most of the issues you discussed I already have to deal with with lightweight foaming pla.

My models are mostly large very complicated vase mode prints so in theory much of what you discussed shouldn't be a problem.

I'm looking to mix standard pla, foaming pla and carbon fibre pla to achieve different material properties / densities in different regions of my prints so proper mixing is really important.

I'm also hoping that vigorous mechanical mixing with a relatively small mixing region will reduce the lag between mix change and mixed filament composition at the nozzle. I'm assuming preprocessing the gcode to change the mix ratio ahead of time should cover that.

Having some form of valve at the exit of the mixing chamber could be interesting

albeit it would increase composition lag at the nozzle due to added volume, and would need to operate at high temperatures.

albeit it would increase composition lag at the nozzle due to added volume, and would need to operate at high temperatures.I have several other technical issues to address, but for now just want to get a working prototype mechanical mixing nozzle that doesn't leak filament!

Anyway thanks again for everyone's thoughts.

All the best

Barry M -

@o_lampe thanks yeah I am considering a separate Arduino+ step stick based controller that jus takes a pwm input from a fan header or the spindle output.

-

@CNCModeller The only other advice I can give is that the inside pressures are much greater than one would have thought. My multi sectioned hot ends involved lots of lapping of faces and more fixings than I would have thought necessary. Sealing the shaft from filament leakage whilst still allowing it turn reasonably freely is another challenge that won't be easy to overcome.

But good luck and please keep us informed of progress. Although age and lack of funds have led me to abandon my own efforts, it's still a subject of interest to me.

-

@deckingman will post updates as I go.