Sovol SV08 Multiple Motion System Upgrade.

-

@dwuk said in Sovol SV08 Multiple Motion System Upgrade.:

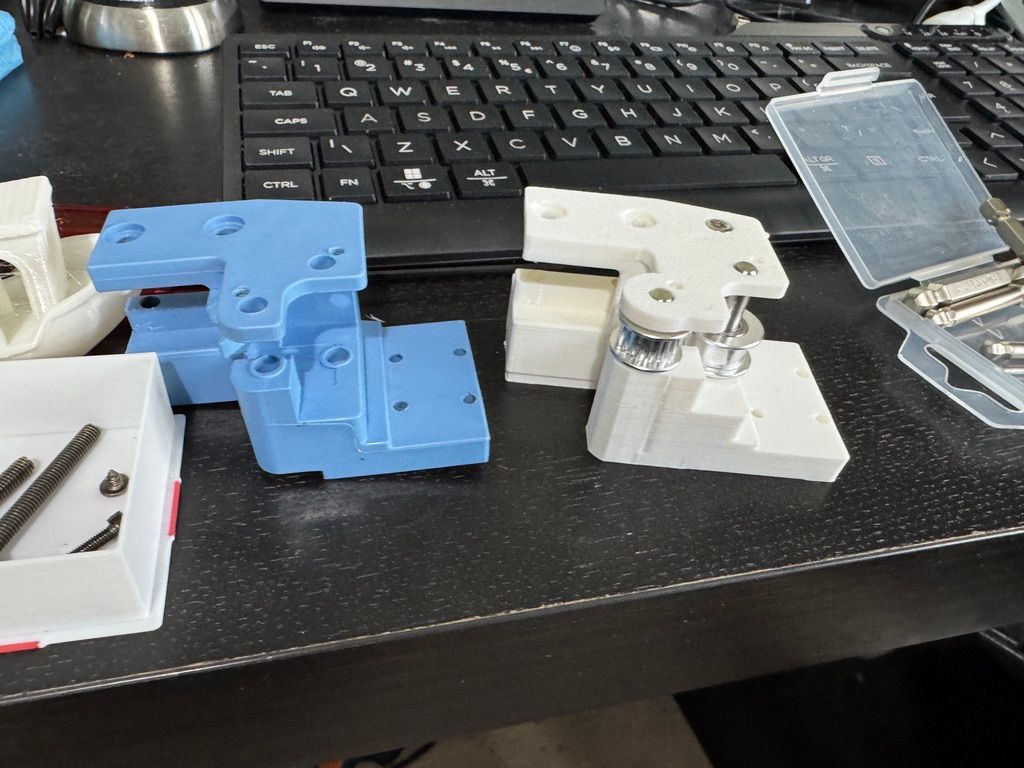

about the excenter bearings

They aren't available off the shelf, you just have to use regular bearings and make an offcenter shaft for it.

When the shaft rotates (max 180°) , the bearings translate the offset to the housing where they are pressed in.

That's a much easier task than to overcome the stiktion of linear bearings.I have a vision of a planetary gear with three planets and a rotating orbit. This would give you a compact, yet powerful setup with a NEMA14 pancake stepper (they often come with a pinion, like the orbiter motors)

-

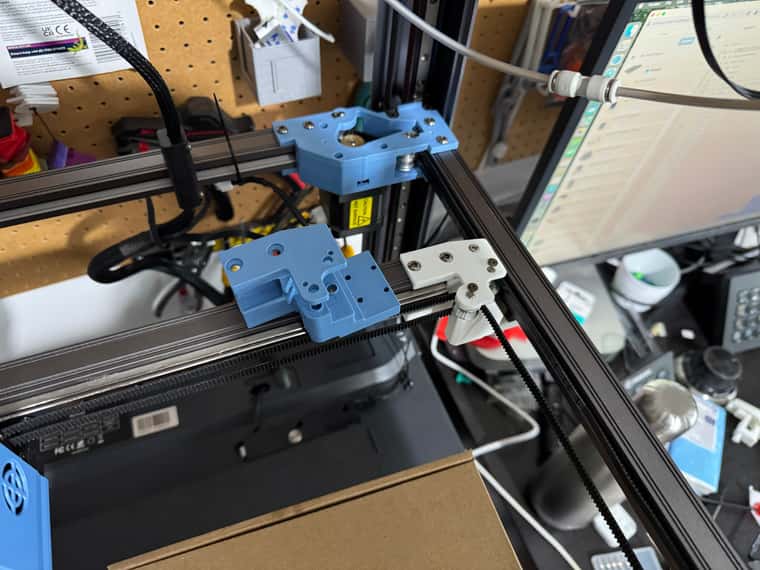

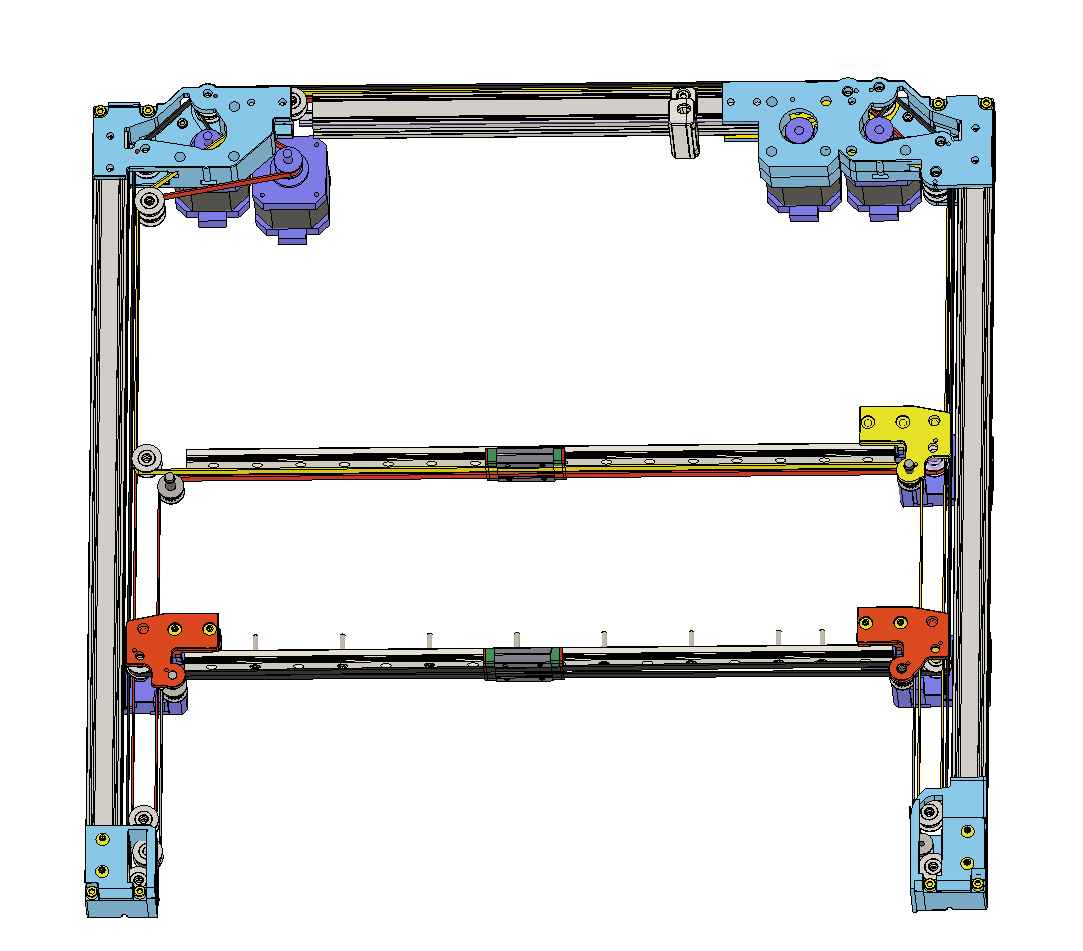

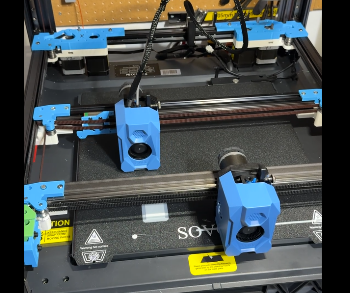

New parts progressing - original gantry pulley repositioning done.

-

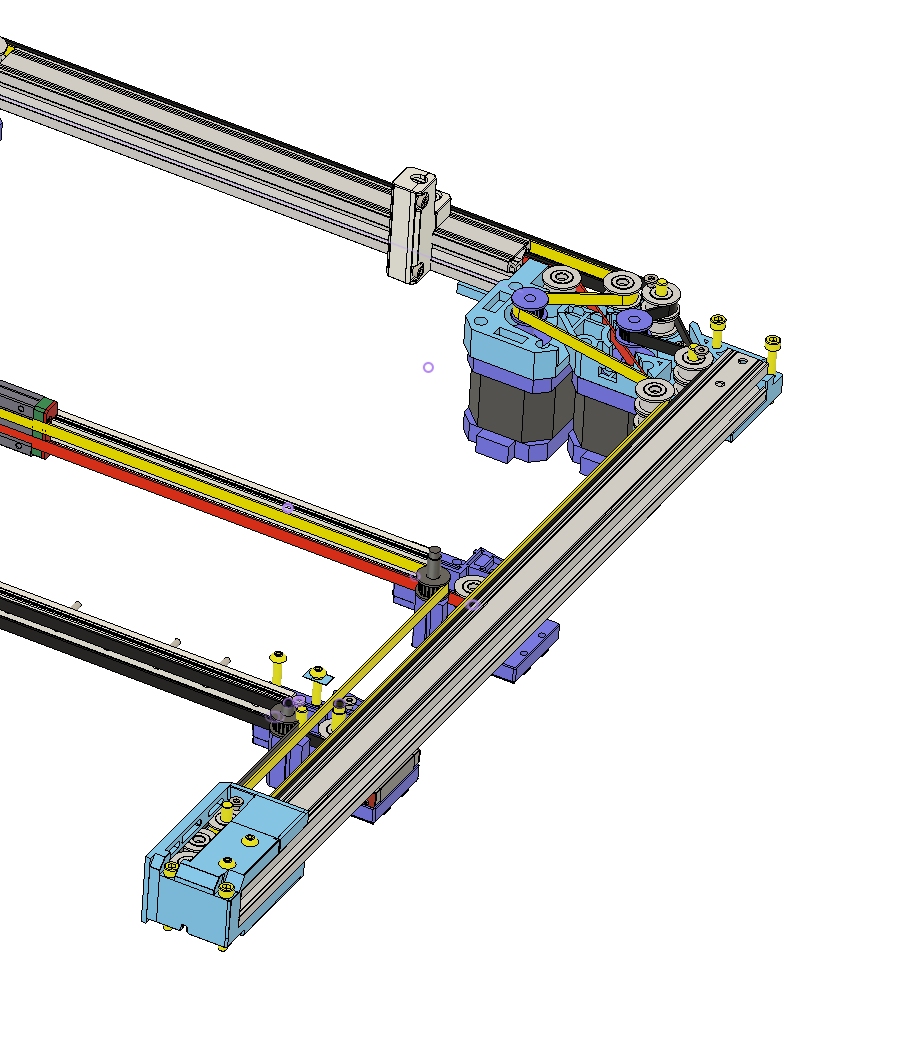

@dwuk Designs for all parts on right hand side now completed - and printing underway. Left hand side fairly easy to derive as is mostly a mirror copy - with some height changes.

Biggest issue is losing about 25mm build volume at front due to idler and about 15mm at the back. Will need to address these two issues at some point.

Also had to remove the tensioner spring part to save a bit of space - so will need to so how well the tensioning works with just the side bolts.

-

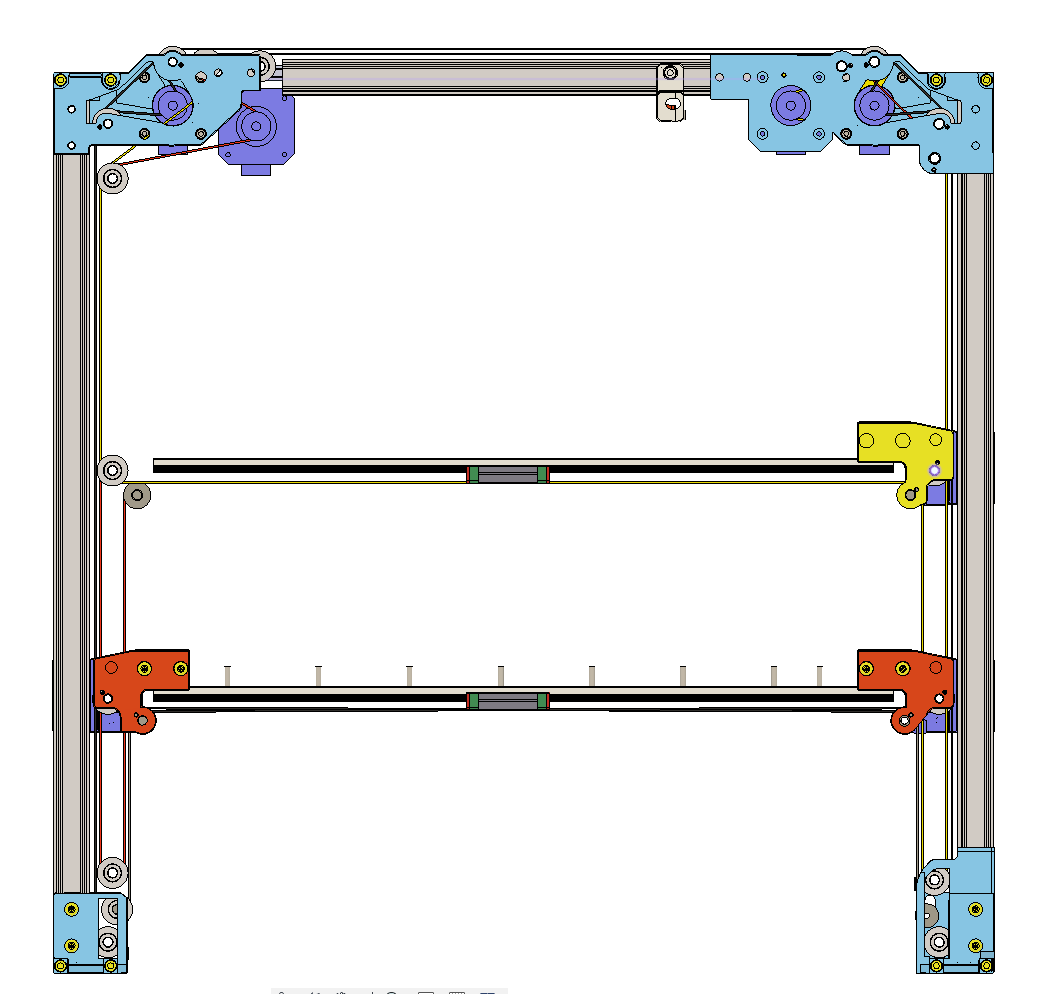

@dwuk Equal belt tension is a critical part for a CoreXY. I hope you are still able to adjust all belts individually.

-

@o_lampe thanks. Yes tensioning will still be possible. In the factory design there are bolts that pull against springs to adjust the tension from the back, which are then locked off from the side.

I've removed the bolts and springs for space reasons - will try to add them back in - but probably coming in from the front.

All three pulleys at the front still have about 10mm of independent movement.

I think I will also try removing most of the lost build area too by repositioning the pulleys before I go much further.

-

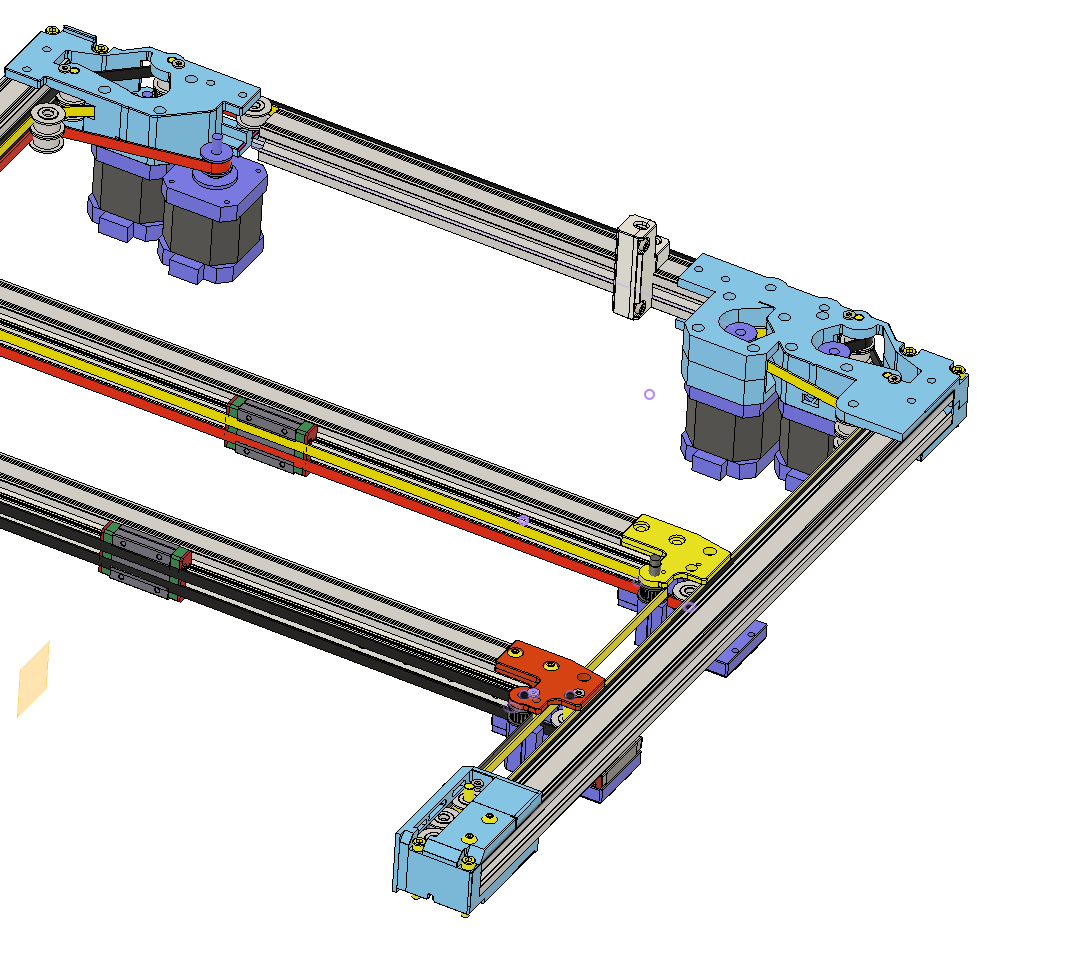

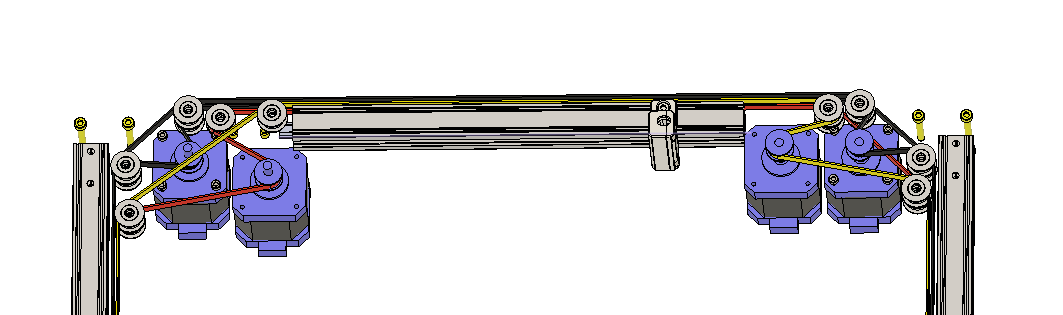

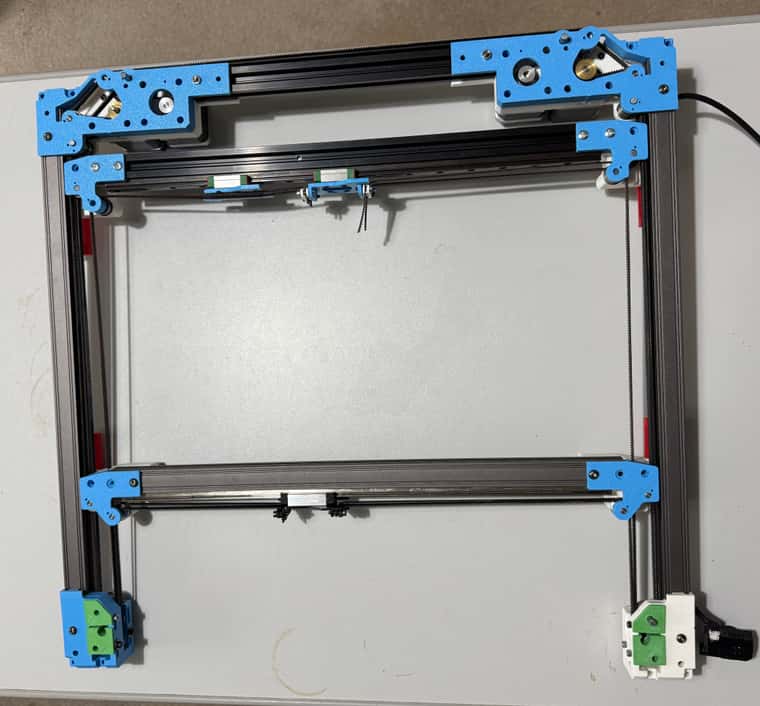

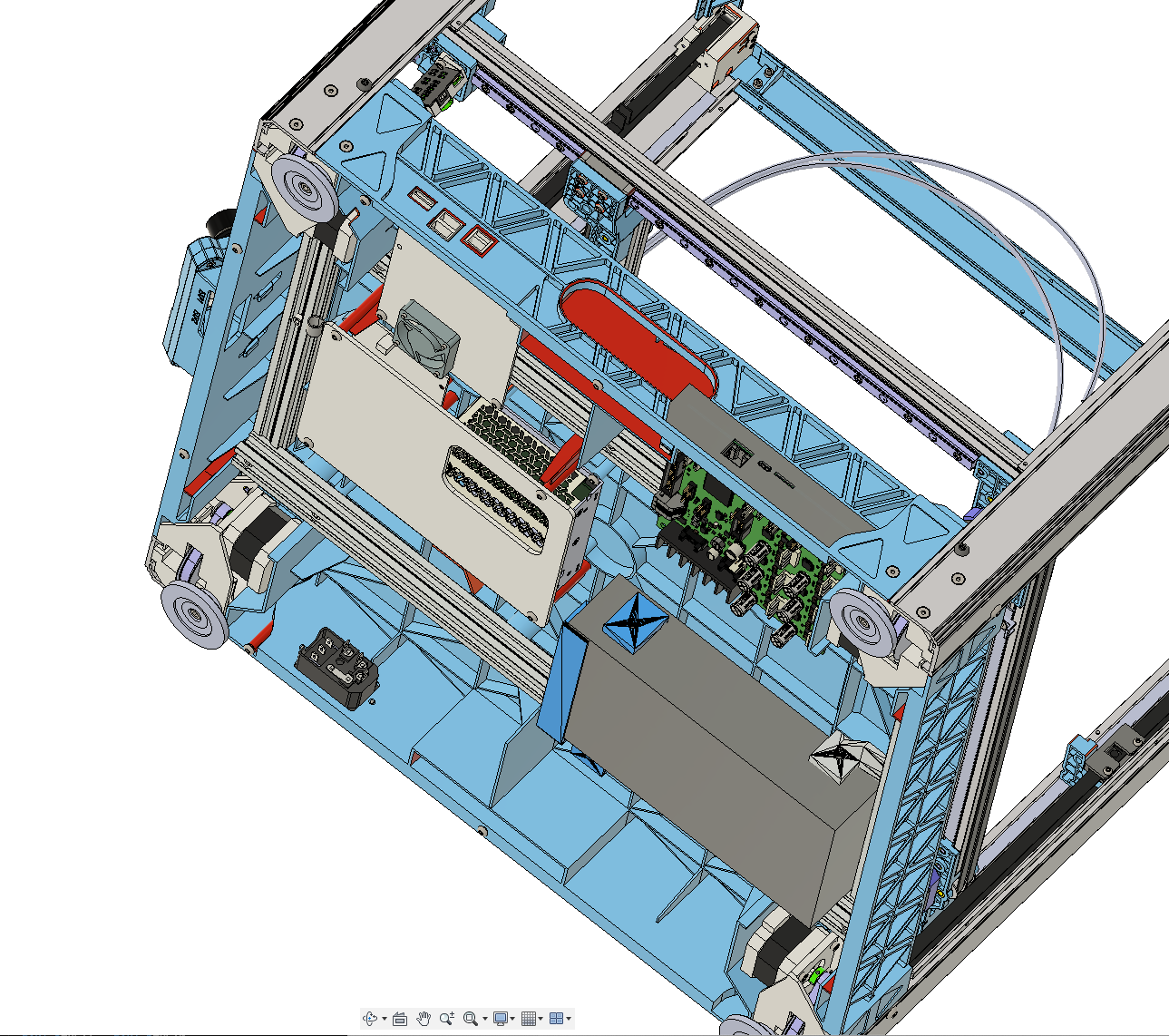

@dwuk Reworked the design of the right hand parts and belt paths - to make to routing more compact - so a lot less build plate now lost.

These screenshots show the factory single gantry front and rear part on the left - with the new double gantry parts on the right.

Improved more compact belt routing on right hand side

-

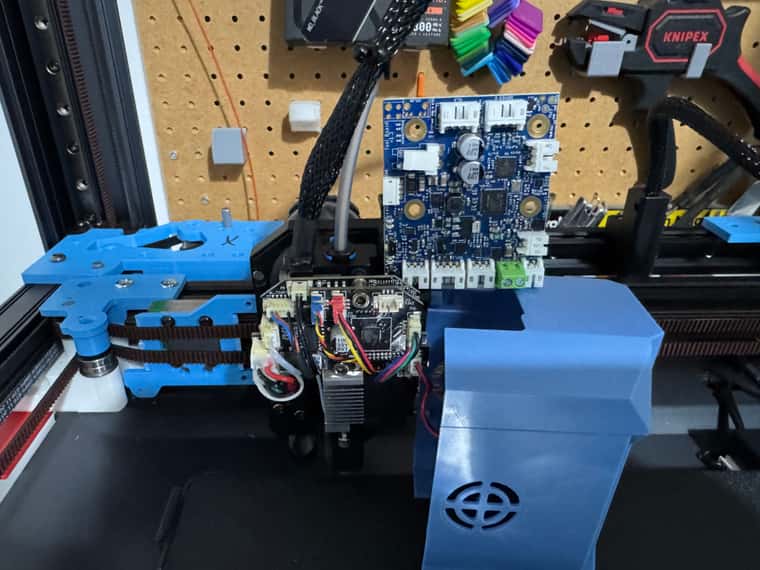

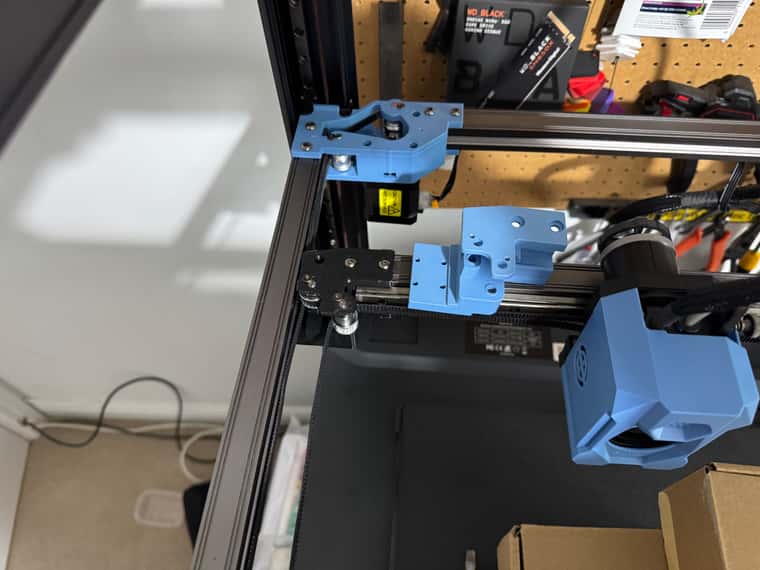

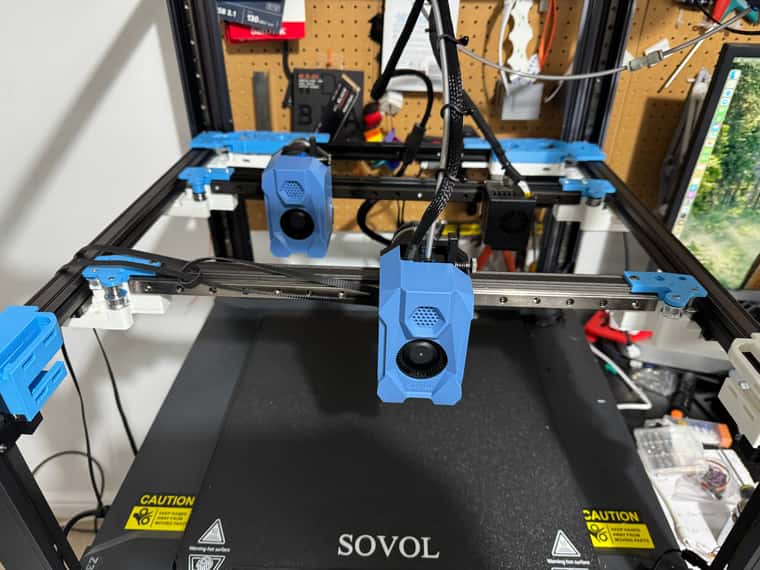

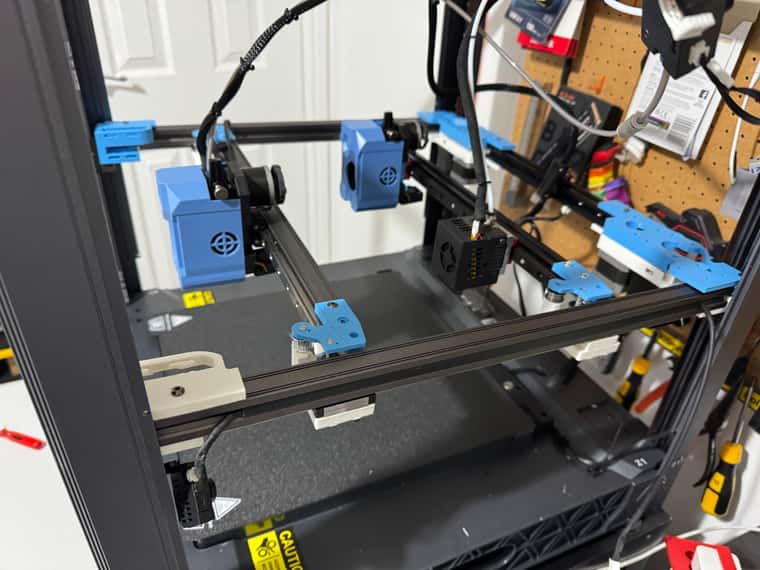

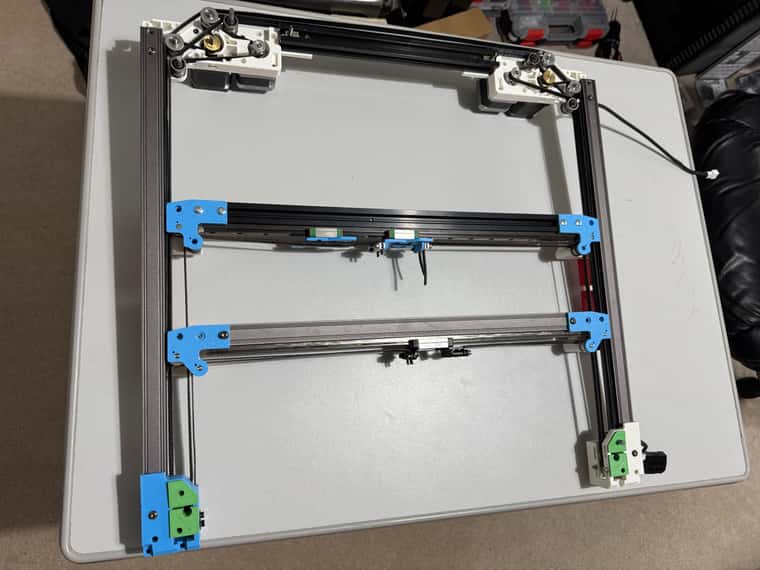

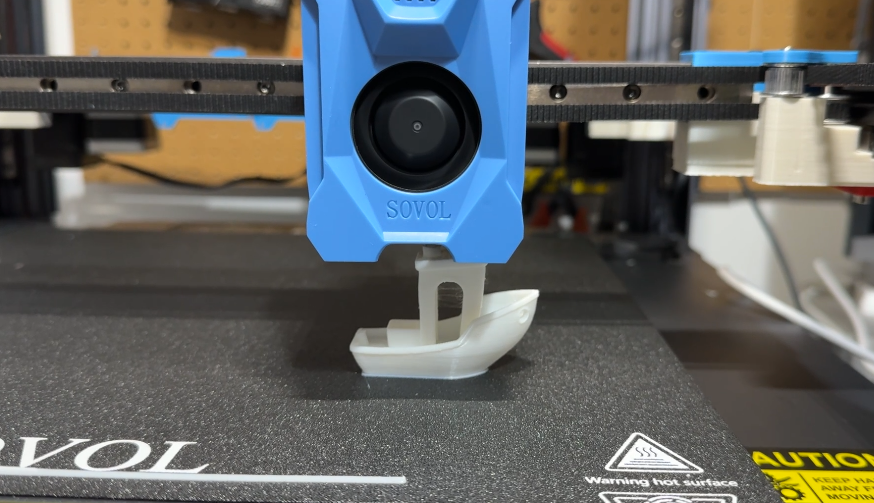

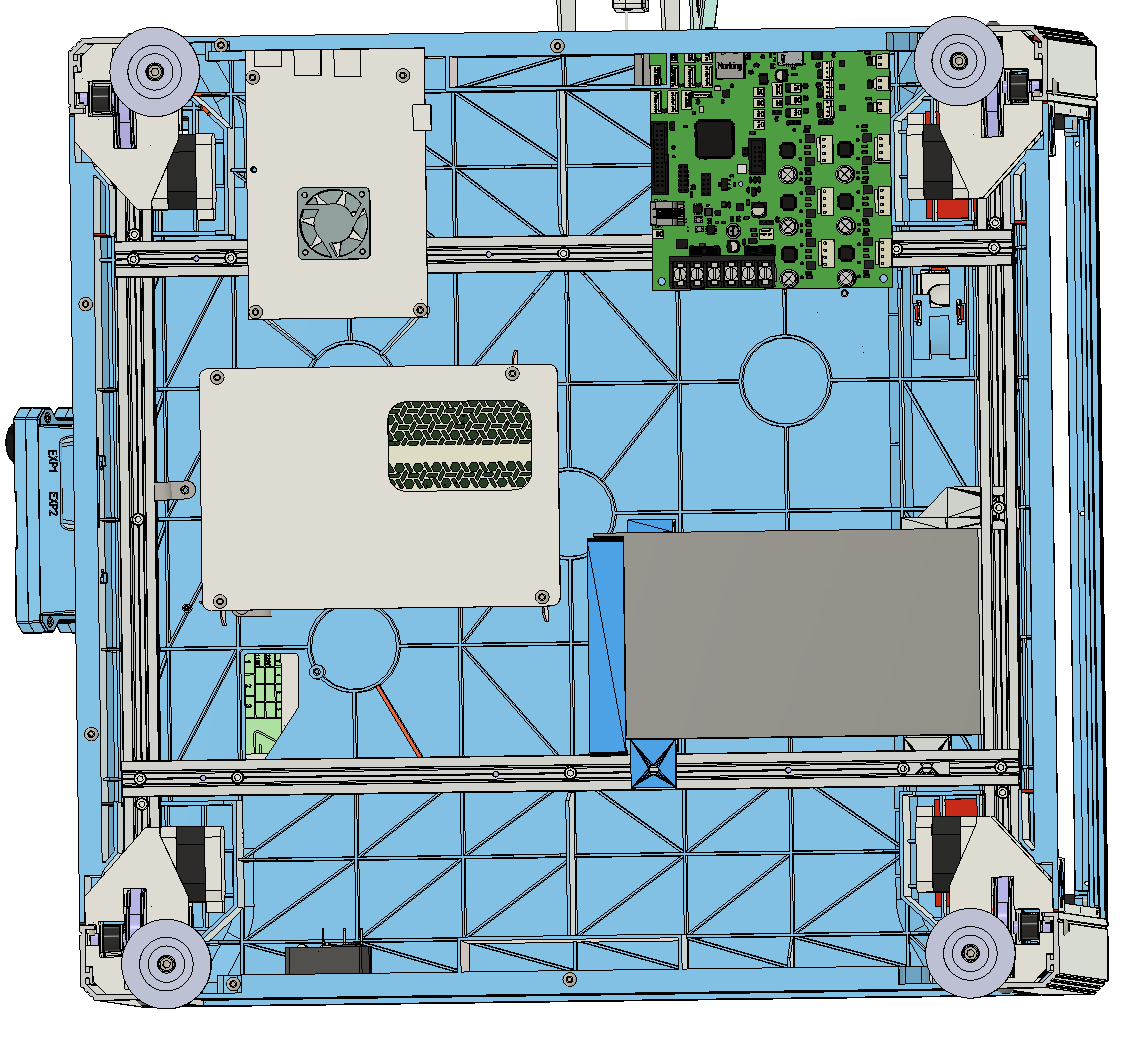

Still waiting for a few parts - but basic Phase1 structure now complete - just needs to be belted up.

Next step if to belt up both gantries and try running the original front gantry using the existing Klipper board just to see if it still works with the new belt routing and the 2nd gantry in the back.

Still awaiting Mini 5 Duet Board delivery - but rest of boards arrived ok.

Have used smaller New

2nd extruder on back gantry just there for illustration purposes of size target - it is a Bowden extruder from the WeedoX40 donor machine.

-

@dwuk Having a bowden extruder in the mix makes sense if you want to print infill_every_nth_layer with a bigger nozzle.

-

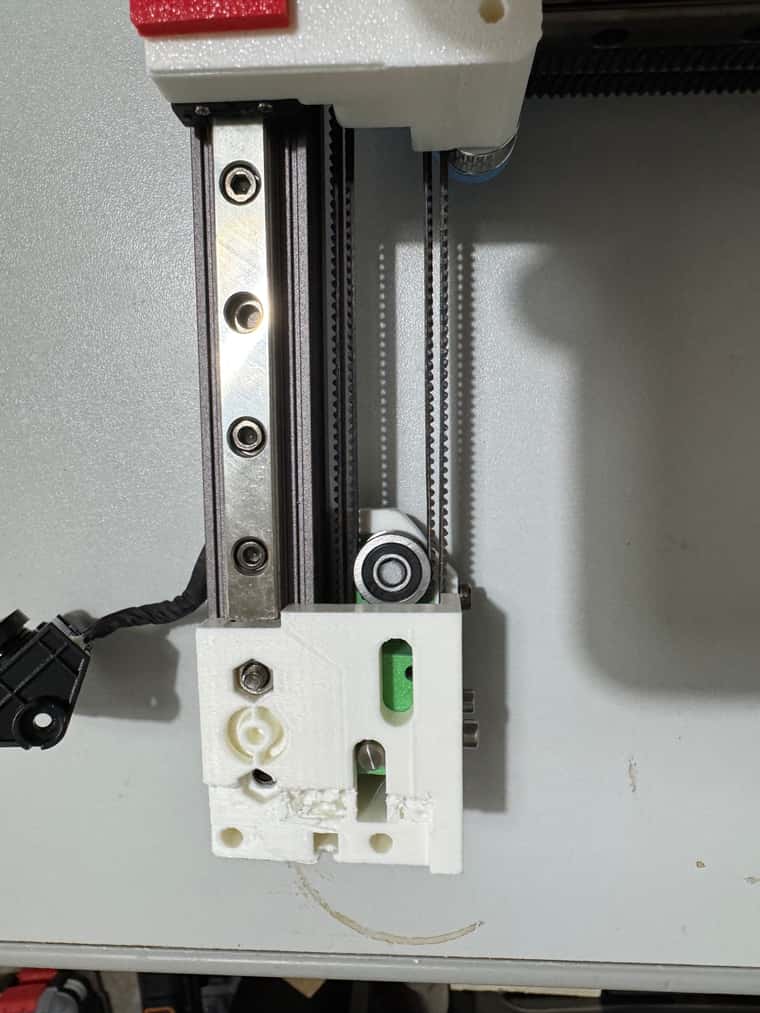

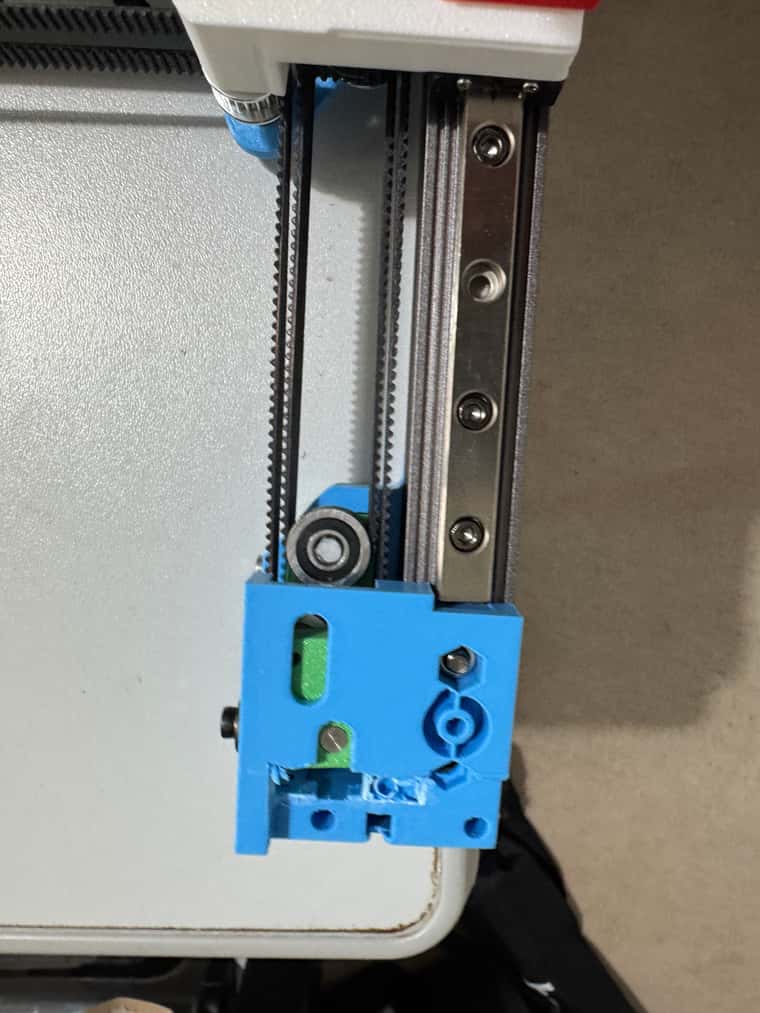

All belted up.

Short a few parts before I can do a proper test - most important of which is the linear rail carriages for the 2nd gantry, plus some idler posts.Some belts quite close to each other - will try both gantries out next - will have to swap the carriages.

Rear left

Rear right

Front left

Front right

Top with rear top halves on

-

@dwuk really enjoying following along with this build. Good to see the multiple motions systems code getting a chance to be used on a two head toolchanger!

-

First test of the mechanics - to make sure I haven't messed up Gantry1.

Worked surprisingly well on existing Klipper board - see short video demo.

https://youtu.be/3d6z5srohSQ

Can't yet get gantry 2 to work - due to lack of linear rail carriages, plus motors are probably not powerful enough - as for first try they didn't move.

Will try Swapping the motors around before upgrading.

Set smaller motors at 0.85a (the rating printed on them) - which didn't work.

Update - rear gantry moves ok with original sovol motors at both 0.85a and 1.5a (even with 3d printed carriages).

-

Managed to get 2nd gantry working.

Had a lot of trouble with Motors - the ones I saved from a WeedoX40 wouldn't work.

Eventually I discovered that they have different pin connections to Sovol motors - with have the coils connected on pins 1+4 and 3+6. My motors were 1+3 and 4+6.

So found some other motors - from my MPCNC - which are more powerful - 1.7a - and they eventually worked.

Then had a lot of trouble withy homing and setting values for TMC drivers - will probably switch to end stops for the final build - but eventually got it working.

Then next problem was prints keep losing position - eventually worked it out that I was moving too fast for the MPCNC motors - F36000 was too fast for them - so slowed down to 18000 (300mm/s). And that sorted out the problem.

Decided to try a print - despite plastic bearing posts, and plastic linear rail carriages - ran the print at half speed - but it worked.

Did an initial print on the from gantry - then swapped over the extruder and stepper connections - and reconfigured Klipper for the different motors.

Demo of print on 2nd gantry here

https://youtu.be/7ar74Ne5ryI

Have learn't quite a lot about configuring steppers which will come in useful once I try the Duet migration - which is probably now the next step.

-

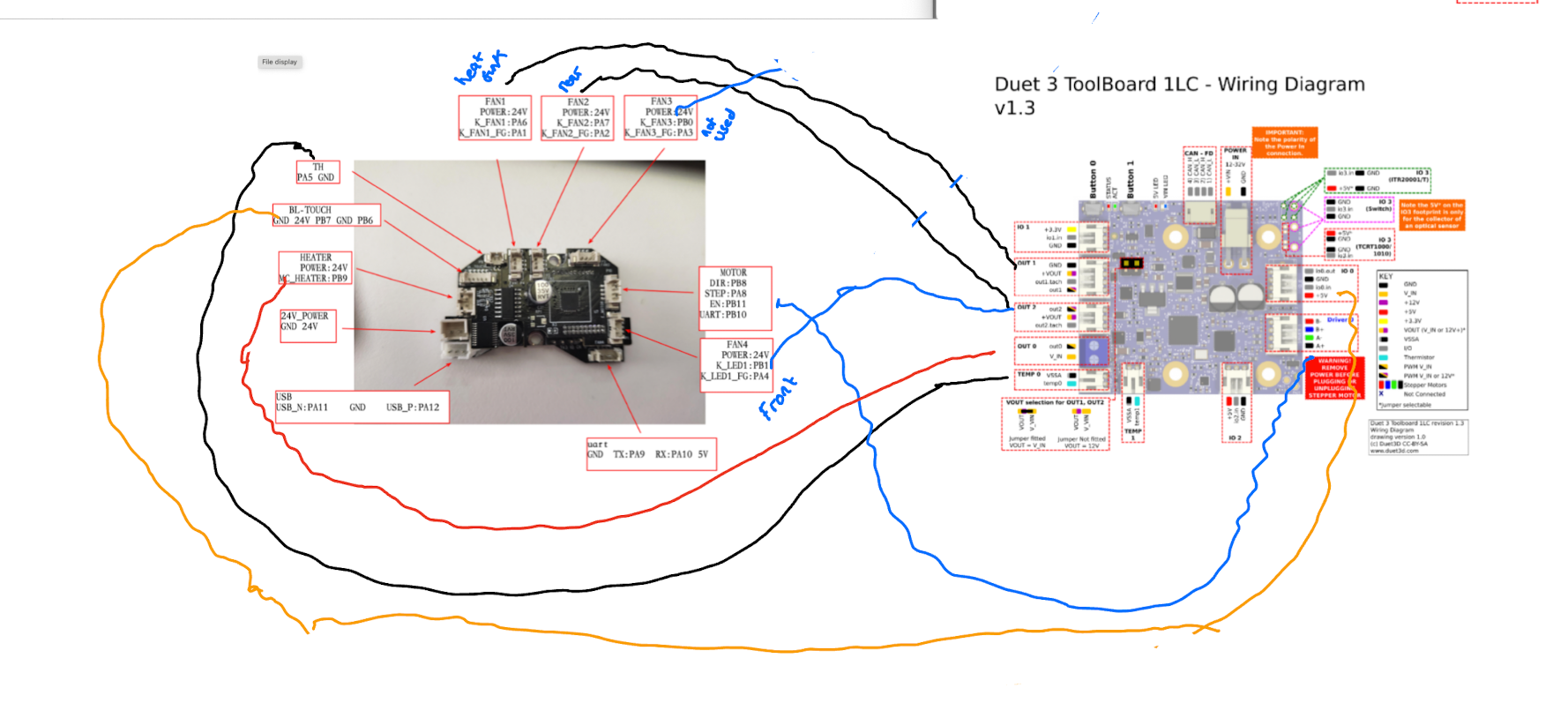

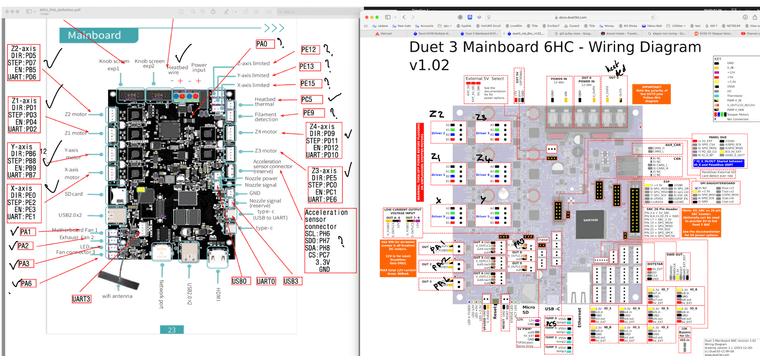

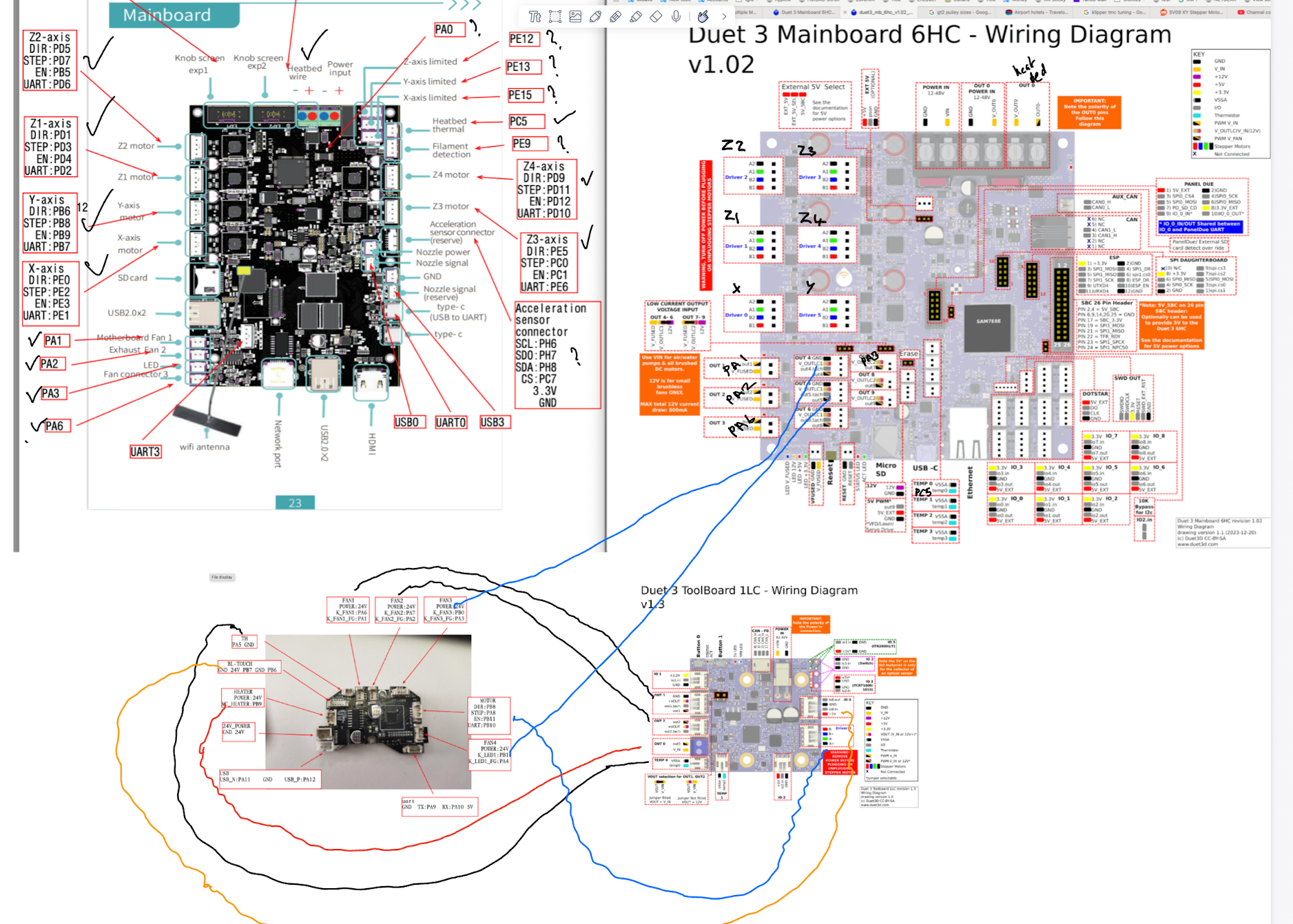

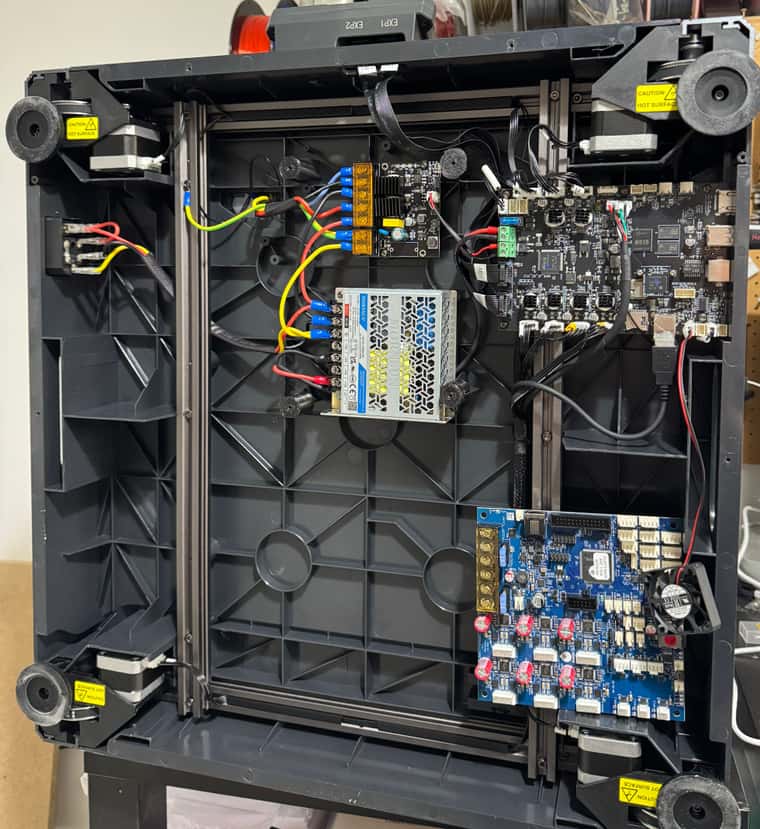

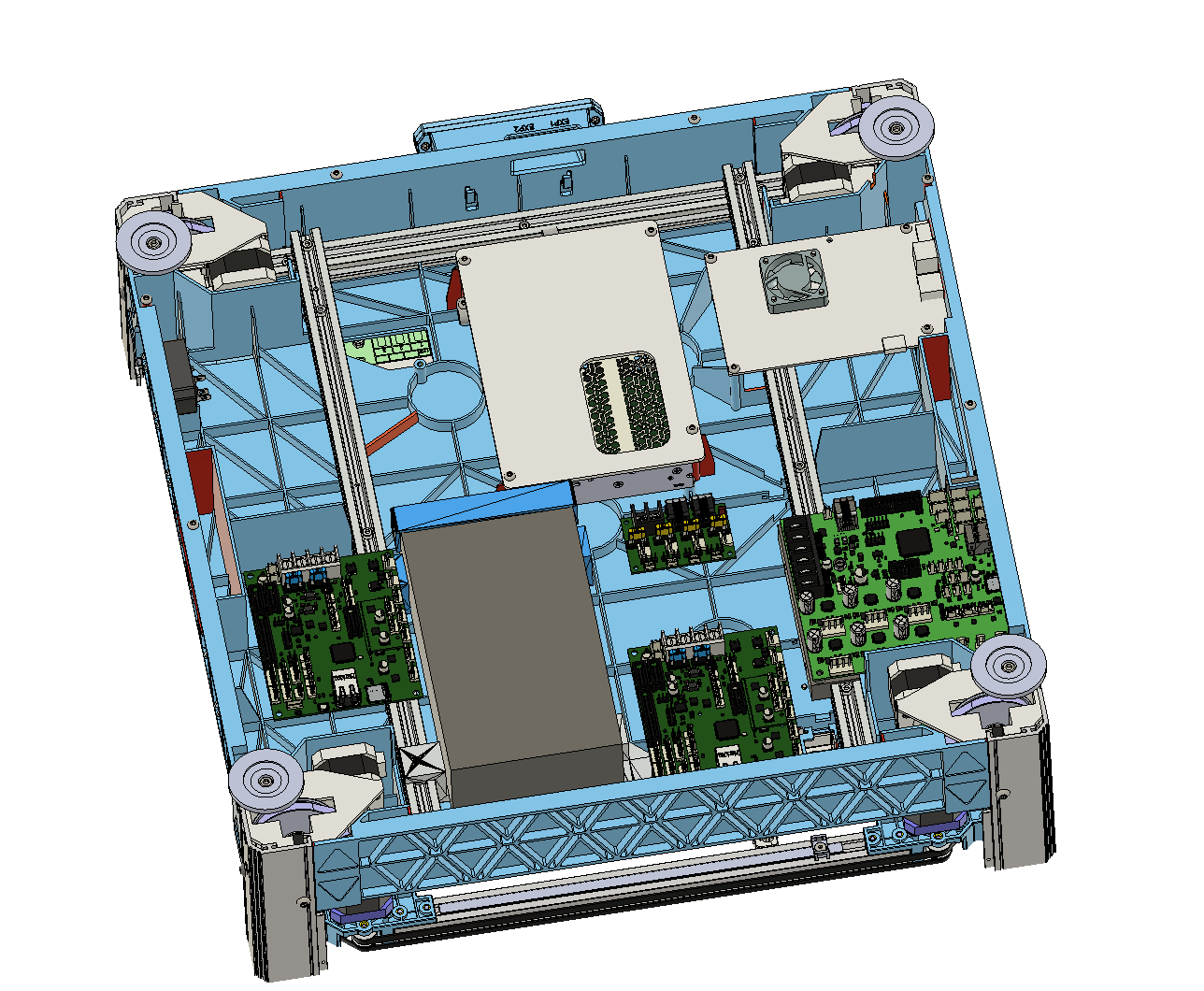

Starting to plan Duet Conversion - initially with just one Gantry and the 6LC and a single 1LC board

-

Added tool board wiring - looks like there are not enough connections for the 3 fans - so might have to run some extra cables from the main board. I have shown wiring for 4 fans - but I think only 3 are used.

-

-

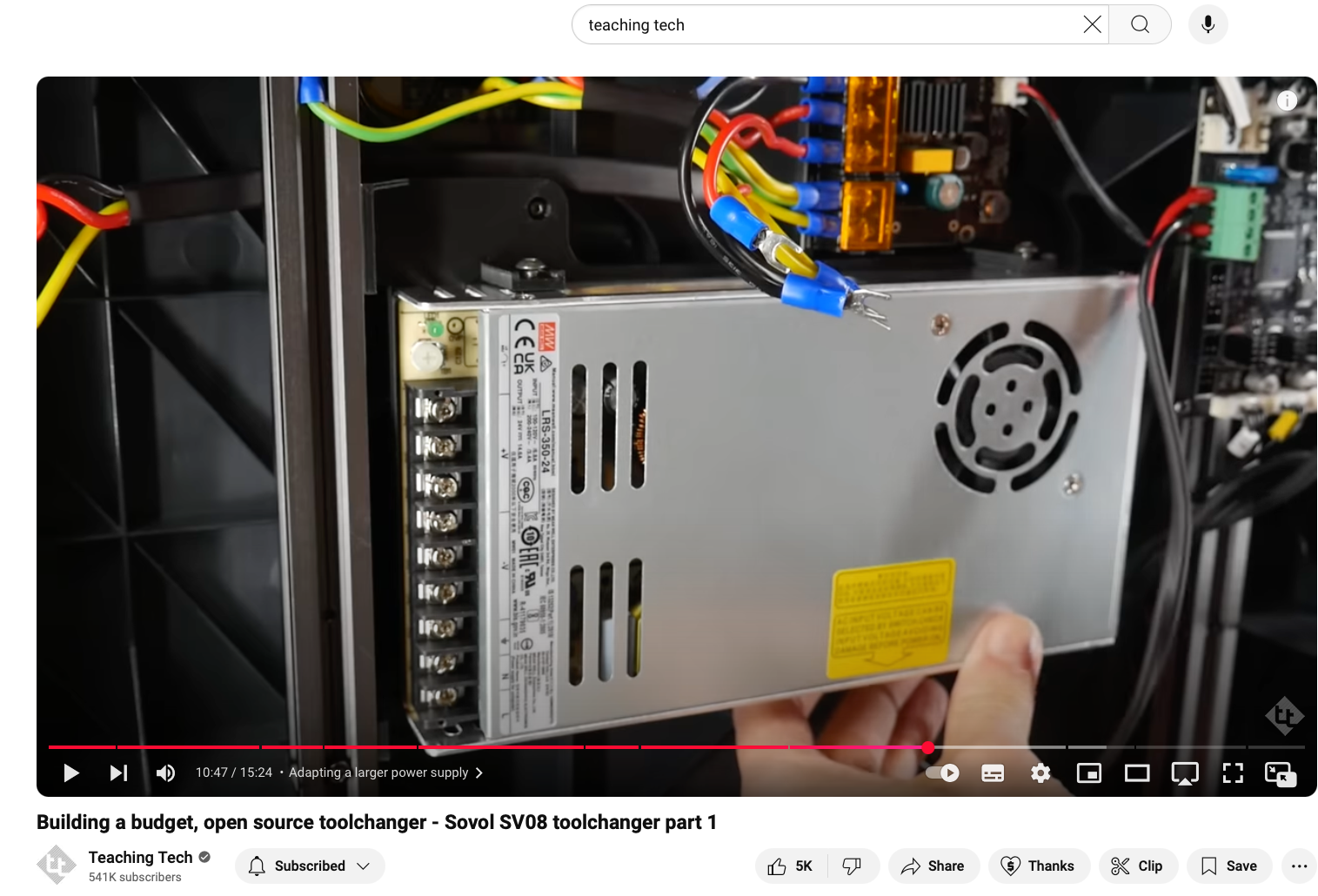

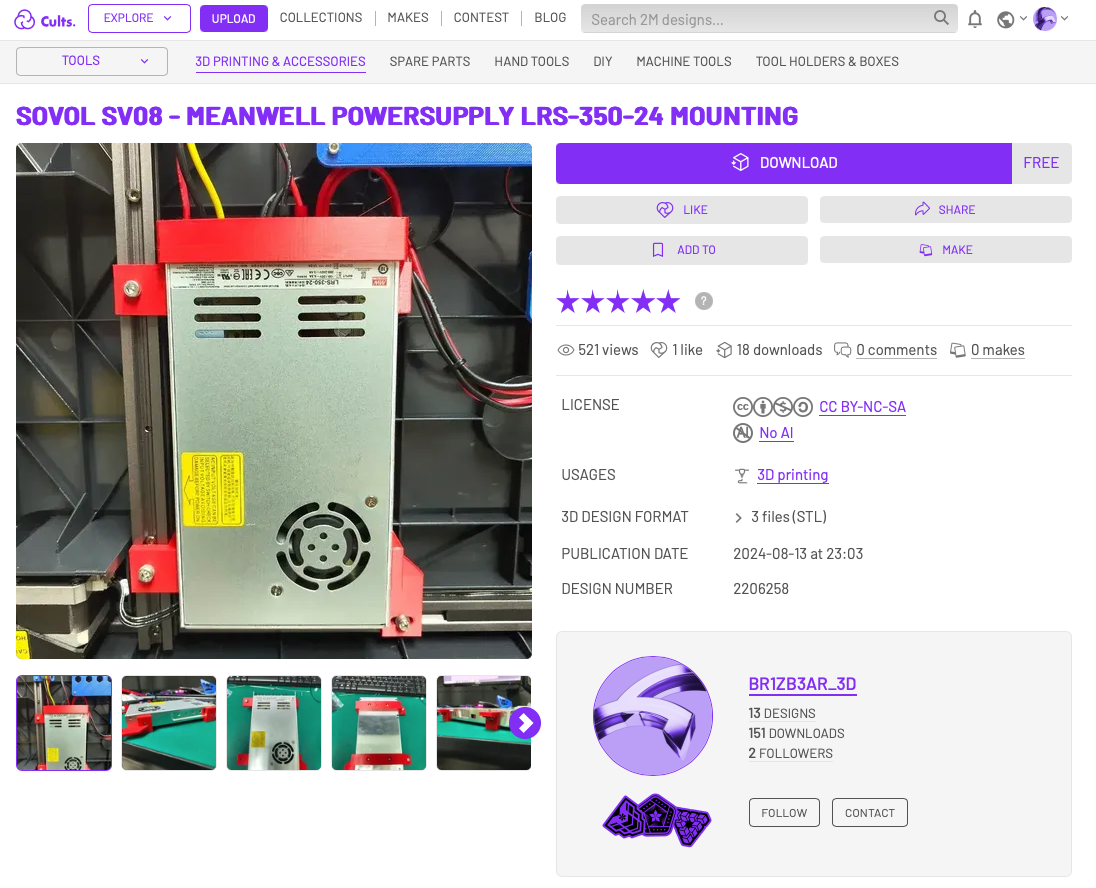

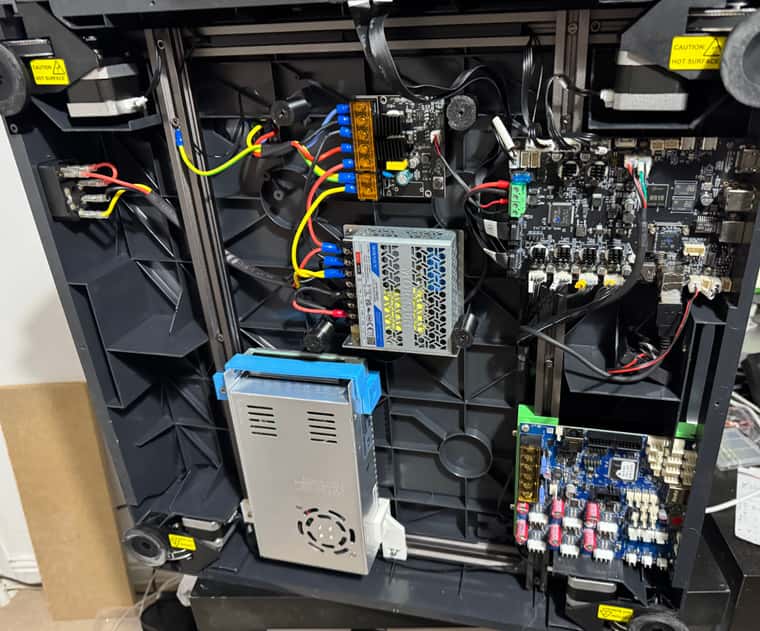

Next job is the power supply upgrade. The stock PSU is tiny - only 6.5a. I've got a 20A PSU from my WeedoX40 - so will put that in there instead. Need to decide whether to take the @TeachingTech approach- and put it in the same place as the existing PSU - which involves cutting some posts off.

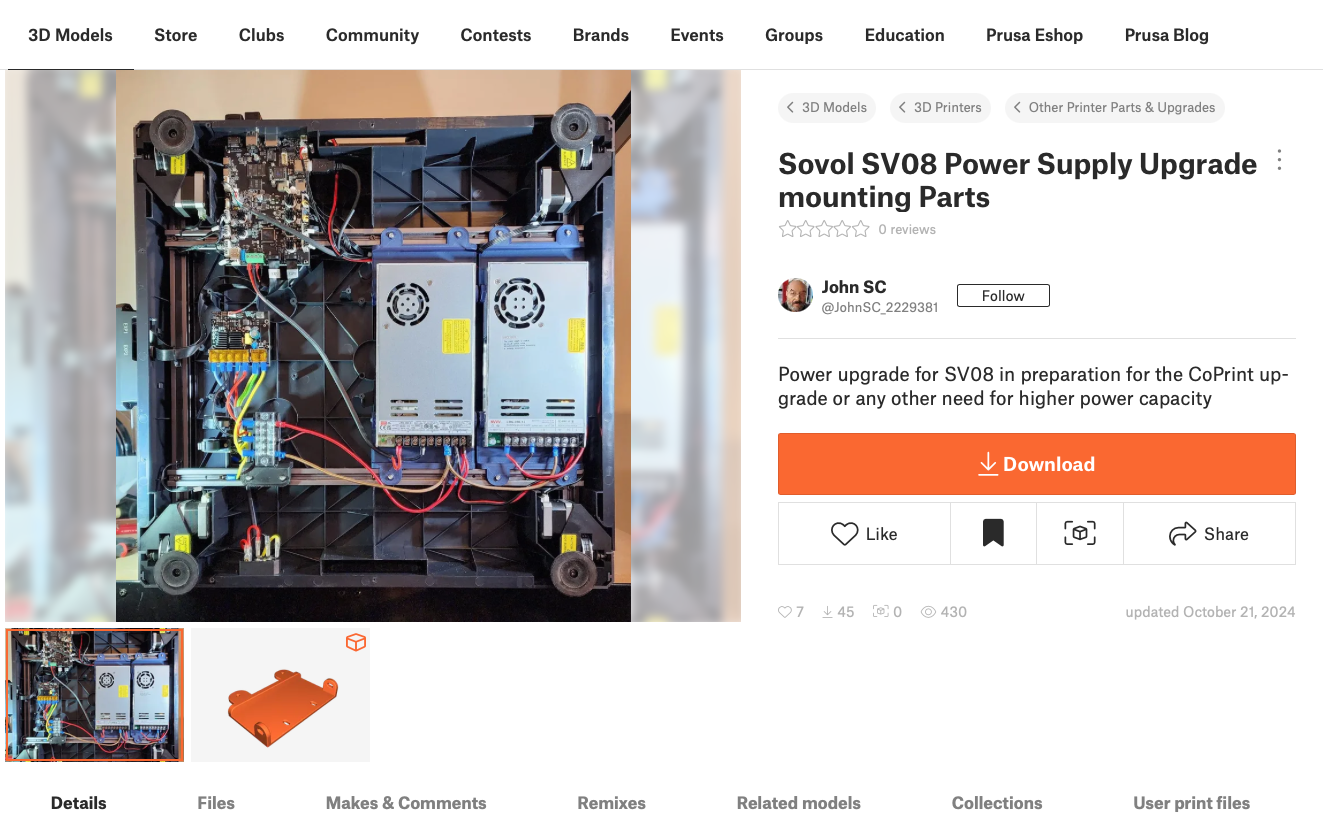

Or go with @JohnSC's approach and mount the new PSU at the bottom -

Then for placement of Duet Boards. The Mini5+ board hasn't arrived yet - but it can be inside somewhere. I'm thinking of putting the Duet 6HC below the existing board - here maybe

Will involve cutting out some new holes to give access to the sd card, usb-c and ethernet. This pushes me towards the teachingTech approach to PSU placement.

In the end decided to go for this model as first attempt at PSU mounting

-

PSU Installed and design for Duet Holder done.

-

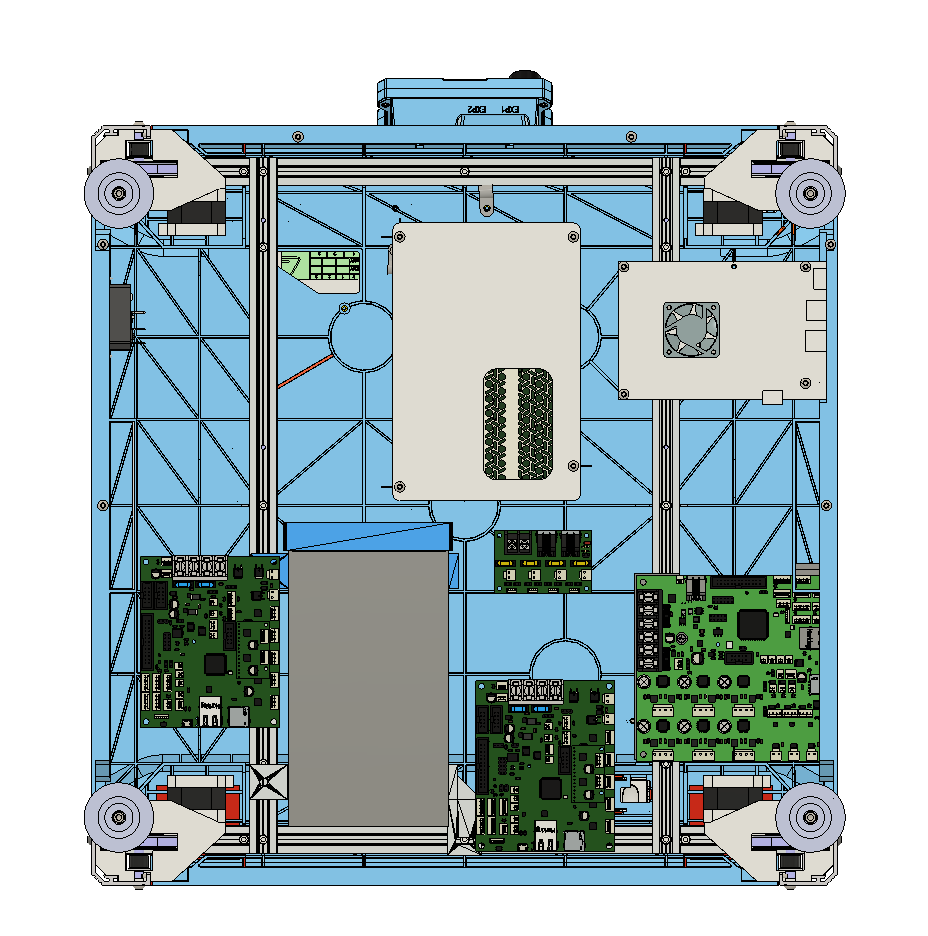

@dwuk Duet3 6HC board now installed - now for lots of wiring up.

-

Starting to plan for expansion boards - looks like there is room,

Tool Distribution board and first Mini5+ needed for Dual Gantry, with further Mini 5 probably needed for IDEX - unless I can reduce the stepper requirement - by using less for IDEX and Servo's for Z Hoppers.

-

@dwuk This is all such an amazing project, along with your work on splitting the slicer output for two tools to print at the same time. Keep up the good work, and thanks for documenting it so well!

Ian