Need help to configure Heaters and Temperature sensors PT100

-

Good morning:

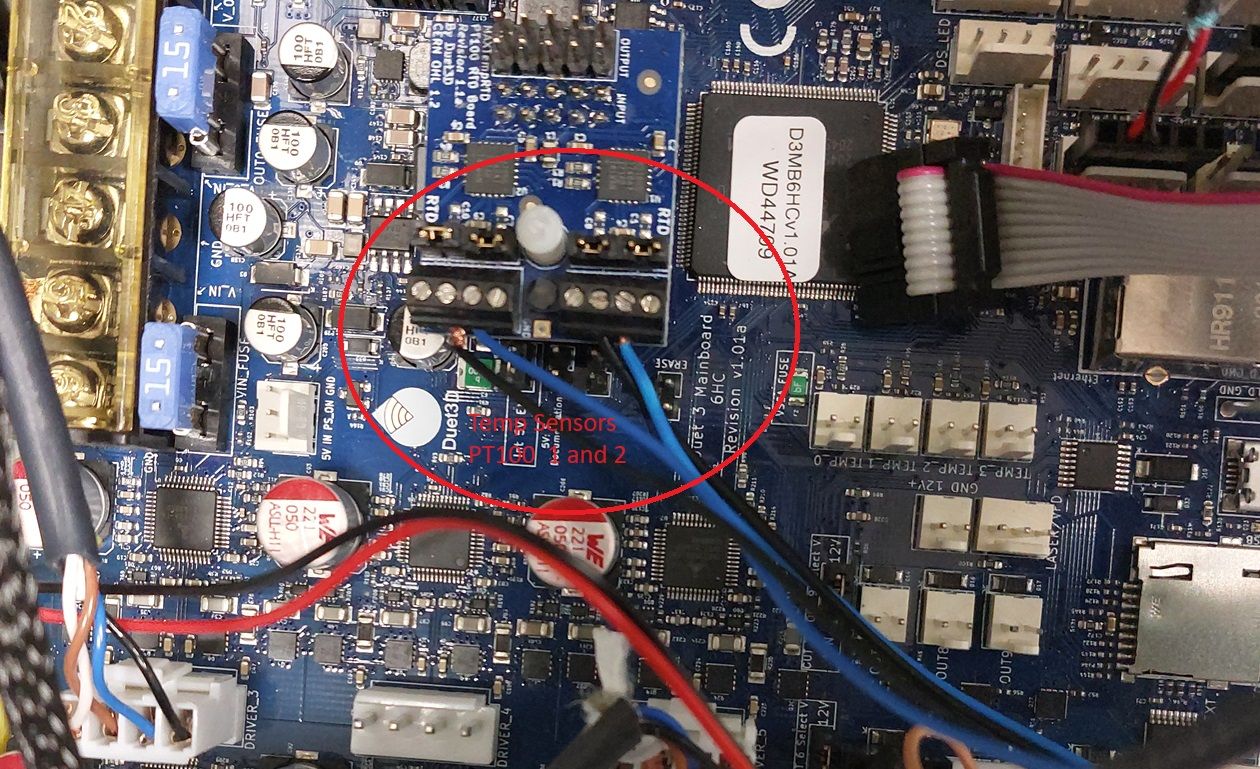

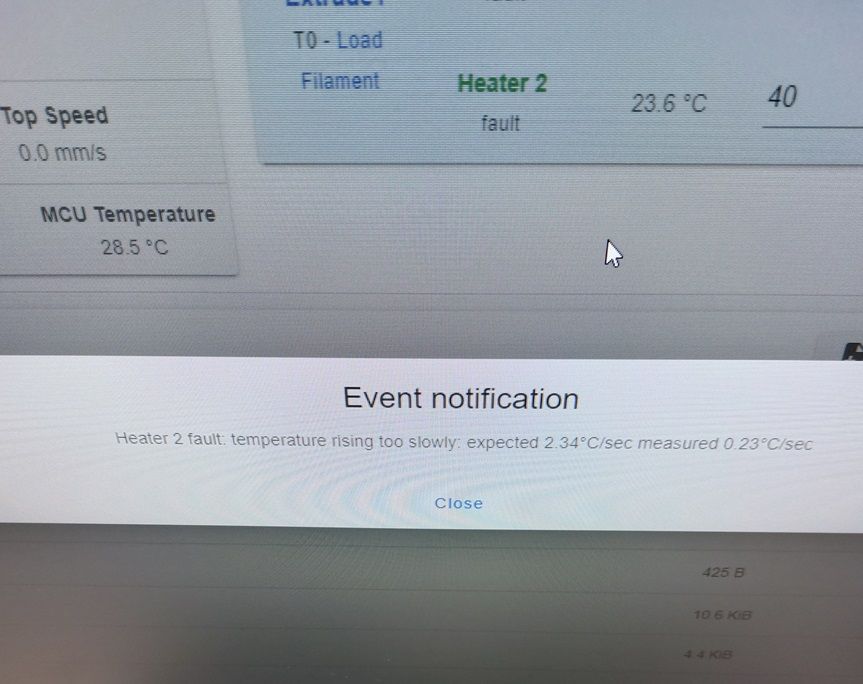

I would need help to configure the heaters on my Duet 3 Mainboard 6HC, I have a print head with a heater and a material dispenser that also has a heater, the temperature sensors are PT100 type. I have a max31865 board for the PT 100 sensors (RTD1 and RTD2), which are 2, the temperatures are displayed well on the screen but it seems that it is not able to control the temperature of the heaters with the sensors, it does not relate them well.

I manage to heat the head and the dispenser but not control the temperature, even though they heat up and up ...., they exceed the limit that I set in the software,

my config.g ....

; General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"ROBO" ; set printer name; Network

M552 P192.168.1.20 S1 ; enable network and set IP address

M553 P255.255.255.0 ; set netmask

M554 P192.168.1.254 ; set gateway

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0.0 S0 ; physical drive 0.0 goes forwards

M569 P0.1 S0 ; physical drive 0.1 goes forwards

M569 P0.2 S0 ; physical drive 0.2 goes forwards

M569 P0.3 S0 ; physical drive 0.3 goes forwards

M569 P0.5 S0 ; physical drive 0.5 goes forwards

M584 X0.0:0.3 Y0.1 Z0.2 E0.5 ; set drive mapping

;M584 0.3 Y0.1 Z0.2 E0.5 ; set drive mapping

M350 X2 Y2 Z2 E4 I1 ; configure microstepping with interpolation

;M350 X4 Y4 Z4 E16 I1 ; configure microstepping with interpolation

;M92 X80.00 Y80.00 Z80.00 E420.00 ; set steps per mm

;M92 X1626.68 Y1626.68 Z1626.68 E420.00 ; set steps per mm

;M92 X200.00 Y200.00 Z200.00 E420.00 ; set steps per mm

M92 X196.00 Y205.80 Z196.14 E420.00 ; set steps per mm

M566 X100.00 Y100.00 Z20.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

;M203 X1200.00 Y1200.00 Z600.00 E1200.00 ; set maximum speeds (mm/min)

;M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

;M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M203 X600.00 Y600.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X50.00 Y50.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X3360 Y3360 Z3360 E2987 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; PanelDue 7i

M575 P1 S1 B115200; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X100 Y400 Z200 S0 ; set axis maxima; Endstops

M574 X1 S1 P"^io1.in"

M574 Y1 S1 P"^io2.in"

;M574 Z2 S1 P"^io3.in"

M574 Z1 S1 P"^io3.in"; Z-Probe

M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M557 X15:99 Y15:399 S200 ; define mesh grid; Fans

M950 F0 C"out4" Q500 ; create fan 0 on pin out4 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"out5" Q500 ; create fan 1 on pin out5 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 F0 H1:2 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R50 S60 ; set initial tool 0 active and standby temperatures to 50C

T0; Heaters

M308 S1 P"spi.cs0" Y"rtd-max31865" ; configure sensor 1 as PT100 on pin spi.cs0

M950 H1 C"out1" T1 ; create nozzle heater output on !out1 and map it to sensor 1

M307 H1 B0 S1.00 V24.0 ; disable bang-bang mode for heater and set PWM limit

M303 H1 P1 S40 ; Heater 1 power 100% Temp limit 40º

M143 H1 P0 S50 A2 ; set temperature limit for heater 1 to 50C

M308 S2 P"spi.cs1" Y"rtd-max31865" ; configure sensor 2 as PT100 on pin spi.cs1

M950 H2 C"out2" T2 ; create nozzle heater output on !out2 and map it to sensor 2

M307 H2 B0 S1.00 V24.0 ; disable bang-bang mode for heater and set PWM limit

M303 H2 P1 S40 ; Heater 2 power 100% Temp limit 40º

M143 H2 P0 S50 A2 ; set temperature limit for heater 2 to 50C; Custom settings are not defined

Thanks

-

@imartinez have you tuned your heaters using M303?

-

@jay_s_uk said in Need help to configure Heaters and Temperature sensors PT100:

M303

No... I don´t know how to use M303 comand.....

-

-

I use this line in my config.g...

M303 H1 P1 S40 ; Heater 1 power 100% Temp limit 40º

But i don´t know this is correct or not.....

-

@imartinez thats not correct. M303 tuning is not done as part of your config. its a command you send separately

-

Ok, I think i must remove this line from mi config.g and execute it like a comand in mi control panel , correct???

is this the execute form i must tu use ????

M303 H1 P1 S40

Thank you very much.....

-

@imartinez correct.

maybe this gives a bit more info https://docs.duet3d.com/en/User_manual/Connecting_hardware/Heaters_tuning -

-

-

Ok... Thank You very much....

should i remove all this lines from my config.g???

M308 S1 P"spi.cs0" Y"rtd-max31865" ; configure sensor 1 as PT100 on pin spi.cs0

M950 H1 C"out1" T1 ; create nozzle heater output on !out1 and map it to sensor 1

M307 H1 B0 S1.00 V24.0 ; disable bang-bang mode for heater and set PWM limit

M303 H1 P1 S40 ; Heater 1 power 100% Temp limit 40º

M143 H1 P0 S50 A2 ; set temperature limit for heater 1 to 50C

M308 S2 P"spi.cs1" Y"rtd-max31865" ; configure sensor 2 as PT100 on pin spi.cs1

M950 H2 C"out2" T2 ; create nozzle heater output on !out2 and map it to sensor 2

M307 H2 B0 S1.00 V24.0 ; disable bang-bang mode for heater and set PWM limit

M303 H2 P1 S40 ; Heater 2 power 100% Temp limit 40º

M143 H2 P0 S50 A2 ; set temperature limit for heater 2 to 50C -

@imartinez no, you need all those. either replace the M307 lines or use M500 and config-override.g

-

-

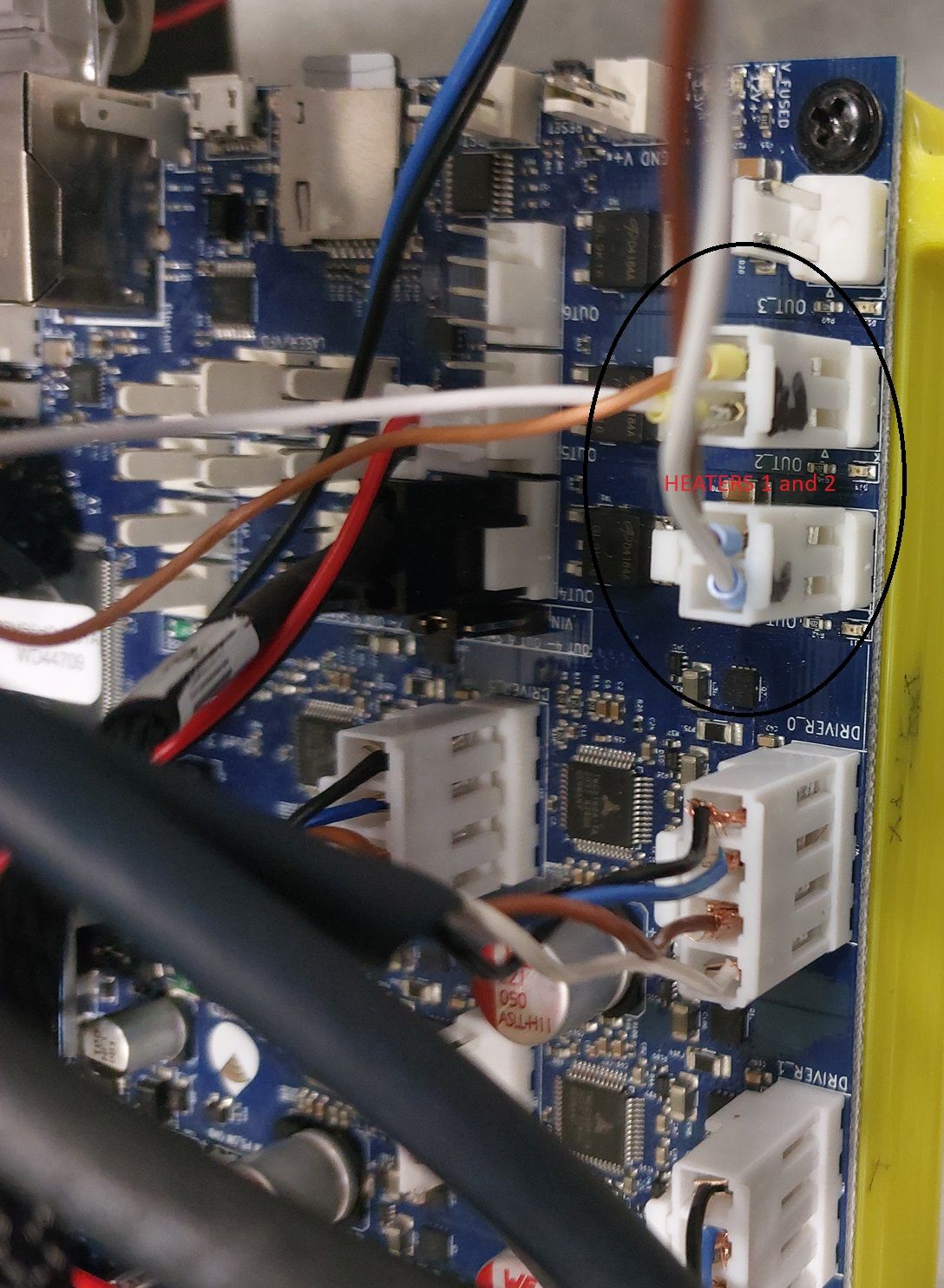

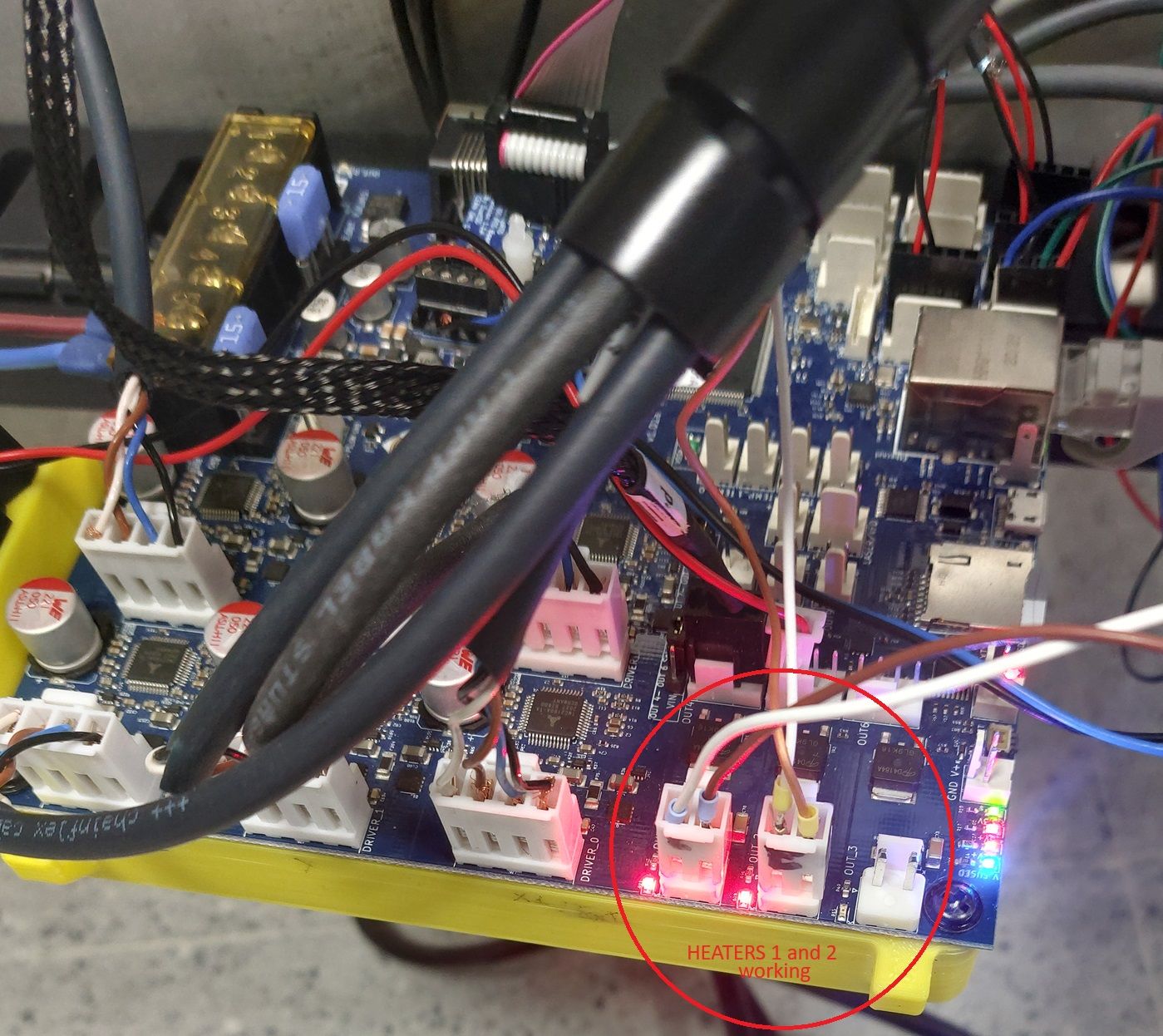

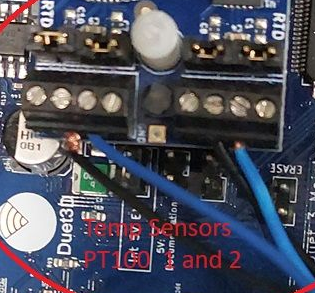

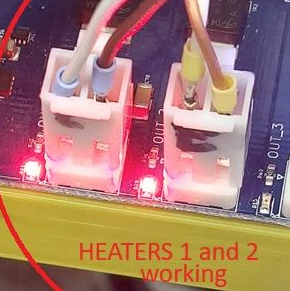

@imartinez you may want to revisit your wiring as all of your crimping looks very dodgy!

There are wires that are bare and almost coming into contact which will cause a short and could lead to board damage.

You also have bare wires in terminals that should be crimped with bootlace ferrules.

And I'm not sure what's going on with your heater wires. It looks like you've crimped the JST VH pins onto existing ferrules. Thats also a very bad idea -

@imartinez I second @jay_s_uk's comments about your wiring. You're risking shorting out a stepper driver with this:

Inconsistent temperature readings with this:

And potentially creating heat at the junction of the crimp and ferrule with this:

Ian

-

@jay_s_uk Ok.... Thank You ....

-

@droftarts Ok

Thank You

-

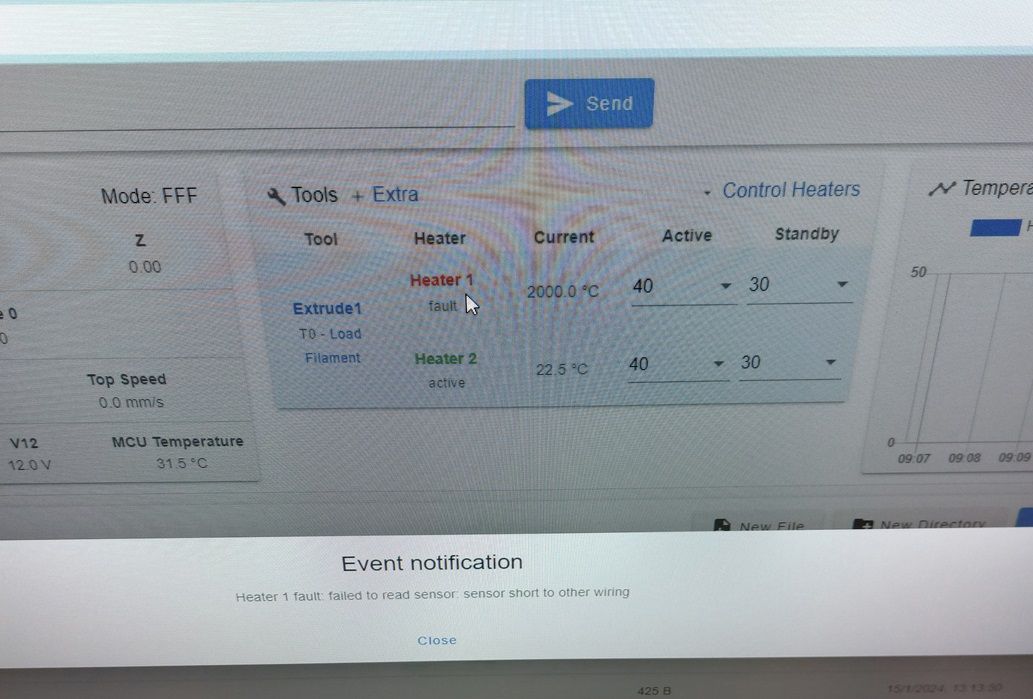

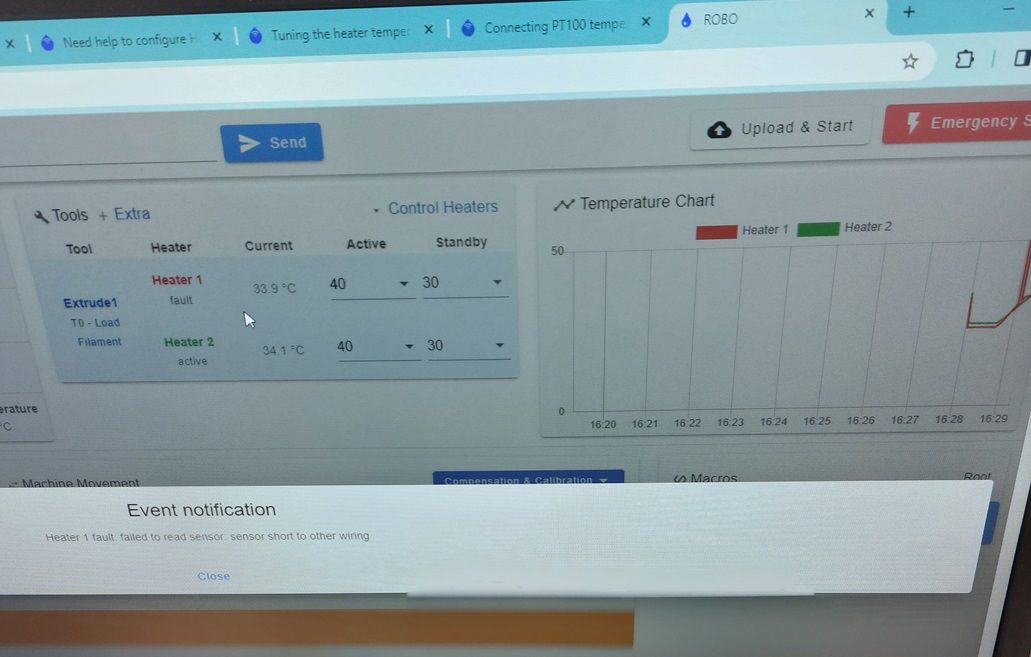

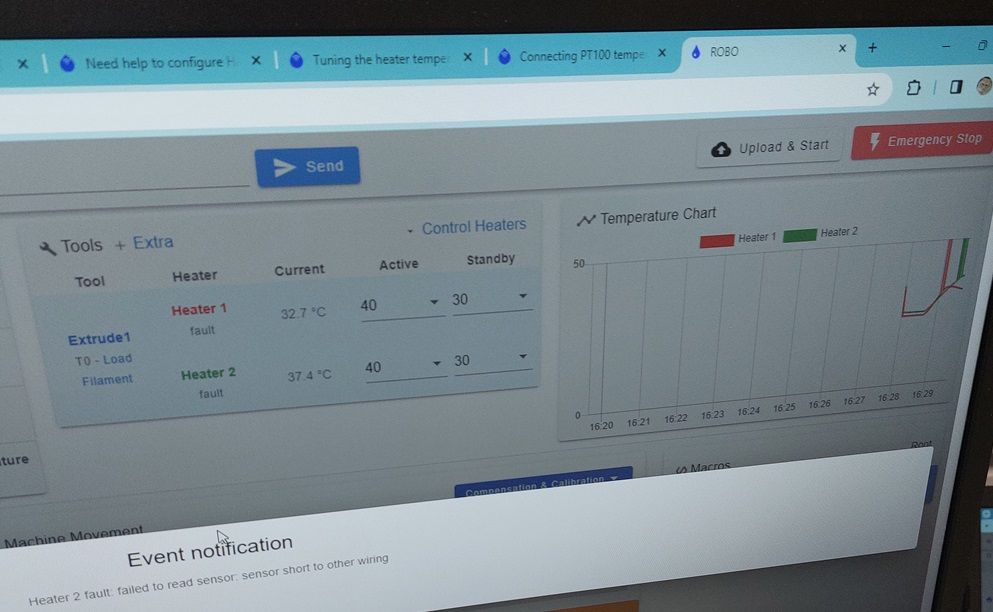

Hello again....

I revised my wiring conexions and fixed it , but i have problems again , i remplaced my 307 lines with the parameters of the tunning but , when i try to use the heaters I have a notification "Header 2 fault: failed to read sensor: sensor shot to other wiring" , i resised wiring 2 or 3 times and i think was Ok, Do you think the cause could be the length of the cables or it could be something else??????

parameters of M307

M307 H1 R0.337 K0.402:0.000 D11.85 E1.35 B0

M307 H2 R0.238 K0.228:0.000 D8.78 E1.35 B0

Thanks

-

@imartinez Yes, the sudden jumps in temperature reading are usually because the wiring is shorting out, or is being disconnected. It's also possible it is interference; does the temperature jump happen at the same time as motor movement, or heater turning on and off?

I can see you have the 'Connecting PT100 temperature sensors' wiki page open! See particularly this section on the subject of interference: https://docs.duet3d.com/User_manual/Connecting_hardware/Temperature_connecting_PT100#wiring-the-pt100-temperature-sensor

2-wire connections have the advantage of wiring simplicity. 4-wire connections have the advantage of greater accuracy; the extra wires compensate for the resistance drop in the wires, making readings more accurate. 4-wire does not improve resistance to interference; better approaches to reduce noise include twisted wiring, isolation from noise sources, shielded wiring, better grounding of components etc.

See the troubleshooting advice at the end of the page here to check the problem isn't the temperature board: https://docs.duet3d.com/User_manual/Connecting_hardware/Temperature_connecting_PT100#troubleshooting

Ian

-

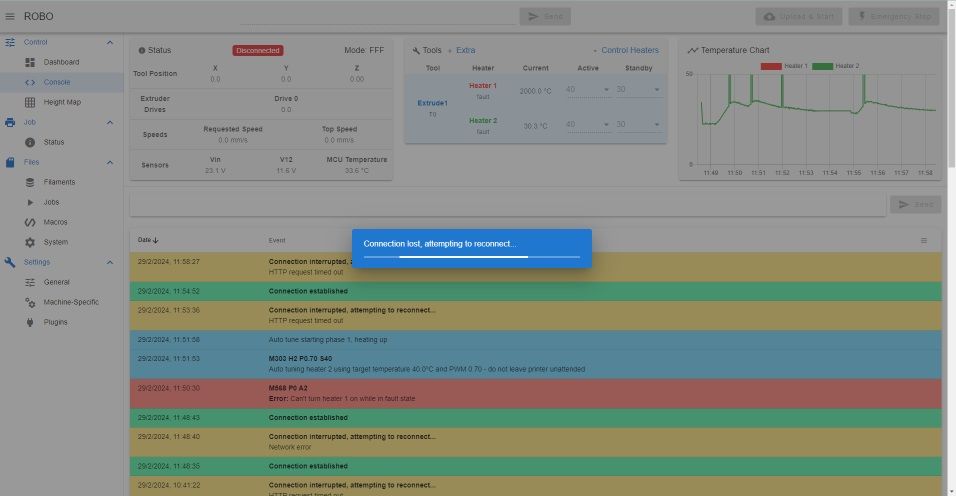

@droftarts Good Morning....

I already put the sensors with 4 wired conexion and i have the error again , i don´t know what is happend .......

The pt100 sensors read 2000 ºC when the heater is on every 10 or 15 seconds , is no always the same time , do u think is a interference problem???? , do u think a ferrita core is a possible solution??????

Thanks