Linear Rail X Gantry Support (MGN12)

-

@Dizzwold said in Linear Rail X Gantry Support (MGN12):

Hi Ian,

Just to revisit this before I consider getting some items machined;

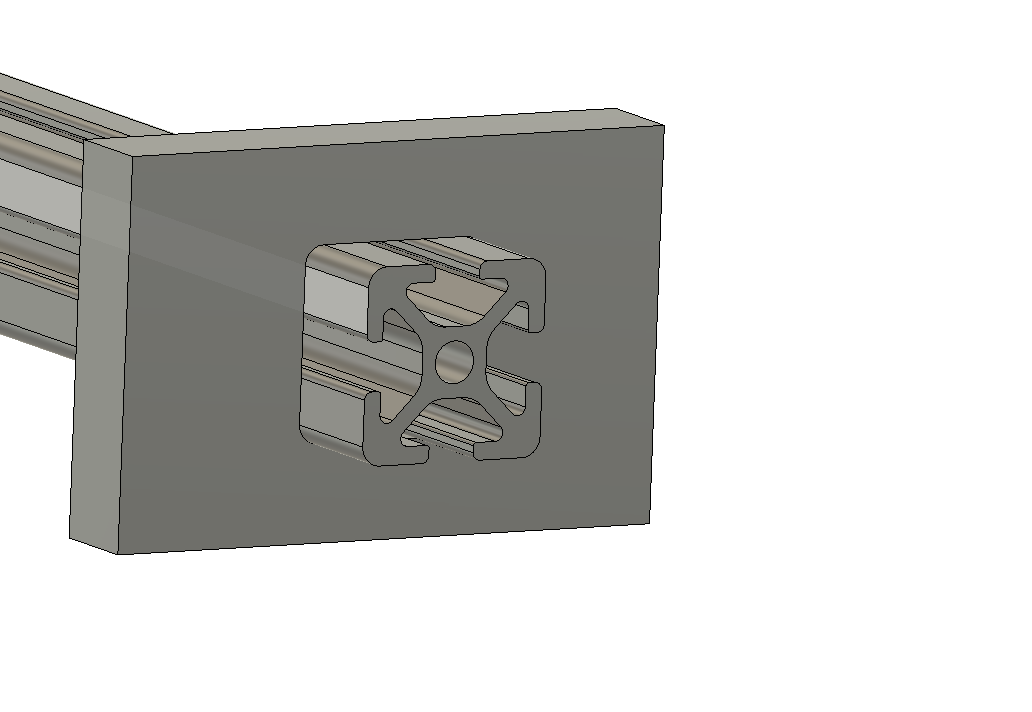

What, if any gap should I add to the hole for the extrusion to fit. I'll be using something along the lines of your solution of adding a T nut perpendicular to the extrusion, but should the hole be machined exactly to the dimensions of the extrusion?If you are going to clamp it in place, then a small amount of clearance will make assembly easier. I'd give your machinist a tollerance of -0, +0.5 mm. I.e the hole must be no smaller than than the extrusion but can be up to 0.5mm larger. It's important that the distance from the bottom of the block to the bottom of the hole must be the same for both blocks otherwise the rail will be higher one end than the other.

-

@Dizzwold Thanks! Page 63, bottom right - smooth idlers should have diameter equivalent of the pitch diameter of a 40 tooth pulley. Page 18 shows the pitch diameter of a 40 tooth pulley (for 2mm pitch belt) is 25.46 mm. So the 608 bearings are a little small at 22 mm, but I haven't seen any issues with them.

-

Hi Ian,

Thank you for your advice. I'm most grateful.

Hi Mark,

Glad to help and actually contribute for a change.

Are either of you moderators, or can put the Gates Timing Belt info in a file somewhere, where everyone can access it easily from the forum main page or something?

I think most users of the forum use Gates belts (or similar), so could be very handy for others.Thanks again,

Dizzwold.