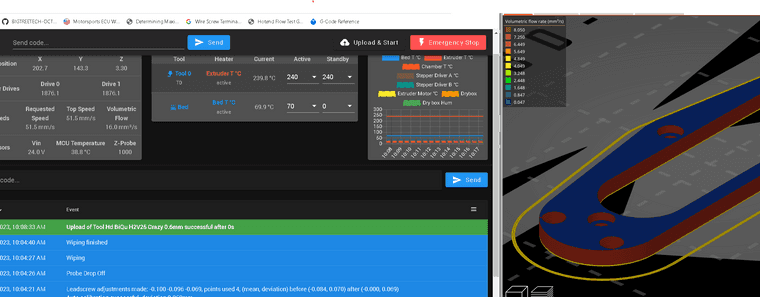

DWC volumetric flow that 2 x that of prusa slicer

-

the volumectric flow rate reported in DWC is 2 x what prusa slicer shows.

prusa slicer v2.5.2

-

I didn't even notice that the last upgrade to DWC set up a display for volumetric flow . Cool new feature. Sorry that I can't help you out with your question.

-

as discussed in the discord when you presented your issue there, people would need to see your machine configuration, an output of M122, your slicer configuration, and example gcode to have a fighting chance of figuring out what the issue is.

I can only add that I cannot replicate this issue with PrusaSlicer 2.6.0 and RRF 3.5b4.

-

@oliof thought i would move it to DWC

M122

=== Diagnostics ===

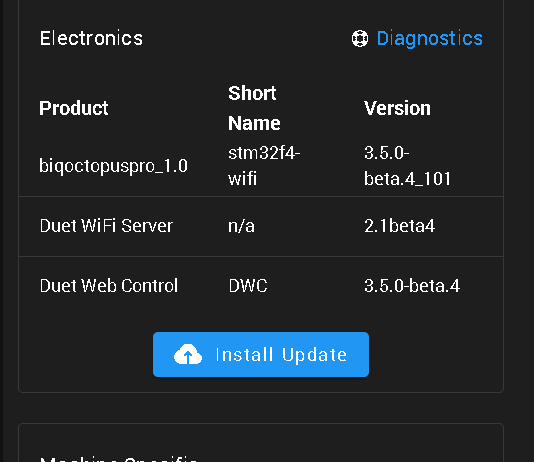

RepRapFirmware for STM32F4 based Boards (biqoctopuspro_1.0) version 3.5.0-beta.4_101 (2023-06-10 19:03:47) running on STM32F4 (standalone mode)

Board ID: 32063-002JU-NJ38P-6T18S-HFUN7-70000

Used output buffers: 3 of 40 (33 max)

=== RTOS ===

Static ram: 19636

Dynamic ram: 92072 of which 0 recycled

Never used RAM 18336, free system stack 105 words

CCMRam static ram: 24276 dynamic ram: 34380 free ram 6876

Tasks: NETWORK(2,nWait,118.2%,176) HEAT(3,nWait,0.4%,324) Move(4,nWait,0.9%,275) TMC51xx(4,delaying,70.1%,116) FSWRITE(2,nWait,0.0%,492) MAIN(1,running,36.4%,538) IDLE(0,ready,0.3%,29), total 226.2%

Owned mutexes: WiFi(NETWORK)

=== Platform ===

Last reset 07:37:25 ago, cause: software

Last software reset at 2023-07-07 12:15, reason: User, Gcodes spinning, available RAM 18132, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x08

MCU temperature: min 35.1, current 37.3, max 41.5

Supply voltage: min 24.0, current 24.0, max 24.0, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 99/13, heap memory allocated/used/recyclable 2048/1540/1340, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: standstill 5160, SG min 0, mspos 952, reads 43963, writes 55, write errors 1

Driver 1: standstill 5160, SG min 0, mspos 632, reads 43963, writes 55, write errors 1

Driver 2: standstill 5160, SG min 0, mspos 744, reads 43989, writes 30

Driver 3: standstill 5160, SG min 0, mspos 884, reads 43976, writes 43, write errors 1

Driver 4: standstill 5160, SG min 0, mspos 548, reads 43977, writes 42, write errors 1

Driver 5: standstill 5160, SG min 0, mspos 4, reads 43977, writes 42, write errors 1

Driver 6: not present

Driver 7: standstill 5160, SG min 0, mspos 24, reads 43991, writes 28

Driver 8:

Driver 9:

Driver 10:

Driver 11:

Driver 12:

Driver 13:

Date/time: 2023-07-07 19:53:22

Slowest loop: 320.96ms; fastest: 0.07ms

=== Storage ===

Free file entries: 20

SD card 0 detected

SD card longest read time 5.9ms, write time 25.4ms, max retries 0

=== Move ===

DMs created 83, segments created 34, maxWait 107224ms, bed compensation in use: none, height map offset 0.000, ebfmin -1.00, ebfmax 1.00

no step interrupt scheduled

=== DDARing 0 ===

Scheduled moves 57782, completed 57782, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 2], CDDA state -1

=== DDARing 1 ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

Heater 0 is on, I-accum = 0.1

Heater 1 is on, I-accum = 0.5

=== GCodes ===

Movement locks held by null, null

HTTP is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

File2 is idle in state(s) 0, sync state 2

Queue2 is idle in state(s) 0

Q0 segments left 0, axes/extruders owned 0x0006003

Code queue 0 is empty

Q1 segments left 0, axes/extruders owned 0x0000000

Code queue 1 is empty

=== Filament sensors ===

Extruder 0 sensor: ok

=== CAN ===

Disabled

Longest wait 0ms for reply type 0, peak Tx sync delay 0 free buffers 0 (min 0), ts 0/0/0

Tx timeouts 0,0,0,0,0,0

=== Network ===

Slowest loop: 242.65ms; fastest: 0.00ms

Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0)

HTTP sessions: 1 of 8

Uploads/Errors: 3/0

= WiFi =

Interface state: active

Module is connected to access point

Failed messages: pending 0, notready 0, noresp 0

Bad header: 0/0

Firmware version 2.1beta4

MAC address e8:68:e7:d9:f9:a3

Module reset reason: Turned on by main processor, Vcc 3.39, flash size 2097152, free heap 42916

WiFi IP address 192.168.0.21

Signal strength -57dBm, channel 1, mode 802.11n, reconnections 0

Clock register 00002002

Socket states: 0 0 0 0 0 0 0 0 -

-

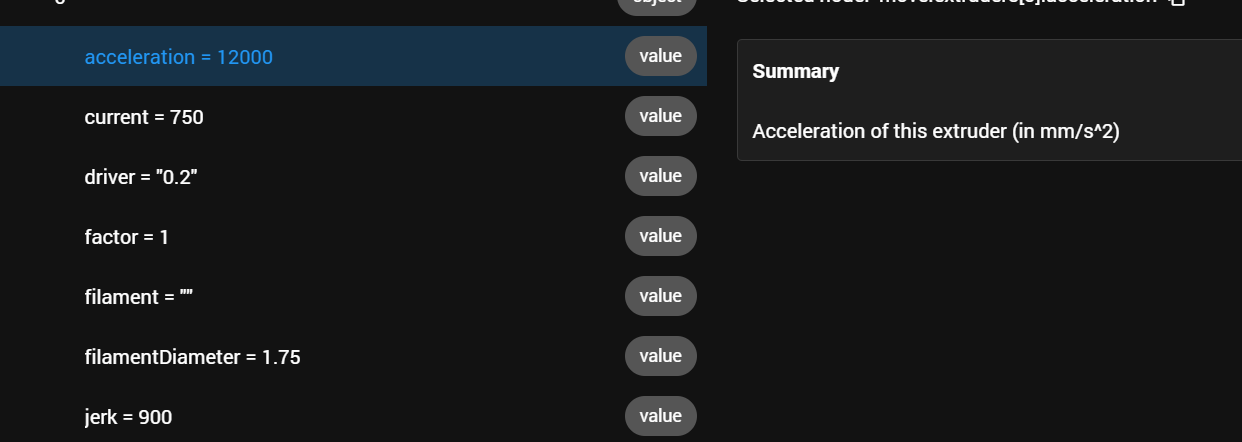

@moth4017 also check in the object model browser that move.extruders[0].filamentDiameter is correct. RRF passes the extrusion rate in mm/sec to DWC, and DWC uses the filament diameter to convert it to mm^3/sec.

-

-

@moth4017

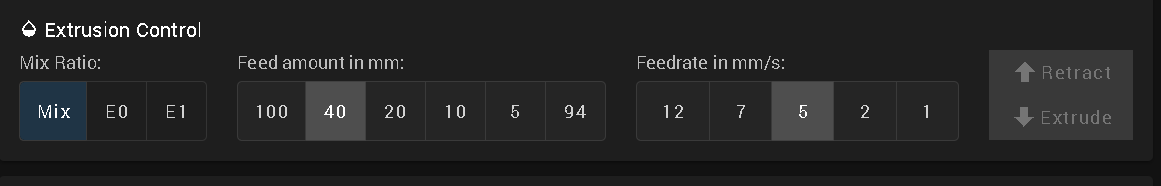

i do have 2 extruders running at the same time in a push pull configuration is it possible its adding both values? -

@moth4017 Set the mixing ratios to 50%:50% and double your E steps/mm (and potentially other E-related settings), else your filament-based estimation is probably off, too.

-

@moth4017 said in DWC volumetric flow that 2 x that of prusa slicer:

@moth4017

i do have 2 extruders running at the same time in a push pull configuration is it possible its adding both values?Yes. The firmware has no way of knowing if the mechanical configuration is a single input hot end with two extruders in push-pull configuration, or if it's a two in one out mixing hot end with both extruders feeding different filaments. So it will combine the flow for each extruder in accordance with the mixing ratio in use (in your case that would be 1.00:1.00 so 200%).

-

@deckingman if the esteps are different on each extruder is it still 50:50 or does it have to be in the estep ratio?

-

@moth4017 said in DWC volumetric flow that 2 x that of prusa slicer:

@deckingman if the esteps are different on each extruder is it still 50:50 or does it have to be in the estep ratio?

Not sure I fully understand your question but for the purposes of calculating volumetric flow correctly, the sum of mixing ratio should add up to unity. As @chrishamm has said, you could double the steps per mm for both extruders then use 0.5:0.5 instead of 1.0:1.0. If you have different steps per mm for each extruder and the system works but the only problem is the displayed volumetric flow values is exactly double what it should be, and if your current mixing ratio is 1.00:1.00, then double both extruder steps per mm from their current values and halve the mixing ratio to 0.5:0.5.

-

@deckingman

interesting at 50% its is half the speed of prursa slicer so:at

M567 P0 E0.5:0.5 half the speed of the prusa rate DWC 4mm^3 Prusa 8mm^3

M567 P0 E1:1 is twice the speed of the prusa rate DWC 16mm^3 Prusa 8mm^3 in DWC if i extrude 40mm on 20mm is extruded

in DWC if i extrude 40mm on 20mm is extruded

M567 P0 E0.5:0.5 it is also only extruding half the amount of filamenti guess because it is selected in "Mix" but it also Prints in "Mix" because it assumes the extruders are in parallel.

@dc42 may be there needs to be an added option to M567 2P ( for 2 extruders in parallel) or 2S (for 2 extruders in series

) etc . -

@moth4017 Did you change the extruder steps per mm as well as the mixing ratio?

-

@deckingman no only the ratios , i left the steps/mm correct for the extruder

-

@moth4017 That's your problem. DWC will report the extrusion amount based on the sum of each extruder in accordance with the mixing ratio. So when you used 1.0:1.0 you were seeing the volumetric extrusion reported as being double but the actual amount extruded was correct. By changing it to 0.5:0.5 in a push pull arrangement, each extruder will physically half the amount needed. That's why both @chrishamm and I told you to double the steps per mm for each extruder so that the amount physically extruded would remain the same.

-

would it make more sense for the software to adjust the steps/mm so that you can set up the extruders with the correct steps, because when your using multiple tools keeping track of them is fun .

thanks for all the help