Recommend an extruder/hotend.

-

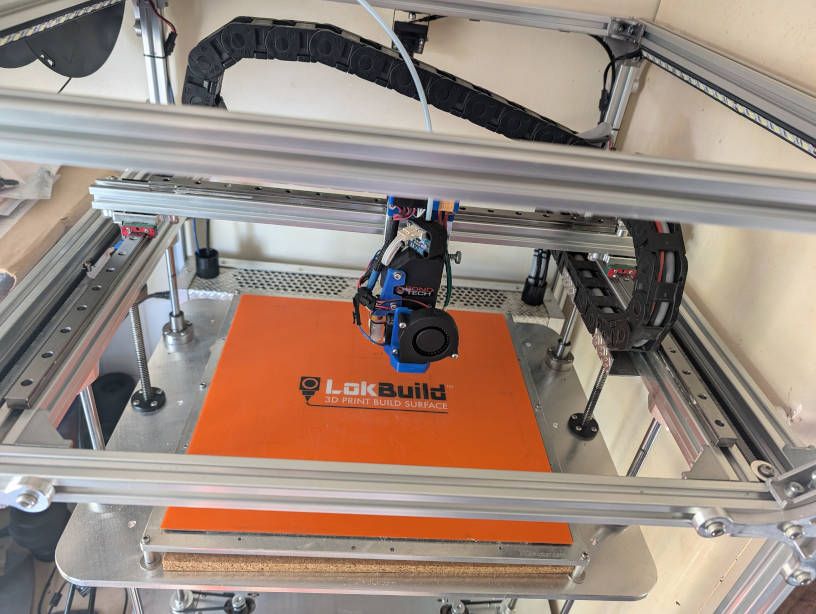

I refitted an old folgertech ft-5 with a duet3 6hc/pi5 recently and have had lots of trouble with the extruder/hotend jamming in the ptfe tube and other extruder feed rate errors. I've stripped it down a few times, replaced the ptfe tube multiple times, spend too many hours tuning the extruder feed rates and it's still causing problems. This is a bmg/e3d v6 combination.

I've had enough of playing with this and am just going to replace the entire assembly.

Any recommendations? This is not a 'fast' printer. There are a few options that can use the nozzle touch as a bed levelling sensor, like the e3d voron hotend/probe, are these reliable? I like the idea of probing the z height from the print nozzle as it would remove any other errors in the printer build geometry that I currently have to adjust for with the offset probe position of the bl-touch. I have an e3d hemera xs on another printer which works fine, are there better options? I think the ease of adding part cooling is important as I do print a lot of pla.

-

@bug2k22 The big thing with V6 hot ends (especially the "all metal" version) is to not use too much retraction; I think 2mm is supposed to be the absolute maximum. Too much causes filament to lift out past the heatbreak, and solidify on the cold side, causing a jam. Also use the silicone hot end sock, and make sure the hotend is assembled correctly to avoid leaks in the heater block, see https://e3d-online.zendesk.com/hc/en-us/articles/360017013257-V6-Assembly-Guide-Edition-2

I have a bed slinger with a Hemera and V6 with prints PLA and PETG nicely, but it's a heavy and bulky combination. I also haven't been printing very fast, so the 15mm^3/s limit of the V6 (see CNC Kitchen testing here) hasn't been much of an issue; I could always switch to a CHT nozzle if I wanted to go faster, but I think it would shake the machine apart. I don't really have many other 'normal' hotends; most are machine-specific or very old, like the J-Head I use for 2.85mm filament!

I have some Revo nozzles to try out, but still haven't built a machine/toolhead for them yet. I think the E3D Revo Voron PZ Probe looks really interesting; I haven't heard anything negative about it. Just that it's out of stock! But there doesn't seem to be much of a change in performance between V6 and standard Revo; both have a 15mm^3/s limit (see CNC Kitchen's Revo test). The Revo just seems more convenient and less prone to failure. Revo HF, though, has better flow, very much like a CHT nozzle.

I recently got a Sovol SV08, and have been impressed by the hot end on that, which is very similar to the Bambu Lab hot ends in design, and can keep up happily with 300mm/s print speeds (0.4mm nozzle, 0.2mm layer height, about 24mm^3/s). There are mods for the Bambu Lab X1C/X1 hotend for Voron Stealthburner, eg https://www.printables.com/model/323196-voron-stealthburner-for-bambu-lab-x1cx1-hotend.

Lastly, I have been recommended to avoid the Dragon or anything that shape, but the Dragonfly is supposed to be okay, though I have no direct experience with either. Hope that helps!

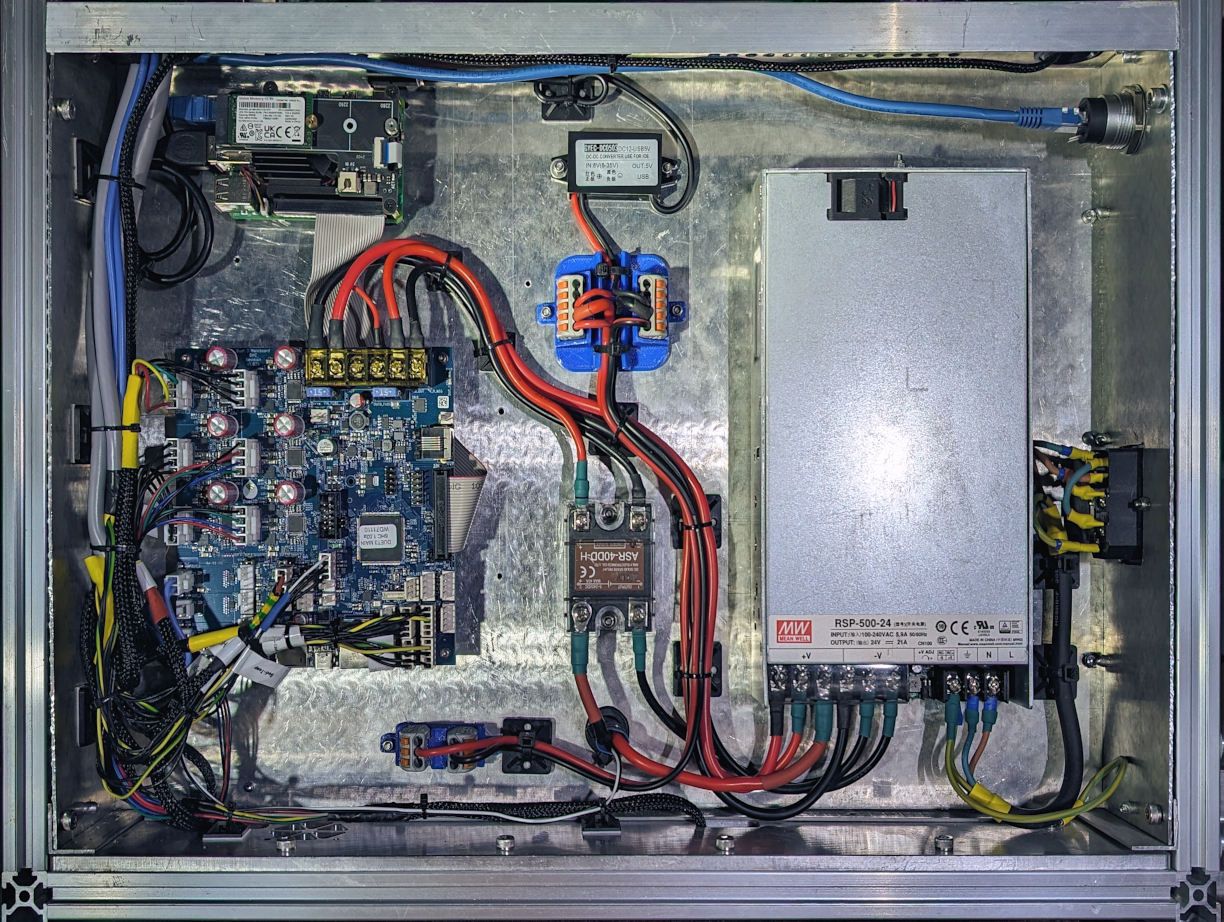

Edit: Lovely wiring, by the way.

Ian

-

@droftarts Thanks Ian. This one has the v6 with a ptfe tube of which I've lost count how many times I've had to strip down and clear. I think retraction is currently ~0.8mm if I remember. The bmg I have found to be inconsistent and not reliably and consistently pulling the filament, again I've lost many hours taking it apart, cleaning and adjusting and tuning the tension. For whatever reason the working window with this setup is just way too narrow as it is.

I'm just going to remove the entire print head and replace it with something... else.

I have another printer which is running a duet2 and a hemera xs with the revo nozzles and it's worked fine for a while now. Having a solution with built in optimized part cooling would be nice too.I don't think this machine is going to push past 12-14mm^3 so high flow hot ends are not really required, but I might go that way just in case I feel the need to upgrade the motion system in the future.

-

@bug2k22 A recommendation from the RRF Discord server:

it's quite unpopular but I've been using Dragon hotends on both of my printers (with SF and HF heatbreaks) and haven't noticed the issues people allegedly witness (poor cooling of the heatbreak leading to clogs and/or toolhead meltdown)

anything modern and fast will do tho, everyone seems to love the rapido around hereExtruders are another matter. I have a BMG clone on my delta, and that's been reasonably reliable. I also have and Orbiter v1.5 that I like. The Hemera has been reliable, I have a Titan that I've never used, and a Revo Roto that I've yet to try out.

I haven't tried the current crop of extruders, but I hear good things about the Galileo and HextrudORT. BondTech LGX Lite and Hemera XS get mentioned a lot, too.

Ian

-

@bug2k22 I like the galileo and HextrudORT. I have both, one fitted to a Voron V0.2 (the galileo) and the other fitted to a VzBoT 235. The HextrudORT is the larger geared version.

I wasn't very impressed with the orbiter v2 and I was getting woodgrain on the original LGX Lite.

I also plan to build a papilio at some point. -

If you want to build a fun extruder, look into the Papilio Lite.

-

@jay_s_uk , that kinda funny in some way i have an orbiter 2 with a mosquito hotend and that things will not print any kind of flexible filament without any problem , even ASA sometime give me problem it seem orbiter 2 has too much space in the gear area ..

him in the process of building another printer and this time i when with the extrudort wit the goliath hotend ...

-

A really nice one: The APUS extruder. I have been using since I got it,

-

Thanks for all the suggestions, some really interesting designs.

I've been given a micro swiss ng extruder which takes e3d revo nozzles, I already have a printer running a hemera xs and have a few spare nozzles for that. It looks like it will be easy to mount with a simple adapter plate.

I don't know how this will perform compared to some of the newer 'exotic' extruders but it should be an improvement over the original setup. Hopefully it can handle flexible filaments too. -

undefined droftarts referenced this topic

undefined droftarts referenced this topic