Tevo Little Monster - 80 mm + Direct Drive and Remote Fans

-

Hi All,

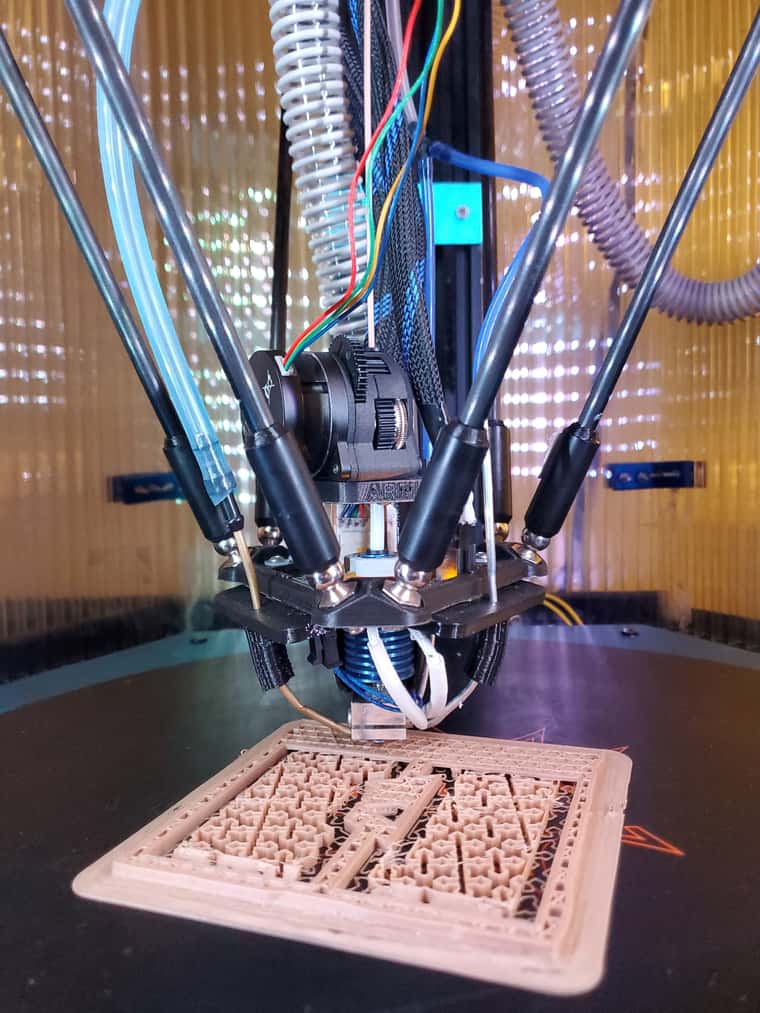

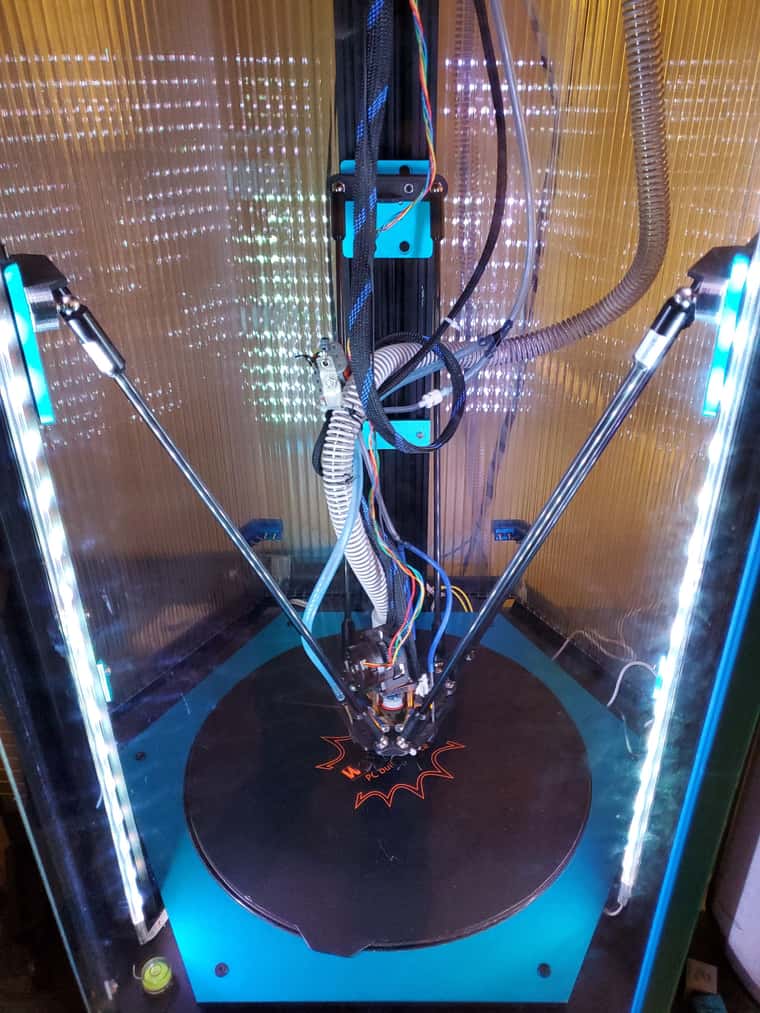

My holiday project for this year has been converting my Tevo Little Monster with Smart Effectors for use with a direct drive, getting rid of the last of the original knockoff parts, and switching to a remote blower fan to make my printer much quieter. I used Asyborgs 80mm adapter for the smart effector, and did up the remaining parts to mount a direct drive extruder and cooling.

Previously my flying extruder always shook around a bunch and seemed to make artifacts in the print regularly. It also didn't work particularly well with soft plastics. The direct drive mount shakes much less, seems to print better and faster, and gave me a good chance to remove the heatsink fan from the effector.

I've now got the part cooling fan (berd air pump) and the heatsink blower fan remote mounted in my printer table, where I don't hear them. It's great. Super quiet.I had to design a few new parts including:

- 80mm Carriage Adapter - link

- LGX Lite Adapter Plate - link

- Berd air pipe carriers for smart effectors - link

- CPAP hose carrier for smart effector - link

- CPAP hose joiners

- Blower Fan Mount

Other stuff I've made for this is up on my printables profile now.

-

undefined droftarts moved this topic from Duet Hardware and wiring

undefined droftarts moved this topic from Duet Hardware and wiring

-

@moocowsia you can post links after you have a couple of upvotes to avoid people posting spam here as a first post.

-

@T3P3Tony said in Tevo Little Monster - 80 mm + Direct Drive and Remote Fans:

@moocowsia you can post links after you have a couple of upvotes to avoid people posting spam here as a first post.

No worries. Thanks for the upvote. I've added the links to the printables parts.

-

@moocowsia I guess you had to raise the LGX so much, because of the extruder motor sticking out?

I know these Orbiter and LGX extruders are en vogue but I still prefer my "tall and slim" sherpa mini -

@o_lampe said in Tevo Little Monster - 80 mm + Direct Drive and Remote Fans:

@moocowsia I guess you had to raise the LGX so much, because of the extruder motor sticking out?

I know these Orbiter and LGX extruders are en vogue but I still prefer my "tall and slim" sherpa miniI mostly just put the riser on it so I have a bit of room to adjust the heatsink under the mounting plate. I could probably get away with a smaller rise, but I only had 5mm and 20mm brass standoffs to pick from.

Based on geometry, I could probably get away with zero standoff on the extruder, but I couldn't figure out how to assemble it.

I've got a kit of various standoffs coming from AliExpress in the next month or two, so I might rejig it then. I've also got a Orbiter and another (my fourth) smart effector to do up as well. We'll see how that all goes together soon. I might be able to ditch the brass and simplify it on the second attempt.

-

@moocowsia said in Tevo Little Monster - 80 mm + Direct Drive and Remote Fans:

I couldn't figure out how to assemble it.

You could print an adapter plate that holds the heatsink-nut and fits under the LGX.

Then screw the heatsink in before you mount the hotend/heatbrake.

You might have to rotate the nut in the adapter a few times, before everything is tight and aligned nicely. -

@moocowsia Neat to see all you have done.

I was wondering how to get a bit more speed from the Little Monster. Those blue aluminium carriages felt quite heavy, and by the looks of it quite a lot of material could be removed with no effect whatsoever. Have you thought about that as a mod?

What were the changes that you made that had the biggest effect?

The best thing I did was to move from an original (not knock off) E3D titan to a Bondtech LGX. Plus the change to textured PEI print sheet. I love textured PEI. I would like to try a direct mount Orbiter as they seem quite light, and I'm not a fan of the (even short) Bowden tube.

-

Hey Martin, I haven't tried playing around with the carriages yet. I don't think I'll bother with that, as I'd probably just upgrade to linear rails instead. I was contemplating that on this recent set of upgrades, but haven't decided if I'll bother.

The best change I've made so far was upgrading to a 0.9° stepper motor on the drive axes. It really made the prints come out quite a bit nicer. The switch to a whambam PC sheet also helped a lot.

Getting rid of the flying extruder in this recent set of mods has also helped the quality quite a bit, as the fast prints would make the Bondtech knockoff I had before swing around a bunch, causing artifacts at speed. I even noticed this during my autolevelling, the extruder moving would sometime make the levelling irregular, so I had to have a pause before each probe. It was annoying.

For high quality prints before, I used to stick to 30mm/s. Now 50-60 mm/s seems to be fine. I haven't pushed it much faster. I'm pretty sure I can move up to 100 mm/s and get decent quality now, but honestly most of my mods were to make the printer quieter rather than faster.

I'll let you know when I figure out my Orbiter mount. It should be in the next month or so when I get some time.