Having problems getting extruder working... v3.5.2

-

I think I have correctly wired and configured my config.c file but I'm still having some issues, I'm almost certain its config.c related.

Duet 2 Wifi

CoreXY

Bowden extruderAll axes are moving and performing as expected...1 item of note is that on my Duet where the drive is plugged in I do not see a red led lit, similar to the other drives (x,y,x)??

From the config file:

; Smart Drivers M569 P0.0 S0 D2 ; driver 0 goes backwards (X axis) M569 P0.1 S0 D2 ; driver 1 goes backwards (Y axis) M569 P0.2 S1 D2 ; driver 2 goes forwards (Z axis) M569 P0.3 S1 D2 ; driver 3 goes forwards (extruder 0) ;M906 X1700 Y1700 Z1700 ; set motor driver currents ; Motor Idle Current Reduction M906 I30 ; set motor current idle factor M84 S30 ; set motor current idle timeout ; Axes M584 X0.0 Y0.1 Z0.2 ; set axis mapping M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation M906 X1700 Y1700 Z1700 ; set axis driver currents M92 X100 Y100 Z1600 ; configure steps per mm M208 X0:300 Y0:300 Z0:320 ; set minimum and maximum axis limits M566 X900 Y900 Z12 ; set maximum instantaneous speed changes (mm/min) M203 X6000 Y6000 Z180 ; set maximum speeds (mm/min) M201 X500 Y500 Z20 ; set accelerations (mm/s^2) ; Extruders M584 E0.3 ; set extruder mapping M350 E16 I1 ; configure microstepping with interpolation M960 E1700 ; set motor driver currents M92 E420 ; configure steps per mm M566 E120 ; set maximum instantaneous speed changes (mm/min) M203 E3600 ; set maximum speeds (mm/min) M201 E250 ; set accelerations (mm/s^2) ; Kinematics M669 K1 ; configure CoreXY kinematicsand additional config relevant protion

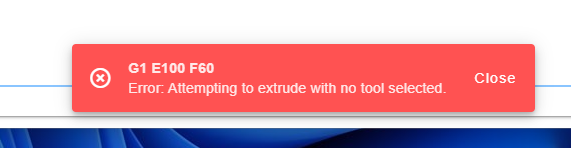

; Tools M563 P0 D0 H1 F0 ; create tool #0 M568 P0 R0 S0 ; set initial tool #0 active and standby temperatures to 0C ; Miscellaneous ;T0 ; select first toolWhen sending an G1 E100 F60 I get the following error.

After researching this error, I add the last line in the config.c file, uncommented of course. I didn't get the specific error any longer but still no extruder movement.

I'm getting a little confused on the T0, P0, E0.3, etc. lots of movement there, I thought T0 was the hotend and not the same as the extruder which I thought would be E0, ugh!

; Miscellaneous ;T0 ; select first tool -

@vbtalent2 uncomment T0 from the end of your config

-

@jay_s_uk I had tried that earlier but it seems like there is some confusion between the Extruder and the HotEnd... after uncommenting the HotEnd stopped working.

Should I also be seeing an LED on where the extruder plugs into the Duet?

-

I'm getting a little confused on the T0, P0, E0.3, etc.

All commands start with the letters ”G” (the GCodes), ”M” (the M-commands) or ”T” (Tool commands), always followed by a numeric specifier. That’s the easy part. Then come the parameters …

Some letters are used for axes (X, Y Z are obvious, U, W, a, b, c … not so). For parameters to GCodes (M- and T-commands as well), other letters have to be used, which makes memorising them difficult for simple minded users like me. That’s why I very often refer to the GCode dictionary. Without this reference, I’d be lost.

@jay_s_uk already pointed you at the T0 command. There is a potential second trap to observe: Extrusion is disabled if the hotend is too cold (by default, that’s at less than 160°C) to prevent a filament jam. See M302 on how to allow cold extrudes or to change the 160° limit.

-

@infiniteloop So just made a change from

; Miscellaneous T0 ; select first toolto the following

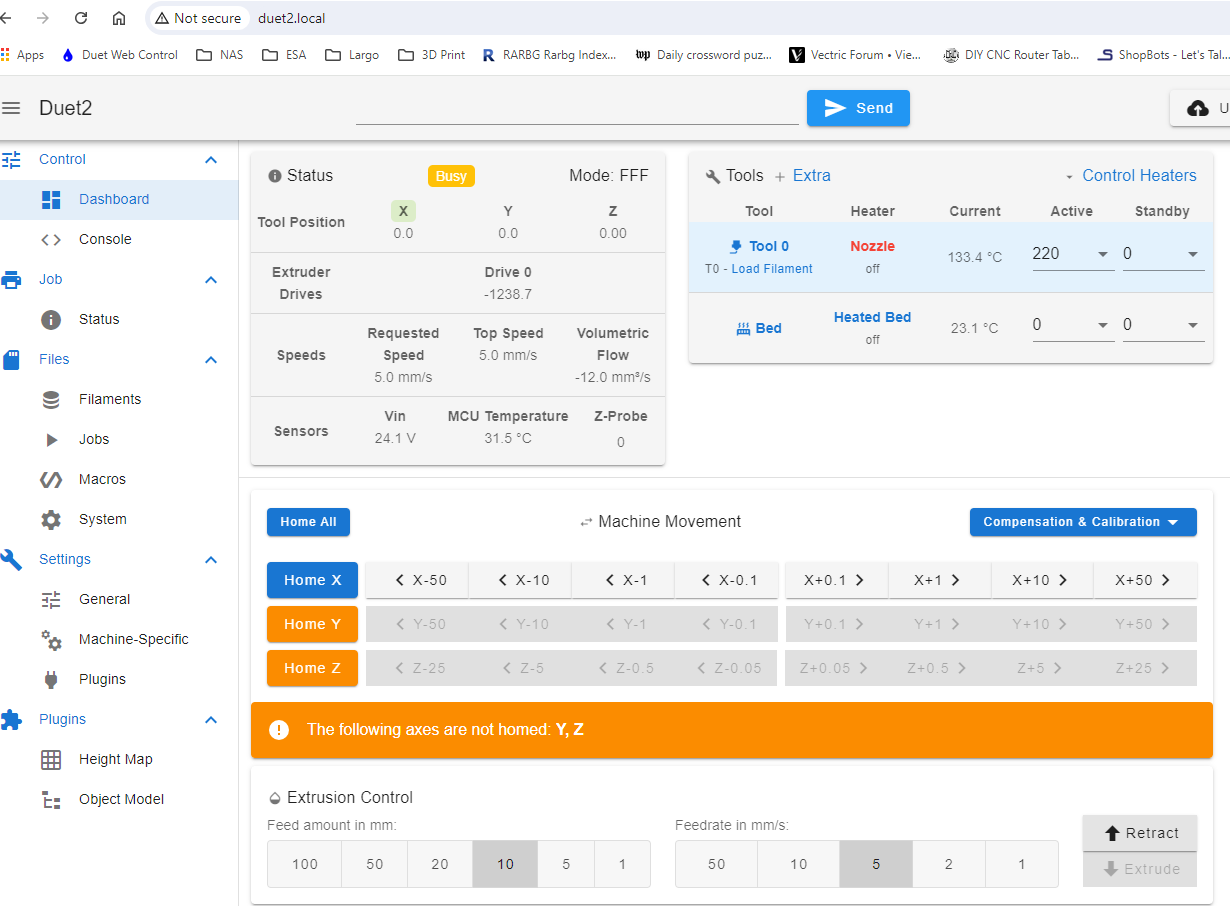

; Miscellaneous T0.3 ; select first toolI've got the HotEnd up to temp and I've sent a commands to the extruder... its giving some vibrations and even some noise when running the "unload" macro.

What's strange is I can turn the extruder motor end freely back and forth, unlike any of the other axis which appear to be getting power to hold them in place.

If I place my finger on the end of the extruder and send an extrude command, I can feel it vibrating.

It flashes "Busy" and I feel the end vibrating... but it not actually moving.

-

@vbtalent2 said in Having problems getting extruder working... v3.5.2:

to the following

; Miscellaneous

T0.3 ; select first toolNo that's not right. T0 is the first tool. T1 would be the next, etc.

Please share your full config.g

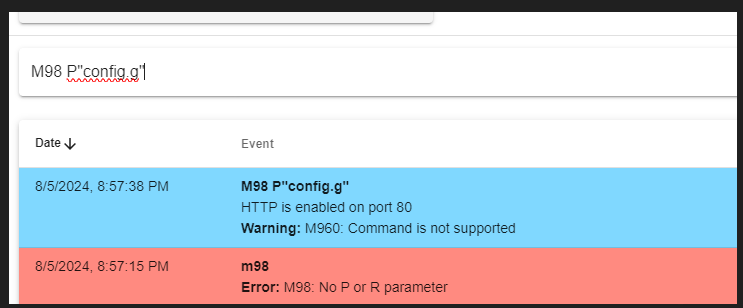

Also please share the results of M122 and M98 P"config.g"

And make sure your firmware version and DWC version match.

-

@vbtalent2 To my knowledge, the dot-notation does not apply to tools, you assign a number (”0”) in your config with M563 - to select it, simply use T0.

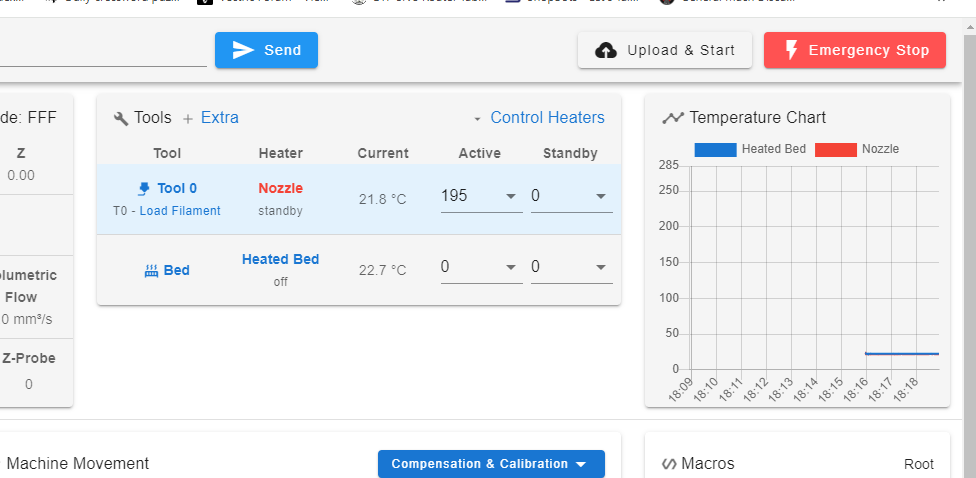

In your screenshots, the tool 0 (called ”Nozzle”) is either in standby mode or off - why? Do you cycle through the states by clicking into the ”Heater” column of the DWC?

Finally, the screenshots indicate a hotend temperature below the limit of 160°C which I mentioned in my first post above. This would prevent the extrusion controls (of DWC) to work as expected.

-

Wouldn't T0 be the HotEnd and not the Etruder??

config.g as requested in its current state..

; Configuration file for RepRapFirmware on Duet 2 WiFi ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.5.4 on Mon Jul 29 2024 07:12:52 GMT-0400 (Eastern Daylight Time) ; General G90 ; absolute coordinates M83 ; relative extruder moves M550 P"Duet2" ; set hostname ; Network M551 P"closet_p2345" ; set machine password M552 S1 ; configure WiFi adapter M586 P0 S1 ; configure HTTP ; Smart Drivers M569 P0.0 S0 D2 ; driver 0 goes backwards (X axis) M569 P0.1 S0 D2 ; driver 1 goes backwards (Y axis) M569 P0.2 S1 D2 ; driver 2 goes forwards (Z axis) M569 P0.3 S1 D2 ; driver 3 goes forwards (extruder 0) ;M906 X1700 Y1700 Z1700 ; set motor driver currents ; Motor Idle Current Reduction M906 I30 ; set motor current idle factor M84 S30 ; set motor current idle timeout ; Axes M584 X0.0 Y0.1 Z0.2 ; set axis mapping M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation M906 X1700 Y1700 Z1700 ; set axis driver currents M92 X100 Y100 Z1600 ; configure steps per mm M208 X0:300 Y0:300 Z0:320 ; set minimum and maximum axis limits M566 X900 Y900 Z12 ; set maximum instantaneous speed changes (mm/min) M203 X6000 Y6000 Z180 ; set maximum speeds (mm/min) M201 X500 Y500 Z20 ; set accelerations (mm/s^2) ; Extruders M584 E0.3 ; set extruder mapping M350 E16 I1 ; configure microstepping with interpolation M960 E1700 ; set motor driver currents M92 E420 ; configure steps per mm M566 E120 ; set maximum instantaneous speed changes (mm/min) M203 E3600 ; set maximum speeds (mm/min) M201 E250 ; set accelerations (mm/s^2) ; Kinematics M669 K1 ; configure CoreXY kinematics ; Probes M558 P9 C"^zprobe.in" H5 F120 T6000 ; Duet 2 WiFi/Ethernet, DueX2/5 G31 P500 X28.575 Y12.7 Z1.06 ; set Z probe trigger value, offset and trigger height M950 S0 C"exp.heater3" ; Duet 2 WiFi/Ethernet ; Endstops M574 X1 P"xstop" S1 ; configure X axis endstop M574 Y1 P"ystop" S1 ; configure Y axis endstop M574 Z1 S2 ; configure Z axis endstop ; Sensors M308 S0 P"bedtemp" Y"thermistor" A"Heated Bed" T100000 B3975 ; configure sensor #0 M308 S1 P"e0temp" Y"thermistor" A"Nozzle" T100000 B4725 C7.06e-8 ; configure sensor #1 ; Heaters M950 H0 C"bedheat" T0 ; create heater #0 M143 H0 P0 T0 C0 S120 A0 ; configure heater monitor #0 for heater #0 ;M307 H0 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #0 M307 H0 R0.472 K0.381:0.000 D3.86 E1.35 S1.00 B0 ; Autotuned configuration M950 H1 C"e0heat" T1 ; create heater #1 M143 H1 P0 T1 C0 S285 A0 ; configure heater monitor #0 for heater #1 ;M307 H1 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #1 M307 H1 R1.871 K0.319:0.000 D6.56 E1.35 S1.00 B0 V24.0 ; Autotuned configuration ; Heated beds M140 P0 H0 ; configure heated bed #0 ; Fans M950 F0 C"fan0" ; create fan #0 M106 P0 S0 L0 X1 B0.1 ; configure fan #0 M950 F1 C"fan1" ; create fan #1 M106 P1 S0 B0.1 H1 T45 ; configure fan #1 ; Tools M563 P0 D0 H1 F0 ; create tool #0 M568 P0 R0 S0 ; set initial tool #0 active and standby temperatures to 0C ; Miscellaneous T0.3 ; select first toolI'm not sure where to find the M122 and M98 if not in the config.g file... ??

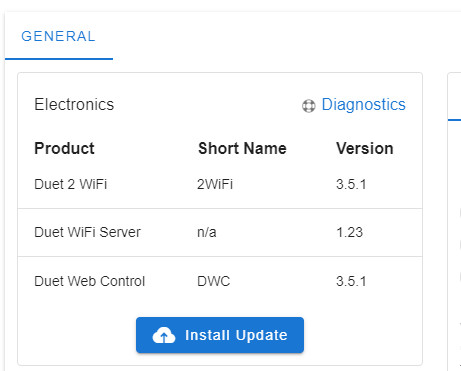

I was mistaken, I'm on 3.5.1.. not 3.5.2

-

The screenshot was taken after I had shut down the HotEnd, sorry for that..

Yes, I have been clicking in the column for on/off...

-

-

Wouldn't T0 be the HotEnd and not the Etruder??

A tool is composed from several components who must act together, e.g. a hotend with its heater and thermistor plus the extruder and a part cooling fan. Repeating myself, I strongly recommend intense lecture of the GCode dictionary, in this case, M563: Define or remove a tool. The list of parameters tells us what components may belong to a tool.

I have been clicking in the column for on/off...

Talking of tools: having just a single tool (as most of us have), the "standby" state doesn’t really make sense. You don’t have to bother with standby temperature definitions, either. DWC, however, accounts for printers with multiple extruders as well, one tool being selected and the others prepared for active duty, I.e. on standby. So, in your case, look to avoid the ”standby” state.

BTW: are you familiar with the concept of ”tuning”? This is part of the commissioning process (see: Commissioning your machine). Interestingly, you can either tune a heater (bed heater, hotend, …) or an entire tool, the latter alternative having the advantage to take the thermal effects of a part cooling fan into account. See Tuning the heater temperature control for details. In the config, you’ve entered model parameters for bed and hotend - if you encounter problems with extrusion, it may be worth to retune the latter one as a tool.

Referring to the screenshot from DWC, General / Diagnostics, you might want to update to the latest stable RRF (3.5.2). The WiFi Server (1.27) looks quite outdated, it should be 2.something. If, after the update, the Wifi server stays at 1.x, run

M997 S1from the console. -

Thanks for all of the information, I will continue to perform the upgrades to get to 3.5.2, I thought the WIFI would have upgraded when I did full fresh install with 3.5.1 but I will also perform that upgrade as well;

As for the extruder, it's now working. I think it might have been a mixture of issues,,, the code error M960 and the tool not being uncommented. I was able to calibrate the extrusion and all seems to be working fine.

Much appreciate the assistance.

VB,

-

I was able to calibrate the extrusion and all seems to be working fine.

Glad to hear that. Good luck, and don't hesitate to return to the forum in case of trouble.

-

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

undefined Phaedrux has marked this topic as solved

undefined Phaedrux has marked this topic as solved