smarteffector v2 sensitivity not stored

-

Had some trouble with a smarteffector v2 and sensitivity.

I use this macro on all my other deltas.

;Set smarteffector sensibility (standard is 50) ; Lower numbers need less nozzle contact force to trigger the sensor. However, there is a greater risk that vibration from the stepper motors will cause false triggering. ; M672 S105:aaa:bbb replacing aaa by the desired sensitivity and bbb by 255 - aaa ;M672 S131:131 ; reset sensibility ;M672 S65:65 ;Factory Settings ;M672 S99:99 ; responds with two or three flashes of the LED according to whether default or custom sensitivity has been set G4 S3 ; pause 3s M672 S131:131 ; reset sensibility G4 S4 ; pause 4s M672 S105:105:150 ; set smarteffector sensibility TEVO BIG G4 S3 ; pause 3sI power up the printer and sensitivity seams to be default, because it´s too sensible with my setup.

I try to set it and the smart effector does not respond as it should.

I power cycle the printer once o twice more, and I can run the macro and works fine.

But if I power down the printer, next time I power it up, need to do de sentitivity adjustment again, and again.

This is my config

; Configuration file for RepRapFirmware on Duet 2 WiFi for a Tevo Little Monster XL ; ; ========================================================================================================= ; General ; ========================================================================================================= M111 S0 ; debugging off G21 ; work in millimetres G90 ; absolute coordinates M83 ; relative extruder moves ; ========================================================================================================= ; global variables ; ========================================================================================================= M98 P"0:/sys/settings/Set-Global-Variables.g" ; set global variables ; ========================================================================================================= ; Network ; ========================================================================================================= M550 P"TEVO" ; set printer name M552 S1 ; configure WiFi adapter M586 P0 S1 ; configure HTTP ; ========================================================================================================= ; Kinematics for Delta Printer Haydn´s mag arms ; ========================================================================================================= M665 L400.320:400.320:400.320 R172.293 H1030.009 B170.0 X-0.975 Y-0.686 Z0.000 ; H1026.594 volcano ; H1036.193 V6 M666 X-0.183 Y0.948 Z-0.765 A0.00 B0.00 ; ========================================================================================================= ; Drives ; ========================================================================================================= M569 P0 S0 D2 ; driver 0 goes forwards (ALPHA axis) M569 P1 S0 D2 ; driver 1 goes forwards (BETA axis) M569 P2 S0 D2 ; driver 2 goes forwards (GAMMA axis) M569 P3 S1 D2 ; driver 3 goes forwards (extruder 0) ; ========================================================================================================= ; Drives maping ; ========================================================================================================= M584 X0 Y1 Z2 ; set axis mapping M584 E3 ; set extruder mapping ; ========================================================================================================= ; Set motor currents ; ========================================================================================================= M906 X1200 Y1200 Z1200 ; set axis driver currents M906 E800 ; set extruder driver currents ; ========================================================================================================= ; Motor Idle Current Reduction ; ========================================================================================================= M906 I30 ; set motor current idle factor M84 S30 ; set motor current idle timeout ; ========================================================================================================= ; Set microsteps and steps / mm ; ========================================================================================================= M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation M350 E16 I0 ; configure microstepping without interpolation M92 X80 Y80 Z80 ; configure steps per mm M98 P"0:/sys/settings/Set-E-Steps.g" ; configure steps per mm for extruder ; ========================================================================================================= ; set speeds ; ========================================================================================================= M201 X4000 Y4000 Z4000 E1500 ; set accelerations (mm/s^2) M203 X18000 Y18000 Z18000 E6000 ; set maximum speeds (mm/min) 500mm/s M204 P3000.0 T5000.0 ; set print and travel accelerations (mm/s^2) M566 E600 ; set maximum instantaneous speed changes (mm/min) M201.1 X500 Y500 Z500 E500 ; Set accelerations for special moves (mm/s^2) M205 X9 Y9 Z9 ; set global.x_accel = move.axes[0].acceleration ; save accelerations (mm/s^2) set global.x_jerk = move.axes[0].jerk ; save maximum instantaneous speed changes (mm/min) ; set global.y_accel = move.axes[1].acceleration ; save accelerations (mm/s^2) set global.y_jerk = move.axes[1].jerk ; save maximum instantaneous speed changes (mm/min) ; ========================================================================================================= ; axes limits ; ========================================================================================================= M208 Z-1 S1 ; Set minimum Z ; ========================================================================================================= ; Endstops ; ========================================================================================================= M574 X2 P"xstop" S1 ; configure ALPHA axis endstop M574 Y2 P"ystop" S1 ; configure BETA axis endstop M574 Z2 P"zstop" S1 ; configure GAMMA axis endstop ; ========================================================================================================= ; Probes ; ========================================================================================================= M558 K0 P8 R0.4 C"zprobe.in+zprobe.mod" H5 F1200 T60000 B1 ; configure digital probe via slot #0 G31 P1000 X0 Y0 Z-0.36 ; set Z probe trigger value, offset and trigger height v6 ; ========================================================================================================= ; Mesh Bed Compensation ; ========================================================================================================= M557 R165 S40:40 ; define grid for mesh bed compensation ; ========================================================================================================= ; heaters, fans, thermistors ; ========================================================================================================= ; heated bed ; ========================================================================================================= M308 S0 P"bedtemp" Y"thermistor" A"Heated Bed" T100000 B4092 ; configure sensor #0 M950 H0 C"bedheat" T0 ; create heater #0 M143 H0 P0 T0 C0 S140 A0 ; configure heater monitor #0 for heater #0 M140 P0 H0 ; configure heated bed #0 ; ========================================================================================================= ; hotend ; ========================================================================================================= M308 S1 P"e0temp" Y"thermistor" A"Nozzle" T100000 B4388 C7.06e-8 ; configure sensor #1 M950 H1 C"e0heat" T1 ; create heater #1 M143 H1 P0 T1 C0 S285 A0 ; configure heater monitor #0 for heater #1 M143 H1 S280 ; set temperature limit for heater 1 to 280°C ; ========================================================================================================= ; Fans ; ========================================================================================================= ; Part Cooling ; ========================================================================================================= M950 F0 C"fan0" ; create fan #0 part cooling M106 P0 S0 L0.3 X1 B0.3 ; configure fan #0 ; ========================================================================================================= ; Hotend fan (temperature controlled) ; ========================================================================================================= M950 F1 C"fan1" ; create fan #1 hotend M106 P1 S0 B0.2 H1 T45 ; configure fan #1 ; ========================================================================================================= ; Fan2 = MotherBoard Cooling ;----MCU & DRIVERS sensors------ ; ========================================================================================================= M308 S3 Y"mcu-temp" A"MCU" ; create sensor for MCU temp M308 S3 Y"mcutemp" M308 S4 Y"drivers" A"Drivers" ; create sensor for drivers temp M308 S4 Y"drivers" M912 P0 S-8 ; Calibrate MCU temp M950 F2 C"fan2" Q500 ; create fan 2 on pin out4 - alternative with tacho M950 F2 C"!fan2+^pb6" M106 P2 H3:4 L.3 B.5 X1 T40:65 ; Set fan 2 PWR fan. Turns on when MCU temperature, hits 45C and full when the MCU temperature reaches 65C or any TMC2660 alarms ; ======================================================================================================== ; Tools ; ======================================================================================================== M200 D1.75 M563 P0 D0 H1 F0 ; create tool #0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets M568 P0 R0 S0 A0 ; set initial tool #0 active and standby temperatures to 0C M302 S180 R180 ; allow extrusion starting from 180°C and retractions already from 180°C ; ======================================================================================================== ; Power Restore M911 S19.8 R22 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss ; ======================================================================================================== ; Panel Due ; ======================================================================================================== M575 P1 S0 B57600 ; configure PanelDue support ; ======================================================================================================== ; ========================================================================================================= ; other settings ; ========================================================================================================= M98 P"0:/sys/settings/Set-PID-Bed.g" ; set PID values for the heated bed M98 P"0:/sys/settings/Set-PID-Nozzle.g" ; set PID values for the nozzle ;M307 H1 R1.588 K0.266:0.074 D7.56 E1.35 S1.00 B0 V23.5 ; Volcano 1.2mm ; ========================================================================================================= ; filament handling ; ========================================================================================================= ; execute macros that determine the status of the filament sensor ; M98 P"0:/sys/settings/Set-FilamentSensorStatus.g" ; load filament sensor settings M98 P"0:/sys/settings/Set-AutoLoadStatus.g" ; load autoload settings M98 P"0:/sys/00-Functions/FilamentsensorStatus" ; update sensor status ; ; ========================================================================================================= ; offsets - place off-sets for x and y here. z-offsets are handled in the print sheet macros ; ========================================================================================================= M98 P"0:/sys/settings/Set-Probe-XY-Offsets.g" ; set probe xy-offset M98 P"0:/sys/settings/Set-Probe-Z-Offset.g" ; set probe z-offset ; ========================================================================================================= ; Accelerometer and input Shaping ; ========================================================================================================= ; ;M955 P0 I20 C"spi.cs2+spi.cs1" ; all wires connected to temp DB connector, no temperature daughterboard M593 P"zvddd" F40 S0.10 ; Input Shaping ; ; ========================================================================================================= ; check connectivity ; ========================================================================================================= if {network.interfaces[0].type = "wifi"} echo >"0:/sys/runonce.g" "M98 P""0:/sys/test-WiFi.g""" ; ========================================================================================================= ; Miscellaneous ; ========================================================================================================= M501 ; load saved parameters from non-volatile memory T0 ; select first toolOn the same printer I have another smarteffector that didn´t need to adjust sensitivity to work properly

-

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

@apak it sounds to me that the firmware on the effector needs to be flashed again. Which country are you in? Do you have any equipment that can program an Atmel 8-bit microcontroller?

Is the reason for reducing the sensitivity because there is vibration that causes it to trigger unexpectedly, or is it triggering at the start of the probing move? If the latter then you may be able to suppress that triggering by reducing the M201.1 acceleration of the Z axis.

-

@dc42 I live in spain. The reason to change sensibility it´s because It triggers with any slight touch or movement so it does not trigger as it should. It´s my only smarteffector that ever has this behaviour, but I just got it from a old abandon printer that I am rebuilding.

It also triggers with a fan turn on.

In this case I have two diferent smarteffector, one with volcano and this one with a V6, and this is the only one with problems.

The predator and a v2 also with volcano and no troubles .

Already have low Z acc wih M201.1

M201.1 X500 Y500 Z500 E500 ; Set accelerations for special moves (mm/s^2)

Also I am going to buy this and try to update fw on board

https://es.aliexpress.com/item/1005006888442559.html

-

@dc42 can you confirm me, what version of fw from https://github.com/Duet3D/SmartEffectorFirmware/releases should I flash to this board.

thanks in advance

-

@apak use 2.13. Choose the binary for the version2 hardware.

-

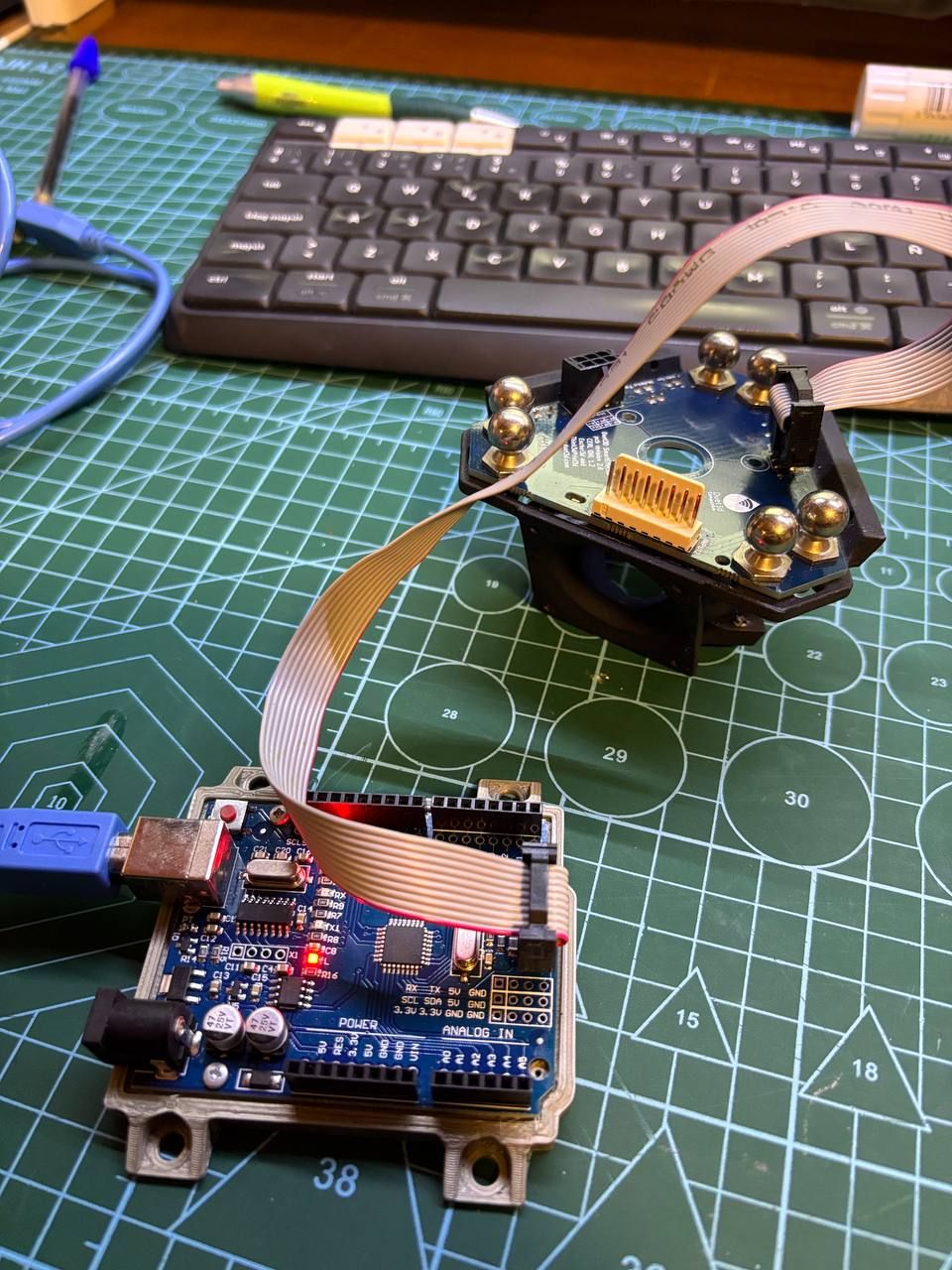

@apak and what app and board should I configure asuming I have a arduino UNO

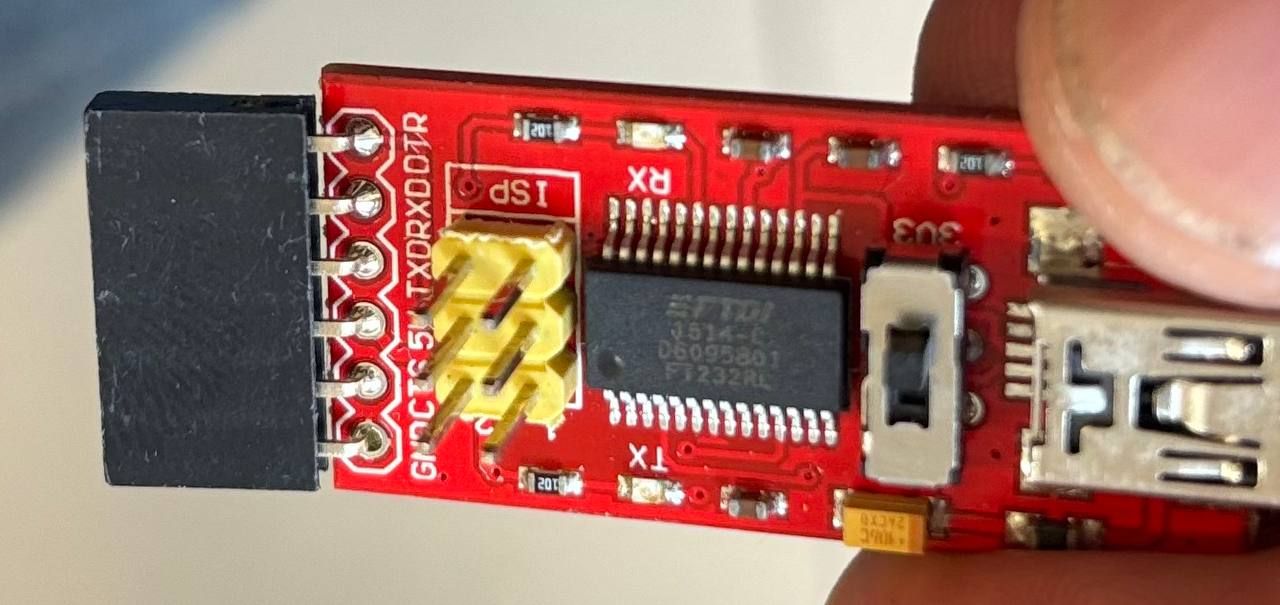

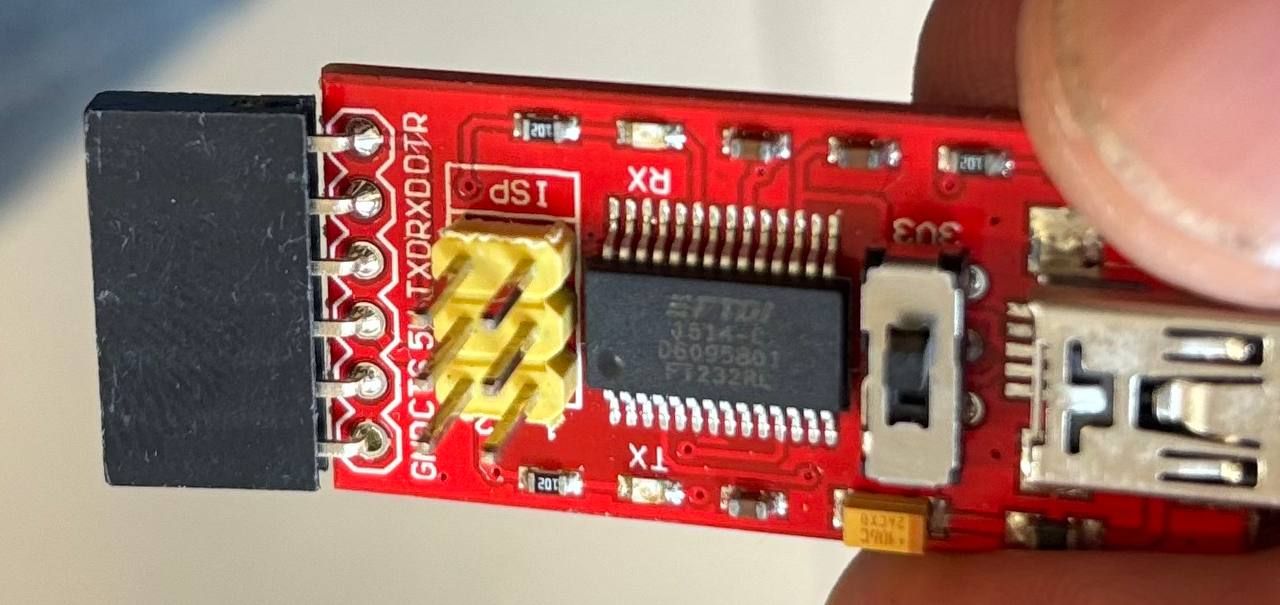

also have this little fellow

-

@apak there are several videos about this, search for "Arduino as isp". For example, https://www.youtube.com/watch?v=TtC6crf_EP4 (this is not a recommendation, I haven't watched all of it).

-

undefined apak referenced this topic

undefined apak referenced this topic

-

@dc42

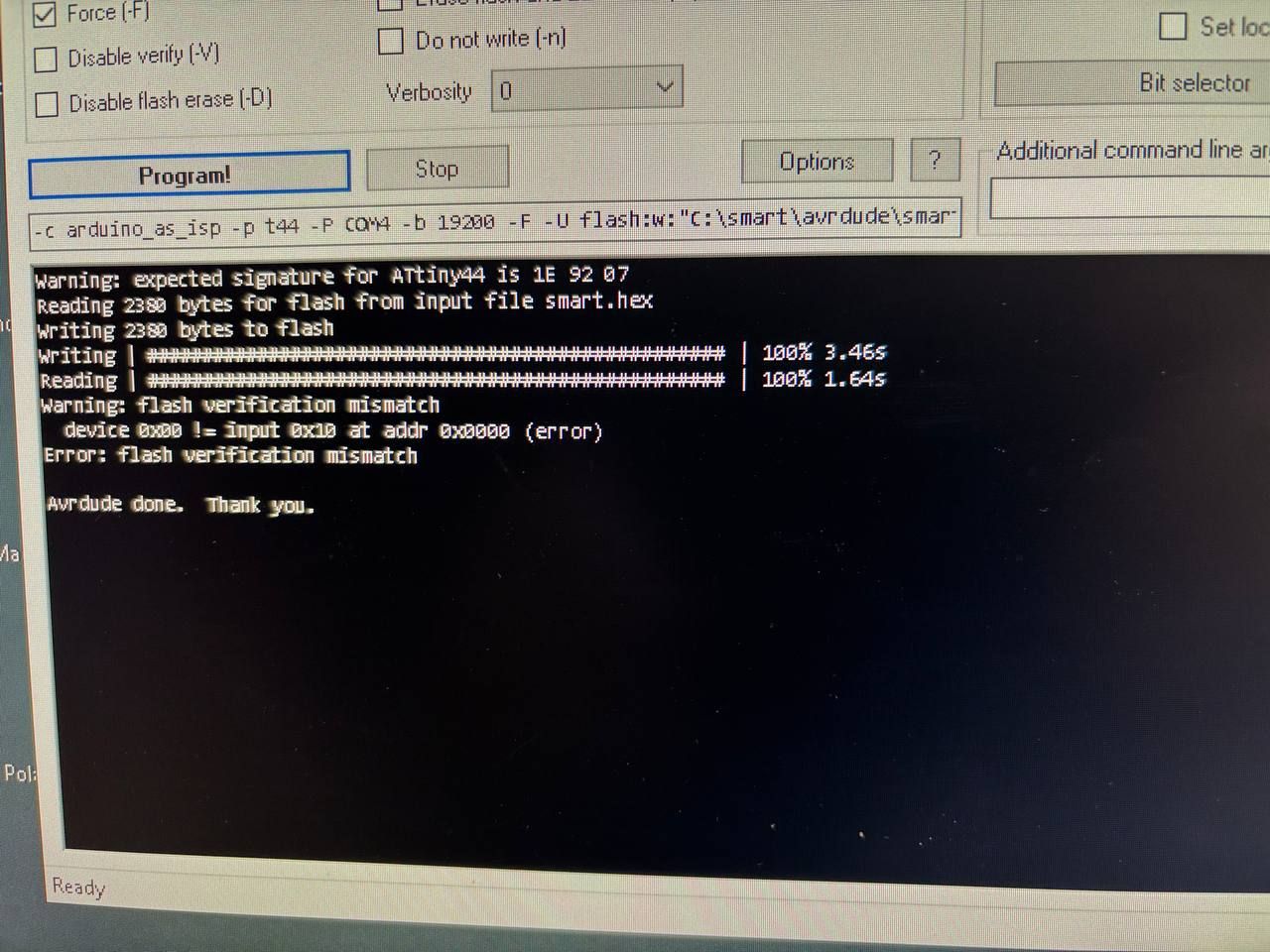

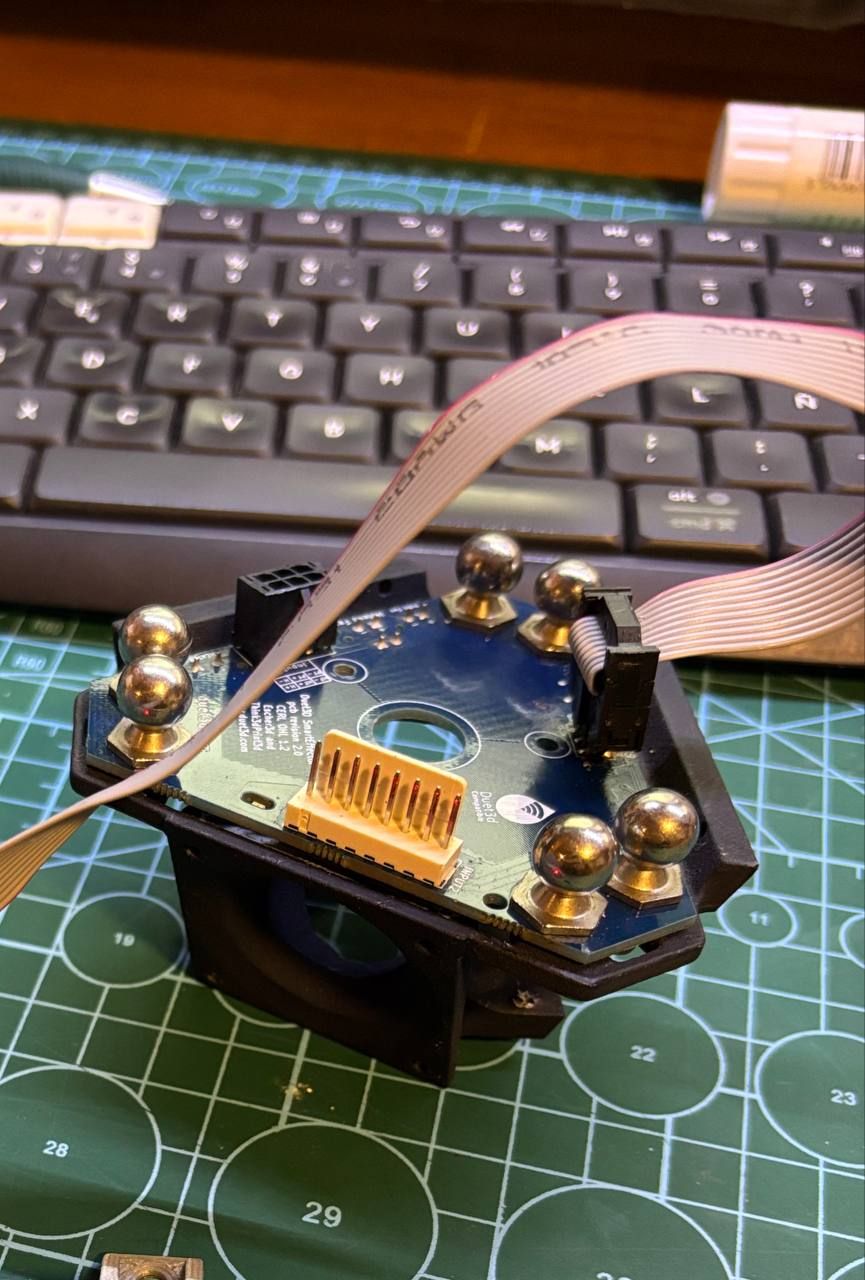

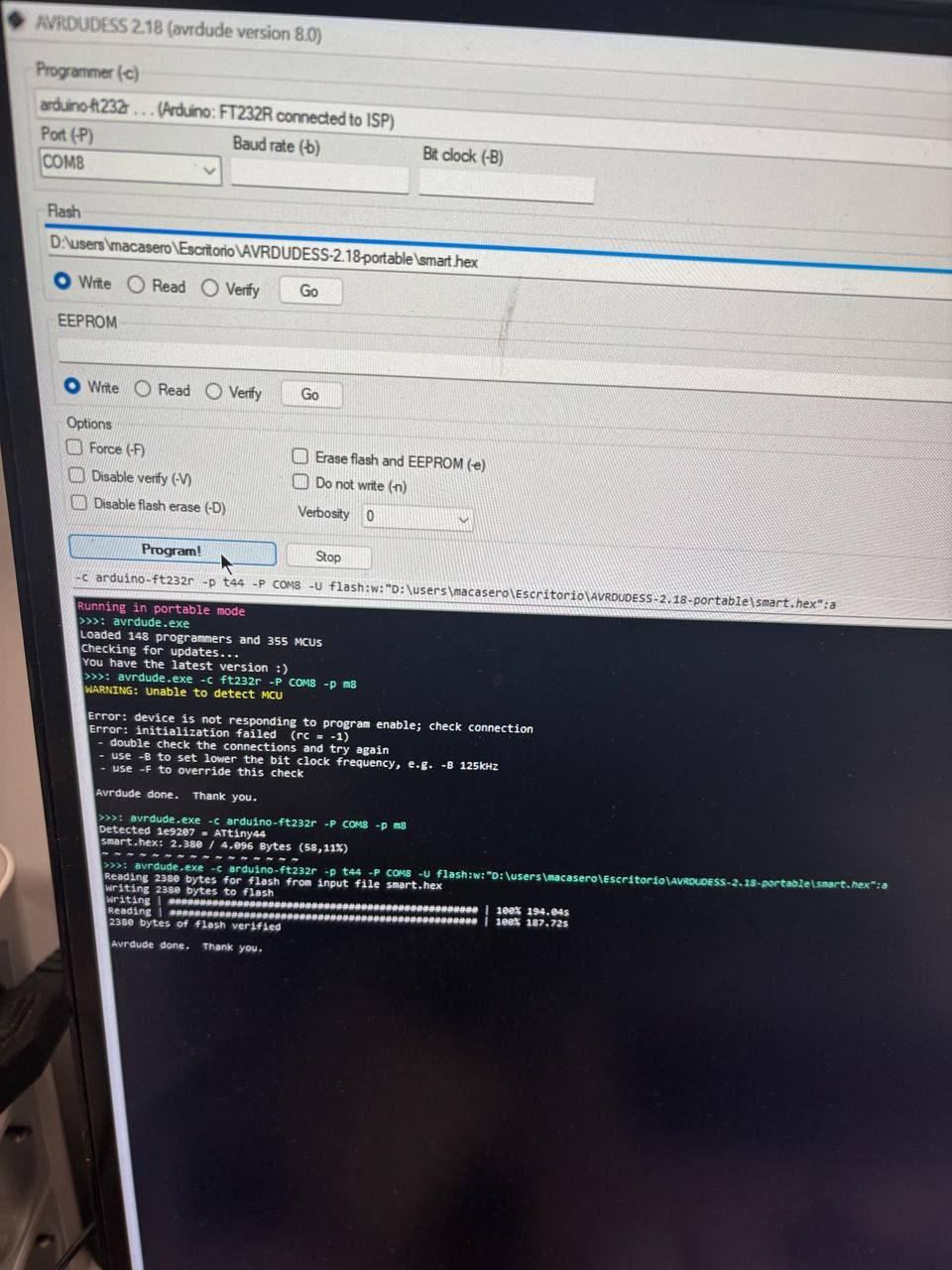

I didn´t wait for the popo pins to arrive, so I soldered some pins and used a Arduino UNO as Arduino ISP Programer, with avrdudes and upload he .hex file you mentioned.At detect (before uploading) it had a checksum mismatch, but I forced the upload and had that log below.

Is it there and way to know what version of fw it uploaded on a smarteffecto?

How could I know it was flashed ok? Maybe with a new M command such as M672 S99:99 that was included in fw 2.13?

I was only able this morning to plug the 8 pin plug and the smarteffector flashed 2 times, but couldnt test any more, had to leave to work

-

@apak Update, It did not flash ok. I set a sensitibity other that stock, power cicle and only 2 led flashing

-

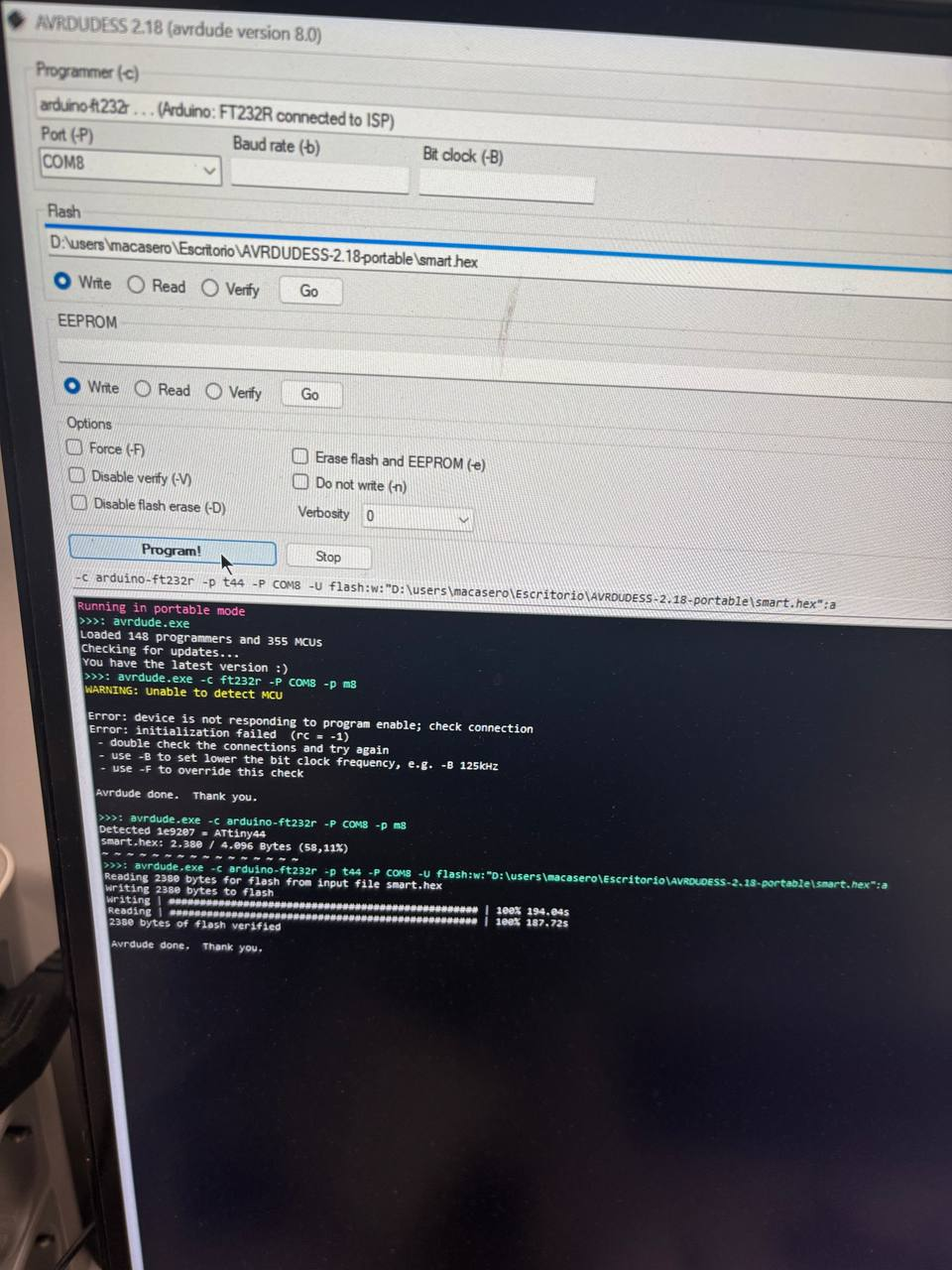

Succesfully updated to 2.13 and solder pad restored

thanks

-

@apak Well done! What did you change to get it to flash? And does it now store the sensitivity?

Ian

-

@droftarts i didn’t use the arduino uno.

Now once changed sensitibity, if power cicle led blinks 3 timesWill upload tomorrow destiled instructions

-

Recap: Old smarteffector v2 that does not remember sensitivity custom settings.

Solution: Flash new firmware V2.13 via PROG pin pads on top board side.

Procedure: Solver pin strip to exposed pads and use a direct pin to pin cable from the ISP port on programer

Programed with a FT232r programer with AVRDUDES app

-

can change it to SOLVE

-

undefined dc42 has marked this topic as solved

undefined dc42 has marked this topic as solved